Short Manual Compact-Change-System CWS

About this Short Manual

This Short Manual describes the use of the manual

Compact-Change-System CWS with a gripper.

If any data listed within this manual vary from the ones

listed in the grippers manual, these data listed here are

valid.

Detailed information about assembly, connection,

installation, use and maintenance of the gripper can be

found on the manual of the gripper.

Safety notes

WARNING

Risk of injury from gripper unit falling!

If the spindle will be lubricated with grease or oil, or the

unit is used in lubricated environment, there is a risk of

the spindle getting loose due to the reduced friction

torque while vibrations. The change adapter CWA with

the gripper can be seperated from the change head CWK

and can fall down!

• Do not lubricate the spindle with oil or grease!

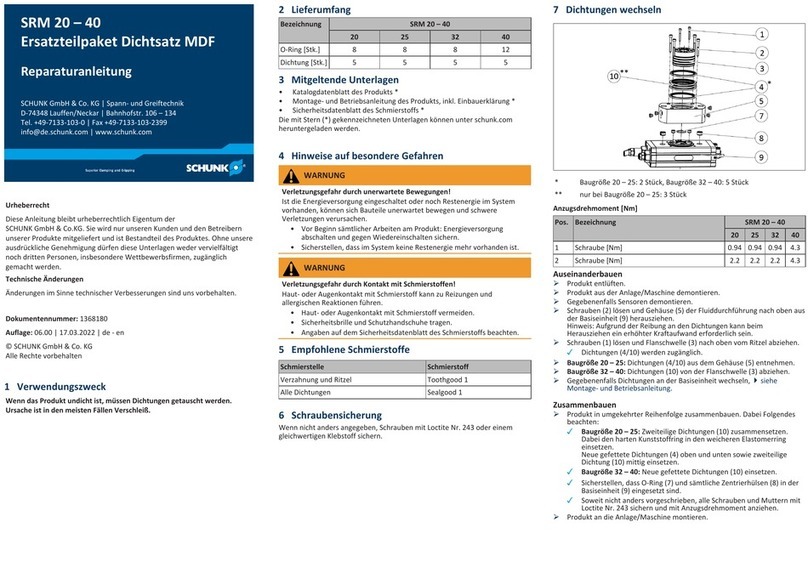

Scope of delivery

The scope of delivery includes

• change head CWK

– Accessory pack: Centering sleeve (2x)

• change adapter CWA

Accessories

•

Adapter plate A-CWA

Accessory pack: 2x O-ring / 2x Centering sleeve / 2x screws

Assembly

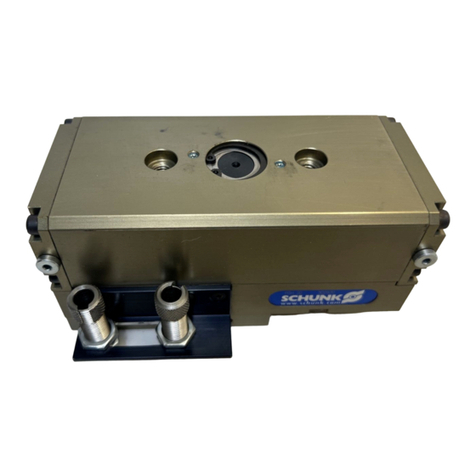

Mechanical connection

Mounting

Mounting of the Compact-Change-System CWS

ØAdjust change adapter CWA with the centering sleeves

(1) (in the enclosed pack of the gripper) at the gripper

and fix it with the screws (2) (not included in scope of

delivery).

Ø

Adjust the change head CWK with the centering sleeves

(3) (in enclosed pack of CWK) at the robot flange or

adapter plate and fix it with the screws (4) (not included).

Alternatively the mounting to the robot flange for sizes

80/10/125 can be done by the integrated ISO-9409 pattern.

For assembling a boss plate (5) and socket head screws (6)

(not included) are needed.

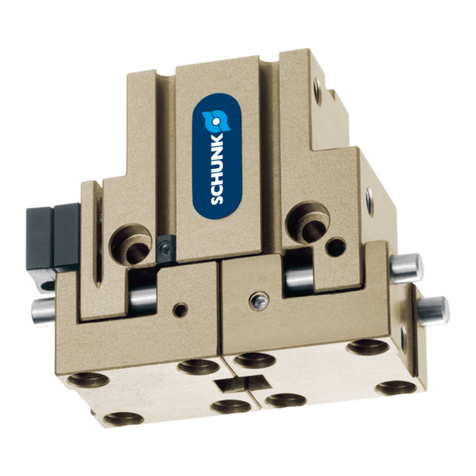

Mounting of optional adapter plate A-CWA

Ø

For mounting the adapter plate A-CWA onto the gripper

side of the CWA, remove the setscrews and put the O-

rings (in enclosed pack of the A-CWA) into the specified

recesses of the CWA.

Ø

Adjust the A-CWA with the centering sleeves at the CWA

and fix it with the screws (centering sleeves and screws

in the enclosed pack of the A-CWA).

03.00 | Short Manual | Compact-Change-SystemCWS | en | 389535