Bay Products 11352 User manual

Level 1 Service Manual

Manhole Odor Control Units

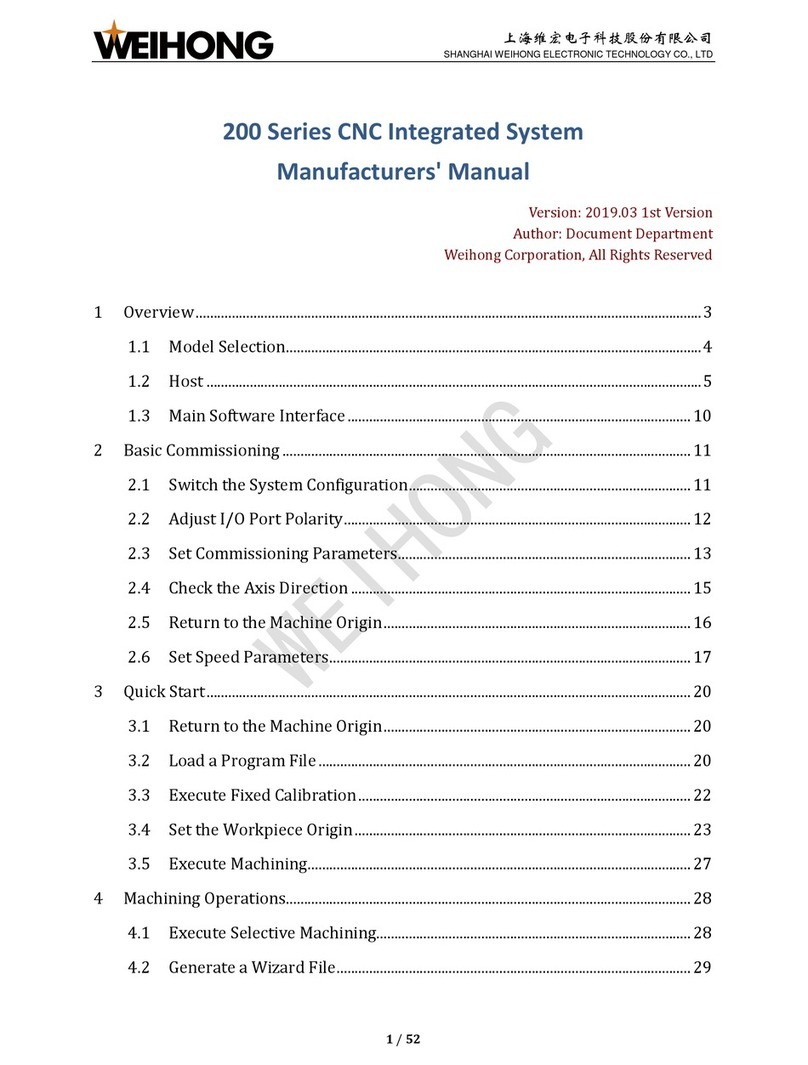

Table Of Contents

SECTION 1: GENERAL INFORMATION FOR OPERATION

AND MAINTENANCE

SECTION 2: DETAILED INSTALLATION, MAINTENANCE,

CALIBRATION AND REPAIR

SECTION 3: DIAGRAMS AND SCHEMATICS

SECTION 4: WARRANTIES, GUARANTIES AND SPARE

PARTS

See Section 2 – 2.G on Pg. 2-12 thru 2-14 for

information needed to Order Replacement Activated

Carbon Media for the Manhole Odor Control Units

SECTION 5: FIELD TESTING RECORDS

SECTION 6: EQUIPMENT DATA SHEETS

Level 1 Service Manual

Manhole Odor Control Units

Table Of Contents

SECTION 1: GENERAL INFORMATION FOR OPERATION

AND MAINTENANCE

1.A General Instructions

1.A.1 Description Of The Equipment and How It Functions

including Location Maps for each Site Area ................Pg. 1-1 thru 1-6

1.A.2 Identification Information ..............................Pg. 1-7 thru 1-12

Safety Precautions ................................................... Pg. 1-7

Manhole Odor Control Units......................Pg. 1-8 thru 1-9

Carbon Canister .................................................... Pg. 1-10

Carbon Media ........................................Pg. 1-10 thru 1-11

Backdraft Dampers ................................Pg. 1-11 thru 1-12

1.A.3 Normal Operation Information

Normal Operation – Passive Odor Control............ Pg. 1-13

1.A.4 General Assembly Drawings, Sections, or Photographic

Views

Equipment Drawing............................................... Pg. 1-14

Typical Installation of Manhole Odor Control Unit with

(Open Bilco Door) showing Backdraft Dampers and

Carbon Media Canister.......................................... Pg. 1-15

1.A.5 Dimensions, Weight, Capacity and Design Conditions

Manhole Odor Control Units................................. Pg. 1-14

Carbon Canister .................................................... Pg. 1-10

Carbon Media ........................................Pg. 1-10 thru 1-11

Backdraft Dampers ................................Pg. 1-11 thru 1-12

Manhole Odor Control Units

1.A.1 – Description of the Equipment and How it Functions

The following paragraphs provide a brief description of the nine (9) Manhole Odor Control Units

installed in the Vent Structures throughout Sites 1995, Site 4, Site 17 and Site 27:

The Manhole Odor Control Units are installed inside of the manhole vent structures and are

designed to remove malodorous compounds from the foul manhole air as it is diffused from the

vent structures. As malodorous air from the manhole enters the bottom of the carbon canister

support in each manhole, it is diffused up through the activated carbon media by the ambient

pressure in the sewer vault. As the foul air is diffused through the activated carbon media, the

odorous compounds are absorbed by the activated carbon media. The carbon canisters can be

easily removed and the carbon media can be replaced as required. The pressure drop through the

carbon canister is less than 1.0 inch water column at a velocity of 35 feet per minute.

Each Manhole Odor Control Unit is comprised of four major components: the Carbon Canister,

the Carbon Media, the Canister Support Plate, and two Backdraft Dampers.

The Carbon Canister, manufactured by Bay Products, Inc., is white in color and composed of 90-

mil thick High-Density Polyethylene (HDPE). This canister has a porous bottom with a

polypropylene carbon retention screen and a closed flat top with treated air release holes. The

Carbon Canister has a 12 inch diameter top, a 10-¾ inch diameter bottom, and is 15 inches in

height.

The Carbon Media provided within the Carbon Canister is virgin, granular, bituminous coal

derived activated carbon. Please find the table below summarizing the Carbon Media

specifications:

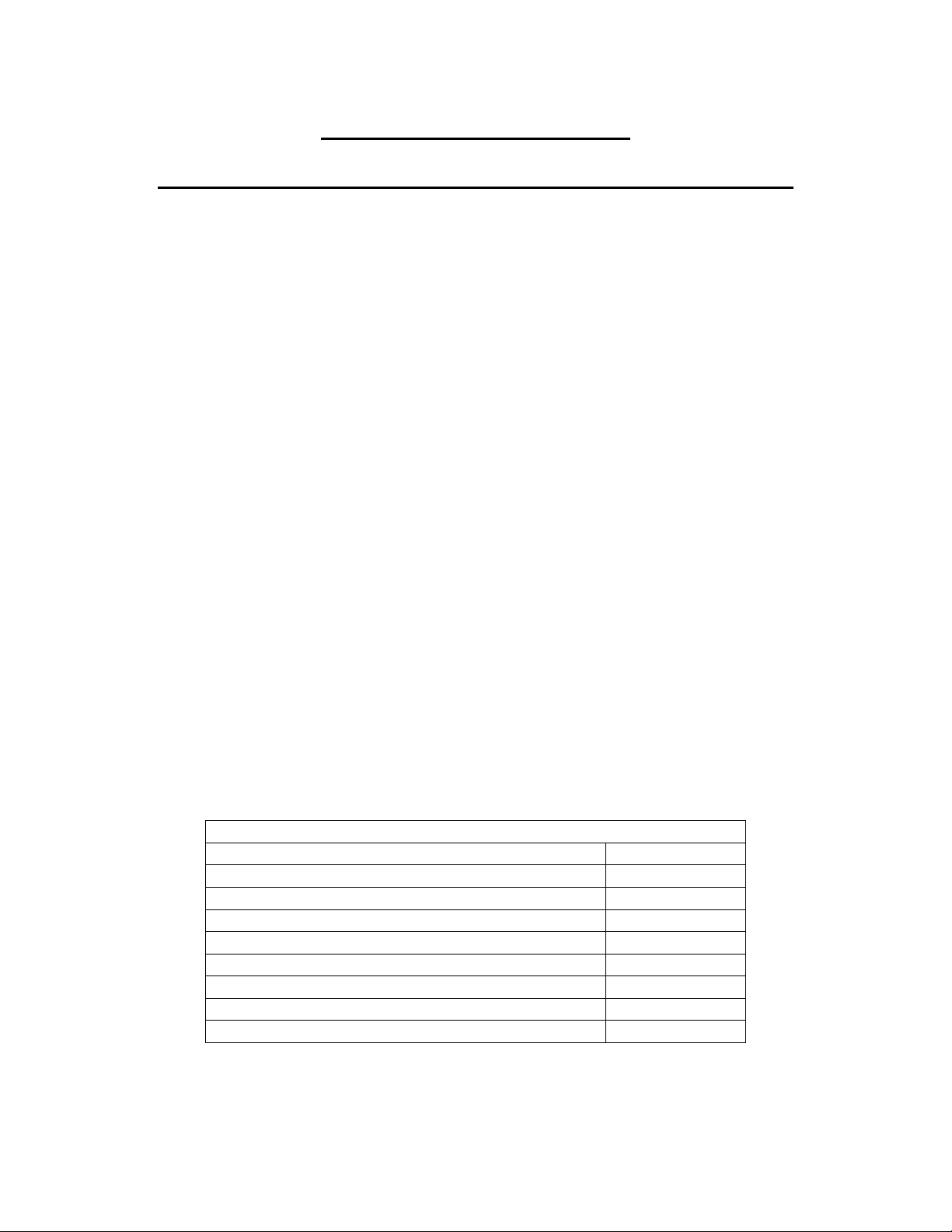

Carbon Media (Activated Carbon) - Specifications

Volume Supplied (ft3) 0.62

Weight Supplied (lbs) 20

Butane Activity (wt. %) 15.6 (minimum)

Hardness Number 97 (minimum)

Iodine Number (mg/g) 800 (minimum)

Ash (wt. %) 7 (maximum)

Apparent Density (g/cc) 0.56 (minimum)

Mean Particle Diameter (mm) 3.7 (minimum)

Minimum Hydrogen Sulfide (H2S) Capacity (g/cc) 0.09

1-1

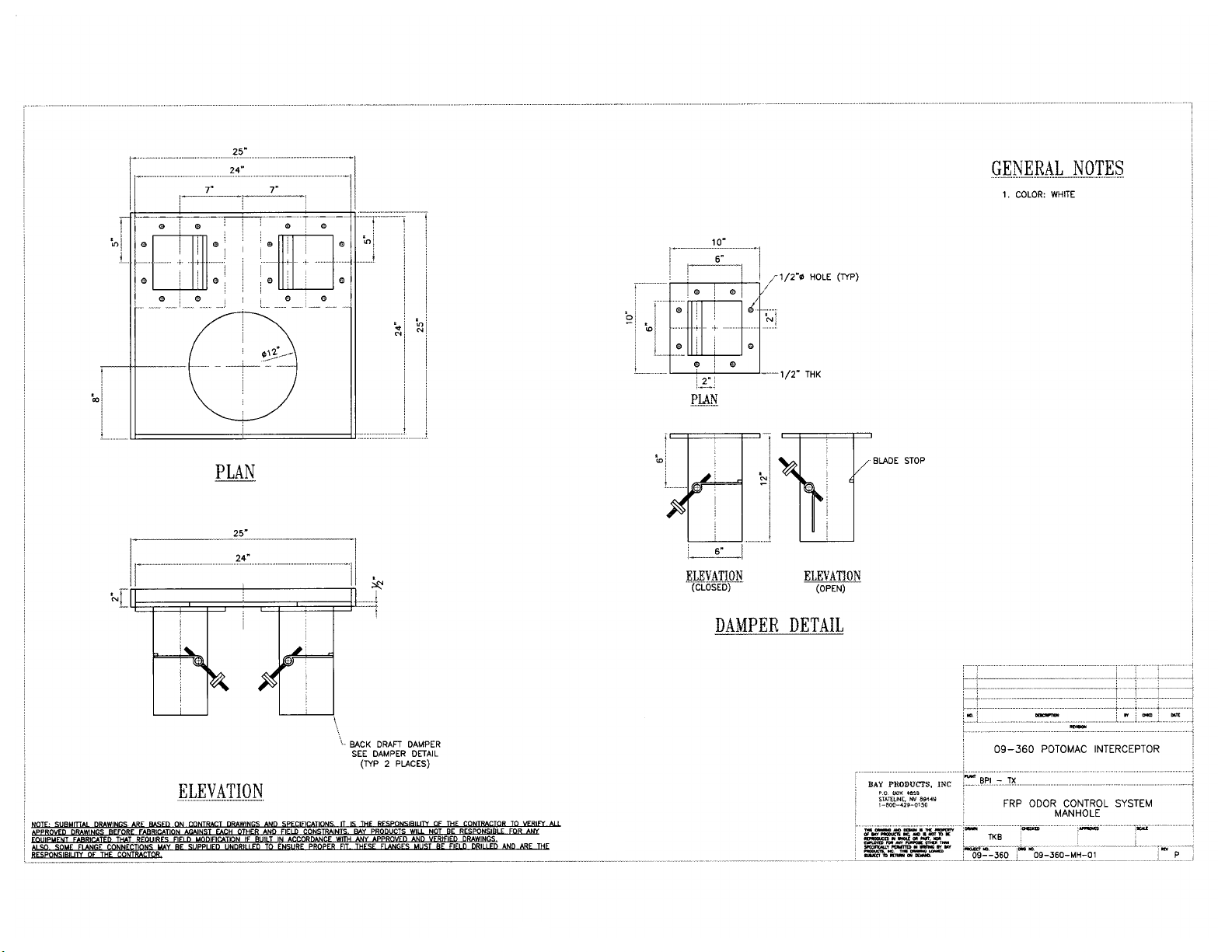

The Canister Support plate, used for holding the Carbon Canister and mounting the

Backdraft Dampers, is 24 inches in length, 24 inches in width and ½ inch in thickness

and composed of Fiberglass Reinforced Plastic (FRP).

The Backdraft Dampers (two per Manhole Odor Control Unit) are designed to allow

atmospheric air in but prevent malodorous air from leaking out of the vent structure. The

dampers are white in color, gel-coated with UV inhibitors, and are composed of AOC

K022, Vinyl Ester Resin with Class 1 Flame Spread Rating, with a 100 mil corrosion

barrier consisting of a 10 mil layer of Nexus surfacing veil, and backed with two layers of

1-½ oz. chopped strand mat. Please see the table below referencing the construction

materials of the individual components associated with the Manhole Odor Control

System Backdraft Dampers:

Backdraft Damper Components – Material Construction

Blade FRP with corrosion barrier

Bearings Graphite-filled Teflon

Axels Premium grade FRP

Hardware 316 Stainless Steel

Flanges 6” x 6” (inside diameter) for mounting to FRP plate

Face-to-face lengths 12 inches

Blade Seal EPDM

Shaft Seal EPDM O-Ring housed in the FRP flange

Bolt/Gasket Set 1/8 inch thick Neoprene gasket material with 316 Stainless Steel

bolts, 6” x 6” (inside diameter)

1-2

Site 1995 –Manhole Odor Control Systems

The below referenced table and photo summarize the locations of the Manhole Odor Control

Systems installed throughout Site 1995:

Site –1995 Manhole Odor Control Systems

Vent

Structure

Longitude (West)

Latitude (North)

Degree

Min

SS

Degree

Min

SS

VS-2

77

7

18.23

38

56

25.29

VS-3

77

7

25.49

38

56

43.57

VS-1994

77

6

5.03

38

55

5.01

1-3

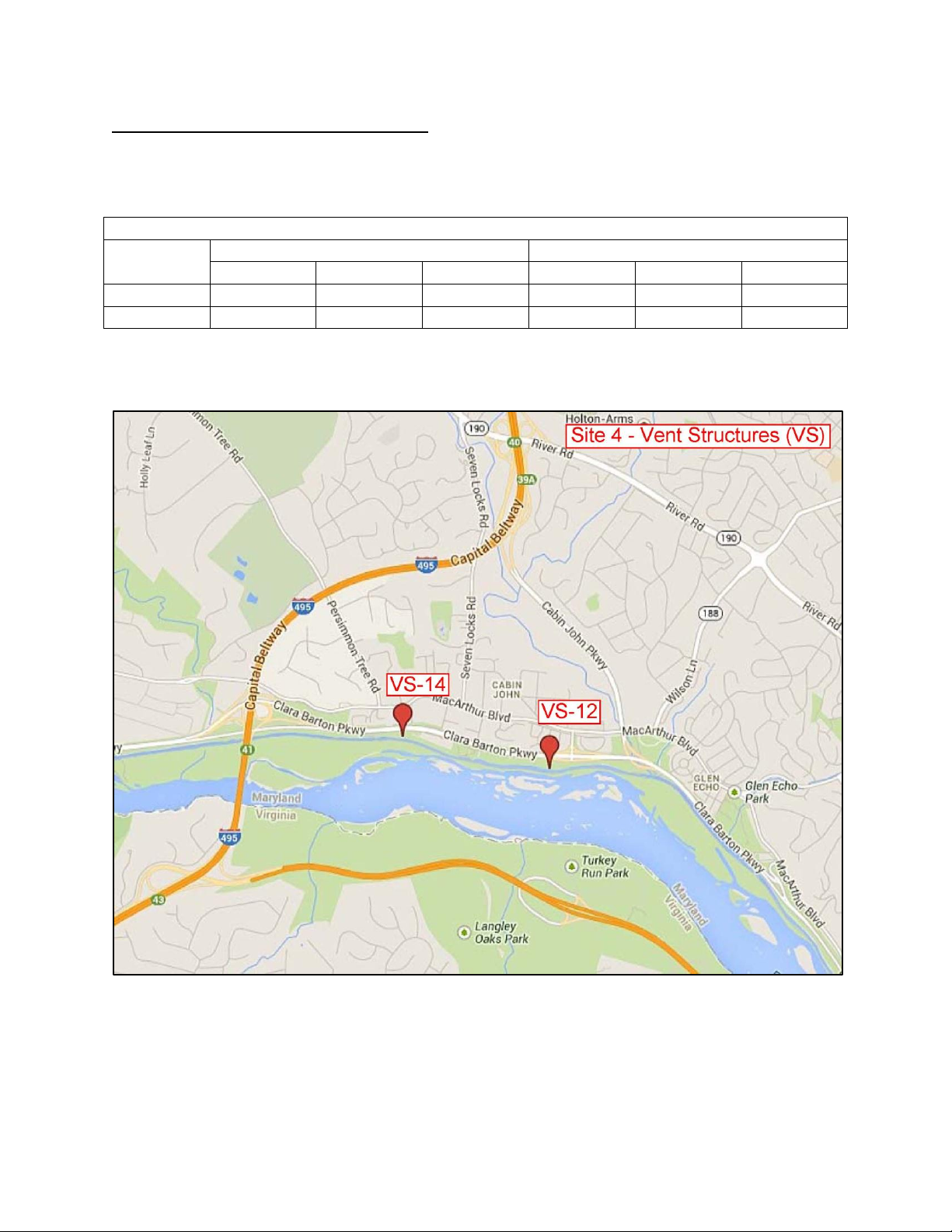

Site 4 –Manhole Odor Control Systems

The below referenced table and photo summarize the locations of the Manhole Odor Control

Systems installed throughout Site 4:

Site –4 Manhole Odor Control Systems

Vent

Structure

Longitude (West)

Latitude (North)

Degree

Min

SS

Degree

Min

SS

VS-12

77

9

16.58

38

58

13.65

VS-14

77

9

59.17

38

58

21.02

1-4

Site 17 –Manhole Odor Control Systems

The below referenced table and photo summarize the locations of the Manhole Odor Control

Systems installed throughout Site 17:

Site –17 Manhole Odor Control Systems

Vent

Structure

Longitude (West)

Latitude (North)

Degree

Min

SS

Degree

Min

SS

VS-24

77

12

22.75

38

58

40.69

VS-25

77

12

48.29

38

58

40.32

VS-26

77

13

15.3

38

58

43.91

1-5

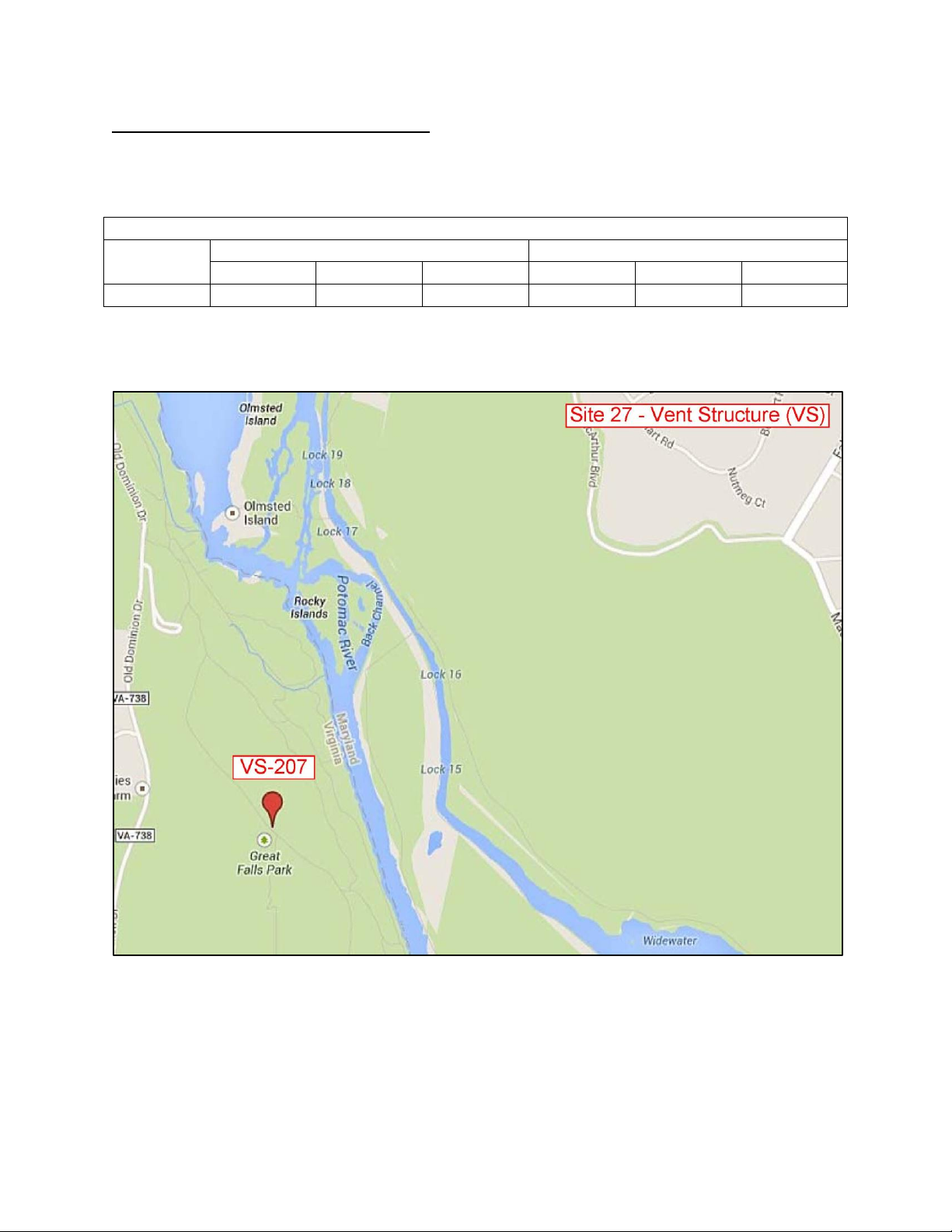

Site 27 –Manhole Odor Control System

The below referenced table and photo summarizes the location of the Manhole Odor Control

System installed on Site 27:

Site –27 Manhole Odor Control System

Vent

Structure

Longitude (West)

Latitude (North)

Degree

Min

SS

Degree

Min

SS

VS-207

77

15

1.84

38

59

15.35

1-6

ACTIVATED CARBON SAFETY PRECAUTIONS

1.A.2 Identification Information

DESCRIPTION

Activated Carbon is a Vapor Phase Virgin Activated Carbon that has been specially developed

for odor removal (adsorbtion) from sewage treatment operations. This bituminous coal based

product is unique in that it provides high adsorbtion capacity for H2S without chemical

impregnates and adsorbs volatile organic compounds (VOCs) in an effective manner.

SPECIFICATIONS

Vapor Phase Virgin Activated Carbon, Bituminous Coal based with high adsorption capacity for H2S

without chemical impregnates.

Butane Activity (wt. %) 15.6 minimum

Iodine Number - 800 minimum

H2S Capacity -(grams H2S / cc of carbon) .09 g/cc minimum

Ash (weight) 7% maximum

Apparent Density (grams / cc) .56 minimum

Hardness - 97 minimum

Mean Particle Diameter - (mm) 3.7 minimum

CAUTION: WET ACTIVATED CARBON DEPLETES OXYGEN FROM AIR

Whenever workers enter a vessel containing carbon media, all precautions must be taken

since dangerously low levels of oxygen may be encountered. Atmosphere sampling and

work procedures for potentially low oxygen areas should be followed.

The Odor Control Manhole vent structure is not an enclosed structure. It is recommended

that after opening the Bilco Hatch that all workers wait 2 minutes for the vent structure to

ventilate to the atmosphere before reaching down to replace the carbon media.

CAUTION: Used Carbon Media is Highly Acidic

Workers must wear protective gloves whenever handling the used “Spent” carbon media.

1-7

1.A.2 Identification Information

MANHOLE ODOR CONTROL UNIT

HIGHLY EFFECTIVE, PASSIVE MANHOLE ODOR CONTROL

Bay Products, MANHOLE OCU is compact, modular unit designed to remove unpleasant odors

such as hydrogen sulfide, mercaptans and other organic odors venting from sewer conveyance

manholes. The unit comes equipped with media that is specially designed to have high-activity

for use in odor control applications. The MANHOLE OCU offers the following features &

benefits:

>- Eliminates Unpleasant Odors - By removing hydrogen sulfide and organic odors from the air

stream, each MANHOLE OCU prevents unpleasant odors from entering the atmosphere around

the manhole covers.

>- No Energy Requirements - There are no mechanical parts. Unpleasant odors are removed by

adsorption from the air stream as a sewer conveyance line breathes through the manhole.

>- Flexible Treatment - Since the MANHOLE OCU is based on adsorption principles it is

passive in operation, which means it can be highly effective on changing flows and odor

concentrations.

>- Non-Corrosive - All MANHOLE OCUs are manufactured from industrial plastics that have

proven reliability in this type of service.

>- Passive Odor Control - By using positive pressures inside the sewer conveyance line,

odorous air passes up through the unit where the unpleasant odors are adsorbed and

stored in the media, allowing purified air to vent through the top of the unit into the

atmosphere. The pressure or surges of pressure with the sewer conveyance line is sufficient

to overcome the pressure drop from the media bed.

>- Cost Effective - The MANHOLE OCU is a simple media adsorption unit, which offers a high

degree of odor control and performance at a low cost.

>- Replacement Media - When odor breakthrough is detected, the media needs to be replaced.

Bay Products can provide replacement media. Media replacement is as simple as dumping out

the old media and filling with fresh media. This can be done at the site in a manner of a few

minutes.

Bay Products Inc.

P.O. Box 4859

Stateline, NV 89449-4859

phone: 800-429-0150

fax: 775-586-8501

Web Site: www.bayprod.com

1-8

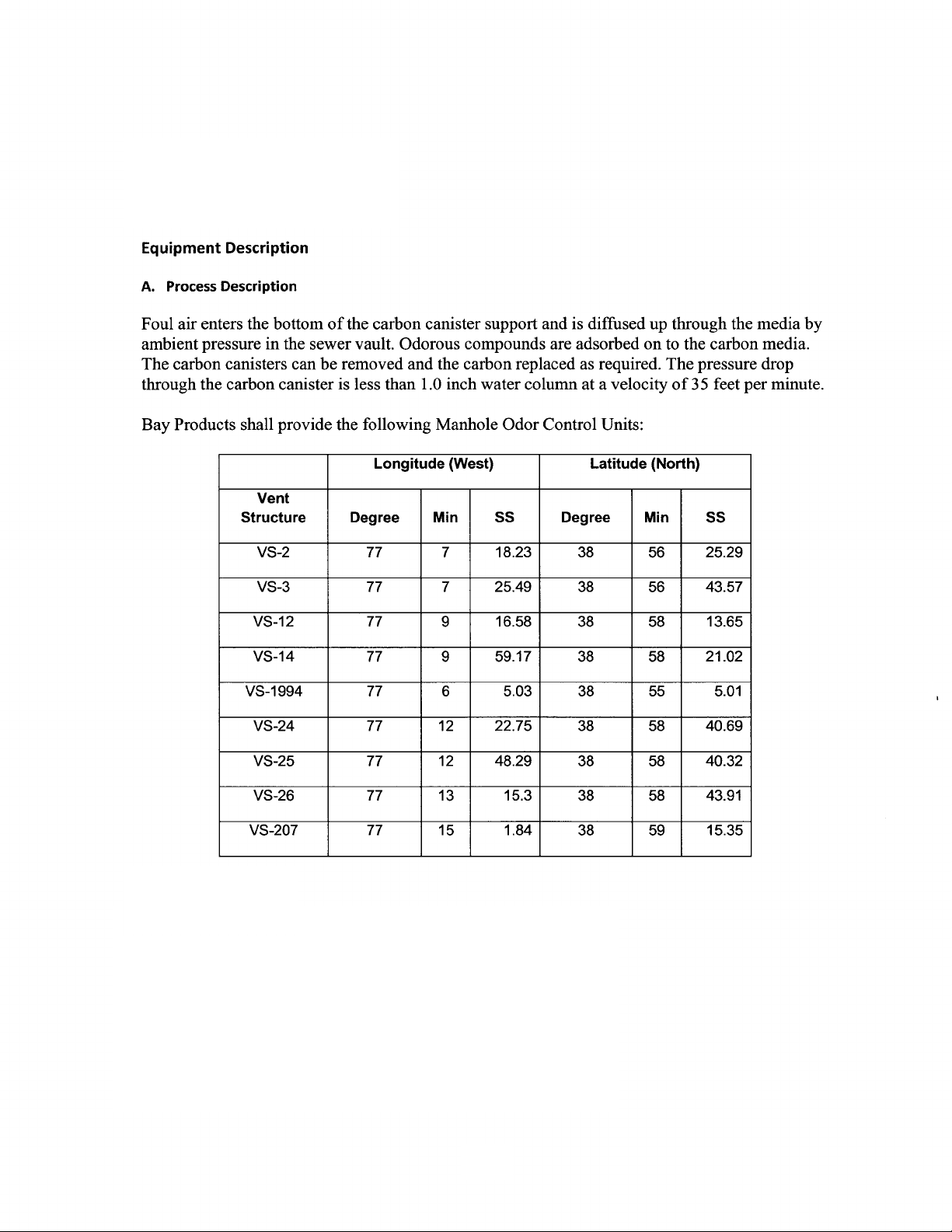

Equipment Description

A.

Process Description

Foul air enters the bottom

of

the carbon canister support and is diffused up through the media by

ambient pressure in the sewer vault. Odorous compounds are adsorbed

on

to the carbon media.

The carbon canisters can be removed and the carbon replaced as required. The pressure drop

through the carbon canister is less than 1.0 inch water column at a velocity

of35

feet per minute.

Bay Products shall provide the following Manhole Odor Control Units:

Longitude

(West) Latitude (North)

Vent

Structure

Degree Min

55

Degree Min

55

VS-2 77 7 18.23 38 56 25.29

VS-3 77 7 25.49 38 56 43.57

VS-12

77

9 16.58 38 58 13.65

VS-14 77 9 59.17 38 58 21.02

VS-1994 77 6 5.03 38

55

5.01

VS-24 77

12

22.75 38 58 40.69

VS-25 77

12

48.29 38 58 40.32

VS-26 77 13 15.3 38

58

43.91

VS-207 77 15 1.84 38

59

15.35

1-9

1.A.2 Identification Information

B. Canister Support Plate

SEE NEXT PAGE

1-10

B. Canister Support Plate

1-11

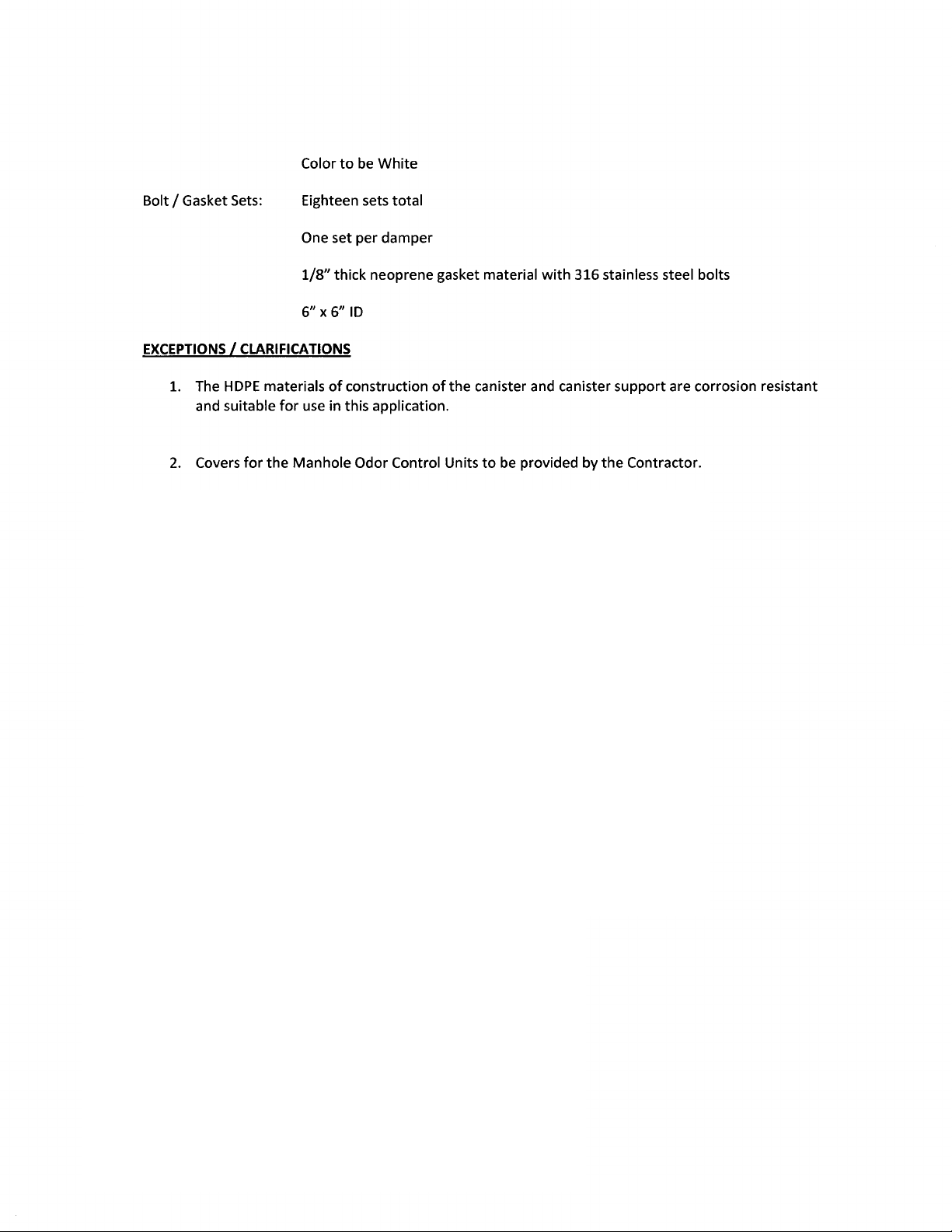

Color

to

be

White

Bolt / Gasket

Sets:

Eighteen sets total

One set per damper

1/8"

thick neoprene gasket material

with

316 stainless steel bolts

6" x 6"

ID

EXCEPTIONS

I

CLARIFICATIONS

1. The

HDPE

materials

of

construction

of

the canister and canister support are corrosion resistant

and suitable

for

use in this application.

2.

Covers

for

the

Manhole Odor Control Units

to

be

provided by

the

Contractor.

1-12

1.A.3NormalOperationInformation

MANHOLE ODOR CONTROL UNIT

HIGHLY EFFECTIVE, PASSIVE MANHOLE ODOR CONTROL

Bay Products, MANHOLE OCU is compact, modular unit designed to remove unpleasant odors

such as hydrogen sulfide, mercaptans and other organic compounds venting from sewer

conveyance manholes. The unit comes equipped with media that is specially designed to have

high-activity for use in odor control applications. The MANHOLE OCU offers the following

features & benefits:

>- Eliminates Unpleasant Odors - By removing hydrogen sulfide and other organic compounds

causing odors from the air stream, each MANHOLE OCU prevents unpleasant odors from

entering the atmosphere around the manhole covers.

>- No Energy Requirements - There are no mechanical parts. Unpleasant odors are removed by

adsorption from the air stream as a sewer conveyance line breathes through the manhole.

>- Flexible Treatment - Since the MANHOLE OCU is based on adsorption principles it is

passive in operation, which means it can be highly effective on changing flows and odor

concentrations.

>- Non-Corrosive - All MANHOLE OCUs are manufactured from industrial plastics that have

proven reliability in this type of service.

>- Passive Odor Control - By using positive pressures inside the sewer conveyance line, odorous

air passes up through the unit where the unpleasant odors are adsorbed and stored in the media,

allowing purified air to vent through the top of the unit into the atmosphere. The pressure or

surges of pressure with the sewer conveyance line is sufficient to overcome the pressure drop

from the media bed.

>- Cost Effective - The MANHOLE OCU is a simple media adsorption unit, which offers a high

degree of odor control and performance at a low cost.

>- Replacement Media - When odor breakthrough is detected, the media needs to be replaced.

Bay Products can provide replacement media. Media replacement is as simple as dumping out

the old media and filling with fresh media. This can be done at the site in a manner of a few

minutes.

Bay Products Inc.

P.O. Box 4859

Stateline, NV 89449-4859

phone: 800-429-0150

fax: 775-586-8501

1-13

1-14

Counterweight

inspection point

Damper inspection

point

Carbon Cannister

1.A.4 General Assembly Drawings, Sections, or Photographic Views

View of typical Manhole Odor Control Unit (Bilco Cover Opened) showing two square openings

for the Backdraft Damper Air intakes, and the Activated Carbon Canister (5 Gallon Bucket).

1-15

Backflow Damper

Carbon Cannister

Level 1 Service Manual

Manhole Odor Control Units

Table Of Contents

SECTION 2: DETAILED INSTALLATION, MAINTENANCE,

CALIBRATION AND REPAIR

2.A Installation

2.A.1 Reference Drawings or Schematics To Assemble and Install

..........................................................................Pg. 2-1 thru 2-2

2.A.2 Equipment Alignment, Clearances, Tolerances, and

Interfacing ...................................................................... Pg. 2-1

2.A.3 Identify Trade Skill Level Required To Install ............. Pg. 2-3

2.A.4 Specify Any Special Rigging Required......................... Pg. 2-3

2.A.5 Specify Any Special Test Equipment Required............ Pg. 2-3

2.B Safety

2.B.1 Identify All Safety and Tag-out Procedures.....Pg. 2-3 thru 2-4

2.C Lubrication

2.C.1 Identify Lubrication Points............................................ Pg. 2-4

Table of contents