Batco 1300 P Series User manual

Part Number: P1512121 R0

Revised: 11/3/10

Read this manual before using product. Failure

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

TOP DRIVE FIELD LOADER GRAIN

CONVEYOR

1300 P, 1500 P SERIES

OPERATION MANUAL

=

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

Date Employee Signature Employer Signature

P1512121 1

BATCO TOP DRIVE FIELD LOADER

1300 P, 1500 P SERIES

TABLE OF CONTENTS

1. Introduction .......................................................................................................................... 3

2. Safety First............................................................................................................................ 5

2.1. General Safety ......................................................................................................... 6

2.2. Transport and Placement Safety.............................................................................. 7

2.3. Operational and Maintenance Safety....................................................................... 8

2.4. Hydraulic Safety..................................................................................................... 10

2.5. Electric Motor Safety.............................................................................................. 10

2.6. Storage Safety........................................................................................................ 10

2.7. Tire Safety.............................................................................................................. 10

2.8. Safety Decal Locations........................................................................................... 11

2.8.1. Decal Installation...................................................................................... 11

2.8.2. Decal Locations........................................................................................ 11

3. Components and Controls................................................................................................ 15

4. Transport............................................................................................................................. 17

4.1. Pre-Transport Checklist.......................................................................................... 17

4.2. Transport Procedure .............................................................................................. 17

5. Placement ........................................................................................................................... 19

5.1. Under Hopper Bottom Bins .................................................................................... 19

5.2. Filling Trucks/Tanks ............................................................................................... 19

6. Operation ............................................................................................................................ 21

6.1. Pre-Operation Checklist......................................................................................... 21

6.2. Machine Break-In And Operation........................................................................... 21

6.2.1. Drive Setup............................................................................................... 22

6.2.2. Starting Conveyor..................................................................................... 22

6.2.3. Conveyor Shutdown................................................................................. 23

6.2.4. Emergency Shutdown .............................................................................. 23

6.2.5. Re-starting (Full Tube).............................................................................. 23

6.2.6. Conveyor Operating Angles ..................................................................... 23

6.2.7. Belt Speed................................................................................................ 23

6.2.8. Operating Tips.......................................................................................... 24

7. Storage................................................................................................................................ 25

2P1512121

BATCO TOP DRIVE FIELD LOADER

1300 P, 1500 P SERIES

TABLE OF CONTENTS

8. Maintenance........................................................................................................................ 27

8.1. Maintenance Schedule........................................................................................... 27

8.1.1. Initial start-up servicing............................................................................. 27

8.1.2. 8 Hours or Daily........................................................................................ 27

8.1.3. 40 Hours or Weekly.................................................................................. 27

8.1.4. 200 Hours or Annually.............................................................................. 27

8.2. Maintenance Checklist ........................................................................................... 28

8.3. Service & Maintenance Procedures....................................................................... 29

8.3.1. Fluids and Lubricants................................................................................ 29

8.3.2. Greasing................................................................................................... 29

8.3.3. Conveyor Belt Tension And Alignment..................................................... 29

8.3.4. Belt Tension Instructions .......................................................................... 30

8.3.5. Conveyor Belt Alignment.......................................................................... 31

8.3.6. Conveyor Belt Replacement..................................................................... 33

8.3.7. Belt Relacing............................................................................................. 34

8.3.8. Drive Belt Tension & Alignment (Electric Drive) ....................................... 35

9. Troubleshooting ................................................................................................................. 37

10. Appendix........................................................................................................................... 39

10.1. Top Drive Field Loader Specifications.................................................................. 39

10.2. Conveyor Product Chart....................................................................................... 40

New Equipment Warranty ....................................................................................................... 41

BATCO - TOP DRIVE FIELD LOADER 1. INTRODUCTION

1300 P, 1500 P SERIES

P1512121 3

1.Introduction

Congratulations on your choice of a Batco Conveyor to complement your agricul-

tural operation. This equipment has been designed and manufactured to meet

the needs of the discriminating buyer for the efficient movement of grain, pulse

crops, fertilizer, and most other granular materials.

Safe, efficient, and trouble-free operation of your conveyor requires that you, and

anyone else who will be operating or maintaining the conveyor, read and under-

stand the safety, operation, maintenance, and troubleshooting information in this

manual.

¨

Equipment is available in various combinations. In most cases, the following

instructions will apply to all machines. Where the assembly information varies,

additional instructions will be included and will be indicated with an arrow.

Keep this manual handy for frequent reference and to pass on to new operators

or owners. Call your Batco distributor or dealer if you need assistance, infor-

mation, or additional copies of the manual.

Always give your dealer the serial number of your Batco Grain Conveyor when

ordering parts or requesting service or other information.

The serial number plate is located where indicated above by the arrow on the

frame. Please mark the number in the space provided for easy reference.

Model#

Serial #

Production Year

1. INTRODUCTION BATCO - TOP DRIVE FIELD LOADER

1300 P, 1500 P SERIES

4P1512121

BATCO - TOP DRIVE FIELD LOADER 2. SAFETY FIRST

1300 P, 1500 P SERIES

P1512121 5

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibil-

ity of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means ATTENTION, BE ALERT!, YOUR SAFETY IS

INVOLVED.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

2. SAFETY FIRST BATCO - TOP DRIVE FIELD LOADER

2.1. GENERAL SAFETY 1300 P, 1500 P SERIES

6P1512121

2.1. GENERAL SAFETY

Important: The general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and under-

stand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and anually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly vis-

ible place.

• Wear appropriate protective gear. This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor, remove ignition key or lock out power source, and wait for all mov-

ing parts to stop.

BATCO - TOP DRIVE FIELD LOADER 2. SAFETY FIRST

1300 P, 1500 P SERIES 2.2. TRANSPORT AND PLACEMENT SAFETY

P1512121 7

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. TRANSPORT AND PLACEMENT SAFETY

• Be sure that conveyor is empty before raising or lowering.

• Check with local authorities regarding transport on public roads. Obey all

applicable laws and regulations.

• Always travel at a safe speed, never exceeding

20 mph (32 km/h). Reduce speed on rough

surfaces. Use caution when turning corners or

meeting traffic.

• Make sure the SMV (slow moving vehicle)

emblem and all the lights and reflectors that

are required by local authorities are in place,

are clean, and can be seen by all over-taking

and oncoming traffic. Always use hazard-warn-

ing flashers on tractor/towing vehicle when

transporting unless prohibited by law.

• Do not allow riders on the machine, towing

vehicle, tractor, or skid steer during transport.

• Stay away from overhead obstructions and

power lines when operating and transporting.

Electrocution can occur without direct contact.

• Fully lower conveyor before transporting, and

only raise when next to storage facility.

• Review the work safety area diagram before

starting work.

• Attach a conveyor to towing vehicle with a pin

and retainer. Always attach safety chain(s).

• Chock front and rear conveyor and tractor

wheels before operating.

• Do not raise the intake end above drawbar,

conveyor upending may occur.

• Be familiar with the machine transport hazard

area. If anyone enters the hazard area, shut

down the machines immediately. Clear the

area before restarting.

• Do not transport conveyor on slopes greater than 20°.

• When lowering the auger the track shoe may become stuck; if this happens,

do not continue to turn the winch handle counter-clockwise because it will dis-

engage the brake mechanism and create an unsafe condition. Too much

slack in the cable may also cause the conveyor to drop suddenly.

2. SAFETY FIRST BATCO - TOP DRIVE FIELD LOADER

2.3. OPERATIONAL AND MAINTENANCE SAFETY 1300 P, 1500 P SERIES

8P1512121

• The winch must make a clicking sound when raising conveyor. If clicking

sound stops, retain grip on handle, lower conveyor fully, and repair winch.

• After lowering conveyor, turn handle clockwise 2 clicks to lock winch brake.

• The winch is designed for manual operation only.

• Always keep a minimum of 3 cable wraps on the winch drum.

• Wheels must be free to move when raising or lowering conveyor. Do not use

conveyor as a crane or hoist.

• Only move your conveyor with a tractor/towing vehicle. Never move by hand.

2.3. OPERATIONAL AND MAINTENANCE SAFETY

• Keep hands, feet, hair, clothing, and jewelery away from all moving and/or

rotating parts.

• Stay away from overhead obstructions and power lines; electrocution may

occur without direct contact.

• Do not operate with any of the guards removed.

• The machine is closely balanced. Do not lift unless there is a downward

weight on the intake end to prevent upending.

¨

• Set park brake on tractor before starting.

• Lower conveyor to its lowest position when not in use.

• Operate conveyor on level ground free of debris. If ground is uneven, anchor

the conveyor to prevent tipping or upending.

• Place stands or blocks under the frame before working beneath the machine.

• Always work with a second person around conveyor in case of accident.

• Empty conveyor before raising or lowering.

• Do not get on or beneath conveyor when raising or lowering.

• Do not lift intake above tow bar height or conveyor may upend.

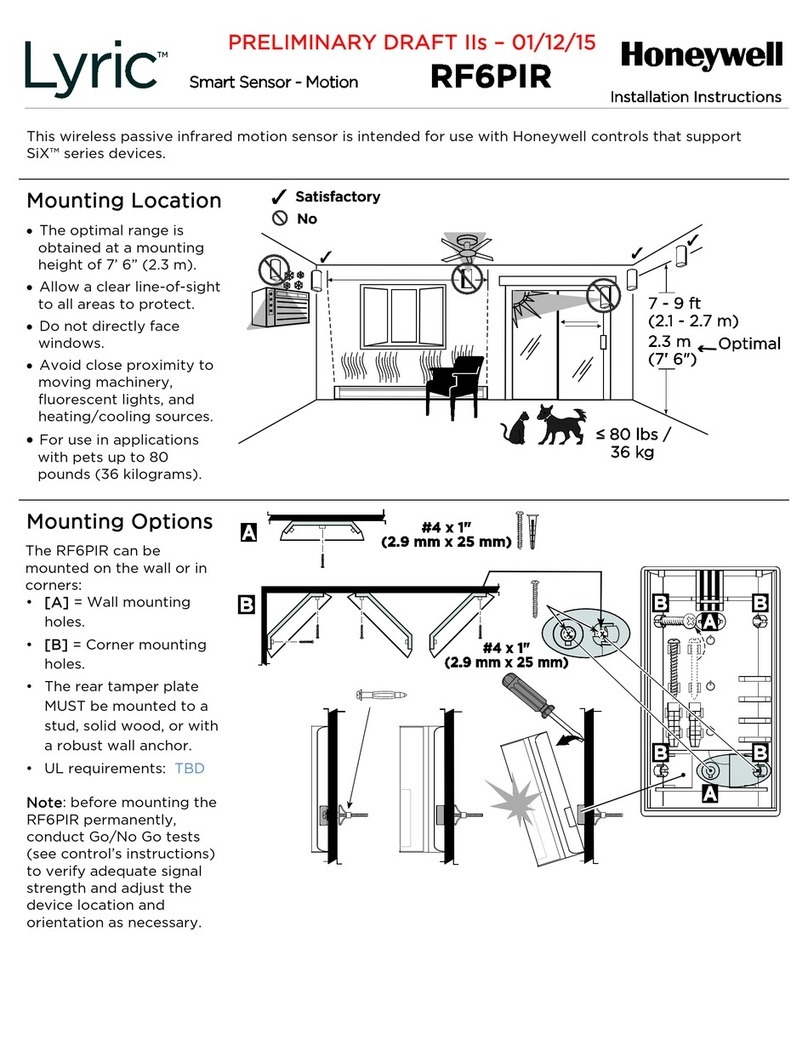

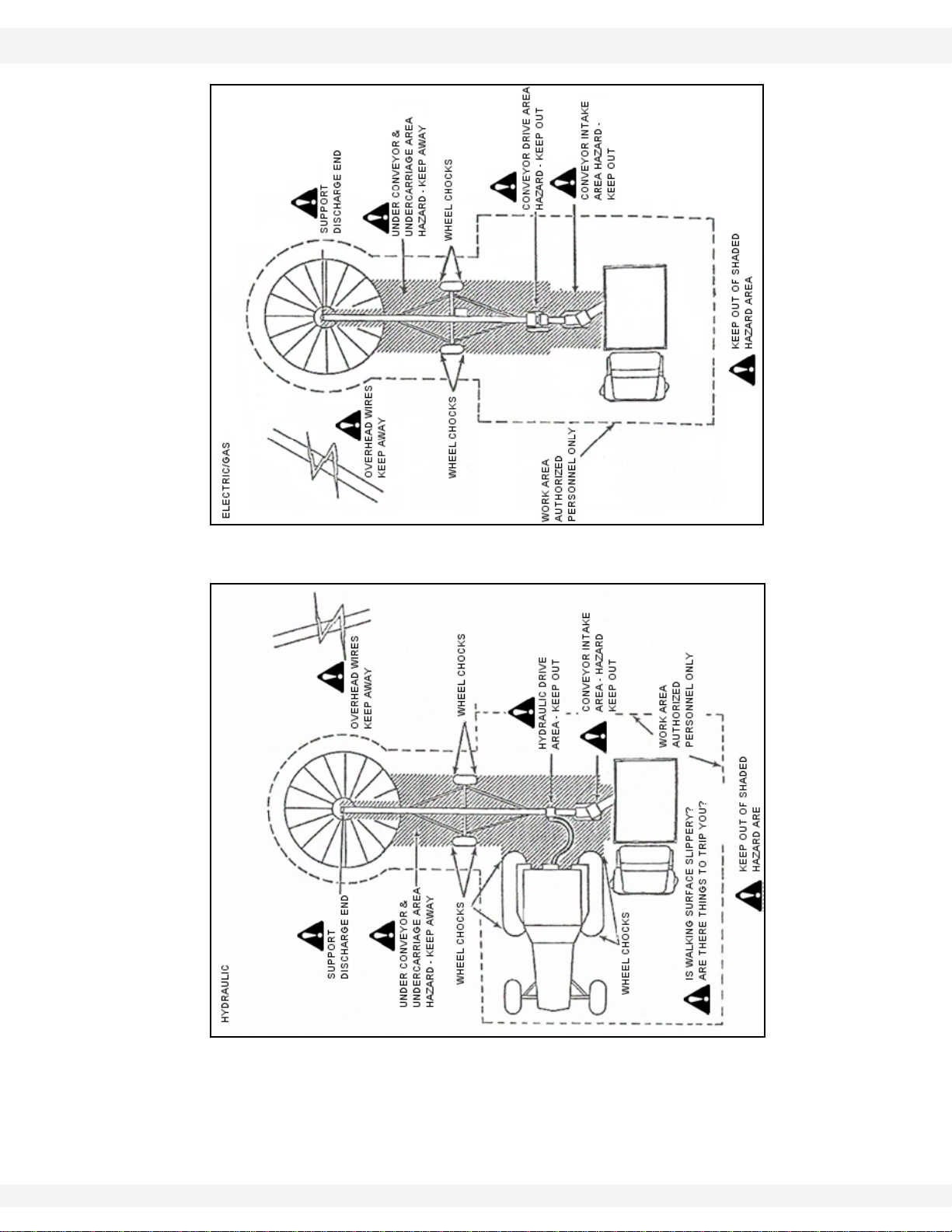

• Be familiar with the machine hazard area shown in Figure 2.1 and 2.2. If any-

one enters the hazard area, shut down the machines immediately. Clear the

area before restarting.

BATCO - TOP DRIVE FIELD LOADER 2. SAFETY FIRST

1300 P, 1500 P SERIES 2.3. OPERATIONAL AND MAINTENANCE SAFETY

P1512121 9

Figure 2.1 Workplace Hazard Area (Electric Area)

Figure 2.2 Workplace Hazard Area (Hydraulic Drive)

2. SAFETY FIRST BATCO - TOP DRIVE FIELD LOADER

2.4. HYDRAULIC SAFETY 1300 P, 1500 P SERIES

10 P1512121

2.4. HYDRAULIC SAFETY

• Always place all tractor hydraulic controls in neutral before disconnecting

from tractor or working on hydraulic system.

• Make sure that all components in the hydraulic system are kept in good con-

dition and are clean.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses by

using tape, clamps, or cements. The hydraulic system operates under

extremely high-pressure. Such repairs will fail suddenly and create a hazard-

ous and unsafe condition.

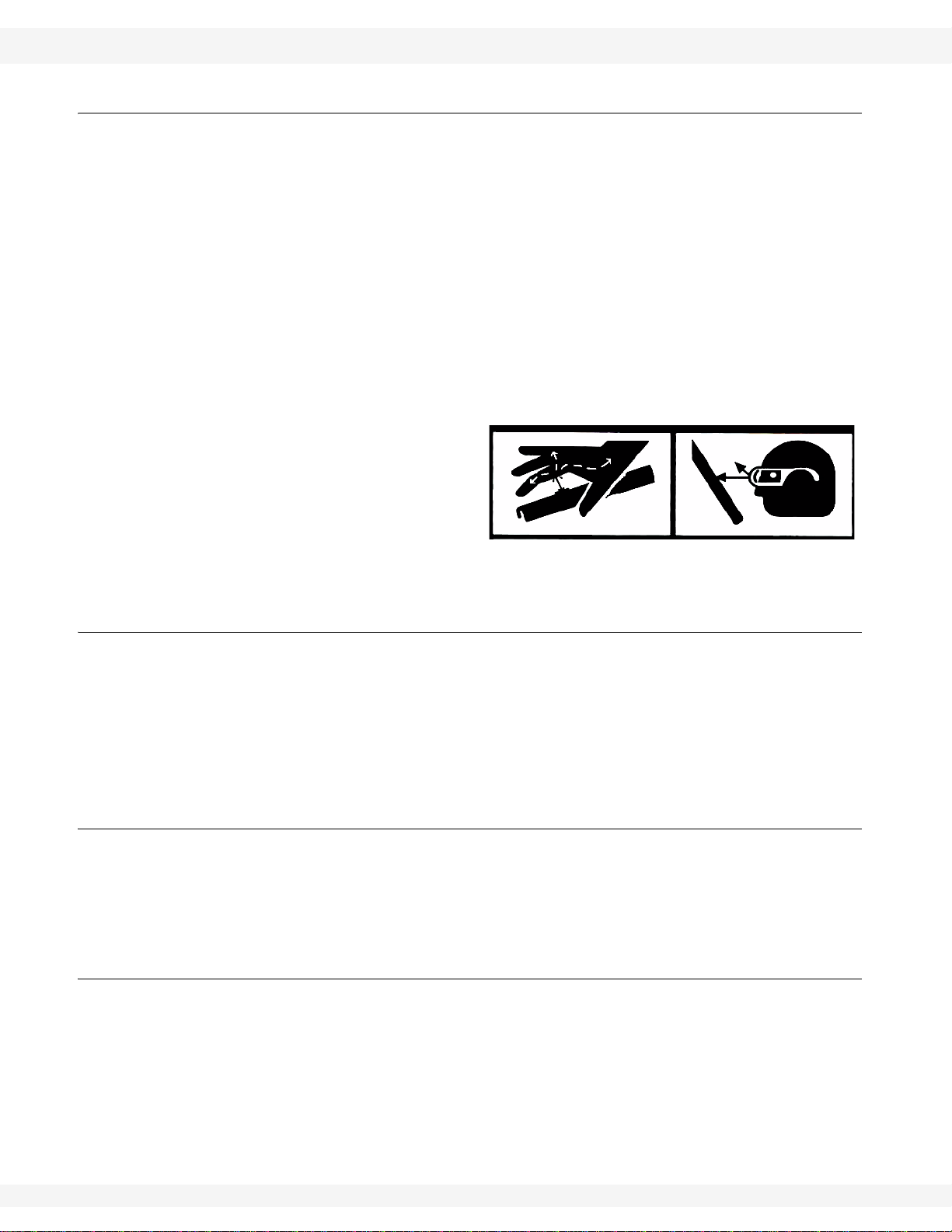

• Wear proper hand and eye protection when searching for a high-pressure

hydraulic leak. Use a piece of wood or cardboard as a backstop instead of

hands to isolate and identify a leak.

• If injured by a concentrated

high-pressure stream of

hydraulic fluid, seek medical

attention immediately. Seri-

ous infection or toxic reaction

can develop from hydraulic

fluid piercing the skin surface.

2.5. ELECTRIC MOTOR SAFETY

• To prevent serious injury or death, only qualified personnel should service

electrical components.

• Keep electrical components in good repair.

• Ground electric motor before using.

• Inspect drive belts before using. Replace if frayed or damaged.

2.6. STORAGE SAFETY

• Store the unit in an area away from human activity.

• Do not permit children to play on or around the stored equipment.

• Fully lower conveyor before storing.

2.7. TIRE SAFETY

• Failure to follow proper procedures when mounting a tire on a wheel or rim

can produce an explosion that may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and

experience to do the job.

• Have a qualified tire dealer or repair service perform required tire mainte-

nance.

BATCO - TOP DRIVE FIELD LOADER 2. SAFETY FIRST

1300 P, 1500 P SERIES 2.8. SAFETY DECAL LOCATIONS

P1512121 11

• When replacing worn tires, make sure they meet the original tire specifica-

tions. Never undersize the replacement tire.

• Do not weld to the tire rim with the tire mounted on the rim. This action may

cause an explosion which could result in serious injury or death.

• Inflate tires to the manufacturers's recommended pressure.

2.8. SAFETY DECAL LOCATIONS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures below.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.8.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 10°C (50°F).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.8.2. DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown

below. Good safety requires that you familiarize yourself with the various safety

decals and the areas or particular functions that the decals apply to as well as

the safety precautions that must be taken to avoid serious, injury, death, or

damage.

2. SAFETY FIRST BATCO - TOP DRIVE FIELD LOADER

2.8. SAFETY DECAL LOCATIONS 1300 P, 1500 P SERIES

12 P1512121

Figure 2.3 Safety Decal Locations (30-55 Conveyors)

Part #: P1513001

Part #: P1513003

Part #: P1513004

BATCO - TOP DRIVE FIELD LOADER 2. SAFETY FIRST

1300 P, 1500 P SERIES 2.8. SAFETY DECAL LOCATIONS

P1512121 13

Figure 2.4 Hydraulic Top drive Safety Decal

Figure 2.5 Electric Top Drive Safety Decals

PART #: P1513002

PART #: P1513009

PART #: 1513008

PART #: P1513002

2. SAFETY FIRST BATCO - TOP DRIVE FIELD LOADER

2.8. SAFETY DECAL LOCATIONS 1300 P, 1500 P SERIES

14 P1512121

BATCO - TOP DRIVE FIELD LOADER 3. COMPONENTS AND CONTROLS

1300 P, 1500 P SERIES

P1512121 15

3.Components and Controls

Before operating the conveyor, all operators should familiarize themselves with

the location and function of the components and controls. See Table 3.1 and

Figure 3.1 for details.

Figure 3.1 Typical Conveyor Components

HOOD

SPOUT

MAIN TUBE

RETURN ROLLER

OR WG ROLLER

A-FRAME

WINCH

HOPPER

COLLAPSIBLE HOPPER

CONTROL

3. COMPONENTS AND CONTROLS BATCO - TOP DRIVE FIELD LOADER

1300 P, 1500 P SERIES

16 P1512121

BATCO - TOP DRIVE FIELD LOADER 4. TRANSPORT

1300 P, 1500 P SERIES 4.1. PRE-TRANSPORT CHECKLIST

P1512121 17

4.Transport

4.1. PRE-TRANSPORT CHECKLIST

Before transporting conveyor, ensure that:

1. Conveyor is in the fully lowered position.

2. Attach conveyor to towing vehicle with a pin and retainer. Always attach

safety chain(s).

¨

3. On electric motor models, unplug the power cord, wrap around frame, and

secure to prevent dragging.

¨

4. On hydraulic powered models, disconnect hydraulic hoses, remove power

source, and wrap hose around frame to prevent dragging.

4.2. TRANSPORT PROCEDURE

1. Check with local authorities regarding conveyor transport on public roads.

Obey all applicable laws and regulations.

2. Make sure the SMV (slow moving vehicle) emblem and all the lights and

reflectors that are required by the local highway and transport authorities are

in place, are clean, and can be seen clearly by all overtaking and oncoming

traffic.

3. Always use hazard warning flashers on tractor or towing vehicle when

transporting unless prohibited by law.

4. Always travel at a safe speed. Use caution when turning corners or meeting

traffic.

5. It is not recommended that the machine be transported faster than 20 mph

(32 km/h). Table 4.1 references the acceptable transport speed as per the

ratio of tractor weight versus conveyor weight. For conveyor weights see

Section 10.

6. Use caution when moving conveyors over rolling terrain. In severe dips the

discharge end may contact the ground.

Warning: Before continuing, please reread the safety information relevant to this section at

the beginning of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

NOTICE

It may be necessary to raise the outlet end

abovethestoragefacilitytoprovideclearance

to raise the intake end.

4. TRANSPORT BATCO - TOP DRIVE FIELD LOADER

4.2. TRANSPORT PROCEDURE 1300 P, 1500 P SERIES

18 P1512121

7. Never go across slopes of more than 11°. It is better to go straight up or

straight down the slope.

Table 4.1 Speed versus Weight Ratio

Road Speed Weight or fully equipped or loaded

implement(s) relative to weight of

towing machine

Up to 32 km/h (20 mph) 1 to 1, or less

Up to 16 km/h (10 mph) 2 to 1, or less

Do not tow if More than 2 - 1

DANGER

Stay away from overhead obstructions and

power lines when operating and transporting.

Electrocution can occur without direct contact.

This manual suits for next models

1

Table of contents

Other Batco Accessories manuals

Popular Accessories manuals by other brands

PCB

PCB TORKDISC 5309D-02A Installation and operating manual

Honeywell Home

Honeywell Home DC311 Series manual

Roland

Roland DUO-CAPTURE EX owner's manual

PCB Piezotronics

PCB Piezotronics 393B12 Installation and operating manual

Rohde & Schwarz

Rohde & Schwarz R&S NRP TWG Series user manual

Waterpik

Waterpik Waterflosser WP-950 Series manual