10 IOM-WKM-BALL-370D5

DISTRIBUTED VALVES

TC9186

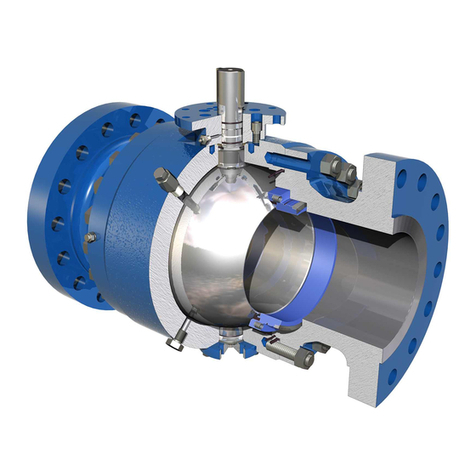

5. Turn the valve on end with the weight spread evenly on one port face of the body,

exercising care not to damage the sealing surfaces if the valve is flanged. Loosen

body nuts on upper closure one full turn and lift on closure to loosen closure,

O-rings, and body.

6. Remove remaining body nuts from upper closure and lift closure off body studs. Be

careful not to damage body O-ring or bearing unit dowel pins. Loosen body nuts

on lower closure one full turn and lift on body to loosen body, O-ring and closure.

7. Remove remaining body nuts from lower closure and remove body. On large valves,

body studs may be replaced by eyebolts for this operation.

8. Remove vent valve and relief valve from body for cleaning.

9. Insert lifting eyebolts in threaded holes provided in bearing plates.

10. Using eyebolts and a spreader bar cut to length, lift the ball up and out of the seat

ring.

Caution: Ball can slide out of the bearing blocks.

11. For reassembly note position of the three or more reassembled drilled holes on

O.D. of outer seat ring. Seat ring must be with these holes at 90° to the vertical

centerline of the stem and ball.

Installation, Operation and Maintenance Manual

6

GRO-IOM-BALL-B4-B4B-B4C

7. Remove remaining body nuts from lower closure

and remove body. On large valves, body studs

may be replaced by eyebolts for this operation.

8. Remove vent valve and relief valve from body for

cleaning.

9. Insert lifting eyebolts in threaded holes

provided in bearing plates.

10. Using eyebolts and a spreader bar cut to

length, lift the ball up and out of the seat

ring.

CAUTION: BALL CAN SLIDE OUT OF THE

BEARING BLOCKS.

11. For reassembly note position of the three or more

reassembled drilled holes on O.D. of outer seat

ring. Seat ring must be with these holes at 90°

to the vertical centerline of the stem and ball

4. Open ball valve about 1/3 to permit pressurizing valve

body.

5. Fill line and valve body until liquid flows from

gland plate body vent port and pressures the

relief port.

6. Raise pressure to desired hydrostatic test pressure.

This pressure must not exceed 1-1/2 times the maximum

operating pressure of the valve - unless prior approval

to test at higher levels is obtained from Engineering.

7. After test is completed:

a. Close ball valve.

b. Vent any remaining body pressure through bottom

vent plug valve and close tightly.

c. REINSTALL THE RELIEF VALVE

This is very important for protection of the body

against over-pressure when the valve is in the

closed position.

CAUTION: DO NOT ALTER THE RELIEF VALVE SETTING.

8. When valve is in the closed position, test pressures

must NOT exceed the maximum rated operating

pressure on the valve.

PART IV - OFF STREAM MAINTENANCE

Major repairs which necessitate removing the valve from

the line.

EQUIPMENT

Handling equipment as required for weight involved,

see current 370D5 Ball Valve catalog for weight of specific

valve. Also required is a plywood sheet to press in large

seat rings.

A. DISASSEMBLY PROCEDURE

1. Turn the valve to open position and open vent to relieve

line pressure before removing the valve from the line.

2. Remove the wrench or gear per instructions in Part III.

3. Remove stem assembly per instructions Part III.

4. Remove body nuts except four (4) on each flange.

5. Turn the valve on end with the weight spread evenly

on one port face of the body, exercising care not to

damage the sealing surfaces if the valve is flanged.

Loosen body nuts on upper closure one full turn and

lift on closure to loosen closure, O-rings, and body.

6. Remove remaining body nuts from upper closure and

lift closure off body studs. Be careful not to damage

body O-Ring or bearing unit dowel pins. Loosen body

nuts on lower closure one full turn and lift on body to

loosen body, O-Ring and closure.

Installation, Operation and Maintenance Manual

6

GRO-IOM-BALL-B4-B4B-B4C

7. Remove remaining body nuts from lower closure

and remove body. On large valves, body studs

may be replaced by eyebolts for this operation.

8. Remove vent valve and relief valve from body for

cleaning.

9. Insert lifting eyebolts in threaded holes

provided in bearing plates.

10. Using eyebolts and a spreader bar cut to

length, lift the ball up and out of the seat

ring.

CAUTION: BALL CAN SLIDE OUT OF THE

BEARING BLOCKS.

11. For reassembly note position of the three or more

reassembled drilled holes on O.D. of outer seat

ring. Seat ring must be with these holes at 90°

to the vertical centerline of the stem and ball

4. Open ball valve about 1/3 to permit pressurizing valve

body.

5. Fill line and valve body until liquid flows from

gland plate body vent port and pressures the

relief port.

6. Raise pressure to desired hydrostatic test pressure.

This pressure must not exceed 1-1/2 times the maximum

operating pressure of the valve - unless prior approval

to test at higher levels is obtained from Engineering.

7. After test is completed:

a. Close ball valve.

b. Vent any remaining body pressure through bottom

vent plug valve and close tightly.

c. REINSTALL THE RELIEF VALVE

This is very important for protection of the body

against over-pressure when the valve is in the

closed position.

CAUTION: DO NOT ALTER THE RELIEF VALVE SETTING.

8. When valve is in the closed position, test pressures

must NOT exceed the maximum rated operating

pressure on the valve.

PART IV - OFF STREAM MAINTENANCE

Major repairs which necessitate removing the valve from

the line.

EQUIPMENT

Handling equipment as required for weight involved,

see current 370D5 Ball Valve catalog for weight of specific

valve. Also required is a plywood sheet to press in large

seat rings.

A. DISASSEMBLY PROCEDURE

1. Turn the valve to open position and open vent to relieve

line pressure before removing the valve from the line.

2. Remove the wrench or gear per instructions in Part III.

3. Remove stem assembly per instructions Part III.

4. Remove body nuts except four (4) on each flange.

5. Turn the valve on end with the weight spread evenly

on one port face of the body, exercising care not to

damage the sealing surfaces if the valve is flanged.

Loosen body nuts on upper closure one full turn and

lift on closure to loosen closure, O-rings, and body.

6. Remove remaining body nuts from upper closure and

lift closure off body studs. Be careful not to damage

body O-Ring or bearing unit dowel pins. Loosen body

nuts on lower closure one full turn and lift on body to

loosen body, O-Ring and closure.

Installation, Operation and Maintenance Manual

6

GRO-IOM-BALL-B4-B4B-B4C

7. Remove remaining body nuts from lower closure

and remove body. On large valves, body studs

may be replaced by eyebolts for this operation.

8. Remove vent valve and relief valve from body for

cleaning.

9. Insert lifting eyebolts in threaded holes

provided in bearing plates.

10. Using eyebolts and a spreader bar cut to

length, lift the ball up and out of the seat

ring.

CAUTION: BALL CAN SLIDE OUT OF THE

BEARING BLOCKS.

11. For reassembly note position of the three or more

reassembled drilled holes on O.D. of outer seat

ring. Seat ring must be with these holes at 90°

to the vertical centerline of the stem and ball

4. Open ball valve about 1/3 to permit pressurizing valve

body.

5. Fill line and valve body until liquid flows from

gland plate body vent port and pressures the

relief port.

6. Raise pressure to desired hydrostatic test pressure.

This pressure must not exceed 1-1/2 times the maximum

operating pressure of the valve - unless prior approval

to test at higher levels is obtained from Engineering.

7. After test is completed:

a. Close ball valve.

b. Vent any remaining body pressure through bottom

vent plug valve and close tightly.

c. REINSTALL THE RELIEF VALVE

This is very important for protection of the body

against over-pressure when the valve is in the

closed position.

CAUTION: DO NOT ALTER THE RELIEF VALVE SETTING.

8. When valve is in the closed position, test pressures

must NOT exceed the maximum rated operating

pressure on the valve.

PART IV - OFF STREAM MAINTENANCE

Major repairs which necessitate removing the valve from

the line.

EQUIPMENT

Handling equipment as required for weight involved,

see current 370D5 Ball Valve catalog for weight of specific

valve. Also required is a plywood sheet to press in large

seat rings.

A. DISASSEMBLY PROCEDURE

1. Turn the valve to open position and open vent to relieve

line pressure before removing the valve from the line.

2. Remove the wrench or gear per instructions in Part III.

3. Remove stem assembly per instructions Part III.

4. Remove body nuts except four (4) on each flange.

5. Turn the valve on end with the weight spread evenly

on one port face of the body, exercising care not to

damage the sealing surfaces if the valve is flanged.

Loosen body nuts on upper closure one full turn and

lift on closure to loosen closure, O-rings, and body.

6. Remove remaining body nuts from upper closure and

lift closure off body studs. Be careful not to damage

body O-Ring or bearing unit dowel pins. Loosen body

nuts on lower closure one full turn and lift on body to

loosen body, O-Ring and closure.