Electric Jackhammer

i

Table of Contents

Safety....................................................................................................................................................................... 1

General Operational Precautions....................................................................................................................... 1

Precautions When Using the Jackhammer........................................................................................................2

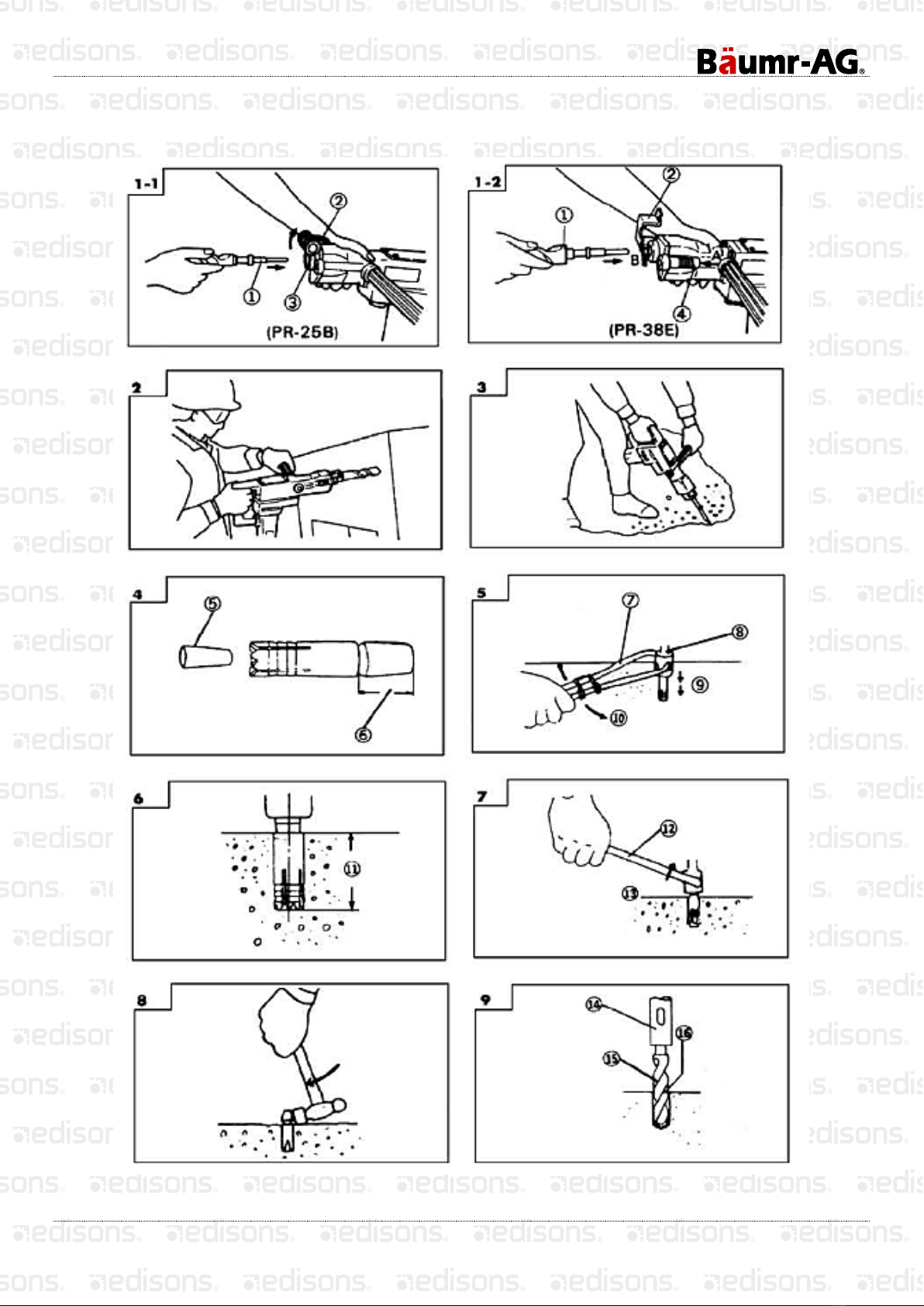

Illustrative Guide .................................................................................................................................................... 3

Applications............................................................................................................................................................ 5

Application Examples.........................................................................................................................................5

Set-Up ......................................................................................................................................................................6

Prior to Operation...............................................................................................................................................6

Power Source...............................................................................................................................................6

Grounding ....................................................................................................................................................6

Power Switch ...............................................................................................................................................6

Extension Cord.............................................................................................................................................6

Operation.................................................................................................................................................................6

How to Use the Jackhammer.............................................................................................................................6

How to Drill Holes.........................................................................................................................................6

How to Clip or Crutch...................................................................................................................................7

Drilling and Driving-In Operations for Self-Drilling Anchors...............................................................................7

When an Impact Anchor Adapter is Used ...................................................................................................7

When a Rotation and Impact Anchor Adapter is Used................................................................................7

When a Taper Shank Adapter is Used........................................................................................................7

Handling the Core Bit......................................................................................................................................... 7

Mounting.......................................................................................................................................................7

Drilling Holes................................................................................................................................................8

Dismounting the Core Bit...................................................................................................................................8

Oil Feeding.........................................................................................................................................................8

Maintenance............................................................................................................................................................8

Inspecting the Tool.............................................................................................................................................8

Inspecting the Mounting Screws........................................................................................................................8

Maintenance of the Motor ..................................................................................................................................8

Inspecting the Carbon Brushes.......................................................................................................................... 9

Replacing the Carbon Brushes.......................................................................................................................... 9

Inspecting the Dust Cover.................................................................................................................................. 9

Specifications .........................................................................................................................................................9