MGM BMS 16i User manual

BMS 16i

Version 5.4

Battery Management System

Operating manual

Development, manufacture, service: Tel.: +420 577

001

350

MGM COMPRO s.r.o. E-mail: info@mgm-compro.com

Růžová 307, 763 02 Zlín, Czech Republic Info: www.mgm-compro.com

BMS-16i page 2 / 38

Table of content

BMS-16i ..................................................................................................................................................................................................................................3

Dictionary...............................................................................................................................................................................................................................3

Parameters.............................................................................................................................................................................................................................4

Warnings and recommendations ........................................................................................................................................................................................5

Basic variants of assembly..................................................................................................................................................................................................6

According to controlling......................................................................................................................................................................................................................6

Master..........................................................................................................................................................................................................................................6

Slave ............................................................................................................................................................................................................................................6

According to balancing........................................................................................................................................................................................................................6

Balancing with the HCBAL8 and with FANs...............................................................................................................................................................................6

Balancing with the HCBAL8 .......................................................................................................................................................................................................6

Balancing with the internal balancing resistors.............................................................................................................................................................................6

Connectors and signals .......................................................................................................................................................................................................7

LED indication of the BMS working modes .......................................................................................................................................................................9

Activation of the BMS 16i.....................................................................................................................................................................................................9

Charging and balancing .......................................................................................................................................................................................................9

Balancing modes .................................................................................................................................................................................................................................9

From balancing voltage................................................................................................................................................................................................................9

From charged cell voltage -10 mV ...............................................................................................................................................................................................9

Always.........................................................................................................................................................................................................................................9

Deactivated ..................................................................................................................................................................................................................................9

Example of the charging modes with different chargers / types of battery cells..........................................................................................................................10

Internal battery resistance .................................................................................................................................................................................................11

Discharging..........................................................................................................................................................................................................................11

Current probe (Internal / External) ....................................................................................................................................................................................12

Internal current probe / Connector K4 ...............................................................................................................................................................................................12

External current probe .......................................................................................................................................................................................................................12

Temperature sensors..........................................................................................................................................................................................................13

Temperature sensor of BMS..............................................................................................................................................................................................................13

Temperature sensor of balancers........................................................................................................................................................................................................13

Temperature sensor of environment...................................................................................................................................................................................................13

Temperature sensor of battery............................................................................................................................................................................................................13

System bus RS485..............................................................................................................................................................................................................13

Communication bus CAN 2.0.............................................................................................................................................................................................14

Example of NMEA connectors & termination ...................................................................................................................................................................................14

Power outputs .....................................................................................................................................................................................................................15

OUT_1 →Switching of the main contactor (without / with external supply).....................................................................................................................................15

OUT_2 →Switching of the charger contactor (without / with external supply).................................................................................................................................15

OUT_3 →Charging ..........................................................................................................................................................................................................................16

OUT_4 →Charging with high current (without / with external supply) ............................................................................................................................................16

HBC Controller / Motor / Battery system / Display / Battery chargers..........................................................................................................................16

Communication interface OPTOCOM6i (BMS 16i ↔ PC)................................................................................................................................................17

MGM ProTool.......................................................................................................................................................................................................................18

Instalation of the MGM ProTool........................................................................................................................................................................................................18

Connection of the BMS 16i with PC..................................................................................................................................................................................................19

Update of MGM ProTool ..................................................................................................................................................................................................................19

Update of BMS 16i firmware.............................................................................................................................................................................................................20

Setting of the user parameters (in MGM ProTool)...........................................................................................................................................................21

List of parameters..............................................................................................................................................................................................................................22

Description of parameters..................................................................................................................................................................................................................23

Real-time monitoring ..........................................................................................................................................................................................................26

Parameters, which can be monitored..................................................................................................................................................................................................28

GSM module ........................................................................................................................................................................................................................29

BMS 16i - Logs overview....................................................................................................................................................................................................31

Examples..............................................................................................................................................................................................................................32

1) BMS 16i Master ....................................................................................................................................................................................................................32

2) BMS 16i Master + Slave........................................................................................................................................................................................................34

Product warranty.................................................................................................................................................................................................................36

Service and Technical Support .........................................................................................................................................................................................36

Appendix..............................................................................................................................................................................................................................37

CAN bus default settings ...................................................................................................................................................................................................................37

BMS-16i page 3 / 38

BMS-16i

BMS 16i is the Battery Management System designed for batteries, which use LiPol, Li-Ion, LiFePO4 cells or other cells with

operational voltage range 1,8V - 5V per cell. BMS 16i provides protection and enlarge the lifetime of the batteries by measuring the

working temperatures (of battery, BMS and balancers) and capacity of the battery and controlling the voltage and flowed current.

BMS 16i control the battery during the charging and discharging, manage the balancing of each cell, communicate with superior

system and handle a system relay and contactors.

BMS 16i is able to control max. 16 cells, but could be connected into the larger system thru the internal bus (RS485), where could be

max. 8× BMS 16i modules (1× Master / 7× Slaves), which could control up to 128 serial connected cells with max. battery voltage 540

V. In the system you could use the BMS 16i and BMS-8i to be able to optimize the amount of the BMS modules for defined amount of

the cells. BMS 16i uses balancing current up to 850 mA (version with assembled additional HCBAL8 and FANs), basic version could

use balancing current up to 100 mA.

BMS 16i is powered directly from the monitored battery and works independently. BMS 16i has very low power consumption around

20uA in the “OFF” mode.

BMS 16i system automatically do the self-testing, has doubled critical components for balancing, to secure, that even if any

component wills failure, then the cells will be protected against the uncontrolled discharging and the system will still correctly works,

inform about the failure (via LED status, inform superior system via CAN, inform via display) and ask for the service .

BMS 16i has, of course as well as all other BMSes from MGM Compro, unique measurement of internal voltage of cells, which is fully

independent to the internal resistance of the cells and resistant of the system.

With SW application MGM-ProTool and communication interface OPTOCOM-6i is possible to do the settings, real time monitoring

and read logs of the system and FW update of the BMS, which helps to have every time the latest version of the SW/FW.

For communication with other systems, BMS-16i uses the CAN bus.

BMS 16i could be modified based on the customer request. In case, that you have any extra requirements, feel free to contact us by

an email: info@mgm-compro.com

Dictionary

BMS 16i system More than one BMS 16i connected together

HCBAL8 PCBA with extra balancing resistors, which allows to use higher balancing currents

CAN Bus for communication with other systems

RS485 Bus for internal communication with different BMS 16i and charger

OPTOCOM-6i HW interface for connection of BMS 16i and PC (USB)

MGM ProTool PC software application for setting parameters of BMS and real-time monitoring

ESC Electric speed controller

Superior system “Higher”system, which could control the BMS system, controllers and other devices

FAN Air cooler, placed on the HCBAL8

PCBA Printed Circuit Board Assembly

N/A Not applicable

CC/CV charger Constant current / constant voltage charger

BMS-16i page 4 / 38

Parameters

Number of cells per one BMS 16i 4 ÷ 16

Max. number of the chained boards 8

Max. number of the cells in BMS 16i system 128

Max. voltage of battery connected to one BMS 16i 68V

Voltage working range per cell 1,8 ÷ 5V

Recommended capacity of the battery up to 655 Ah

Power supply of BMS 16i From monitored battery

Power consumption of the BMS 16i in “ON” mode ~ 20 mA

Power consumption of the BMS 16i in “OFF” mode ~ 20 µA

Balancing current with internal balancing resistors ≤ 100mA *)

Balancing current with balancing PCBAs (HCBAL8) ≤ 850mA **)

2× FAN Max. 12V/350mA

Controlled by BMS 16i according to temperatures and balancing state

Communication interface CAN 2.0 –Communication bus

RS485 –Internal communication bus

PC interface (thru USB) OPTOCOM-6i (+MGM ProTool)

BMS 16i compatibility BMS 16i is compatible with BMS 8i

Weight of BMS 16i 82 g

Weight of BMS 16i with HCBAL8s and FANs 305 g

Dimensions (L × H × W) 140 × 95 × 15 mm

Dimensions (L × H × W) with HCBAL8s and FANs 140 × 95 × 46 mm

Ambient conditions -20 up to +50 °C

*) Depending on the conditions of BMS surroundings

**) With HCBAL8s and FANs, depending on the conditions of BMS surroundings

BMS-16i page 5 / 38

Warnings and recommendations

•HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH. The device might

operate with higher voltage. Safe electrical installation should be carried out only by skilled

professionals (authorized persons).

•Secure correct connections of battery poles (reversal of battery/cells poles will destroy the

BMS 16i, the damage may not be visible immediately, but after some runs).

•Connections must follow the user manual.

•Is recommended to cool the BMS 16i in operation with flowing air. Do not obstruct the

access of cooling airflow to the BMS 16i.

•Never connect more cells (higher voltage) or other cells, than is specified in technical

documentation.

•Is recommended to do wiring of the system at first, after correct connection of the

system, connect traction batteries.

BMS-16i page 6 / 38

Basic variants of assembly

According to controlling

Master

Controlling module of the system. Master module includes all measuring, communicating and controlling interfaces and

powers the system bus (RS485). As standalone (without any other connected slaves) could balance maximum 16 cells.

oRealizes measuring and balancing of all connected cells of the battery

oMeasures and control the voltage, flowed current, working temperatures (of battery, BMS and balancers) and

capacity of the battery

oIncludes file with all measured data from the system, which are available thru the MGM ProTool

oIs active based on the status of the ON/OFF switch (connected to K5)

oActivates the other BMSes (Slaves) in the system and communicate & control them (via RS485)

oCommunicates with the parent system, controller, display (via CAN bus)

oControls the connected charger

oHas to have system address 0 (visible in PC software MGM ProTool –parameter P11)

oHas to be connected on the “lowest” cells of the battery

oCould be used as standalone (for max. 16 cells) as well as master for the whole BMS system (1 master + max. 7

Slaves)

Slave

Measuring modules in the system. Slave modules include interface for only measuring and balancing of cells and for system

communication.

oDoes not have the communication interface CAN

oIs not able to control charger

oThe external and internal current probe could not be connected

oOutput for GMS module and for contactors could not be connected

According to balancing

Balancing with the HCBAL8 and with FANs

oBMS 16i with balancing PCBAs (HCBAL8) and FANs

oBalancing resistors and their temperature sensors are assembled on the HCBAL8

oMaximum balancing currents up to 850mA

Balancing with the HCBAL8

oBMS 16i with balancing PCBAs (HCBAL8), but without FANs

oMaximum balancing currents is very closely dependent on the conditions of environment and intensity of the

cooling

Balancing with the internal balancing resistors

oBalancing resistors and their temperature sensors are assembled directly on the PCBA of BMS 16i

oMaximum balancing currents up to 100mA, depending on the conditions of environment

BMS-16i page 7 / 38

Connectors and signals

RS485 BUS

RS485_GND

RS485_B

RS485_+5V

RS485_A

RS485_GND

Controlled

Outputs

EXT_V2

OUT_2A

OUT_1A

GND_P2

K2

K1

K3

K4

Current probe

(external)

Probe +12V

GND

I_Probe 1

SENSE -

SENSE +

Current probe

(internal)

K5

K6

K6

ON/OFF

GND

ON/OFF Switch

IN_2

GND

GND

IN_1

Inputs

Environment

temperature sensors

ENVx_T

GND

Battery temperature

sensors

K7

K8

K9

Status

LEDs

K10

K11

K12

K13

K14

K15

K17

K16

BATx_T1

GND

BATx_T2

GND

BATx_T3

GND

CAN BUS

CAN_H

CAN_L

CAN_GND

STATUS

INDICATION

OPTOCOM6i

(BMS ↔ PC)

FAN -

FAN +

CELLS 1 –16 MEASUREMENT + BMS SUPPLY

UB

(U16)

U16

U15

U14

U13

U12

U11

U10

U9

U8

-

-

U7

U6

U5

U4

U3

U2

U1

U0

GND_V2ND

OUT_4

OUT_3

IN_V

OUT_1

GND_V1

OUT_2

FAN

Power

Outputs

BMS-16i page 8 / 38

Connector

Name

Signals

Description

Master

Slave

K1

RS485 BUS

Pin. 1 - RS485_GND

Pin. 2 - RS485_B

Pin. 3 - RS485_+5V

Pin. 4 - RS485_A

Pin. 5 - RS485_GND

- Internal communication between BMS16i system

(Master & Slaves) and with charger

- At the end of the RS485 bus has to be placed the

termination (Chapter …)

- BMS16i Slave is ON/OFF based on the connection via

the RS485

1×

(not

isolated)

1×

(isolated)

K2

Controlled Outputs

Pin. 1 - EXT_V2

Pin. 2 - OUT_2A

Pin. 3 - OUT_1A

Pin. 4 - GND_P2

… Power supply for chargers

… For MEANWELL chargers

…For activation of GSM module

…Ground of the power supply

1×

-

K3

Current probe

(external)

Pin. 1 - Probe +12V (Supply)

Pin. 2 - GND

Pin. 3 - I_Probe 1 (Signal)

Measurement of charging and discharging current by

external current sensor HALL 400 B (recommended) or

others

- I_Probe 1 –External current probe 1 (recommended

use for currents higher than 60 A)

1×

-

K4

Current probe

(internal)

Pin. 1 - SENSE –

Pin. 2 - SENSE +

Internal current probe (for currents up to 60 A)

1×

1×

K5

ON/OFF Switch

Pin. 1 - ON/OFF

Pin. 2 - GND

Connector for ON/OFF switch only for Master

ON –Connected // OFF –Disconnected

1×

1×

K6

Inputs

Pin. 1 - IN_1

Pin. 2 - GND

Pin. 3 - IN_2

Pin. 4 - GND

… Identification of connected charger

… Ground of the IN_1

… Input for selection of the charging mode

… Ground of the IN_2

1×

-

K7

Environment

temperature sensors

Pin. 1 - ENVx_T

Pin. 2 - GND

KTY 81-210 Temperature sensor

1×

1×

K8

Battery temperature

sensors

Pin. 1 - BATx_T1

Pin. 2 - GND

Pin. 3 - BATx_T2

Pin. 4 - GND

Pin. 5 - BATx_T3

Pin. 6 - GND

KTY 81-210 Temperature sensors

At least one sensor is required / maximum 3 sensors

could be used for one BMS 16i

3×

3×

K9

CAN BUS

Pin. 1 - CAN_H

Pin. 2 - CAN_L

Pin. 3 - CAN_GND

CAN 2.0 BUS

1×

(isolated)

-

Status

LEDsK10

Status Indication

GREEN

YELLOW

RED

Indication status of the BMS 16i

1×

1×

K11

ICS

Pin. 1 to 4

For OPTOCOM6i - Communication with PC (PC SW

MGM Protool)

1×

1×

K12

FAN

Pin. 1 - FAN+

Pin. 2 - FAN-

FAN for balancers

Max. 12V/350mA

1×

1×

K13

Power Outputs

Pin. 1 - IN_V

Pin. 2 - OUT_1

Pin. 3 - GND_V1

Pin. 4 - OUT_2

Pin. 5 - OUT_3

Pin. 6 - OUT_4

Pin. 7 - GND_V2

… +12V (IN_V)

… Main contactor (OUT_1)

… GND (for OUT_1)

… Charger contactor (OUT_2)

… Charging (OUT_3)

… Charging with high current (OUT_4)

… GND (for OUT_2-4)

1×

-

K14

CELLS (Low)

Pin. 1 - cell 1, - pole

Pin. 2 - cell 1, + pole

Pin. 3 - cell 2, + pole

Pin. 4 - cell 3, + pole

Pin. 5 - cell 4, + pole

Pin. 6 - cell 5, + pole

Pin. 7 - cell 6, + pole

Pin. 8 - cell 7, + pole

Pin. 9 - N/A

Pin. 10 - N/A

- Pin.1 to Pin 8 for voltage measurement of cells 1 - 7

1×

1×

K15

CELLS (High)

Pin. 1 - cell 8, + pole

Pin. 2 - cell 9, + pole

Pin. 3 - cell 10, + pole

Pin. 4 - cell 11, + pole

Pin. 5 - cell 12, + pole

Pin. 6 - cell 13, + pole

Pin. 7 - cell 14, + pole

Pin. 8 - cell 15, + pole

Pin. 9 - cell 16, + pole

Pin. 10 - cell max, + pole

- Pin.1 to Pin 9 for voltage measurement of cells 8 –16

- Pin. 10 BMS supply from the highest cell

1×

1×

K16

HCBAL8_1

Connector for balancing module 1

1×

1×

K17

HCBAL8_2

Connector for balancing module 2

1×

1×

BMS-16i page 9 / 38

LED indication of the BMS working modes

Status of the BMS system is visible on the Master PCBA thru the LEDs (K10).

LED

OFF

ON

FLASHING

GREEN

-

BATTTERY

CHARGED

BALANCING

YELLOW

-

BALANCER

OVERTEMP

CHARGING

RED

BMS OFF

BMS

ERROR

BMS OK

Activation of the BMS 16i

BMS system is activated by ON/OFF Switch (K5). Activation in the system needs to be done only for Master BMS, other BMSes

(Slaves) will be activated by internal bus (RS485). After switching OFF (K5) the master BMS 16i switch off itself and all BMS

slaves on the bus (RS485) as well.

Charging and balancing

One of the key feature, which BMS 16i has, is management of battery charging. According to the measured parameters of the cells,

adjusted charging voltage and current, is running management of the battery charging. At the end of the charging cycle is running

the balancing of each cell according to balancing mode and according to set charging voltage. Actual capacity of the battery is

calculated according to the charging current and set capacity of battery (in MGM ProTool Parameter P4).

Balancing modes

Setting of the balancing mode is possible in Protool parameter P3 (Cells balancing mode).

From balancing voltage

Balancing is starting, when voltage of the most charged battery cell is higher, than the value of Balancing voltage (parameter P17 in

ProTool). Balancing is running until all battery cells are balanced / charged to value of Charged cell voltage (parameter P18 in

ProTool).

From charged cell voltage -10 mV

Balancing is starting, when voltage of the most charged battery cell is higher, than the value of Charged cell voltage –10 mV

(parameter P18 in ProTool). Balancing is running until all battery cells are balanced / charged to value of Charged cell voltage.

Always

Balancing is starting, when voltage of the most charged battery cell is higher, than the value of Balancing voltage (parameter P17 in

ProTool). Balancing is running even after the deactivation of the BMS 16i (Switch [K5] is OFF). Balancing is finished, when all

battery cells are balanced / charged to value of Charged cell voltage (parameter P18 in ProTool). In case, that the charger is

disconnected, the balancing continues until all cells are balanced, after that the BMS 16i is switched OFF.

Deactivated

Balancing is OFF.

BMS-16i page 10 / 38

4.2V

4.0V

3.8V

3.6V

3.4V

3.2V

3.0V

2.8V

2.6V

2.4V

2.2V

2.0V

1.8V

Charging current

100%

10%

4.2V

4.0V

3.8V

3.6V

3.4V

3.2V

P18

3.0V

2.8V

2.6V

2.4V

2.2V

2.0V

1.8V

Charging current

100%

10%

P18

P17

3

P17

Charged

Charged

4.2V

4.0V

3.8V

3.6V

3.4V

3.2V

3.0V

2.8V

2.6V

2.4V

2.2V

2.0V

1.8V

Charging current

P18

Charged

4.2V

4.0V

3.8V

3.6V

3.4V

3.2V

3.0V

2.8V

2.6V

2.4V

2.2V

2.0V

1.8V

Charging current

100%

P18

P17

Charged

Example of the charging modes with different chargers / types of battery cells

Capacity

[Ah]

Capacity

[Ah]

Capacity

[Ah]

SB point

Lipol cell charging by CC/CV charger

U

100%

Capacity

[Ah]

U

100%

LiFePo4 cell charging by CC/CV charger

Cell voltage

Charging current

Cell voltage

Lipol cell charging by CC charger with reduction of the

current to value A2 OR

Lipol cell charging by CC charger without reduction of the

current, with connected second low current CC charger

U

100%

Lipol cell charging by CC charger

U

100%

Area with charter switch OFF / ON

with balancing the most charged

cells to reference level

Fig. A

Fig. B

Fig. C

Fig. D

A2: Low current of low power charger

or reduced current of main charger

< 10% nom. current

<balancing current

P17

Current of main charger

or high power charger

Main charger

Charging current

Constant current area „CC“

Constant voltage

Nominal charging

current = 100%

Cell voltage

Cell voltage

Charging current

Balancing area

Balancing area

area „CV“

BMS-16i page 11 / 38

3.3V / cell

3.0V / cell

2.7V / cell

3.6V / cell

4.2V

cell

3.0V / cell

3.3V / cell

3.6V / cell

3.7V / cell

3.8V / cell

4.2V

cell

2.7V / cell

Internal battery resistance

Standard BMSes / controllers, which doesn´t use internal battery voltage [case a) bellow], switch-off controller or starts

reducing power in case, that the battery terminal voltage UTERM (resp. input voltage ULOAD) drops below set limit [3,0V

/cell on the example a)]. However Input voltage (ULOAD), which significantly depends on current and internal battery

resistance, is not equal to the rest of battery charge and controller switch-off the battery even with remain battery energy

40%.

Comparing to this behavioral, MGM COMPRO BMSes / controllers (chart b) ensures, that the remaining energy (after the

motor is switched off by the controller) is practically independent on currents and inner resistance of the battery, thanks

to special measurement method and counting with all resistances in circuit (as internal battery resistance, cables

resistance, connector resistance). Motor switch-off in case of full and correct discharged battery (remain energy is

depending on BMSes / controller parameters settings).

Discharging

During the discharging, BMS system is measuring the temperature, voltage of battery cells and discharging current. Based on the

measured discharging current, the BMS calculates actual capacity of the batery. As an outcome from the measurement and the

calculation, the BMS evaluate actual state of the battery.

Measured parameters are sent via the CAN bus to other devices like Display, HBC Controller, parent system or others. If the

parameters are not aligned with defined limits, then the BMS change status to caution, warning or error variables (more information

in chapter Monitoring).

If the system includes main contactor (more information in chapter Power outputs) and voltage of the cells drop under the limit, then

this status is sent thru the CAN bus as a “battery error”and after 10 seconds, the BMS disconnect the main contactor as protection

against the damage of the battery.

Regular BMSes / controllers (even Lipol compatible) have either a solid

switching off voltage (for example 3V per cell) or it is possible to set

this value. For example for set boundary 3V per cell the controller is

switch off or it starts to reduce power, when this value is reached, no

matter, how big the drawn current is. It means, that the residual

energy significantly changes according to a instantaneous

current load of the batteries (and also according to inner resistance

of the cells, cables, …) from 0 to 95 % - depending only on the set

voltage limit. If the example on the graph above is considered with a

set boundary of 3V per cell the BMS / controller will switch off, when

drawn current is 20C, when there is still 40% of energy still left, while

for 5C current when only 5% of energy is left. For boundary of 3.3V per

cell the controller would switch off for currents of 20C when only few

percent of energy were consumed while for 5C after 92% of energy

would be consumed.

MGMCOMPRO BMSes / controllers handle the situation quite differently.

The switching-off voltage is always recalculated to „internal“ voltage of the

battery –therefore is independent on both drawn current as well as inner

resistance of the battery or resistances in circuit. It means the set residual

energy is always the same and does not depend on currents and inner

resistance of the battery. Batteries are then always discharged to same

level, regardless how big currents are drawn. The value of set residual

energy is therefore not so dependent on the features of battery and the

discharging current. For example for switching voltage 3.7V per cell, BMS /

controller switches off the motor or starts to reduce revolutions always after

90% of energy is used up, no matter, if the drawn current is 20C or 5C.

The voltage of battery after switch of the current always rises to a value

close to curve of 0.5V –this discharging curve is practically identical to

„inner“ voltage of the battery. This curve describes how much the Lipol

battery is discharged.

U

60%

80%

0.5C

5C

a) Standard BMS/controllers, settings for Lipol battery

Battery voltage for current:

Residual energy is

very depend on the

actual current and

inner battery

resistance

10C

20C

Cut off voltage:

95%

100%

Capacity [Ah]

b) MGM COMPRO BMS/controllers, settings for Lipol battery

U

100%

(Starting point

of reduce

motor power)

Capacity [Ah]

Battery voltage for current:

Cut off voltage:

Defined residual

energy

75%

90%

95%

0.5C

5C

10C

20C

Remaining Battery Energy

Remaining Battery Energy

Internal Battery

Voltage.

(not depend on

current and Internal

Battery resistance)

Terminal Battery

Voltage

Terminal Battery

Voltage

BMS-16i page 12 / 38

Current probe (Internal / External)

Current probe is used for measuring of the charging / discharging currents. Correct setup use positive value during the discharging

and negative value during the charging.

Internal current probe / Connector K4

-Is designed for currents up to 60A

-In the MGM ProTool (parameter P30) needs to be set “Current probe 2“

-Has to be connected to the “-“(minus) battery pole !

External current probe

-Galvanicaly isolated current probe

-Has to be connected thru connector K3

-In MGM ProTool (parameter P30) needs to be set “Current probe 1“

-Default setting of the BMS 16i is adjusted for an external probe HAL-400A, for different probes the current constant has to

be re-adjusted

Current sensor HALL 400

Box dimension 55 × 43 × 23 mm

Weight 75 g

Hole for current cable Ø 22 mm

Sensing current ± 400 A

Insulating voltage 2500 VAC

Supply from control unit CN-B15

Connection to current circuit Current cable through sensor hole

Orientation Current must flow through the probe according to direction of arrow (on picture)

BMS-16i page 13 / 38

Temperature sensors

Temperature sensor of BMS

-Internal temperature sensor placed on PCBA

-Measure working temperature of PCBA

Temperature sensor of balancers

-Measure temperature of balancing resistors

-In case that balancing temperature exceed the allowed temperature, then the BMS reduce the balancing currents

-The temperature sensors are placed on HCBAL8 balancers or in case of internal balancing resistors on BMS PCBA

Temperature sensor of environment

-Measure temperature of environment, where BMS 16i is placed

-Use external temperature sensor KTY 81-210

-External temperature sensor has to be connected to the connector K7

Temperature sensor of battery

-Measure working temperature of battery / cells

-Use external temperature sensors KTY 81-210

-Three independed temperature sensors could be connected to one BMS 16i (connector K8)

Remark : Case of temperature sensor has to be in contact with measured cells

Remark : Temperature sensor KTY 81-210 could be connected without respect of the polarity

System bus RS485

RS485 is an internal communication bus for communication between BMSes and charger in the system. Everytime you need in the

system one Master BMS 16i (has to be connected on the “lowest” cells of the battery), which control comunication with other BMS

16i modules (Slaves) or the charger.

Remark : To secure correct behavior, MGM compro recommends to use twisted pair cable for the A & B and NMEA 0183

connectors. Communication has to be terminated. Master BMS 16i already includes the termination, but the “last”slave BMS

module has to be terminated by 120 Ω (connect Pin RS485_A and Pin RS485_B thru resistor 120 Ω).

Parameters of the bus :

Standard RS485

Speed 9600 bit/s

Startbit 1

Stopbit 2

Parity No parity

Termination 120 Ω / min. 0.25W

BMS-16i page 14 / 38

Communication bus CAN 2.0

CAN is comunication interface between BMS 16i and other devices like HBC Controller, display, superior system. BMS 16i is

compatible with CAN A and CAN B. The communication protocol is specific for MGM Compro products (more information in

appendix), but modifications of CAN bus are possible based on customer request.

Remark : To secure correct behavior, MGM compro recommends to use twisted pair cable for the L & H and NMEA 2000

connectors. Comunication has to be terminated. Master BMS 16i already includes the termination, but termincation on the “last”

module of the CAN bus needs to be terminated by 120 Ω (connect CAN_H and CAN_L thru resistor 120 Ω).

Parameters of the bus :

Standard CAN 2.0 A,B

Speeds 125 kbit/s, 250 kbit/s, 500 kbit/s, 1 Mbit/s

Termination 120 Ω / min. 0.25W

Example of NMEA connectors & termination

BMS-16i page 15 / 38

Power outputs

Power outputs are designed for controlling of relays, contactors and chargers (controlled by switching outputs). OUT 1-4 are

working as an “open collector” - in state CLOSE are connected to the GND_V1 (for OUT 1) or GND_V2 (for OUT 2-4).

OUT_1 -4 - Max. working current 3A (max. peak current 5A), galvanicaly isolated from BMS

External power supply is needed 12 V (IN_V).

Internal supply from connector K3, could be used for max. 100mA/12V in other case plase use extermal supply.

OUT_1 →Switching of the main contactor (without / with external supply)

According to parameter P96 (set in MGM ProTool) is contactor closed everytime, when BMS is active or if the voltage is upper the

discharging limit of the battery cells.

OUT_2 →Switching of the charger contactor (without / with external supply)

According to parameter P96 (set in MGM ProTool) is contactor closed everytime, when BMS is active or if BMS has request for

charging (voltage under the charging limit of the battery).

BMS-16i page 16 / 38

OUT_3 →Charging

OUT_4 →Charging with high current (without / with external supply)

OUT3 –Charging (ON/OFF current)

OUT4 –Charging with high current (ON/OFF high current)

In case, that is used only OUT3, then the charging is only switching ON or OFF.

Parameter P54 has to be set according to used charger.

Connection / usage of BMS16i and Charger has to be consulted with MGM Compro.

HBC Controller / Motor / Battery system / Display / Battery chargers

Based on the deep experiences, MGM Compro could propose complete system, which could fit to customer needs - in case of any

BMS-16i page 17 / 38

Communication interface OPTOCOM6i (BMS 16i ↔ PC)

Communication module OPTOCOM6i is used for communication of the MGM compro devices (HCBs, BMSes) and PC software

MGM Protool (V3.2.2. or later).

Parameters :

•PC interface : USB 2.0

•Compatibility : BMS16i, BMS 8i

LED statuses :

LED

ON

FLASHING

GREEN

NA

Communication (questioning)

RED

NA

Communication (answering)

YELLOW

Supply from device

NA

Parts :

•Communication module

•USB cabel

•UART cabel

Instalation :

1) Connect OPTOCOM 6i with USB cabel

2) Connect OPTOCOM 6i with your PC

3) Download PC SW MGM ProTool (web link) / ensure that you are using the latest version of the SW or make an update

4) Connect OPTOCOM 6i with your MGM device / ensure, that you are using the latest version of the FW or make an update

5) Functions / parameters are ready to use / adjust

BMS-16i page 18 / 38

MGM ProTool

To set parameters or read data from the BMS 16i, is necessary to instal the PC software MGM ProTool and connect BMS 16i to PC

via the OPTOCOM 6i.

Instalation of the MGM ProTool

PC software "MGM ProTool", is free to download from our web.

1) Download the MGM ProTool from follow web link

2) Connect the OPTOCOM 6i with your PC

3) Instal the SW on your computer

BMS-16i page 19 / 38

SW version before update

Connection of the BMS 16i with PC

First of all the OPTOCOM6i has to be connected with PC via the USB and then the OPTOCOM6i has to be connected via the

UART to the connector K11 placed on the master BMS 16i. Open the PC software MGM Protool on your computer and turn on

BMS16i. The green led on BMS 16i (K10) indicate the correct connection between BMS16i and MGM Protool.

Update of MGM ProTool

Update SW version of your program MGM ProTool is possible to make by two ways

1. After start program automatically

advice to new version in left upper

corner (in case that the new

version exists) –start update by

this way.

2. Choice “Download updates”

3. Push Update

OR

1. You can check, if new

version is available

any time →click to

SYSTEM

and Application

update

3. Wait for finishing

4. Last step is restart, after this you

have the newest version.

1

1.1

1.2

2

2

3

4

3

2. If the new version is

available, click to Yes

and Update

2

BMS-16i page 20 / 38

Current FW version

1Select “SYSTEM”

2Select “Firmware update”

3a Switch the BMS-16i ON

3b Select version, which

corresponds with your system

4. Push button “Update firmware”

5. Confirm firmware updating

6. Updating procedure starts

7a. When procedure correctly finished, this message will appear

Push OK

7b. When procedure is interrupted (communication error etc.), is

necessary to start the update again !

8. Follow next instructions

10. After restart device (= your BMS 16i), newest version of its

firmware is displayed. Update procedure is complete.

Update of BMS 16i firmware

Remark :

Please remember the parameters, which was already set before the update of the firmware. Data, which was set, might be lost during the

firmware update.

Remark:

All BMSes 16i in the system, have to have the same FW version of the device as the others.

In case, that you want to make an update of firmware in your BMS 16i to the latest version, you will need to connect the OPTOCOM 6i to PC

(with an internet connection) and to the BMS 16i.

0. Start program MGM ProTool

Remark :

You can start updating procedure for unlimited amount of tries, the BMS cannot be broken down by failed update, but you have to

finish the update procedure without errors [7a], before you will use your system or you set the parameters, etc.

When procedure don´t finished correctly [7b], the BMS after next turn-on doesn´t work, is not possible to set parameters, etc. In this

case is necessary to repeate the updating procedure !

2

1

3b

7a

4

Table of contents

Other MGM Control System manuals

Popular Control System manuals by other brands

American DJ

American DJ DMX OPERATOR User instructions

Stryker

Stryker SwitchPoint Infinity 3 Operation and maintenance manual

LG

LG V-NET PQCPC22N0 Installation & user manual

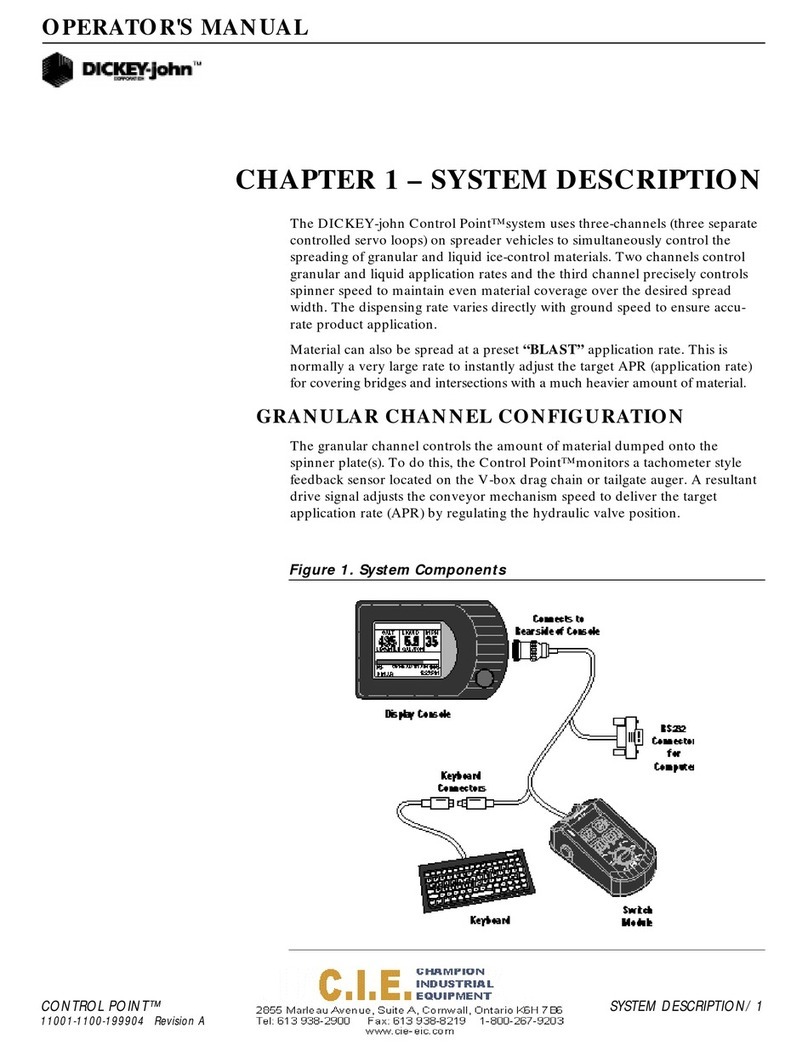

Dickey-John

Dickey-John Control Point Operator's manual

Mitsubishi Electric

Mitsubishi Electric AG-150A-A installation manual

Edwards

Edwards D397-00-000 instruction manual

E.ON Energy Solutions

E.ON Energy Solutions EcoMeter user guide

Loctite

Loctite EQ RC24 RD operating manual

Link

Link L1125 user guide

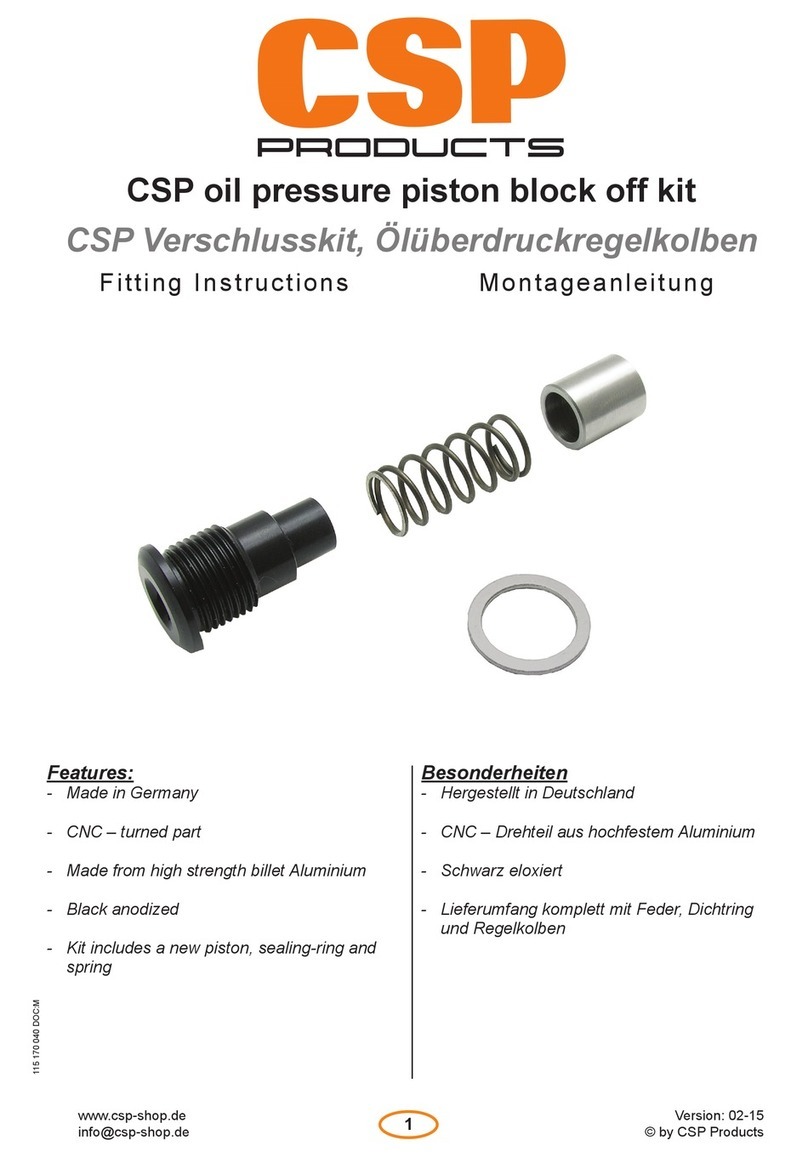

CSP Products

CSP Products 115 170 040 Fitting instructions

eqss

eqss OverWatch 6253 installation manual

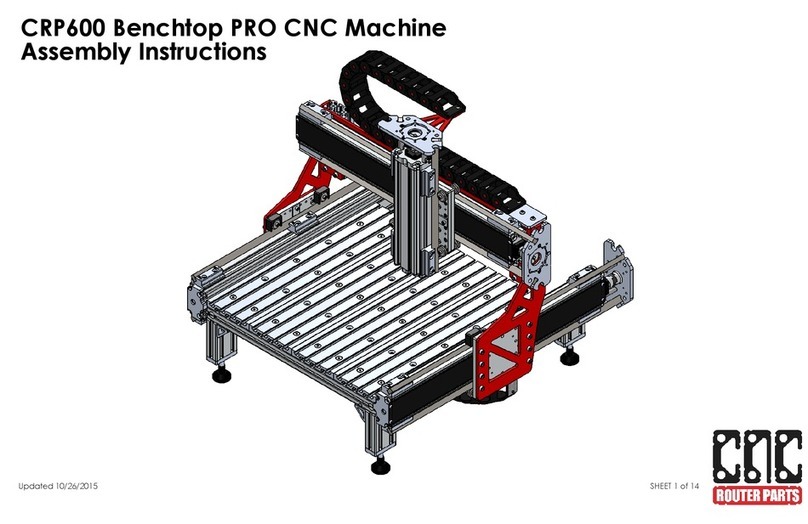

CNC Router Parts

CNC Router Parts CRP600 Benchtop PRO Assembly instructions