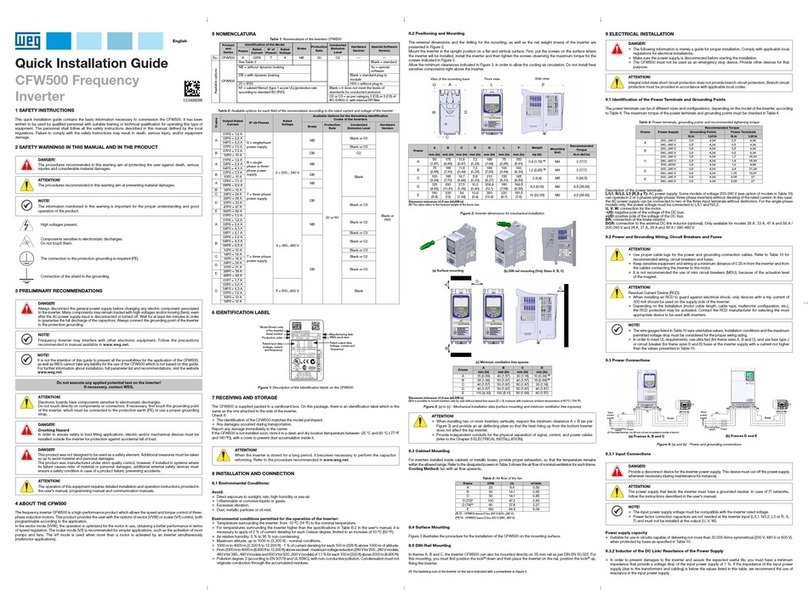

SUMMARY

1 SAFETY INSTRUCTIONS .......................................................................... 5

1.1 SAFETY WARNINGS IN THE MANUAL .............................................................................................5

1.2 PRELIMINARY RECOMMENDATIONS ..............................................................................................5

1.3 HANDLING...........................................................................................................................................6

1.3.1 Panel Handling...........................................................................................................................6

1.3.1.1 Representative Image of the AFW11 Packaged for Land Transport ........................6

1.3.1.2 Representative Image of the AFW11 Packaged for Land or Sea Transport in a

Closed Container.......................................................................................................................7

1.3.1.3 Representative Image of the AFW11 Handled by the Lifting Eyes...........................7

2 GENERAL INFORMATION......................................................................... 9

2.1 ABOUT THE MANUAL ........................................................................................................................9

2.2 TECHNICAL DATA ..............................................................................................................................9

2.3 FUSES................................................................................................................................................ 11

2.4 ACCESSORIES.................................................................................................................................. 11

2.4.1 IOE-02 Board............................................................................................................................ 11

2.4.2 IOB-01 Board ........................................................................................................................... 12

2.4.3 Probus Communication ....................................................................................................... 13

2.4.4 DeviceNet Communication .................................................................................................... 13

2.4.5 Modbus TCP-IP Communication ...........................................................................................14

2.4.6 Pronet IO Communication.................................................................................................... 14

2.4.7 Ethernet IP Communication................................................................................................... 14

2.4.8 Selector Switch for Operating Mode (Local/Remote) ......................................................... 15

2.4.9 Output Reactor (According to the Inverter Rated Current)................................................ 15

2.5 POWER AND CONTROL UNITS.......................................................................................................16

2.6 LABEL................................................................................................................................................ 17

3 TYPICAL SCHEMES ................................................................................ 18

4 INSTALLING ............................................................................................. 22

4.1 MOUNTING THE PANELS ON THE FLOOR ....................................................................................22

4.2 MOUNTING THE PANELS ON THE WALL ......................................................................................24

4.3 MECHANICAL DETAILS ...................................................................................................................25

4.4 ELECTRICAL CONNECTION............................................................................................................32

4.4.1 Dimension, Weight and Dissipated Power Table .................................................................34

4.4.2 Power Cable Minimum Gauge Table .....................................................................................35

4.4.3 Connecting the Power Supply ...............................................................................................36

4.4.4 Connecting the Output Cables ..............................................................................................36

5 PRODUCT OPERATION........................................................................... 37

6 MAINTENANCE INSTRUCTIONS ............................................................ 38

6.1 PREVENTIVE MAINTENANCE .........................................................................................................38

6.2 CORRECTIVE MAINTENANCES......................................................................................................38

7 ONE-LINE DIAGRAM ............................................................................... 39