Solarflo - Solar Thermal Domestic Hot Water System4

1.0 Commissioning of system

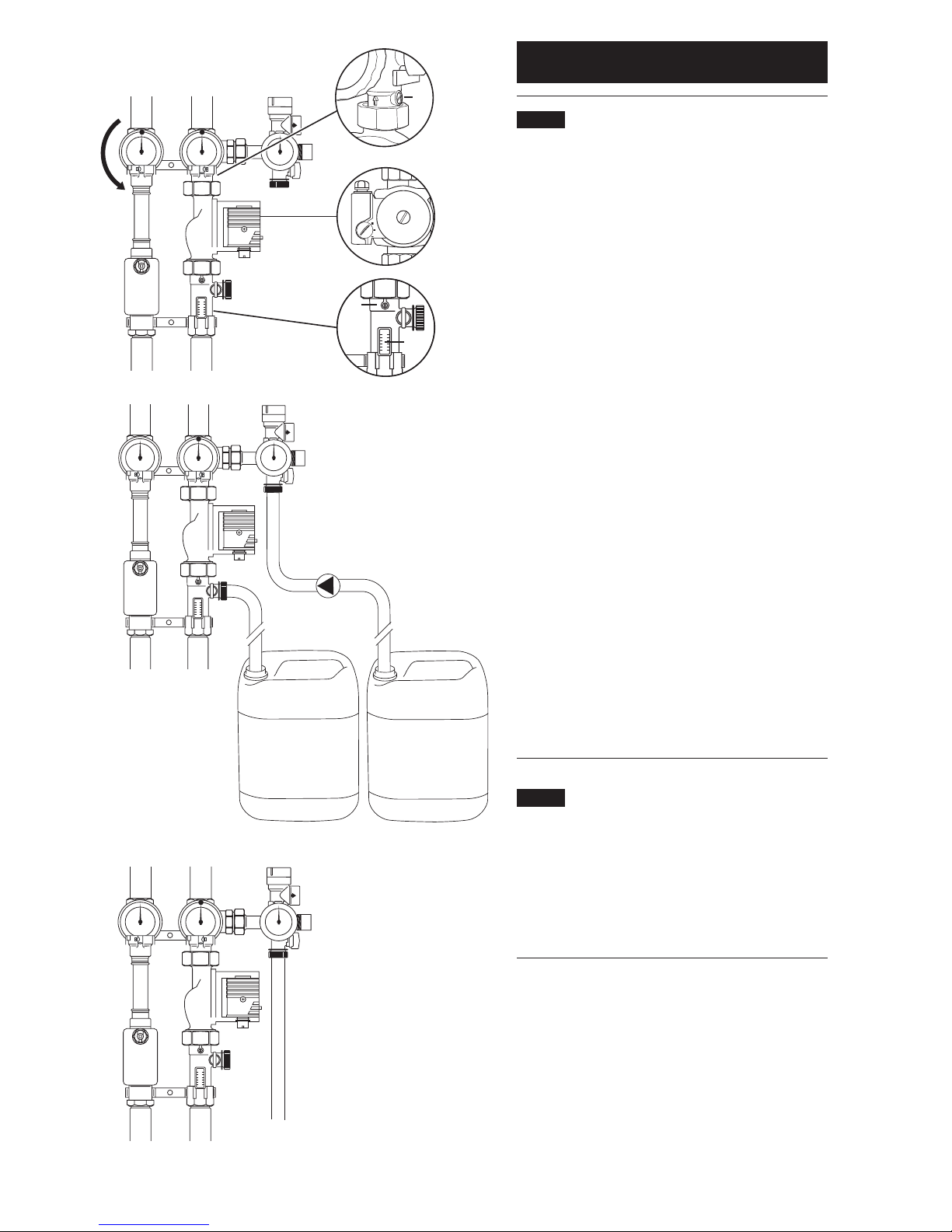

1.2 Flushing the pipework

Before the system is commissioned the pipework must

be flushed to remove any contaminants. It is recommended

that this is done using the solar heat transfer fluid as it

will be impossible to fully drain all parts of the system.

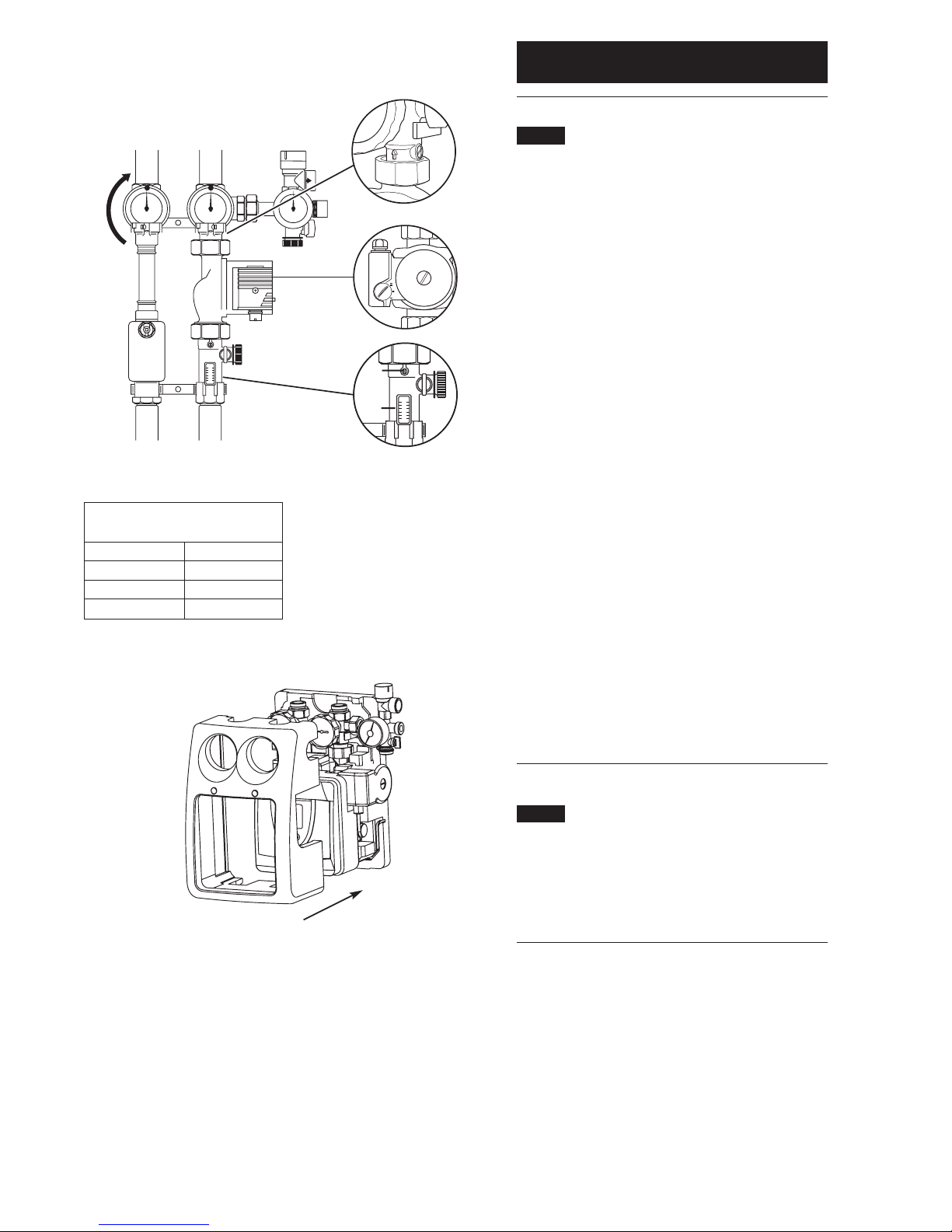

Connect the flushing pipes to the fill & drain valve on

the safety group (Fig. 1 Item 1) and to the fill & drain

valve on the flow meter (Fig. 1 Item 2).

Open the fill & drain valves.

Turn the slot of the adjusting screw (Fig. 1 Item 3) in the

return so the slot is vertical to open the non-return

valve.

Turn the left hand isolating valve with integral

thermometer in the flow (Fig. 1 Item 4) in the direction

indicated by the arrow (to a 45° position) to open the

non-return valve.

Ensure that the right hand isolating valve with integral

thermometer in the return (Fig. 1 Item 5) is open

indicated by the dot on the thermometer bezel being

at the top.

Turn the slot of the adjusting screw of the flow meter

(Fig. 1 Item 6) in the return vertically to open the flow

limiter (Fig. 1 Item 7).

Flush the solar primary pump by pumping the fluid into

the system via the fill and drain valve on the safety group.

Close right hand isolating valve (dot on thermometer

bezel at 9 o’clock position). Flush solar primary pipework

and panels via the fill and drain valve on the safety group.

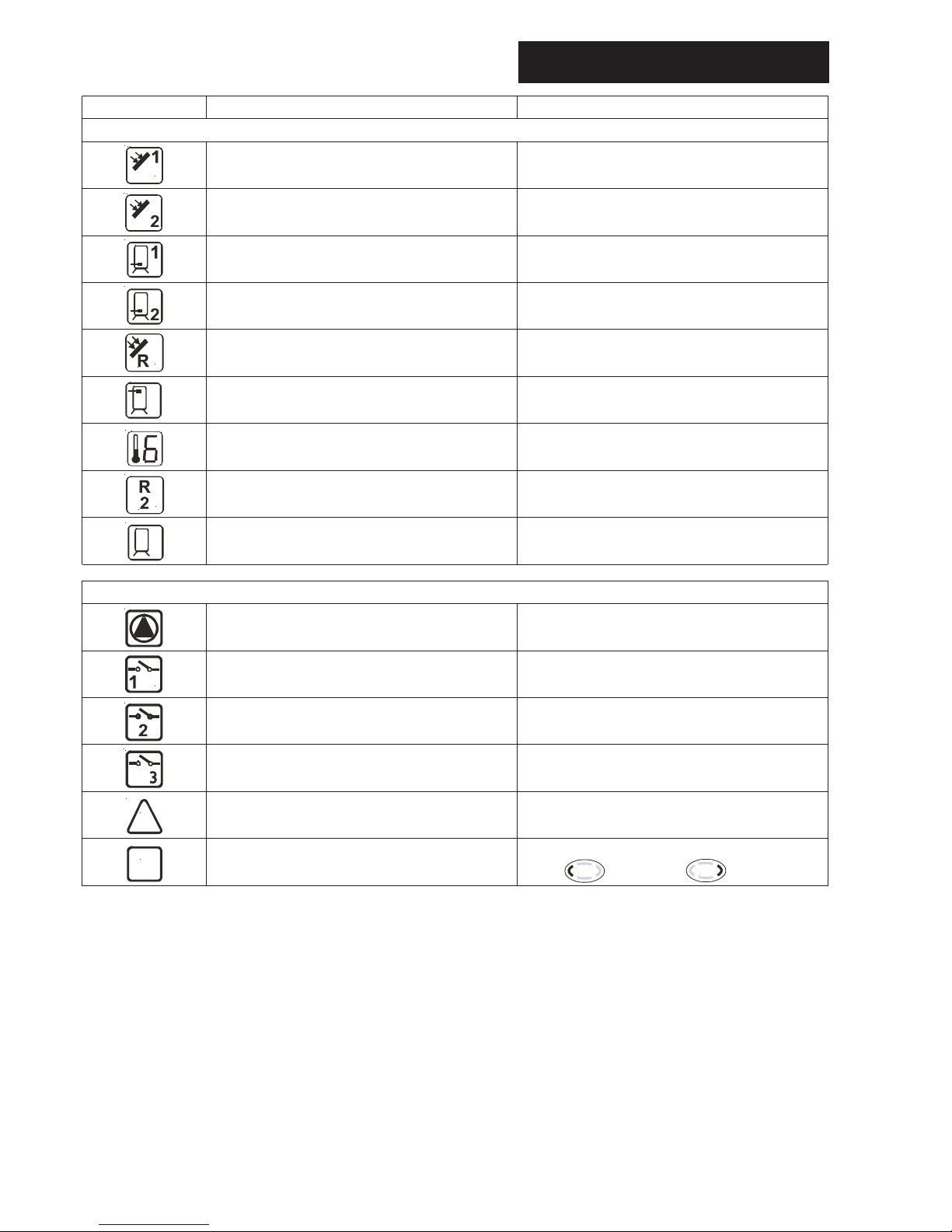

If reusing flushed fluid ensure this is filtered before

re-introducing into the system

(see Fig. 2).

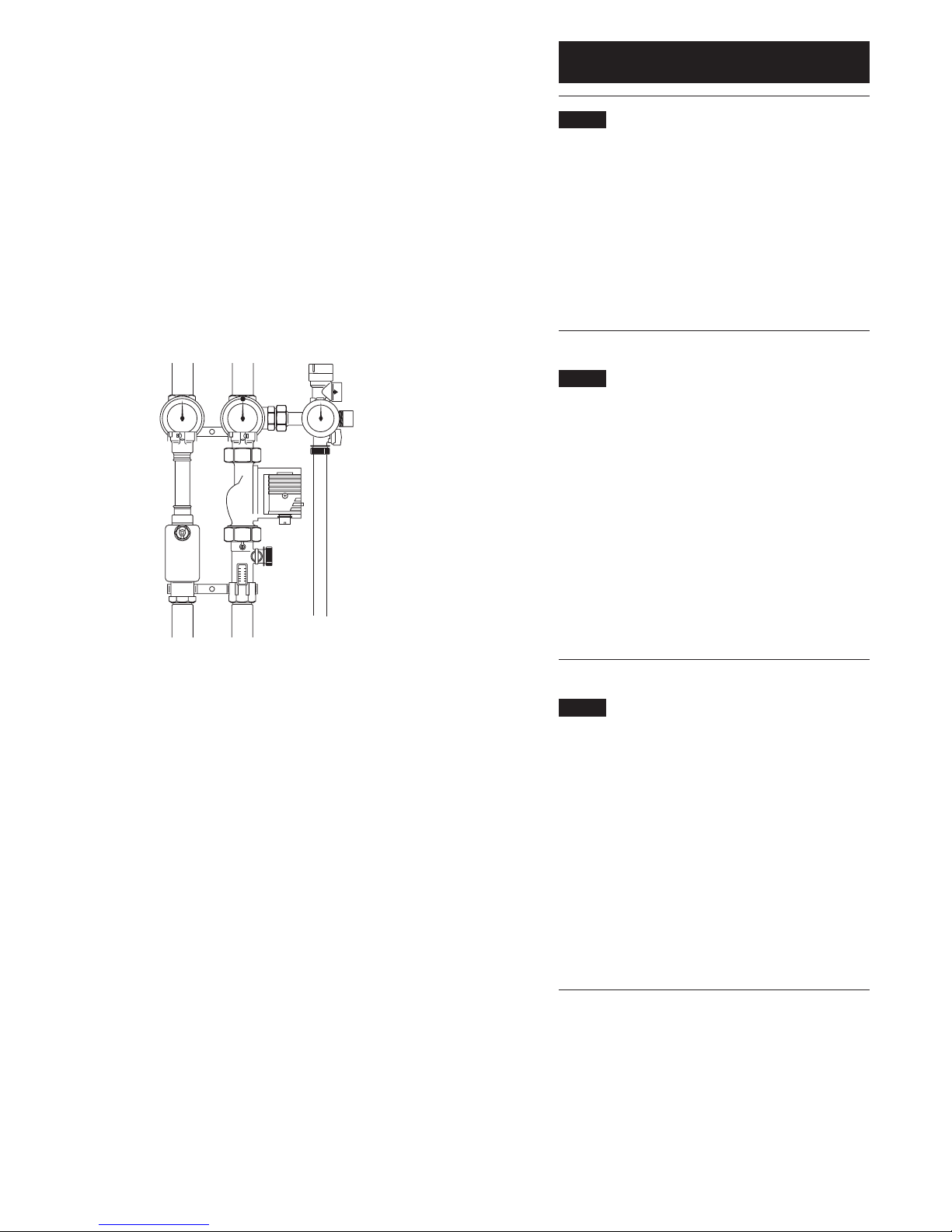

1.3 Filling the pipework

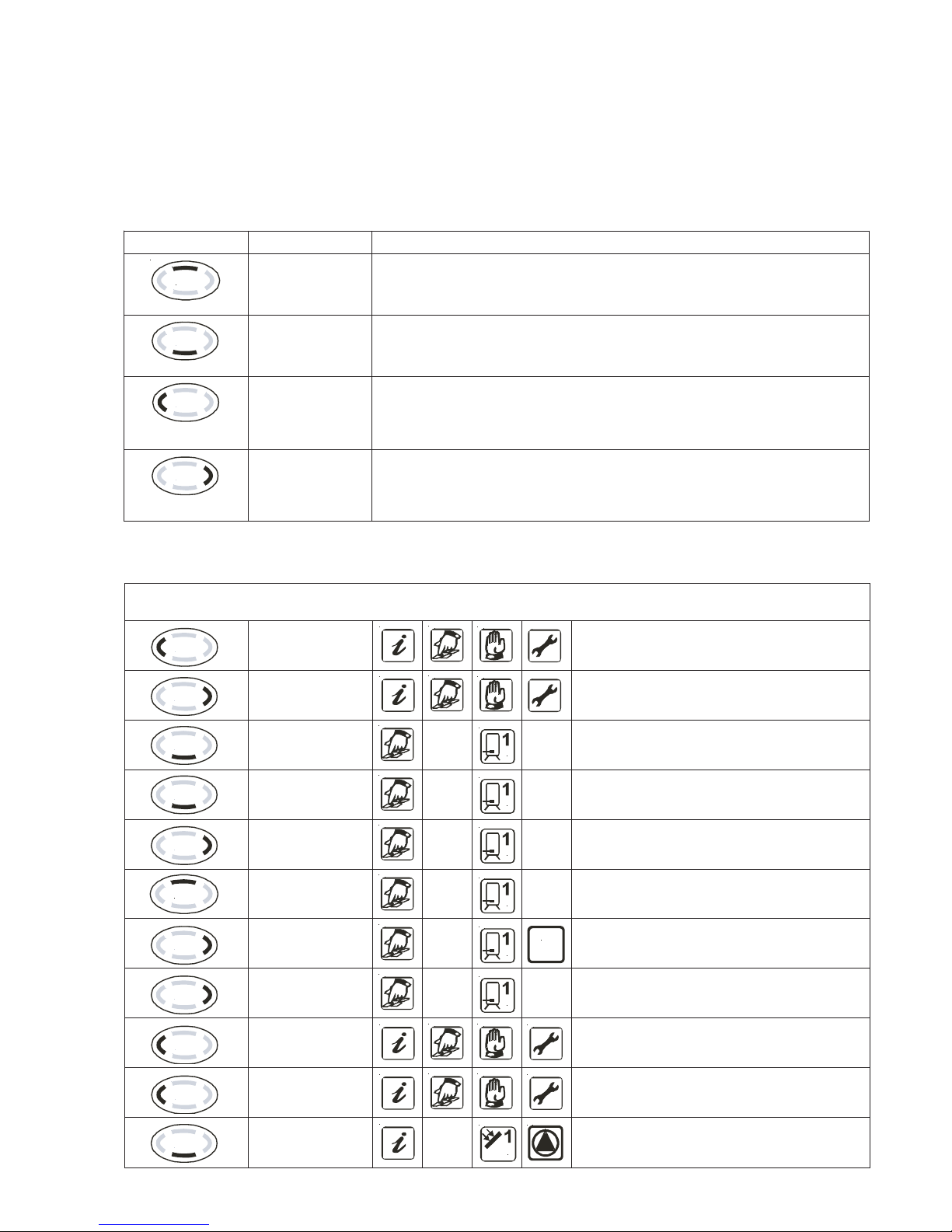

Close the fill and drain valve (Fig. 3 Item 2) on the flow

meter. Open the righthand isolating valve (Fig. 3. Item 1)

with integral thermometer by turning so that the dot on

the bezel is at the top. Fill the solar primary system by

pumping in fluid until the system pressure reads 1.5 to

2.0 bar. Close the fill and drain valve (Fig. 3. Item 3) on

the safety group.

45

3

6

7

Fig. 1

Fig. 2

Fig. 3

Solar fluid Solar fluid

Filling pump

Filter

1

2

1

3

2