BAYKAL APHS Series User manual

BAYKAL

EDITION NO :

APHS

1

DATE OF ISSUE :

May-2011

PAGE :

1

USER’S MANUAL

CNC

HYDRAULIC PRESS BRAKE

MODEL APHS

No part of this User‘s Manual may be reproduced or transmitted by any without Prior permission of Baykal

Makine Sanayi ve Ticaret A..

BAYKAL

EDITION NO :

APHS

2

DATE OF ISSUE :

May-2011

PAGE :

2

MACHINE TYPE DESCRIPTION

APHS XXXXX-xx

STANDARD SUPPLY

VOLTAGE CONTROLLER SAFETY DEVICE HYDRAULIC

BLOCK ACCESSORIES

APHS X X X X X XXX

C – CE

B – BASIC

1 – 220

2 – 230

3 – 240

4 – 400

5 – 415

6 – 440

7 – 480

8 – 600

9 – 220/400

1 – DELEM DW-66

2 – DELEM DM51

3 -- DELEM DA51

4 -- DELEM DA52

5 -- CYBELEC DNC60

6 -- CYBELEC DNC80

7 -- CYBELEC MODEVA

1 – FISSLER AKAS

2 – SICK LIGHT GUARD

3 – REER

4– LAZER SAFE

1-- HOERBIGER

2-- REXROTH

3-- ATOS

!

NOTE:

In order to SEE THE TYPE OF YOUR MACHINE, please see

the electric circuit diagram in section 13. It is written in the left

bottom side of the diagram.

BAYKAL

EDITION NO :

APHS

3

DATE OF ISSUE :

May-2011

PAGE :

3

! ATTENTION

P

UMP ROTATION MUST BE IN

ARROW DIRECTION,

OTHERWISE

THE PUMP WILL BE DAMAGED

CHECK THE MOTOR ROTATION BY PUSHING THE

″

″″

″

GREEN

″

″″

″

START, AND IMMEDIATELY AFTER, THE (RED) STOP BUTTONS ON

THE ELECTRICAL PANEL. THE MOTOR MUST BE ROTATING IN THE

DIRECTION OF

″

ARROW

″

. IF IT IS ROTATING IN THE REVERSE

DIRECTION, CHANGE ANY TWO PHASES IN THE ELECTRICAL

SUPPLY POINT.

BAYKAL

EDITION NO :

APHS

4

DATE OF ISSUE :

May-2011

PAGE :

4

INFORMATION AND WARNING LABELS

DESIGNATION PLATE BENDING TABLE

CE CONFIRMATION DANGER:

ELECTRIC SHOCK

GROUND LUBRICATION PUMP ROTATION

POINT

HANDS MAY BE WHEN BENDING, HANDS WHEN BENDING, SHEET

JAMMED MAY BE JAMMED BETWEEN MAY CRASH SOME PARTS

BETWEEN TOOLS TOP TOOL AND SHEET OF BODY

DESIGNATION PLATE

Manufacturer BAYKAL Mak. San. Tic. A..

Bursa / TÜRKYE

Machine Hydraulic Press Brake

Type

Model

Serial No

Capacity ton

Bending length mm

Main voltage V/Hz/Ph

Motor Power kW

System Pressure bar

Min stroke mm

Max stroke mm

Machine weight kg

Top tool weight kg

Bottom tool weight kg

Length mm

Width mm

Height mm

BAYKAL

EDITION NO :

APHS

5

DATE OF ISSUE :

May-2011

PAGE :

5

C O N T E N T S:

1. GENERAL MACHINE INFORMATION

1.1. Registered trademark

1.2. Machine type

1.3. Serial number

1.4. Year of manufacturer

1.5. Address of the manufacturer

1.6. Address of the authorized dealer

2. IMPORTANT INFORMATION

2.1. Safety features of your Press brake

2.2. Important safety information & instructions

2.3. Noise Measurement

2.4. Stop Time Control

3. OVERALL DIMENSIONS and DRAWING

4. LIFTING & TRANSPORTATION

5. UNPACKING & INSTALLATION

6. OPERATING AND MAINTENANCE INSTRUCTIONS

6.1. Technical data

6.1.1. Specification

6.1.2. Standard Equipment

6.1.3. List of parts subject to rapid wear

6.2. Description of Press brake applications

6.3. Prohibited uses of the Press brake

6.4. Incorrect uses of the Press brake

Using the Press brake

6.5.1. Requirements for the initial test and examination

6.5.2. Electrical connections

6.5.3 .Electrical Cabinet and Control Units

6.5.4 Centerally Adjustable Crowning System (Optional)

6.5.

6.5.5.Check-List of the Finished Product

6.6. Maintenance and inspection

6.6.1. Type and Frequency of inspection

6.6.2 Hydraulic System

6.7. Conditions of storage, re-utilization and scrapping

6.7.1. Storage

6.7.2. Reutilisation after storage

6.7.3. Scrapping

7. LUBRICATION POINTS

8. BENDING CHART

9. FOLDING FACILITIES

10. PRINCIPLES OF PRESS BRAKE BENDING TECHNOLOGY

11. SPARE PARTS LIST

12. HYDRAULIC CIRCUIT DIAGRAM

BAYKAL

EDITION NO :

APHS

6

DATE OF ISSUE :

May-2011

PAGE :

6

13. ELECTRIC CIRCUIT DIAGRAM

14

ADDITIONAL MANUALS

A.CYBELEC ModEva

B.Wila Centrally Adjustable Crowning System (CVB/D)

BAYKAL

EDITION NO :

APHS

7

DATE OF ISSUE :

May-2011

PAGE :

7

1. GENERAL MACHINE INFORMATION

1.1.

Registered trademark

: BAYKAL

1.2. Machine type

: APHS

1.3. Serial number :

1.4.

Year of manufacture

:

1.5.

Address of manufacturer:

BAYKAL Mak. San. Tic. A.

Organize Sanayi Bölgesi

Lacivert Cad. 2. Sokak No1/A

16140 Bursa/TÜRKYE

Tel.int: 90-224-243 16 10

Fax int: 90-224-243 12 86

1.6. Address of the authorized dealer:

BAYKAL

EDITION NO :

APHS

8

DATE OF ISSUE :

May-2011

PAGE :

8

2. IMPORTANT INFORMATION

2.1. Safety features of your press brake

The electrical and hydraulic circuits of your press brake are designed to allow

operation with maximum safety. The following precautions are installed on the

machine for enhanced safety.

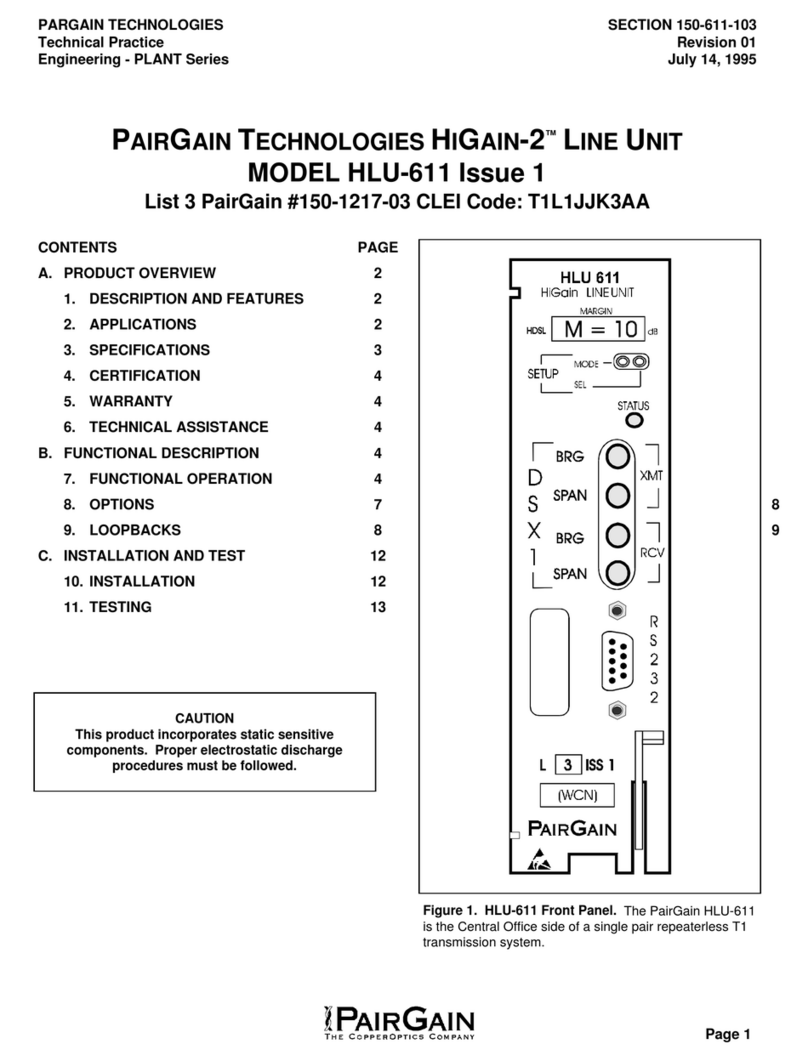

•

Emergency stop buttons ( engaging type ) are available on the cybelec control

(see fig.1.1), on the pedal control stand and on the electrical cabinet cover

Emergency Stop Buttons

Fig.1.1

•

The cylinders are covered by fixed cover plates.

•

Do not close the door from inside the machine

•

Safety Switches are installed on the rear door and side doors. If any of these door

is opened when the beam is downstroking at fast speed, the beam will retract

automatically. If any of the doors are left open before any operation, the

operating modes of the machine are rendered non-functional.

(1)

(2)

BAYKAL

EDITION NO :

APHS

9

DATE OF ISSUE :

May-2011

PAGE :

9

Rear side of the machine

Fig.1.2

•

In case of a power supply failure during operation, the beam will stop at a

standstill. When power supply is recovered, it is Not possible to start the

machine without resetting.

BAYKAL

EDITION NO :

APHS

10

DATE OF ISSUE :

May-2011

PAGE :

10

2.2. Important safety information & instructions

1.

The machine must NOT be operated before reading this User’s Manual. Operate

the machine only if it is in a perfect condition and in accordance with the work

regulations of your factory and operating instructions of this manual.

2.

TRANSPORTATION !

The lifting points are shown in the Lifting Diagram

attached. The dimensions and the weight of the machine are given in section

6.1.1. of this manual.

3.

INSTALLATION !

The press brake is delivered in complete assembled

execution. It must be levelled and firmly bosted on the floor where it is to be

used, according to the Installation Diagram attached. Indoor installation and a

dry working environment without danger of fire and explosion is necessary.

!

The permissible floor load, where the machine is to be installed,

must be accounted for.

4.

The machine must be operated only by authorised and trained personnel.

Operation by unauthorised and untrained personnel in a way that does not

comply with the instructions and regulations may lead to dangerous

situations and is strictly FORBIDDEN.

5.

The press brake is designed in a way it can only be operated by one operator.

Using the machine with more than one operator is forbidden.

6.

In case of any emergency, push the emergency stop buttons and follow the

emergency rules of your factory.

7.

The following instructions must be read carefully for safe operation and

maintenance of your press brake :

!

This press brake is designed for bending only within the meaning

of section 6.2. of this manual regarding press brake applications.

Prohibited uses of the machine are dealt with in section 6.3. of this

manual.

!

DO NOT insert or extend your hands or arms in between

bending tools, under any circumstances, while the machine

is in an operational mode.

BAYKAL

EDITION NO :

APHS

11

DATE OF ISSUE :

May-2011

PAGE :

11

!

Check the machine daily for recognisable external damages and

defects and leakages.

!

Operate the machine only will all protective devices and guardings

!

Take notice of the warning labels on the machine and do not

remove them.

!

In case of malfunction immediately shut down and secure the

machine. All troubles must be eliminated before re-starting.

!

Avoid any operation which may endanger other persons

and immediately shut down the machine when a danger is

noticed.

!

Shut off the machine completely before any repair work is carried

out.

!

DO NOT let yourself be locked in the interior space of the

machine.

!

DO NOT bridge the safety limit switches of the side and rear

protective fences.

!

DO NOT use front support arms for intermediate storage of

workpieces

!

During the bending process the workpiece may leap up. Therefore,

the material must be handled carefully.

!

All connecting bolts on the machine must be checked periodically

and be re-tightened if necessry.

!

Make sure that dirty filters are disposed seperately.

!

The operating temperature rage of the oil is : (10

°

°°

°

C - 65

°

°°

°

C )

!

Any fire in the electric control system must be put out by using a

CO

²

fire extingusher.

BAYKAL

EDITION NO :

APHS

12

DATE OF ISSUE :

May-2011

PAGE :

12

!

Any burning oil must be put out by using a CO

²

or powder

extinguisher.

!

All regulations concerning surface facilities designed for the use

of water polluting liquids must be observed in operation and

maintenance of this press brake.

!

All environmental regulations effective must be observed in use of

this press brake.

8.

In the operation of the press brake no special personal safety equipment is

necessary. It is however recommended to use working gloves when handling the

workpieces.

9.

General maintenance of the press brake can be carried out by universal tools and

equipment while the machine is at a standstill.

10.

The manufacturer is not responsible for any unapproved modifications made on

the machine and/or any replacement of the original safety and protective devices

by other ones then original.

11.

The machine is to be serviced and/or be repaired only by the authorised

personnel of Baykal or its appointed representatives.

BAYKAL

EDITION NO :

APHS

13

DATE OF ISSUE :

May-2011

PAGE :

13

2.3. Noise measurement

The sound pressure level of the press brake at operator’s working position is

under 70 Db (A).

2.4. Stop time control

The stopping time of this press brake is 80 ms and the corresponding miniumum

safety distance for the two-hand control is 130 mm.

BAYKAL

EDITION NO :

APHS

14

DATE OF ISSUE :

May-2011

PAGE :

14

3. OVERALL DRAWING AND DIMENSIONS

Fig.3.1.

CNC

HDROLK PRES A B C D E MAX F G H-MAX

mm mm mm mm mm mm mm mm

APHS 1250x40 1250 1070 1470 1500 1000 1050 810 2550

APHS 2104x60 2100 1600 1580 1650 1000 1050 880 2550

APHS 2106x90 2100 1600 1580 1650 1000 1050 880 2600

APHS 2604x60 2600 2050 1580 1650 1000 1050 880 2550

APHS 2606x90 2600 2050 1580 1650 1000 1150 890 2610

APHS 3104x90 3100 2550 1590 1650 1000 1150 880 2600

APHS 3106x120 3100 2550 1590 1650 1200 1150 890 2910

APHS 3108x160 3100 2550 1600 1660 1200 1150 890 2910

APHS 3110x200 3100 2550 1600 1660 1200 1250 880 2900

APHS 3112x240 3100 2550 1610 1680 1200 1250 880 2900

APHS 3116x300 3100 2550 1820 1920 1400 1350 905 3150

APHS 3120x400 3100 2550 2050 2250 1400 1400 1015 3300

APHS 3706x160 3700 3250 1600 1660 1200 1250 880 2900

APHS 3708x200 3700 3250 1600 1660 1200 1350 880 2900

APHS 3710x240 3700 3250 1610 1680 1200 1350 880 2900

APHS 3712x300 3700 3250 1820 1920 1400 1400 980 3200

APHS 4105x120 4100 3550 1300 1400 1200 1350 870 2300

APHS 4106x160 4100 3550 1600 1660 1200 1350 880 2900

APHS 4107x200 4100 3550 1600 1660 1200 1350 880 2900

BAYKAL

EDITION NO :

APHS

15

DATE OF ISSUE :

May-2011

PAGE :

15

APHS 4109x240 4100 3550 1610 1680 1200 1350 880 2900

APHS 4112x300 4100 3550 1820 1920 1400 1400 980 3200

APHS 4116x440 4100 3550 2235 2355 1400 1400 1105 3500

APHS 6104x160 6100 5100 1960 2000 600 1400 1000 2850

APHS 6106x240 6100 5100 1960 2000 600 1400 1100 3000

APHS 6108x300 6100 5100 2060 2150 600 1400 1115 3280

APHS 6112x440 6100 5100 2250 2340 600 1400 1100 3700

APHS 6114x500 6100 5100 2350 2440 650 1500 815 3500

APHS 6116x600 6100 5100 2400 2500 650 1500 1050 4100

APHS 8100x1200 8100 6050 3800 3810 - - 1050 5550

BAYKAL

EDITION NO :

APHS

16

DATE OF ISSUE :

May-2011

PAGE :

16

4. LIFTING & TRANSPORTATION

The following points should be taken into account :

•

The lifting points are illustrated in Fig.4.1.The dimensions and the weight of the

machine are given in section 6.1.1.of this manual.

•

Make sure that the lifting rope or chain are of sufficient capacity for the lifting

operation.

!

On press brakes the centre of gravity is on the front side.

Therefore, the machine must be handled with extreme caution

when lifting and installing to prevent it from falling forward, or

even falling down.

!

Make sure that the machine is no subject to impact

during loading or unloading.

!

The crane to lift the machine must be controlled by a single

operator.

WARNING On press brakes, the center of gravity is on the front

side. Therefore the machine must be handled with

extreme caution when lifting and installing to

prevent it from inclining forward or even falling

down.

Fig.4.1

BAYKAL

EDITION NO :

APHS

17

DATE OF ISSUE :

May-2011

PAGE :

17

5. UNPACKING & INSTALLATION

The press brake is covered in plastic, and is bolted on wooden crates.

!

Prior to installation, remove the cover and wooden crate seperately and safely in

accordance with environmental regulations.

After unpacking, check the machine visually against any damage during

transport.

Install the machine in an indoor area which is free from humidity and excessive

dust.

!

Make sure that the machine is installed in accordance with the work and

maintenance space indicated in the enclosed Installation Diagram to enable the

operator to visualise the work area without obstruction.Therefore, the hazardous

sitauations regarding the operator, other persons, or materials due to incorrect

installation will be reduced.

It is important to leave a work space of both sides of the machine, which is not

less than the tool length. Otherwise, the tool can only be changed from the front

of the machine.

Floor conditions for installation : Flat and concrete surface ( BS 25 ).

Bolt the machine down to the floor by anchorage bolts or steel expansion inserts

as illustrated in the Installation Diagram.

Remove the steel supports ( Part ″C ″in the Installation Diagram ), and store

away for possible future use.

Level the machine by using a water level.

Mount the front support arms ( Part ″D″) as illustrated in the Installation

Diagram.

As the top and bottom tools are already fitted, the machine is now ready to be

connected to an power supply.

BAYKAL

EDITION NO :

APHS

18

DATE OF ISSUE :

May-2011

PAGE :

18

Intentially left in blank

BAYKAL

EDITION NO :

APHS

19

DATE OF ISSUE :

May-2011

PAGE :

19

6. OPERATING AND MAINTENANCE INSTRUCTIONS

6.1.Technical Data

6.1.1. Specification

1. Bending length mm

2. Bending capacity - St.42 mm

3. Bending force tons

4. Length mm

5. Width mm

6. Heigth mm

7. Weigth kg

8. Approach speed mm / sec

9. Bending speed mm / sec

10. Return speed mm / sec

11. Standard stroke mm

12. Pump flow rate cm

3

/ rev.

13. Oil tank volume lt.

14. Back-gauge range mm

15. Main motor, 3 phase 380 V 50Hz kw

6.1.2. Standard Equipment

Electric motor : 380 V 50 Hz 3phase

Standard top and bottom tools

Two-hand control system or pedal control system

CNC Control unit

Front support arms

Wedge system top tooling

750 mm Power back-gauge

Oil tank level indicator

Side and rear fence guardings

Hand screw clamps and chains for alignment

and rotation of bottom die.

Light guard or Laser safety system

BAYKAL

EDITION NO :

APHS

20

DATE OF ISSUE :

May-2011

PAGE :

20

6.1.3. List of parts subject to rapid wear

No Part name Size specification Qty

1. Bottom tool -

2. Top tool -

3. Piston seal

(Busak+Shamban)

O-ring (Piston seal)

2

2

4. Rod seal (Busak+Shamban)

O-ring (Rod seal)

2

2

5. Scraper

2

6. O-ring ( cylinder ) 2

Table of contents

Popular Industrial Equipment manuals by other brands

Engcon

Engcon DC2 QSC user manual

Eriez

Eriez 58B Installation, operation and maintenance instructions

Neptune

Neptune G-50-1 Operating instructions manual

Yoshitake

Yoshitake PG-2 product manual

Saferoad

Saferoad MEGARAIL INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL

Rittal

Rittal RiLine Compact SV 9635.000 Assembly and operating instructions

SWR ENGINEERING

SWR ENGINEERING ProGap operating instructions

Vestil

Vestil H Series instruction manual

Rockwell Automation

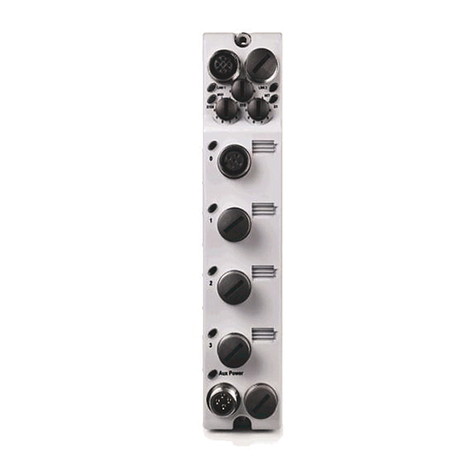

Rockwell Automation Allen-Bradley 1732E-IT4IM12R user manual

Maggi

Maggi STEFF SUPERSONIC 3 manual

Siemens

Siemens 3TX7002 operating instructions

MARKEN

MARKEN neotech NK-25 instruction manual