Bastl Instruments Little Nerd User manual

lastupdate:9.3.2016

LITTLENERDv1.1AssemblyGuide

bastlinstruments.com

INTRODUCTION

This guide is for building Little Nerd module from Bastl Instruments. It is good to have basic soldering

skills and to be able to identify electronic components before starting this kit. However if you have never

soldered before, check out this tutorial first . We even included some of the best quality solder we have

1

foundtohelpyousoldereverythingfasterandbetter.

1http://www.instructables.com/id/Howtosolder/

1

The Little Nerd module consists of three boards. All the parts comes in four bags separated for Bottom

board,Connectorboard,PotsboardandAssemblyparts.SeeBillofMaterials(BOM)fordetailedlist.

Beforestartingthiskit,preparethefollowingtools:

Solderingiron(1520W)

Multimeter

Flushcutters

n2.hexscrewdriverorallenkey(enclosedwithkit)

Phillipsscrewdriver(cross)

WrenchNo.8

Protectiveeyewear

We suggest that you work in a clean and a well lit and ventilated environment to avoid accidents or

losinganyofthesmallcomponents.

Alsobrieflygothroughthisguideandmakesurethatyouunderstandallthesteps.

2

CONNECTORBOARD

Let’s start with the connector board PCB. Before you start soldering, take your time and find all the

resistorsvaluesusingamultimeter (oryoucancheckthecolorcodesifyouareseasonedenough).

2

Now insert and solder 21 resistors (7x 10k, 14x 1k). Then snip the leads as close to the PCB as you

can(besuretomakethissteponallremainingleadsinthecourseofthisguide).

Turn around the PCB and insert seven

transistors (2N3904). Watch out for

orientation! Flat side of transistors must

match the outline drawn on the PCB. You may

also want to push the leads in the upper part

closer to each other to insert the transistors

closer to the PCB (although they should not

beflatwiththePCB).

Next insert seven jacks and seven green LEDs. Be careful to put the longer lead of LEDs into the

plus (+) hole. Jacks must sit flat on the board, otherwise they will not come easy through the front

panel.Donotsolderanythingyet.

2https://learn.sparkfun.com/tutorials/howtouseamultimeter/measuringresistance

3

Now take the front panel and lower it down on the connector board. Hold it together and mount it with

two jack nuts on the first and the last jack connector (you do not have to tighten them too much as you

maydamagethewoodenpanel).

Then turn around this unit facing it with PCB upwards. Now push the LEDs leads to fit their heads on

panel. Make sure that everything is properly aligned. Finally you are ready to solder all the

components

4

The last thing to solder is to close two solder jumpers indicated by “IN” under the first and fifth jack

connector.Thisnormalizestheinputtogroundwhennothingispluggedin.Seetheimagebelow.

Unmount the connector board from the panel. As you can see some male pinheaders left. You will use

theminanotherstep.

POTSBOARD

Next you will build the pots board. Firstly insert three resistors (15k) and solder them. You should be

aware to let enough space for the 5 pin holes on the side (you will be soldering a male pinheader

therelater).

Take the six potentiometers and put them

on the board. They have to sit right on the

board and stand vertically. You can start

soldering only one leg of each pot, then check

the alignment and make an adjustment if

needed. Solder the other legs. Then let’s insert

andsoldertwosmallbuttons.

5

Now you want one 1x5 and one 1x8 male pinheader. If it is necessary cut the required length with

your flush cutters. Then put them from the other side and solder them. Be careful to solder the

pinheaders straight! You may first solder the middle pin, then take the board in your hand and reheat

that pin while pressing down on the header to align it (be careful though, you don’t want to touch the pin

youareheatingup).Waitforittocoolandsoldertherestofthepins.

Now it is time to insert RGB LED. The

longest lead should be in the third

hole as well as the flat sides of the

LED should match the printing. See

the picture to check the orientation. Do

notsolderyet!

Before soldering LED you should mount the board to the wooden panel first. Take two screws along

with two 10 mm spacers and fix them with the panel. Then let the board go through and secure it

withnutand11mmspacer.

6

Push the LED leads to fit it’s head

on panel and solder it. You can

keeptheboardonpanel.

BOTTOMBOARD

Now let’s make the bottom board. Again start with the resistors. There are five of them (3x 10k, 2x 1M)

and they are pretty signed on the board. After that solder the 1N4007 diode.Be careful, diodes are

polarized!Makesurethatthemarkingringonthediodebodymatchesthemarkingonthecircuitboard.

Next solder the 7805 voltage regulator. Bend

its legs as close to the body as possible, at a

right angle to make sure that it lies flat on the

circuitboard.

7

Then solder two IC sockets (1x 14 pin, 1x 28 pin). Make sure that the notch on the socket matches

theprintontheboard.

Now let’s do some other parts. There are three 100nF capacitors (marked 104), one protective fuse

(it looks quite similar to a ceramic capacitor but is placed in the “PTC” rectangular) and one 16MHz

resonator (the orange component with 3 leads). None of these parts are polarized so you can insert

theminanydirection.

It is time for more capacitors. Insert two 10μF

electrolytic capacitors and solder them.

However be careful, these are polarized!

There is a plus (+) sign on the PCB that should

match the longer lead of the capacitor (actually

the minus (–) side is also marked on the body of

thecapacitorwithawhitestrip).

8

Now insert two

transistors

(2N3906). Again,

watch out for

orientation! Flat side

of transistors must

match the outline

drawn on the PCB.

You also want to push

them closer to the

PCB. Next don’t forget

to place the ICs in the sockets (1x Atmega, 1x 74HC595). There is a notch on each IC that should

matchwiththesignonthesockets.Checkthepicture.

Turn around the PCB and prepare the four following male pinheaders parts with your flush cutters: 2

pin, 3 pin, 6 pin and 2x5 pin. You can see their placement on the next picture. Again you should be

carefultosolderthepinheadersstraight.

9

MOUNTINGOFTHEBOARDS

You are almost done now. You have to finally

connect all the boards together. Take the bottom

board and connector board first. Prepare two 3

pin headers (male and female), two 2x3 pin

headers (male and female) and pair them

together as shown on the picture. The female

headers goes on the bottom board. Use two 11

mm spacers and four screws to get the boards

together. Now solder both female and male

pinheaders.

Now prepare two female headers (5 pin, 8

pin). Press it on pots board male headers and

then take the two units, put them together

(use the last screw for mounting) and solder

thefemaleheadersonbottomboard.

10

FINALASSEMBLY

Congratulations! You have made it

through, now just secure the jacks to the

panel with the washers and the nuts

(keep in mind not to tighten the jack

nuts too much as you may damage the

panel!), install two jumpers and a

screw with the small nut on the

voltageregulator(seethepictures).

11

Before you connect anything, make sure that your system is disconnected from power. Also double

check the polarity of the ribbon cable, the red cable should match the 12V rail both on the module and

onthebusboard!

TROUBLESHOOTING

Thismaybethecommonproblemsandsolutions:

Inputsdon’tworkastheyshould

Checkoutthesolderedjointsagain.Ifneededheatupthemandaddabitofsolder.

Seetheinstalledpositionsofjumpers(seepage11)

CheckouttheICsorientation(seepage9)

RGBLEDisnotworkinghowitshould

Isitorientedtherightway?(seepage6)

Ifyouarehavingsomemoretrouble,thebestthingistotakeanap!Especiallylateatnight!

If you are still in trouble, you can send the detailed description of the problem with enclosed

highresolutionphotosondiy@bastlinstruments.com.

If you think that you are unable to make the module work on your own, consider our “Come to Daddy”

service.

12

Table of contents

Other Bastl Instruments Control Unit manuals

Popular Control Unit manuals by other brands

SMC Corporation

SMC Corporation EX250-SCN1 Technical specification

Pepperl+Fuchs

Pepperl+Fuchs ICE11-8IOL-G60L-V1D manual

Domestia

Domestia DMC-012-003 S manual

SMART Embedded Computing

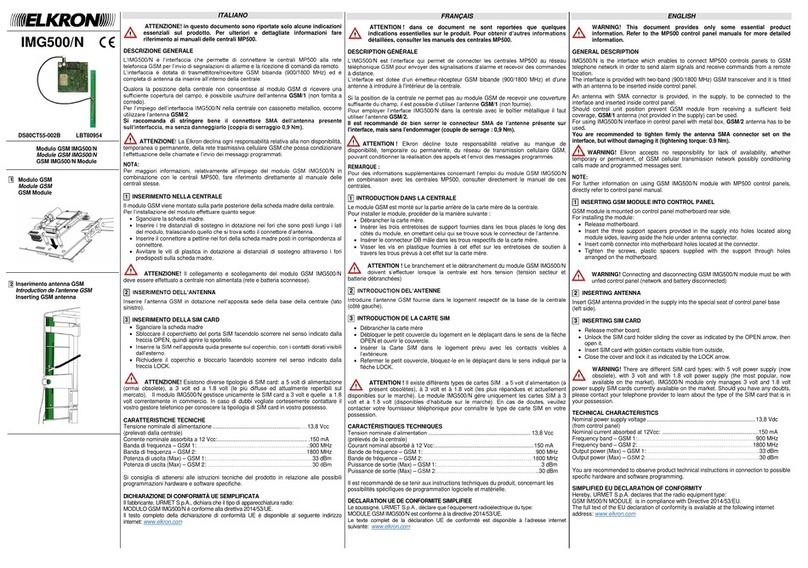

SMART Embedded Computing PrAMC-7311 Installation and use

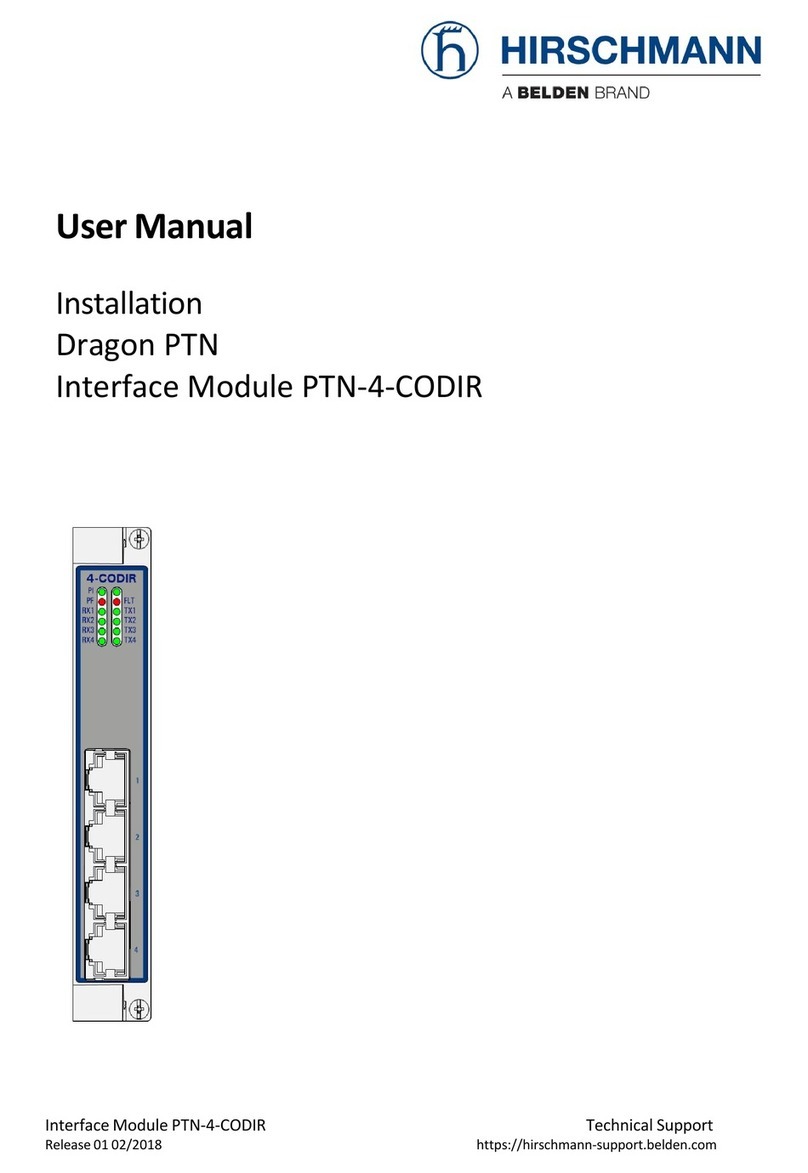

Hirschmann

Hirschmann Dragon PTN Series user manual

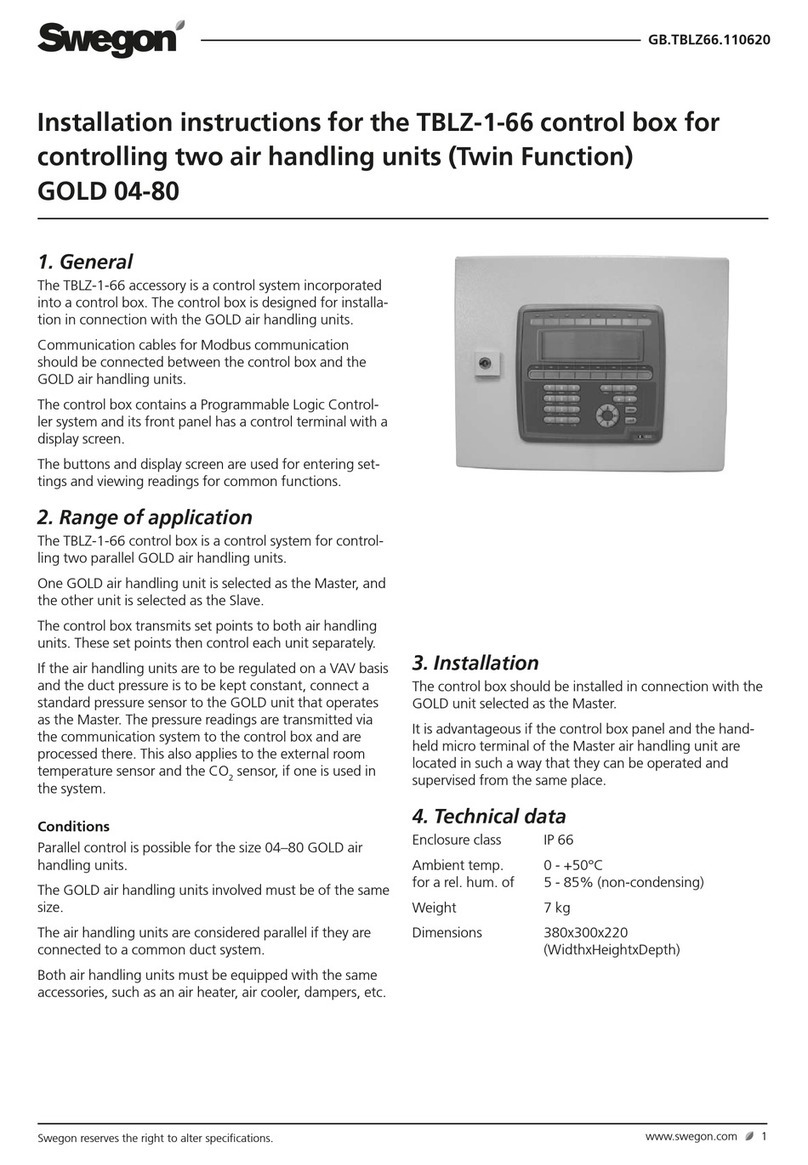

Swegon

Swegon TBLZ-1-66 installation instructions