GB.TBLZ66.110620

Swegon reserves the right to alter specifications.

2 www.swegon.com

7. Description of functions

The ordinary control circuit card in the GOLD air handling

units controls its respective functions, but obtains set

points for certain functions of the control circuit card in

the control box.

The type of temperature and fan regulation to be used are

selected in the control panel of the control box.

All the other functions are set in the hand-held micro

terminal on the GOLD air handling unit that is the opera-

tional Master. The settings in the Master AHU are auto-

matically copied over to the Slave AHU.

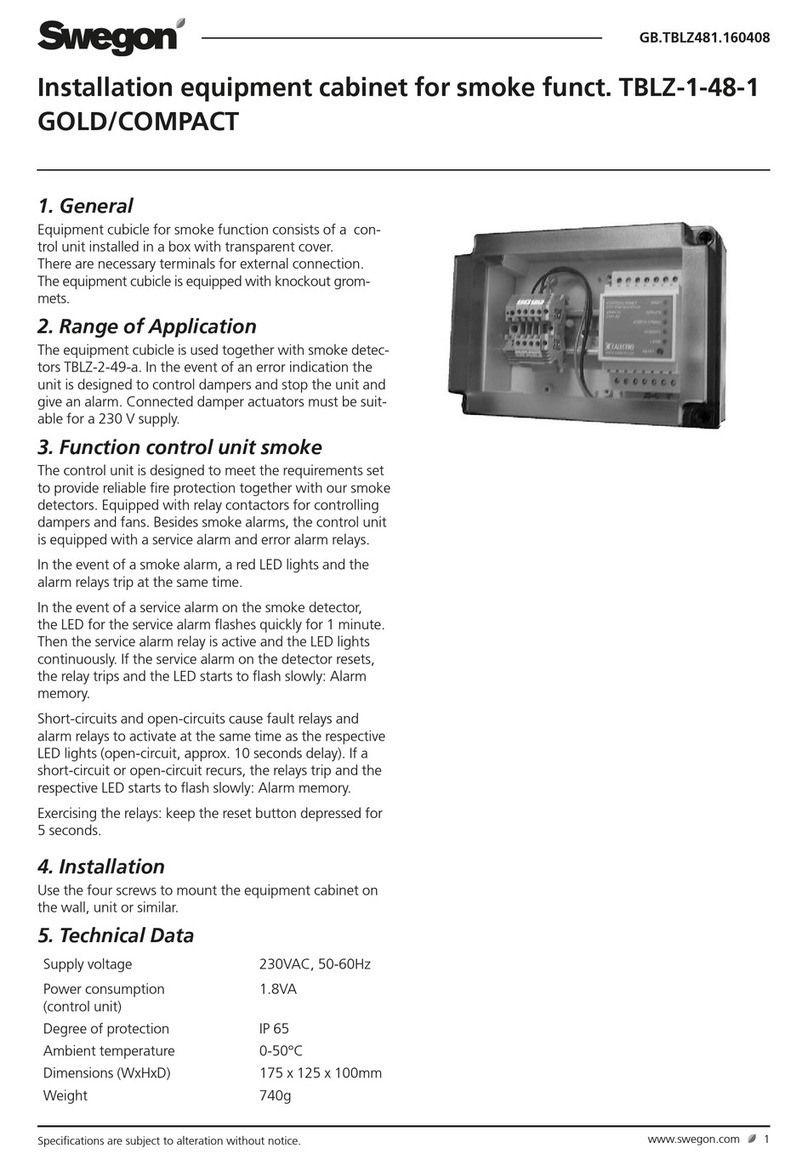

5. Electrical connections

The electrical connections are to be wired by a qualified

electrician in accordance with local electrical safety regula-

tions.

The supply voltage to the control box must be single-

phase, 230 V, and the cable conductors must be con-

nected to wiring terminals 101 (L) and 102 (N).

The control box must be connected to the control circuit

card of the GOLD air handling unit with twisted-pair,

shielded communication cables. Communication is con-

ducted via Modbus RTU and the control circuit card of the

control box is the communication Master.

The following wiring terminals must be connected as

specified below:

Terminal in the control box Terminal in GOLD unit

401 28 in the Master AHU

402 27 in the Master AHU

403 28 in the Slave AHU

404 27 in the Slave AHU

6. Commissioning

Energize the control box and both GOLD air handling

units.

Set the Modbus addresses for communication in both

GOLD units.

In the hand-held micro terminal, go to communication

below the Settings level.

Select EIA-485 and check under Protocol that Modbus

RTU is selected.

Go to Settings and set the following parameters:

Address 1 for the Master AHU and Address 2 for the Slave

AHU.

The speed should be 38,400; the parity should be “Even”;

Stop bits should be 1. This applies to both GOLD air han-

dling units

7.1 Temperature regulation:

ERS and Supply air regulation

ERS and supply air regulation are controlled in each GOLD

unit. The settings in the control box are automatically

transmitted over to the air handling units.

Extract air regulation.

The extract air controller is located inside the control

box. The extract air controller transmits set points to the

supply air controllers of the GOLD air handling units. The

air handling units are then automatically set for supply air

regulation.

The extract air controller in the control box receives values

for extract air temperature from the Master AHU’s extract

air temperature sensor or via communication from exter-

nal extract air /room sensors connected to the Master

AHU.

7.2 Fan regulation

Flow regulation

The total flow set on the control box panel is split equally

and is transmitted to the flow controllers of the GOLD air

handling units. The air handling units are then automati-

cally set for flow regulation.

Pressure regulation

The pressure regulation controller is located inside the

control box. The pressure controller controls how the air

handling units operate by transmitting flow set points to

both GOLD air handling units. The control circuit cards of

the air handling units maintain constant airflow in both air

handling units. The air handling units are then automati-

cally set for flow regulation.

The standard pressure sensor of the GOLD units are used

as duct pressure sensors in the common ducts. The duct

pressure sensors are connected to the Master AHU’s con-

nections marked Internal EIA-485.

The control box controller receives pressure values from

the Master AHU via the communication system.

Demand regulation

If demand regulation is used, the Master AHU’s extract

air fan is controlled via signals on wiring terminals, inputs

32-33. The supply air fan of the Master AHU is control-

led in response to the extract airflow as a Slave. The Slave

AHU copies the current flow regulation values and set

points from the Master air handling unit. The air handling

units are then automatically set for their respective func-

tions.