TABLE OF CONTENTS

Introduction....................................................................................................................................................3

Safety Information..............................................................................................................................................................4

Specications.......................................................................................................................................................................6

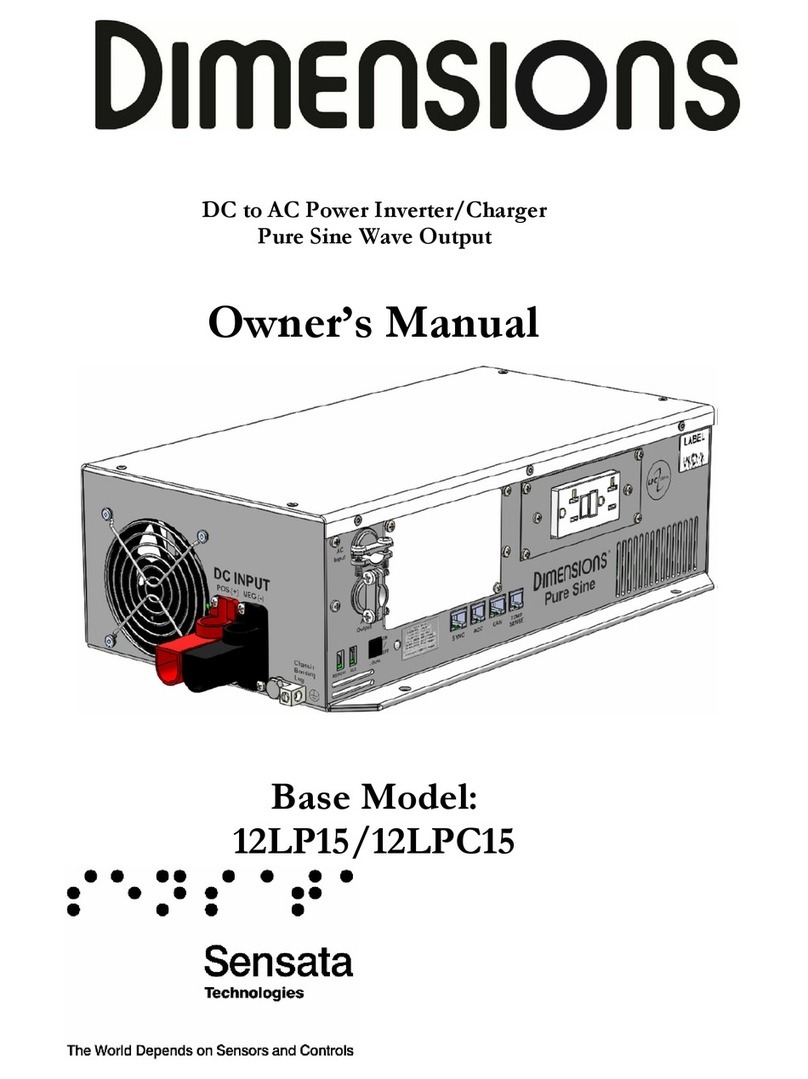

Components ........................................................................................................................................................................7

Design Features...................................................................................................................................................................8

Installation ......................................................................................................................................................9

Mount the Inverter .............................................................................................................................................................9

Wiring Diagram.................................................................................................................................................................10

DC Wire Gauge & Fusing...............................................................................................................................................11

AC Input & Output Connections ..................................................................................................................................12

BTS Connection................................................................................................................................................................13

Remote Operation ............................................................................................................................................................15

NP Control Board Pinout ...............................................................................................................................................17

Operation ...................................................................................................................................................... 18

Inverter Power Mode .......................................................................................................................................................18

External Power Mode.......................................................................................................................................................18

Operation Using 7-Segment Display .............................................................................................................................22

Operation Using Remote On/Off Switch ...................................................................................................................26

GFCI Operation ...............................................................................................................................................................27

Optional LCD Remote ....................................................................................................................................................28

Congurations .............................................................................................................................................. 29

NVM Setup Utility............................................................................................................................................................29

Congurations...................................................................................................................................................................30

Ignition Switch Control with the 7-Seg Display Panel................................................................................................32

Branch Circuit Rating (BCR) Max Limit with the 7-Seg Display Panel ...................................................................33

Battery Type and Prole with the 7-Seg Display Panel...............................................................................................33

Troubleshooting ........................................................................................................................................... 34

7-Seg Display Panel Messages.........................................................................................................................................34

LED Status Chart .............................................................................................................................................................38

Troubleshooting Guide....................................................................................................................................................40

Appendix....................................................................................................................................................... 41

Accessories & Replacement Parts ..................................................................................................................................41

System Default Settings ...................................................................................................................................................42

Inverter Charger Model Options....................................................................................................................................42

CAN....................................................................................................................................................................................43

Limited Warranty Terms & Conditions ....................................................................................................... 45