Baur SSG 500 User manual

0-1

02/2011

Surge Voltage Generator

SSG 500

Operating Instructions

Ident. Nr. 822-016

BAUR Prüf- und Messtechnik GmbH

Raiffeisenstrasse 8, A-6832 Sulz / Austria

Tel +43 / 55 22 / 49 41-0

Fax +43 / 55 22 / 49 4 13

e-mail: [email protected]

internet: http://www.baur.at

0-2

0-3

© BAUR Prüf- und Messtechnik GmbH,

A-6832 Sulz / Austria

All rights reserved.

No part of this publication may be reproduced, transmitted, stored

in a data processing system or translated into another language

without the written permission of BAUR / Sulz, Austria.

In the interest of our customers we reserve the rights for

modifications due to technical progress.

Illustrations, descriptions and delivery content are therefore not

binding.

For fast finding of important information the corresponding text

passages are marked with symbols (symbols not stated here are

self-explaining).

More and special information concerning the respective subject are

available from BAUR.

Important unit information!

In any case, read carefully!

Important information text.

The surge voltage generator SSG 500 is built in accordance with

today's state of engineering and is safe to operate. Individual

components and the finished unit are inspected continually by our

qualified staff within the framework of our Quality Assurance

Provisions. Each unit is subjected to thorough testing prior to

shipment.

Safety Precautions

Guide to this Operating Instruction

Observe

info signs!

Copyright

BAUR Prüf- und Messtechnik GmbH, Raiffeisenstrasse 8

A-6832 Sulz / Austria

or refer to your nearest BAUR representative.

Tel +43 / 55 22 / 49 41-0

Fax +43 / 55 22 / 49 41-3

☞

Preface This manual contains all information necessary for the correct

handling and use of the surge voltage generator SSG 500. Before

using the surge voltage generator, please read carfully this

Operating Instruction:

If you have any question, please contact directly:

Guide to this Operating Instruction, Copyright, Preface

Subject to modification!

0-4

It is imperative to every person who is involved with the installation,

start-up, operation and maintenance of the SSG 500 to have read

and understood the complete Operating Instruction.

It is the responsibility of the customer to ensure that only authorized

persons may be allowed to use the surge voltage generator

SSG 500.

The user

- is qualivied and properly instructed and has the necessary

experience.

- knows the relevant standards, accident prevention rules and

operating conditions.

- is able to carry out the necessary operations and is aware of

the possible dangers involved.

- must immediately inform his superior about any conditions of

the unit that coult affect safety.

The surge voltage generator SSG 500 is used for cable fault

location at layed power cables.

Any other or additional use is deemed to be in contravention of the

intended use. The manufacturer shall not be liable for damage

resulting from any such us. In such a case the risk shall be borne

solely by the user.

The local safety and accident prevention regulations are

always applicable to the operation of the surge voltage

generator unit.

Especially the surge voltage generators may not be used in

potentially explosive atmosphere or at test objekts which are

in service.

Garantie

Safety Precautions, Continued

At the customer's written request we undertake to repair or

replace at our discretion and as quickly as possible allparts that

become faulty or useless as the demonstrable result of poor

material, faulty design or defective execution.

We bear the costs for repairs and replaced parts, exclusive

transportation of the goods, packing and insurance.

The 12 month warranty time starts with delivery.

We shall bear the costs of any faulty parts requiring replacement,

but not the costs of transport to us an back to the customer, not the

costs of packing and insurance! We shall not be liable for any

damage resulting from normal wear and tear, improper handling,

non-observance of Operating Instruction and safety regulations. We

shall also refuse to accept any liability if the customer carries out

repairs or changes to the unit himself or has others carry out them!

The warranty does not cover damage in transit, batteries, fuses and

any readjustments in accordance with the Operating Instruction!

We draw attention in addition to the "General Terms of Sales and

Delivery".

Please read now and

avoid damage and injury later!

Sicherheitshinweise, Garantie

12 month warranty time

Only authorized personnel!

Use the SSG 500

unit as directed!

☞

0-5

Contents

1. Product Information .........................................................................1-1

Overview ......................................................... 1-1

Design and function ........................................ 1-2

Display and operating elements...................... 1-3

Technical data ................................................. 1-5

2. Packing and Delivery .......................................................................2-1

Damage during transport ................................ 2-1

3. Setting into operation ......................................................................3-1

Overview ......................................................... 3-1

Modes ............................................................. 3-2

Connection of instrument ................................ 3-4

Connection of mains ....................................... 3-6

Switch on ........................................................ 3-7

Switch off ........................................................ 3-8

EMERGENCY SWITCHING OFF ................... 3-9

4. Maintenance......................................................................................4-1

Overview ......................................................... 4-1

Safety precautions .......................................... 4-2

Fuses .............................................................. 4-2

Checking the discharge unit............................ 4-3

Replacing high voltage connection lead ......... 4-3

5. Options, Accessories and Ordering Information...........................5-1

Overview ......................................................... 5-1

Options ........................................................... 5-2

Accessories .................................................... 5-2

Ordering information ....................................... 5-3

Contents

0-6

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes

Notes

1-1

1. Product Information

1. Product Information

Overview

In this section you will find all necessary product information for the

Surge Voltage Generator SSG 500.

This section covers the following subjects:

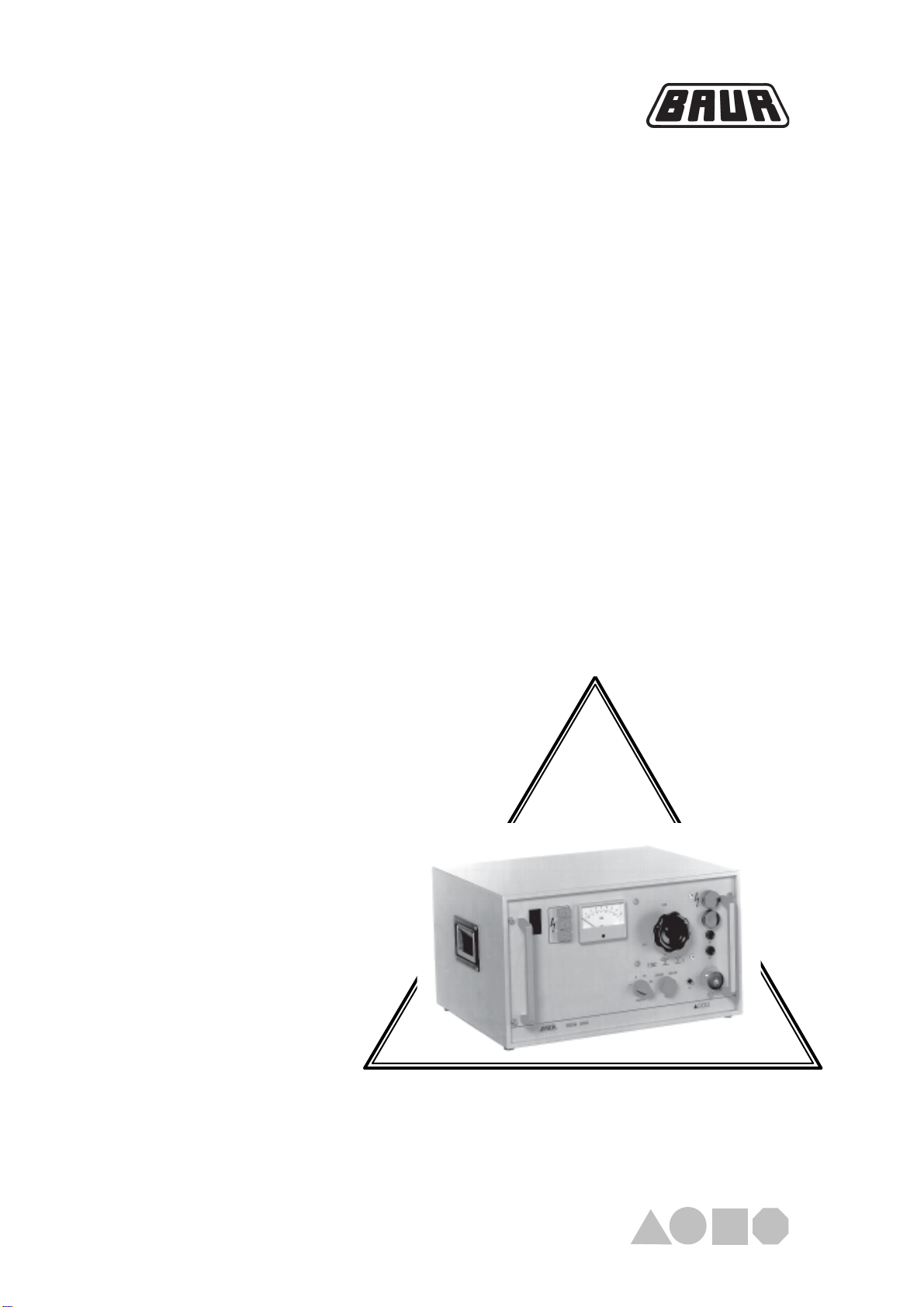

Subject Page

Design and function 1-2

Display and operating elements 1-3

Technical data 1-5

1-2

1. Product Information

Instruments of the SSG family are rack mounting units in the 19"

format. Various operating and indicating elements are mounted on

the front panel, connecting elements are mounted on the back-

plate. The instruments contain their own high voltage generator,

impulse-proof surge capacitors, automatic and manually triggered

spark gaps and an internal discharge device.The instrument control

contains the necessary safety circuits also for connection of an

external Emergency Stop unit and for the operation of the SA 32

option.

The mains voltage is applied to the primary winding or a tapping of

the primary winding of the high voltage transformer via the

reduction switch (13), depending on its position.The secondary

windings of the high voltage transformer features four high voltage

windings, fully isolated of each other, which are connected each to

a partial capacitor through a half-wave rectifier. With the aid of the

range selector switch (6) the partial capacitors become connected

to each other. The series connection allows a maximum voltage of

16kV. The connection of two capacitors each in series and parallel

allows a maximum 8kV and the complete parallel connection of the

capacitors leads to a maximum voltage of 4kV. In this configuration

it can be accomplished, that the maximum surge energy of the

capacitors is available in three voltage ranges. Through the

selection of the three ranges 3 / 6 / 12kV using the reduction switch

(13) 56% of the surge energy are available.

The Surge Voltage Generator SSG 500 is designed in such a way

that it generates pulse-shaped voltages with a steep edge, which

should start to break down the cable fault. The high surge current

flowing at the cable fault generates electromagnetic and acoustic

waves which radiate from the cable fault. These waves can be

detected on the ground surface with appropriate detection devices

such as search coils or ground microphones. The SSG 500

however can also be implemented for pre-location. In this case it is

used as burn down device for short time operation or it can be used

with an echometer and the SA 32.

Design and function

Design

High voltage generation

Function

1-3

1. Product Information

Display and operating elementes

Front panel

1 Mains switch as overload protection switch with thermal

release

2 Pushbutton switch „Ready to switch on“ ( )

3 Pushbutton switch „H.V. On“ (I ) with warning lamp for

high voltage clearance. The indicator lamp serves as

feedback for the operating state „IN OPERATION“

4 Pushbutton switch „H.V. Off“ ( ) returns the instrument

into the operating condition "READY FOR OPERATION“.

5 Voltmeter of class 1.5 for display of output voltage in kV

6 w 4 / 8 / 16kV

7 Red indicator lamp for feedback of operating condition

„READY TO SWITCH ON“ and „IN OPERATION“

8 Green indicator lamp for feedback of operating condition

„READY FOR OPERATION“

9 Fuse F3 (3,15A slow-blow) for control of lifting magnet and

control of SA 32 (option)

10 Fuse F4 (3,15A slow-blow) for control of lifting magnet and

control of SA 32 (option)

11 EMERGENCY OFF SWITCH pushbutton (lockable) for

activating the EMERGENCY OFF function and to protect

against unauthorized switching on

12 Overload protection switch with thermal and magnetic

tripping

13 Reduction switch for voltage reduction to 3 / 6 / 12 kV

(56% surge energy)

14 Mode selector switch for selecting operating modes „D.C.

operation“, „Zero position“, „Impulse sequence 10/min“,

„Impulse sequence 20/min“.

11

7

8

9

10

14 13 12

1324 56

1-4

1. Product Information

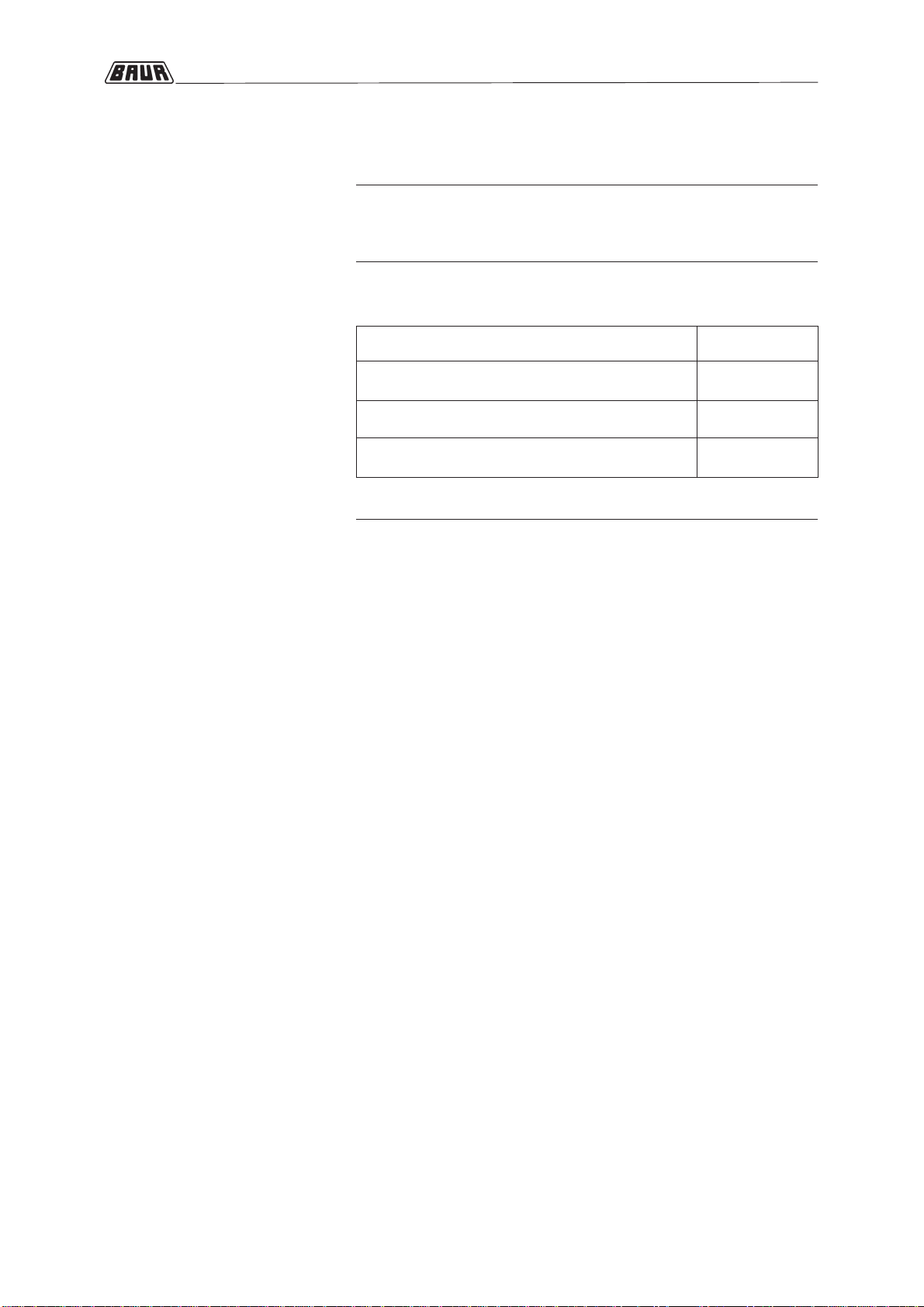

15 Connection socket for external EMERGENCY OFF unit

with jumper plug

16 Connection for mains to SA 32

17 Connection for mains

18 Terminal for connection of protective earth lead

19 Type plate

20 High voltage connecting lead

Backplate

17 15 201618 19

1-5

1. Product Information

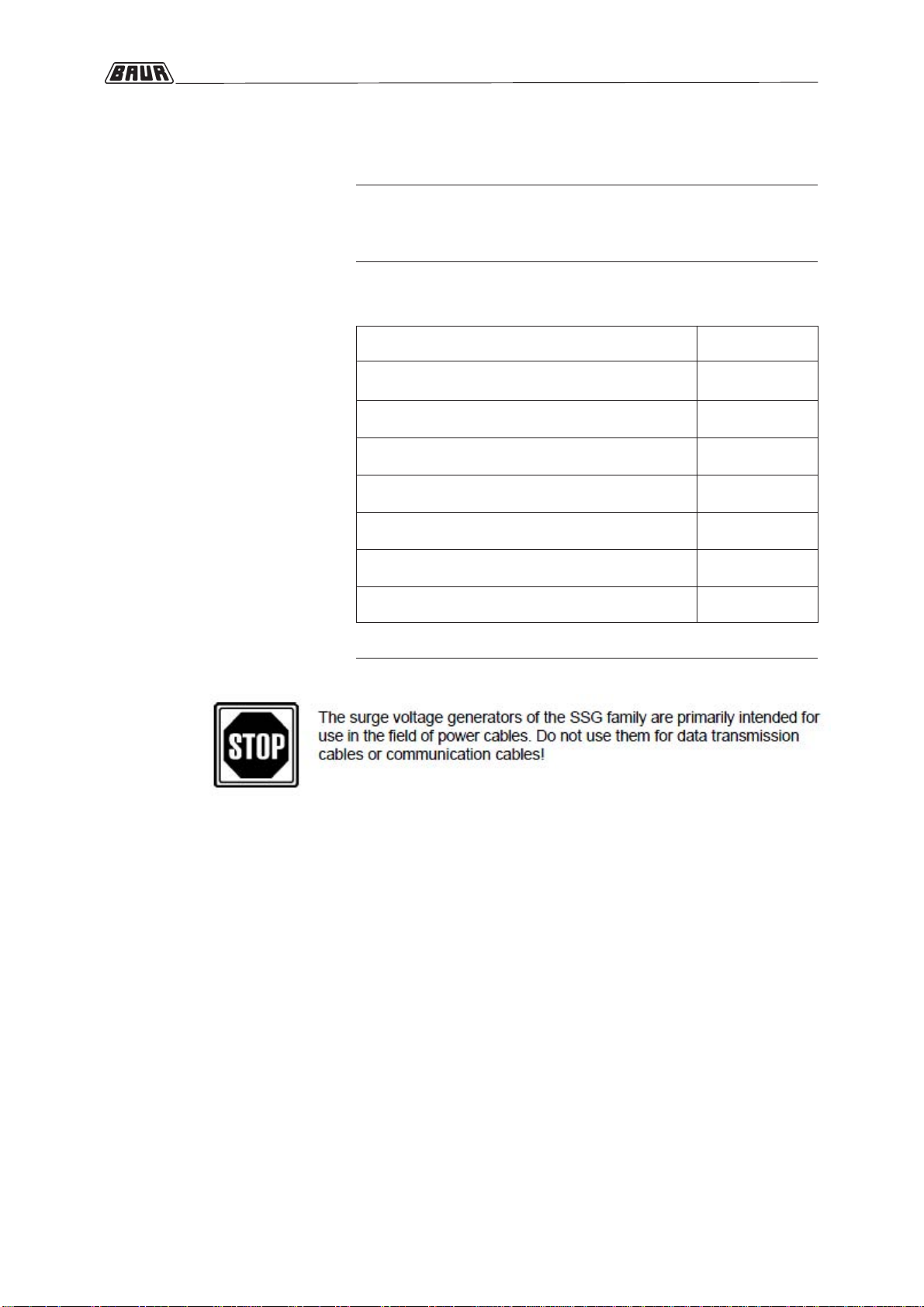

SSG 500 unit

Mains voltage see type plate

Mains frequency 45 to 60 Hz

Max. power consumption

(at short ciruit condition) 1.500 VA

Max. output voltage 16 kV

Max. surge energy 512 Ws

Accuracy of kV-meter 1,5 %

Dimensions of housing (W x H x D) 502 x 286 x 390 mm

Weight 48 kg

Technical data

1-6

1. Product Information

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes

2. Packing and Shipping

2-1

2. Packing and Shipping

The instruments are shipped in robust cardboard cartons on

wooden pallets. If the instruments are not used immediately, always

keep in closed carton and store in dry rooms!

Complaints concerning damages should be made to us without

delay, using a standard transport damage claims form.

Confirmation of visible damage should immediately be obtained

from the carrier.

The extent and the probable cause of damage should be stated.

If damage is discovered during unpacking, contact the responsible

transportation company immediately. Request a written loss

assessment and make them responsible for the damage!

We also refer to the “General Terms of Sale and Delivery„ of:

Damage during

transport

BAUR Prüf- und Messtechnik GmbH,

A-6832 Sulz / Austria

2. Packing and Shipping

2-2

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes

3-1

3. Placing into operation

3. Placing into operation

Overview

In this section you will find all necessary information to put the

Surge Voltage Generator SSG 500 into operation.

This section describes the following subjects:

Subject Page

Modes 3-2

Connection of instrument 3-4

Connection to mains 3-6

Switch on 3-7

Switch off 3-8

Discharge 3-8

EMERGENCY OFF 3-9

3-2

3. Placing into operation

Operating modes

Impulse operation The impulse operation serves first of all for fault locating and is

divided into manual and automatic impulse triggering.The mode

selector switch (14) allows to switch between positions „Zero

position“, „Slow impulse sequence“ and „Fast impulse sequence“

even during operation and under voltage.

Manual impulse triggering is primarily intended for application of the

surge voltage generator in pre- locating, as for example in

connection with the Intercom SA 32 (option) and the echometer. By

applying the secondary impulse method in high resistance faults,

an assessment of the fault distance with one or a few impulse

trigger actions can already be made.

zIf instrument is in operating condition „IN OPERATION“ place

operating mode selector switch (14) from zero position into =

position momentarily and reset again.

Automatic impulse triggering is primarily used for pin-pointing a

cable fault.

The SSG 500 is equipped with a timer coupled to the mains

frequency which allows automatic impulse triggering with impulse

frequencies of 10/min and 20/min. The regularity of the subsequent

impulses serves to better differentiate between the signals of the

fault location and interferences.

zSwitch operating mode selector switch (14) to impulse sequence

10/min or 20/min.

If the instrument is in the operating condition „READY

TO SWITCH ON“ it closes the spark gap automatically

according to the appropriately selected impulse sequence.

Manual impulse triggering

Automatic impulse triggering

3-3

3. Placing into operation

In connection with the Intercom SA 32 (option) with mA-meter the

output current can be measured and be limited by activating the

reduction switch (13). Additionally, there is a possibility to limit the

output current by a high-power resistor.

DC Operation

Fault location

Testing

The Surge Voltage Generator can be put into D.C. operation via the

mode selector switch (14).

zTurn mode selector switch (14) to the fully left position =.

The spark gap will be permanently closed and therefore

connects the high voltage output directly with the surge

capacitor.

In D.C. operation, with the surge capacitors connected, the voltage

is increased until the cable fault breaks down. This mode of

operation is recommended especially for estimating the breakdown

voltage in order to conduct an optimal range selection for the

impulse operation. In combination with the SA 32 option and the

echometer, the D.C. operation can also be implemented in pre-

locating of cable faults.

D.C. voltage tests can also be conducted in the D.C. operation.It is

however important that the connected surge capacity, in case of a

breakdown, is discharged through the fault location and that the

surge generator switches to burn down operation. The instrument

protects itself from overloads switching off automatically after a

certain time by the overload protection switch (12). During short-

term operation, maximum output currents can be found during the

burn down process according to the following table.

Range selector switch max. output current (IMAX)

in 4 kV position 480 mA

in 8 kV position 240 mA

in 16 kV position 120 mA

3. Placing into operation

3-4

Connection of instrument

Observe correct position of connection terminals!

(also see Note on page 3-5)

Connection to a single-phase shielded cable

Connection of a three-phase shielded cable

Connection to a three-phase unshielded cable with neutral

1. Rear view of device

2. High voltage connection cable

3. Protective ground cable

4. High voltage connection cable conductor

5. High voltage connection cable screen

6. Station ground

- Protective ground connection

- Operating ground connection

Pulse current flow

3. Placing into operation

3-5

Preparing test object

•Isolate the test object

•Lock against reconnection

•Make sure that zero voltage condition exists.

•Insulate nearby items which are under voltage

•It must be assured that nearby items of the station or cable system under

voltage do not result in breakovers or breakdowns, due to applying surge or

D.C. voltage of the surge generator to the test object.

•Connect all strands in the cable station, with the exception of the fault afflic-

ted strand, to the station earth.

Attention! Wire size and insulating capacity of the cable system must be in

an appropriate relationship to the amplitude of surge voltage and to the

surge energy. Otherwise, overloading to the still intact parts of the system

might occur.

Connecting the protective ground

•Connect the surge voltage generator with the station ground through the

protective ground connection on the rear plate of the device (18)

Attention! Connect the protective ground cable as close to the station

ground connection as possible (see connection examples on page 3-4).

The protective earth lead should be kept as short as possible and must

have low impedance (min. cross section 10 mm², copper).

Connecting the operating ground

The high voltage connection cable screen is used as operating ground.

The operating ground closes the electric circuit and is used for the re-

turn cable of the impulse current!

Connect the operating ground carefully because it must withstand the

full surge current. Observe the correct terminal position!

•Connect the high voltage connection cable screen (operating ground con-

nection) to the station ground. Select the location for the connection of the

screen to the station ground as follows:

- as close as possible to the location where the test object screen is

connected to the station ground and

- as close as possible to the location where the test object conductors

that will not be tested are connected to the station ground (see con-

nection examples on page 3-4

3. Placing into operation

3-6

Estabilshing H.V. connection

•Connect strand of the high voltage connecting lead with the fault afflicted

strand of the test object.

It is very important that all connections are of low resistance as possible.

Bad connections can lead to weldings or contact wear.

•Install external EMERGENCY OFF unit (option) at appropriate location and

plug in the connection plug instead of the jumper plug (15) on back plate of

surge generator.

Connection to mains

Mains operation

•Connect instrument to mains supply using appropriate mains voltage and

minimum fuse rating.

The protective conductor of the mains supply must have the same

potential as the station earth!

Operation with emergency power generator

The generator must have adequate power to meet the maximum power re-

quirements of the instrument (see technical data) without break down of voltage

or frequency, due to its load. Otherwise, it could happen that the instrument will

be switched off automatically.

•Set generator voltage according to mains voltage as indicated on type plate

and connect instrument.

The separate network may not be electrical isolated but must

be connected to protective earth!

Table of contents