Batco 1800 Series User manual

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: P1512126 R3

Revised: June 2017

Portable Grain Belt Conveyor

PitStop with Hopper

Assembly Manual

This manual applies to:

1800 Series

2400 Series

Gas, Electric, and Hydraulic Drives

Original Instructions

2 P1512126 R3

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 3

CONTENTS

1. Introduction ............................................................................................................................................ 4

2. Safety....................................................................................................................................................... 5

2.1. Safety Alert Symbol and Signal Words..................................................................................... 5

2.2. General Safety .......................................................................................................................... 5

2.3. Moving Conveyor Belt Safety................................................................................................... 6

2.4. Rotating Parts Safety................................................................................................................ 6

2.5. Drives and Lockout Safety........................................................................................................ 6

2.5.1 Electric Motor Safety.................................................................................................. 7

2.5.2 Hydraulic Power Safety .............................................................................................. 8

2.6. Tire Safety................................................................................................................................. 9

2.7. Personal Protective Equipment................................................................................................ 9

2.8. Safety Equipment ................................................................................................................... 10

2.9. Safety Decals .......................................................................................................................... 10

2.9.1 Decal Installation/Replacement............................................................................... 10

2.9.2 Safety Decal Locations and Details .......................................................................... 10

3. Features................................................................................................................................................. 16

4. Assembly ............................................................................................................................................... 17

4.1. Assembly Safety ..................................................................................................................... 17

4.2. Required Tools........................................................................................................................ 17

4.3. Check Shipment...................................................................................................................... 18

4.4. Before You Begin .................................................................................................................... 18

4.5. Assemble the Tube Inlet and Return Roller........................................................................... 18

4.6. Install the Wheels and Axle.................................................................................................... 20

4.7. Install the Tube and Rollers.................................................................................................... 22

4.8. Install the Belt ........................................................................................................................ 24

4.9. Install the Flashing.................................................................................................................. 25

4.10. Install the Spout Hood.......................................................................................................... 27

4.11. Assemble the Hopper........................................................................................................... 29

4.12. Install the Electric Top Drive ................................................................................................ 38

4.13. Install the Hydraulic Wet Kit for the Electric Top Drive (Optional) ..................................... 40

4.14. Install the Hydraulic Top Drive............................................................................................. 44

4.15. Install the Manual Container ............................................................................................... 45

5. Specifications ........................................................................................................................................ 47

6. Batco Limited Warranty ....................................................................................................................... 49

4 P1512126 R3

1. Introduction

This manual describes how to assemble a Batco Portable Grain Belt Conveyor.

Before assembling the conveyor, please read this manual. Familiarize yourself with the process and the

necessary precautions for efficient and safe assembly.

Everyone present at the assembly site is required to be familiar with all safety precautions.

Keep this manual available for frequent reference and review it with new personnel. Call your local

distributor or dealer if you need assistance or additional information.

1. INTRODUCTION PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 5

2. Safety

2.1. Safety Alert Symbol and Signal Words

This safety alert symbol indicates important safety messages in this manual. When you see

this symbol, be alert to the possibility of injury or death, carefully read the message that

follows, and inform others.

Signal Words: Note the use of the signal words DANGER,WARNING,CAUTION, and NOTICE with the safety

messages. The appropriate signal word for each message has been selected using the definitions below as a

guideline.

Indicates an imminently hazardous situation that, if not avoided, will result in serious injury or

death.

Indicates a hazardous situation that, if not avoided, could result in serious injury or death.

Indicates a hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation that, if not avoided, may result in property damage.

2.2. General Safety

The safety information in the safety section of this manual applies to all safety practices. Specific safety

information (such as Operation Safety), can be found in the appropriate section.

YOU are responsible for the SAFE use and maintenance of your conveyor. YOU must ensure that you and

anyone else who is going to work around the conveyor understands all procedures and related SAFETY

information contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect you, but also the people around

you. Make these practices a working part of your safety program. All accidents can be avoided.

• It is the conveyor owner, operator, and maintenance personnel's responsibility to

read and understand ALL safety instructions, safety decals, and manuals and follow

them when assembling, operating, or maintaining the equipment.

• Owners must give instructions and review the information initially and annually with all personnel before

allowing them to operate the conveyor. Untrained users/operators expose themselves and bystanders to

possible serious injury or death.

• The conveyor is not intended to be used by children.

• Use the conveyor for its intended purposes only.

• Do not modify the conveyor in any way without written permission from the manufacturer. Unauthorized

modification may impair the function and/or safety, and could affect the life of the conveyor. Any

unauthorized modification of the conveyor will void the warranty.

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

6 P1512126 R3

2.3. Moving Conveyor Belt Safety

• DO NOT step on or touch moving conveyor belt.

• Shut off and lock out power to adjust, service, or clean.

2.4. Rotating Parts Safety

• Keep body, hair, and clothing away from rotating pulleys,

belts, chains, and sprockets.

• Do not operate with any guard removed or modified. Keep

guards in good working order.

• Shut off and remove key or lock out power source before

inspecting or servicing machine.

2.5. Drives and Lockout Safety

Inspect the power source(s) before using and know how to shut down in an emergency.

Whenever you service or adjust your equipment, make sure you shut down your power

source and follow lockout and tagout procedures to prevent inadvertent start-up and

hazardous energy release. Know the procedure(s) that applies to your equipment from the

following power source(s).

For example:

WARNING

• De-energize, block, and dissipate all sources of hazardous energy.

• Lock out and tag out all forms of hazardous energy.

• Ensure that only 1 key exists for each assigned lock, and that you are the only one that holds that key.

• After verifying all energy sources are de-energized, service or maintenance may be performed.

• Ensure that all personnel are clear before turning on power to equipment.

For more information on occupational safety practices, contact your local health and safety organization.

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 7

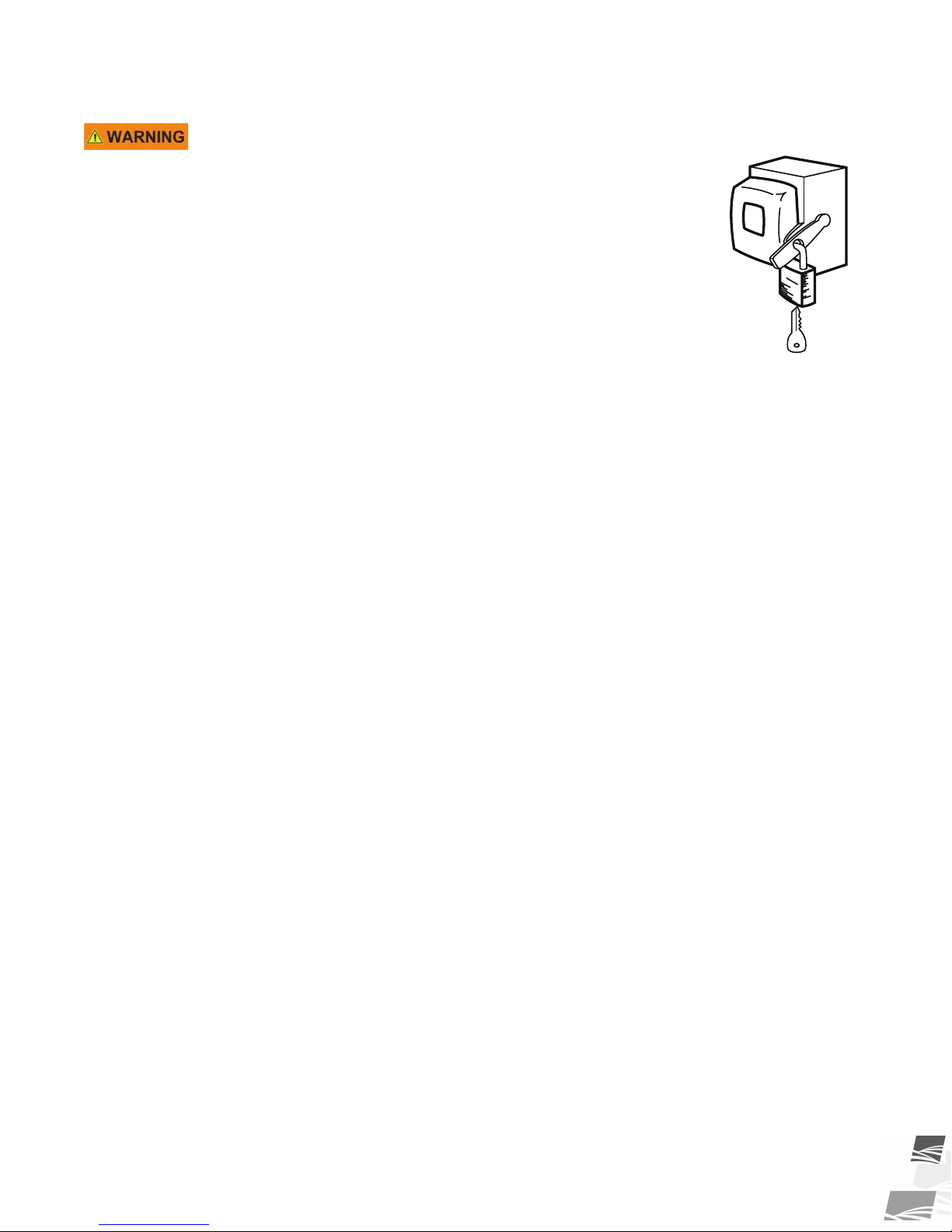

2.5.1 Electric Motor Safety

Power Source

• Electric motors and controls shall be installed and serviced by

a qualified electrician and must meet all local codes and

standards.

• A magnetic starter should be used to protect your motor.

• You must have a manual reset button.

• Reset and motor starting controls must be located so that the

operator has full view of the entire operation.

• Locate main power disconnect switch within reach from

ground level to permit ready access in case of an emergency.

• Motor must be properly grounded.

• Guards must be in place and secure.

• Ensure electrical wiring and cords remain in good condition;

replace if necessary.

• Use a totally enclosed electric motor if operating in

extremely dusty conditions.

SERVICE DISCONNECT

ON

OFF

Lockout

• The main power disconnect switch should be in the locked position during shutdown or

whenever maintenance is performed.

• If reset is required, disconnect all power before resetting motor.

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

8 P1512126 R3

2.5.2 Hydraulic Power Safety

Power Source

• Refer to the rules and regulations applicable to the power

source operating your hydraulic drive.

• Do not connect or disconnect hydraulic lines while system is

under pressure.

• Keep all hydraulic lines away from moving parts.

• Escaping hydraulic fluid under pressure will cause serious

injury if it penetrates the skin surface (serious infection or

toxic reaction can develop). See a doctor immediately if

injured.

• Use metal or wood as a backstop when searching for

hydraulic leaks and wear proper hand and eye protection.

• Check all hydraulic components are tight and in good

condition. Replace any worn, cut, abraded, flattened, or

crimped hoses.

• Clean the connections before connecting to equipment.

• Do not attempt any makeshift repairs to the hydraulic fittings

or hoses with tape, clamps, or adhesive. The hydraulic

system operates under extremely high pressure; such repairs

will fail suddenly and create a hazardous and unsafe

condition.

Lockout

• Always place all hydraulic controls in neutral and relieve

system pressure before disconnecting or working on

hydraulic system.

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 9

2.6. Tire Safety

Failure to follow proper procedures when mounting a tire on a

wheel or rim can produce an explosion that may result in

serious injury or death.

• DO NOT attempt to mount a tire unless you have the proper

equipment and experience to do the job.

• Have a qualified tire dealer or repair service perform

required tire maintenance.

• When replacing worn tires, make sure they meet the original

tire specifications. Never undersize the replacement tire.

• DO NOT weld to the tire rim with the tire mounted on the

rim. This action may cause an explosion which could result in

serious injury or death.

• Inflate tires to the manufacturer’s recommended pressure.

• Tires should not be operated at speeds higher than their

rated speed.

• Keep wheel lug nuts tightened to manufacturer’s

recommendations.

• Never reinflate a tire that has been run flat or seriously

under-inflated without removing the tire from the wheel.

Have the tire and wheel closely inspected for damage before

remounting.

2.7. Personal Protective Equipment

The following Personal Protective Equipment (PPE) should be worn when assembling the equipment.

Safety Glasses

• Wear safety glasses at all times to protect eyes from debris.

Work Gloves

• Wear work gloves to protect your hands from sharp and rough edges.

Steel-Toe Boots

• Wear steel-toe boots to protect feet from falling debris.

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

10 P1512126 R3

Coveralls

• Wear coveralls to protect skin.

Hard Hat

• Wear a hard hat to help protect your head.

2.8. Safety Equipment

The following safety equipment should be kept on site:

Fire Extinguisher

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and

accessible place.

First-Aid Kit

• Have a properly-stocked first-aid kit available for use should the need arise, and

know how to use it.

2.9. Safety Decals

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Replacement safety decals are available free of charge from your distributor, dealer, or factory.

2.9.1 Decal Installation/Replacement

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion with the exposed sticky backing

in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign backing paper.

2.9.2 Safety Decal Locations and Details

Replicas of the safety decals that are attached to the conveyor and their messages are shown in the figure(s)

that follow. Safe operation and use of the conveyor requires that you familiarize yourself with the various safety

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 11

decals and the areas or particular functions that the decals apply to, as well as the safety precautions that must

be taken to avoid serious injury, death, or damage.

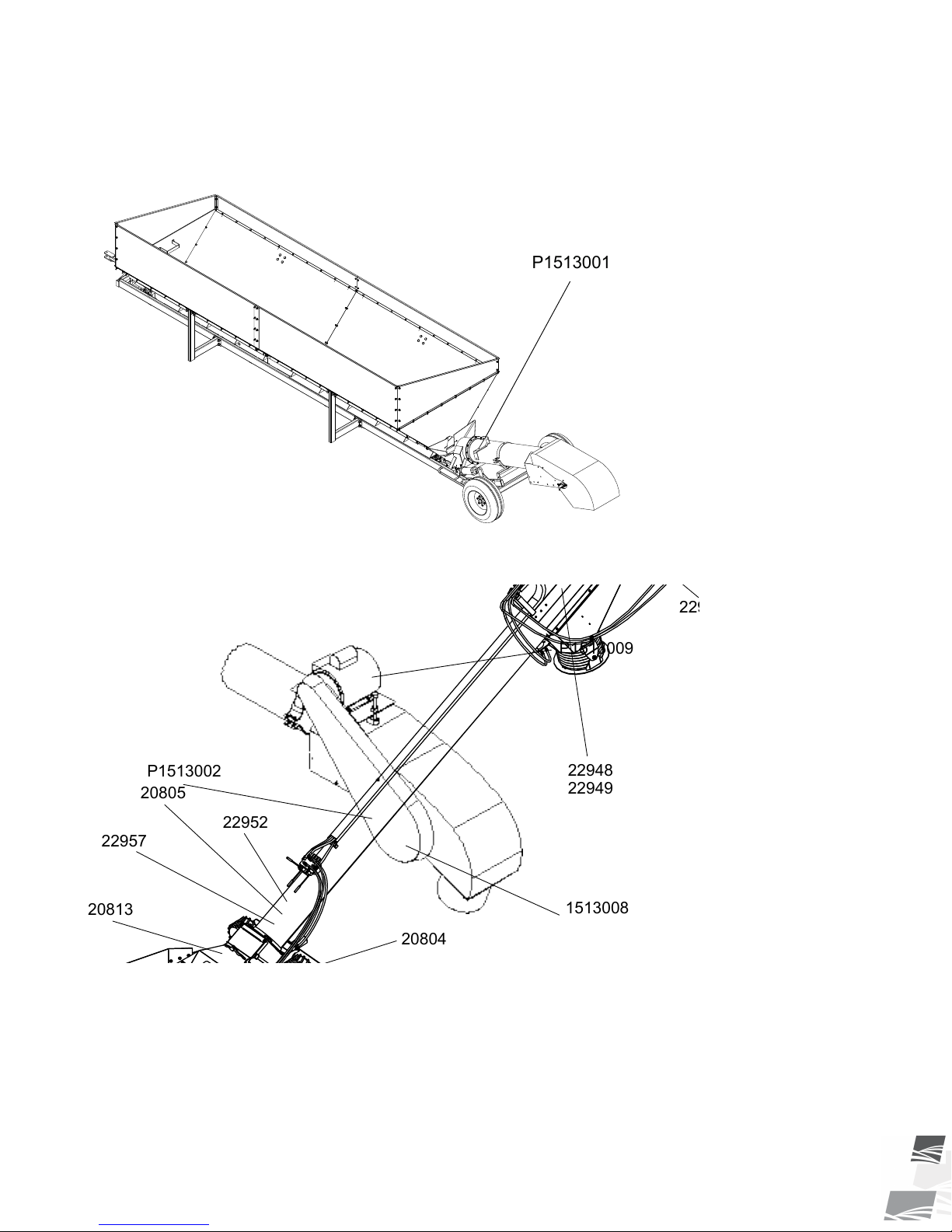

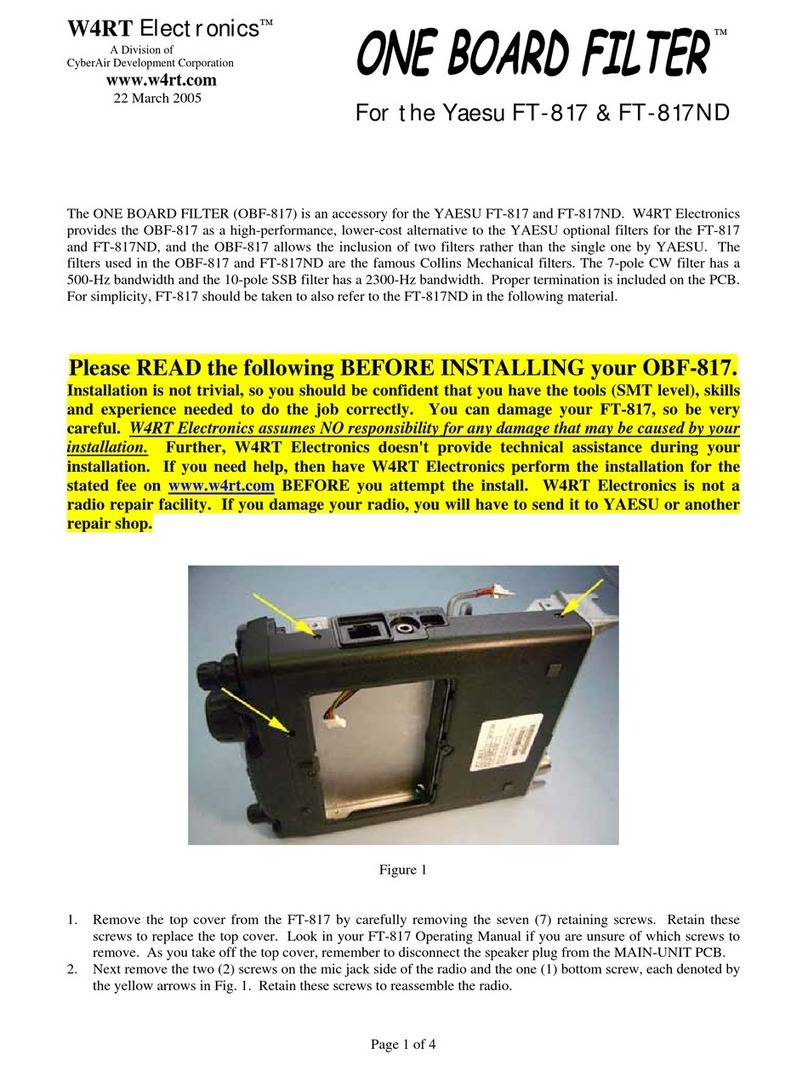

Figure 1. Safety Decal Location

P1513001

Figure 2. Electric Drive Safety Decal Locations

22950

22948

22949

20804

22957

22952

20813

20805

P1513002

1513008

P1513009

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

12 P1512126 R3

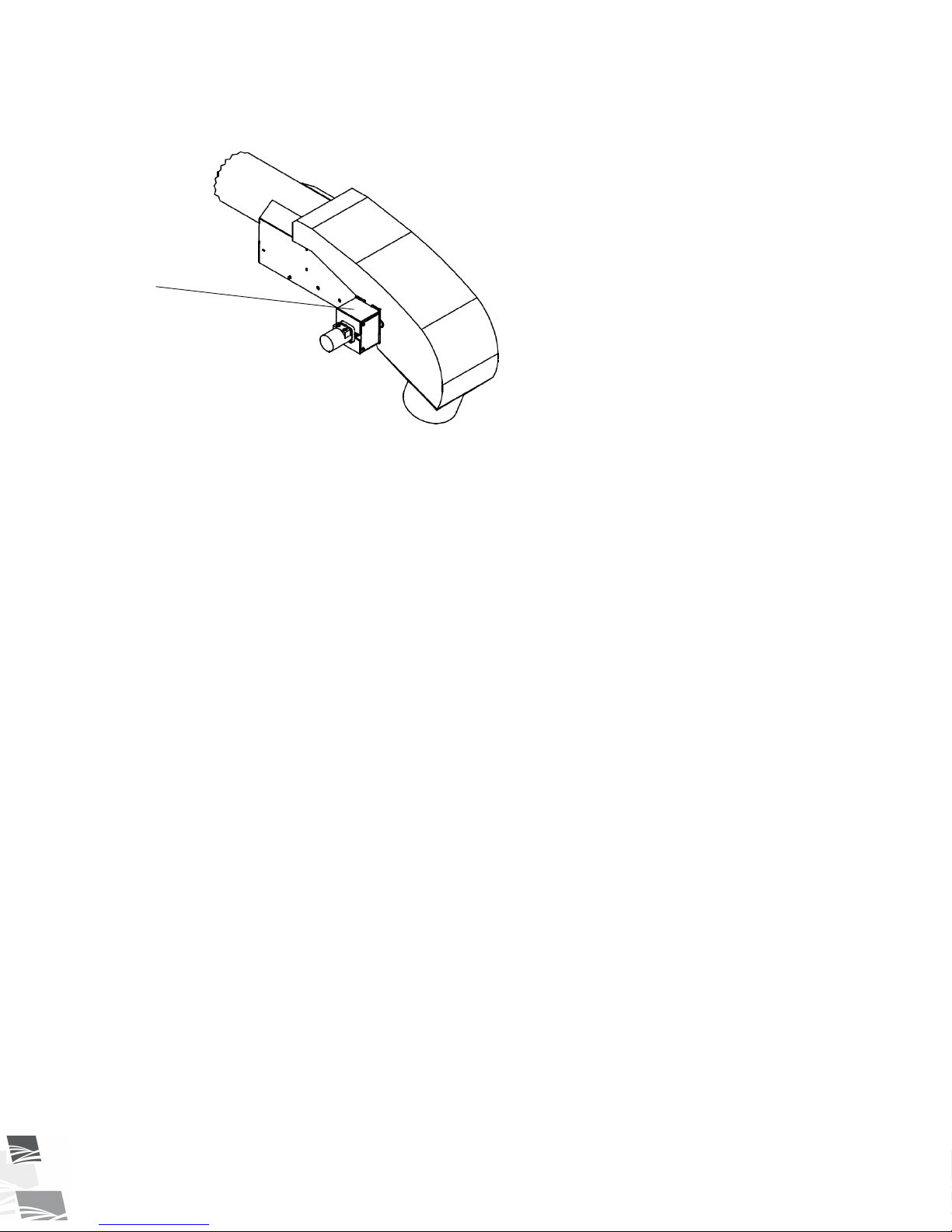

Figure 3. Hydraulic Drive Safety Decal Location

P1513035

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 13

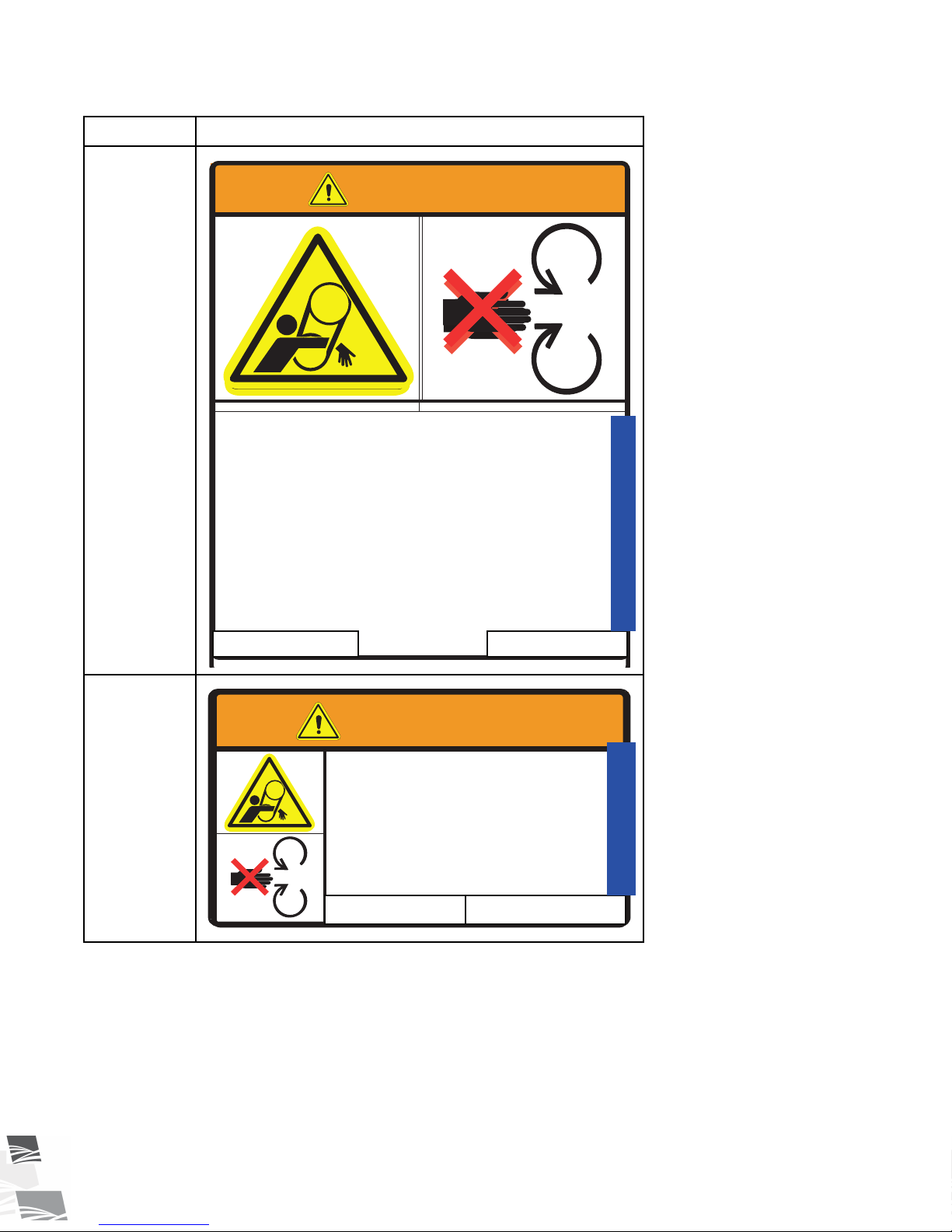

Table 1. Safety Decals

Part Number Description

P1513001

Country of Origin Part Number

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate,

or maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• Do not modify the equipment. Keep in good

working order.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for

replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect

power before resetting overloads.

WARNING

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

14 P1512126 R3

Table 1 Safety Decals (continued)

Part Number Description

P1513002

WARNING

ENTANGLEMENT HAZARD

To prevent serious injury or death:

•Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

•Do not operate with any guard removed or

modified. Keep guards in good working order.

•Shut off and remove key or lock out power source

before inspecting or servicing machine.

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

• Do not operate with any guard removed or

modified. Keep guards in good working order.

• Shut off and remove key or lock out power

source before inspecting or servicing machine.

ENTANGLEMENT HAZARD

WARNING

Country of Origin Part Number

P1513008

WARNING

MISSING GUARD HAZARD

To prevent serious injury or

death, shut off power and

reattach guard before operating

machine.

To prevent serious injury or

death, shut off power and

reattach guard before operating

machine.

MISSING GUARD HAZARD

WARNING

Country of Origin Part Number

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 15

Table 1 Safety Decals (continued)

Part Number Description

P1513009

To prevent serious injury or death:

• Before operating on uneven ground, extend outrigger leg, if provided.

Retract leg before moving.

• If no outrigger leg is provided, use extreme caution when operating on

any slope.

• Follow vehicle instructions when driving on slopes.

ROLLOVER HAZARD

WARNING

To prevent serious injury or death:

• Only qualified personnel should service

electrical components.

• Disconnect and lockout power before

inspecting or servicing unit.

• Keep electrical components in good repair.

ELECTROCUTION HAZARD

WARNING

To prevent serious injury or death:

• Only qualified personnel should service

electrical components.

• Disconnect and lockout power before

inspecting or servicing unit.

• Keep electrical components in good repair.

ELECTROCUTION HAZARD

WARNING

Country of Origin

Country of Origin Part Number

P1513035

To prevent serious injury or death:

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

• Keep all components in good repair.

HIGH PRESSURE FLUID HAZARD

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

HIGH PRESSURE FLUID HAZARD

WARNING

Country of Origin Part Number

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 2. SAFETY

16 P1512126 R3

3. Features

Below are some of the main features of the Batco Portable Grain Belt Conveyor.

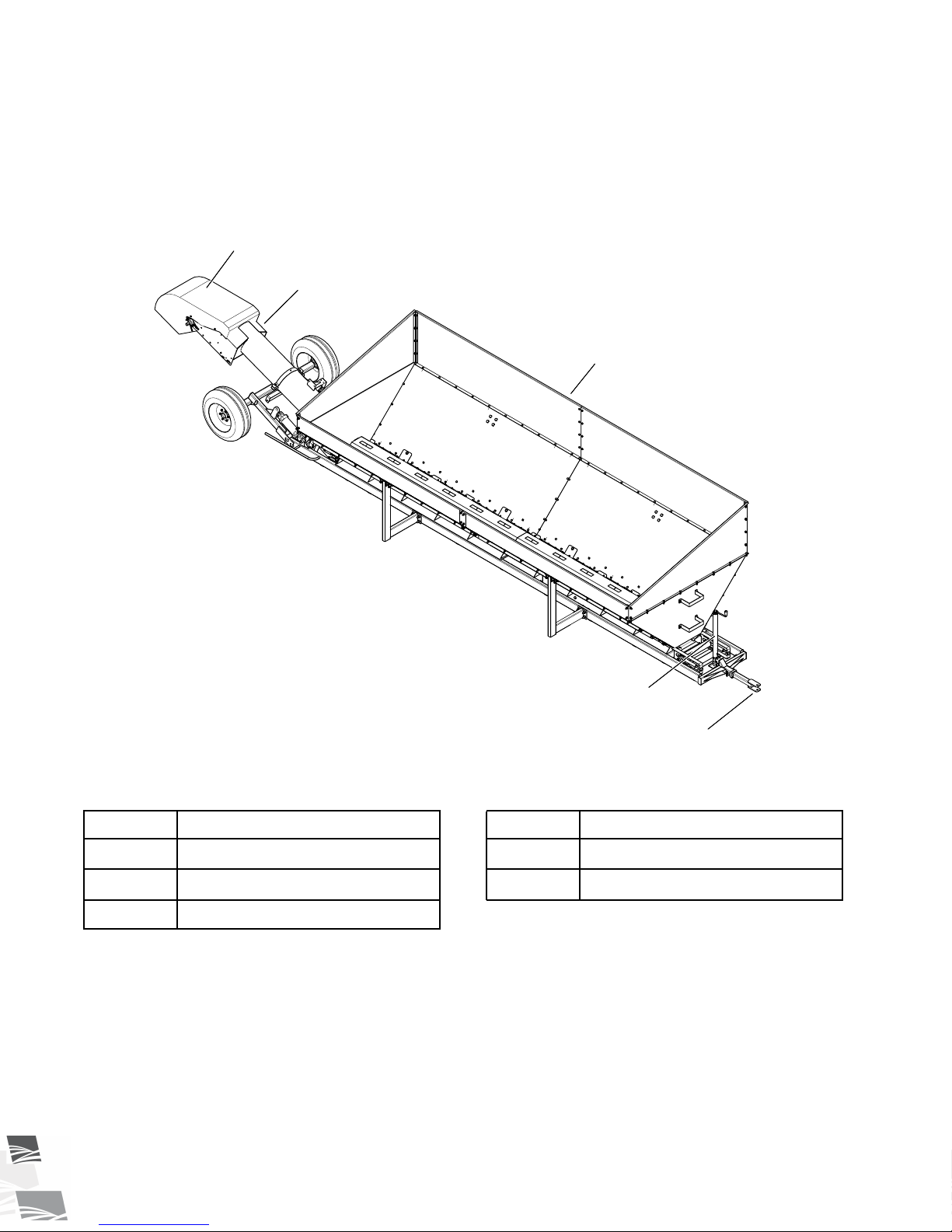

Figure 4. Typical PitStop with Hopper Components

Table 2. Typical PitStop with Hopper Components

ITEM DESCRIPTION ITEM DESCRIPTION

1 Hopper 4 Hitch

2Spout Assembly 5Jack

3Hood

2

3

1

5

4

2

3

1

5

4

3. FEATURES PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 17

4. Assembly

Before continuing, ensure you have completely read and understood this manual’s

Safety section, in addition to the safety information in the section(s) below.

4.1. Assembly Safety

• Do not take chances with safety. The components can be large, heavy, and hard to handle.

Always use the proper tools, rated lifting equipment, and lifting points for the job.

• Carry out assembly in a large open area with a level surface.

• Always have two or more people assembling the conveyor.

• Make sure you have sufficient lighting for the work area.

• Tighten all fasteners according to their specifications. Do not replace or substitute bolts,

nuts, or other hardware that is of lesser quality than the hardware supplied by the

manufacturer.

• Stay away from overhead power lines and other obstructions during assembly. Contact with

power lines can cause electrocution.

• Do not work in high winds.

4.2. Required Tools

• 2 sawhorse(s) • 1 tape measure(s)

• 1 jack or forklift or overhead crane

(850 lb [386 kg] lifting capacity)

• 1 level

(2’ [61 cm])

• 1 standard socket set(s) • 1 level magnetic

(2’ [61 cm])

• 1 wrench set(s)

1-1/2” ratchet & wrench (to attach axle)

• 1 ratchet strap

• 1 1-1/8” ratchet • 1 air impact with ratchet set

• 1 torque wrench(es) • 2 C-clamp(s) or vise grip(s)

• 1 power drill(s) • 1 tire pressure gauge

• 1 self-tapping screw bit

(3/8")

• 1 fish tape

(120’ [36.6 m])

• 1 pry bar • 1 tire chuck

• 1 hammer and punch • 1 set(s) of Allen wrenches

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 4. ASSEMBLY

18 P1512126 R3

4.3. Check Shipment

Unload the conveyor parts at the assembly site and compare the packing slip to the shipment. Ensure that all

items have arrived and that none are damaged.

Report missing or damaged parts immediately to ensure that proper credit is received from Batco or your

distributor/dealer, and to ensure that any missing parts can be shipped quickly to avoid holding up the assembly

process.

Important

Do not assemble or install damaged components.

4.4. Before You Begin

Before you assemble the conveyor:

• Familiarize yourself with all the sub-assemblies, components, and hardware that make up the equipment.

• Have all parts and components on hand, and arrange them for easy access.

• Separate the hardware (bolts, nuts, etc.) and lay them out into groups for easier identification during

assembly.

• If assembling inside, the ceiling must be at least 16' (4.8 m) high and 12'6" (3.81 m) wide to provide

clearance when installing the undercarriage.

• Perform assembly on a firm and level surface in an area large enough to allow access to all sides of the

conveyor.

• Ensure there is adequate space to remove the assembled conveyor from the assembly area.

4.5. Assemble the Tube Inlet and Return Roller

Table 3. Tube Inlet and Return Roller Components

ITEM DESCRIPTION QTY

1Bolt 3/8" x 1" 1

2Bent Adjustment Tab Left 1

3Locknut 3/8" 1

4Adjustment Link Bar 1

5Pitstop Guiding Return Roller 1

4. ASSEMBLY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

P1512126 R3 19

Figure 5. Assembling the Tube Inlet and Return Roller

2

3

1

4

5

PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER 4. ASSEMBLY

20 P1512126 R3

4.6. Install the Wheels and Axle

Table 4. Wheel and Axle Components

ITEM DESCRIPTION QTY

1 Pitstop Base 1

2Axle Weldment 1

36–Bolt Tire 2

4Hair Pin 3/16" x 3-1/4" 4

5Hitch Pin 1" x 3-1/2" 4

6Wheel Bolt 12

7Wheel Nut 1/2" GR5 12

4. ASSEMBLY PORTABLE GRAIN BELT CONVEYOR – PITSTOP WITH HOPPER

Other manuals for 1800 Series

1

This manual suits for next models

1

Table of contents

Other Batco Accessories manuals

Popular Accessories manuals by other brands

Doepke

Doepke Dupline DSS 4R operating instructions

GRAUPNER

GRAUPNER Fatshark Attitude V2 manual

PCB Piezotronics

PCB Piezotronics 116B Installation and operating manual

Waterpik

Waterpik Waterflosser WF-02 quick start guide

W4RT Electronics

W4RT Electronics ONE BOARD FILTER OBF-817 Installation

Rohde & Schwarz

Rohde & Schwarz NRQ6 user manual