Neptune G-50-1 Instruction Manual

NEPTUNE

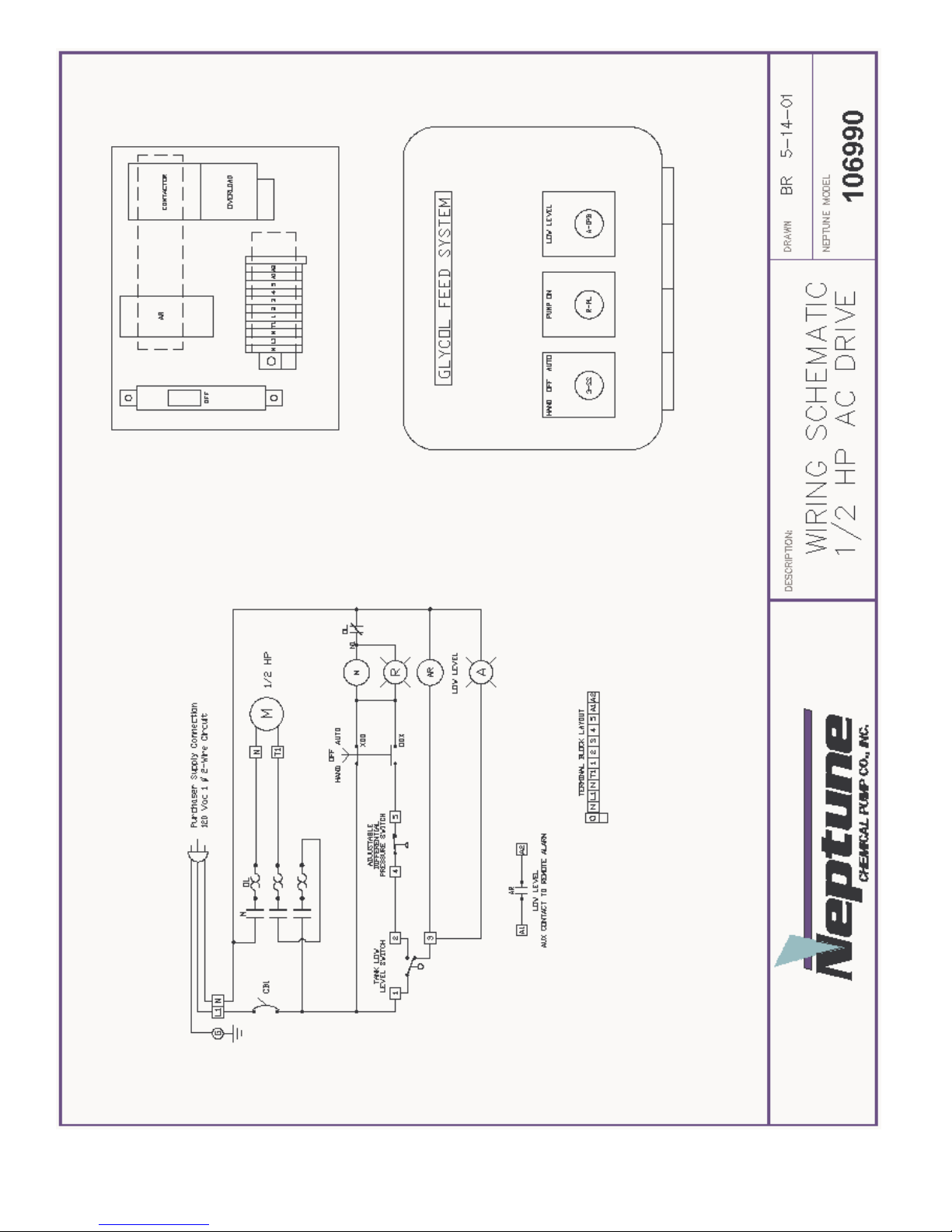

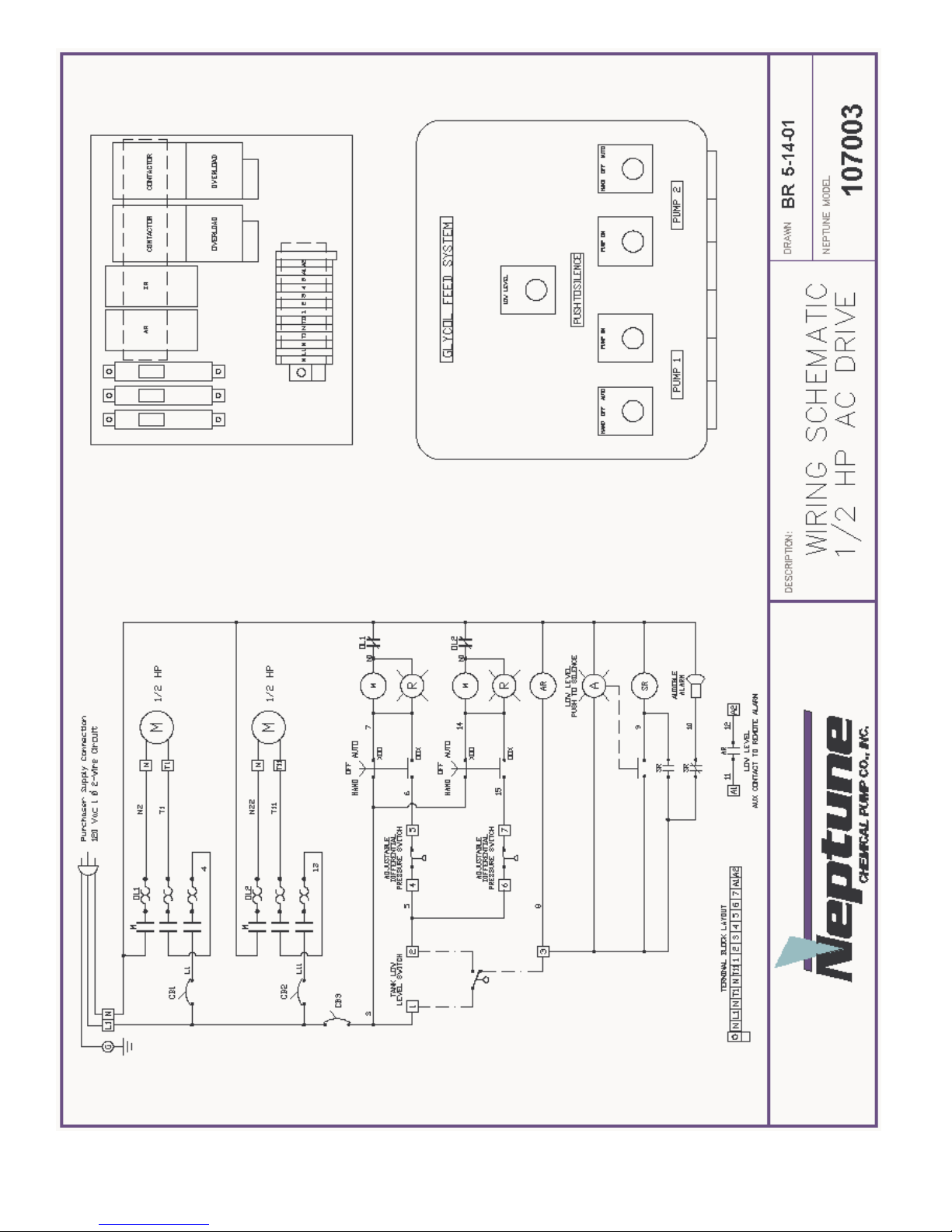

GLYCOL FEED SYSTEM

Models G-50-1, G-50-1A, G-50-2A, G-100-1A, G-100-2A

Lansdale, PA 19446 Tel: 215-699-8700 Fax: 215-699-0370

REV NO 6 – 01/08/04

ZL106838

OPERATING &

INSTRUCTION

MANUAL

I.

GENERAL DESCRIPTION

Neptune Chemical Pump Company’s Glycol Feed System is intended for the automated

addition of glycol into closed loop chilled and hot water systems. The Glycol Feed System

automatically maintains pressure in the loop by adding glycol solution to make up for

losses, which occur due to leakage.

Glycol addition is controlled by a pressure switch with adjustable low and high set points.

When the pressure in the loop reaches the low set point, the pump begins to feed glycol

into the system until the high set point pressure is achieved and stops the pump.

I.

MODELS

The Model G-50-1 or G-100-1 is provided with a 50 or 100 gallon polyethylene tank

mounted in a steel frame, 1.5 gpm bronze rotary gear pump (optional 3.0 gpm pump), float

switch and NEMA 4X control panel. The control panel features a HAND/OFF/AUTO

selector switch for the pump motor, ON indication light for the pump, LOW tank level

indication light and power cord with plug (115V, 60c). The pump suction piping includes

a PVC ball valve and cast iron “Y” strainer. The pump discharge assembly includes a PVC

ball valve, brass check valve, pressure switch, bronze relief valve and pressure gauge.

The Model G-XX-1A is identical to the G-XX-1 and has the addition of an audible

alarm, as well as light for low level tank indication.

The Model G-XX-2A is capable of feeding glycol to two separate closed loop systems

and includes two separate pumps, as well as suction and discharge assemblies.

The LP designation at the end of a model number (ex. G-XX-1-LP) indicates that a 3.0

gpm pump has been provided in place of our standard 1.5 gpm pump.

All glycol systems are provided with a dry contact for remote alarm.

II.

OPERATION

The glycol feeder is provided with a control panel with HAND/OFF/AUTO selector

switch.

When the panel is switched to the AUTO position, the pump is actuated via the pressure

switch, which is mounted in the discharge assembly and sensing the pressure in the loop.

The pressure switch is pre-set to start the pump at 12 psi and stop the pump when 30 psi in

the loop is achieved. The adjustment range for the standard pressure switch is 10-45 psi to

start the pump and 20-60 psi to stop the pump. The minimum differential pressure

between the cut in and cut out set points is 10 psi and the maximum is 30 psi. The float

switch in the bottom of the tank will stop the pump if the glycol solution in the tank gets to

low level.

The MANUAL position of the selector switch in the panel will allow the pumps to run and

inactivate both the pressure switch and the level switch.

PLEASE READ THIS

The initial setting of the pressure switch is critical

to the proper operation of the glycol feeder.

WARNING

The pressure relief valve is factory set at 60 psi.

DO NOT operate the glycol feeder above 100 psi.

If your application requires a higher operating

pressure, consult the factory.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE

Pump is running but is 1. The motor rotation is incorrect. The

not pumping anything proper rotation of the motor is counter-clockwise when

looking at the motor shaft. Check the wiring diagram

on the motor or the attached motor diagram for proper

wiring.

2. On simplex single pump systems – Model G-XX-1 and

G-XX-1A. The motor should be wired for 115V

counter-clockwise rotation. See further information on

the pump, which is attached.

3. Duplex or two pump systems, Model G-XX-2A, require

one pump motor to be wired counter-clockwise and the

other in a clockwise rotation. Looking at the front of

the Model G-XX-2A, the control panel facing you, the

pump motor on the left should be wired counter-

clockwise and the pump motor on the right should be

wired for a clockwise rotation.

Pump is not running when 1. The low level float switch may be

HOA switch is in the AUTO actuated. The low light will be on and

position the audible alarm will sound on some

models. Add glycol to the tank until

the level switch is satisfied.

2. The pressure switch in the discharge piping has been

satisfied. The pressure switch is factory set to actuate

the pump at 12 psi and shut-off at 30 psi. See pressure

switch information for pressure switch adjustment,

which can be found on the inside cover of the pressure

switch.

Bronze Rotary Gear Pumps

Installation, Operation, and Maintenance Instruction

INTRODUCTION

Congratulations for choosing an Oberdorfer pump,the Industry Standard for quality since 1890.

Construction

Bronze Rotary Gear standard pump housings and helical gears are made of top quality bronze. Shafts are stainless steel. Pumps are available

with bronze bearings and grease fittings or with carbon bearings which require no lubrication. Dynamic seal arrangements include packing,

lip, or mechanical seals for a variety of application requirements. Static cover o-ring seals eliminate gasket problems.

Application Range

Bronze Rotary Gear pumps are of the external gear positive displacement type, displacing a finite volume of fluid with each shaft revolution.

As such, capacity varies in direct proportion to pump speed. They are suited to handle clear lubricating and non-lubricating fluids, with PH

ranging from 4 to 11, and temperatures to 400F. These pumps handle viscous fluids to 100,000 cps (462000 SSU) at reduced shaft speeds, with

flow rates to 175 GPM (662 LPM), differential pressures to 150 psig (10.3 BAR), and suction lift capability to 20 feet (6.1 meters) for new

pumps.

Field Inspection

Bronze Rotary Gear pumps may be readily inspected in the field usually without removal from the drive or system plumbing. Simply remove

the cover screws to pull the cover. Before attempting an inspection, follow safety precautions and be sure to read and understand this

manual.

New Pump Receipt Inspection

Upon receipt, check for obvious shipping damage and completeness to purchase order requirements. Shortages or damage should be reported

immediately to the carrier and to your Oberdorfer distributor. Occasionally during shipment, possible misalignment or other damage

including cracked mechanical seal faces can occur. As such, customers are advised to test the pump with water in a convenient location prior

to installing into the intended system.

Storage

If the pump is to be stored prior to installation, it is recommended that it be left in the original shipping carton with all shipping plugs in

place and stored in a dry environment avoiding temperature variations. Contact the motor manufacturer for specific motor storage

information.

Records

These instructions should be kept in a convenient location for ready reference. The manual should be read carefully by persons responsible

for installation, operation, and maintenance of the equipment. For ease of reference, a copy of the order should be kept with the manual.

Write down the pump model number as shown on the pump nametag, and the date the unit was placed into service.

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

INSTALLATION

Site Preparation

Choose a site that allows easy access to the pump for maintenance. Consider protection from the elements. Guard against drips and spray

from nearby equipment. Choose a solid foundation for mounting. If noise is a concern, consider a rubber pad under the pump base to

dampen.

Flow Direction

Gear pumps will perform equally well in either direction however care must be taken for pumps equipped with integral pressure relief valves.

To change flow direction effectively reversing the suction and discharge ports, simply switch driver rotation by following motor wiring

diagram instructions and change the location of the relief valve as shown below. Most pump motor units are factory supplied with

counterclockwise shaft rotation (when viewing the pump from the shaft end).

Suction Plumbing

Suction side plumbing considerations are key to desirable pump performance. Minimize head loss by assuring sufficient pipe size (especially

important for highly viscous services). Generally the same size pipe as the pump ports is adequate. For long runs (beyond 3 feet) or viscous

fluids, use one or two pipe sizes larger. Strive to keep the lines as short and straight as possible. If flexible lines are used, they should be

selected to prevent wall collapse. To keep the pump from being starved or running dry, be sure there is sufficient fluid supply. A flooded

suction is generally preferred. Suction lifts over 3 vertical feet and long horizontal runs (beyond 3 lineal feet) require a foot or check valve

below the level of the liquid being pumped. When taking suction from a tank or vessel, position the inlet above the maximum expected level

of solids. Use full-bore ball valves or gate valves to minimize restriction. Suction strainers should be properly sized to minimize pressure

drop and positioned for easy cleaning access. If start-up screens are used, be sure they are removed prior to placing the system into regular

operation. Orient lines so as to prevent formation of air pockets. Be sure all joints are tight. Flush out all suction lines prior to installing the

pump.

General Piping

For further ease of maintenance, use union fittings to connect the pump to the system. Install a discharge priming tee for convenience. Do not

spring the piping to connect the pump. Use piping supports or hangers as required. When necessary, provide for thermal expansion and

contraction to avoid placing strain on the pump.

Alignment

Proper alignment is key to seal and bearing performance. Improper alignment can lead to premature pump failure. Check the alignment

carefully between the pump and the drive.

Belt Drive

Though alignment is not as critical as direct connected, ensure that the pump and motor shafts are parallel and in line. For units suitable for

belt drive, be sure that the belt tension is adequate (per the belt manufacturer’s recommendation) but do not overtighten. For heavy pulley

loads, models are equipped with external ball bearing supports. A single 1/2” (A or 4L section) V-belt is satisfactory for drive speeds up to 1

HP 3450 RPM. For larger drive sizes, double-V belts are recommended. Install guards around all moving parts in accordance with OSHA to

prevent personal injury.

Fasteners

Unless the pump has been shipped directly from the factory, it is recommended to check all bolts and nuts for tight-ness to eliminate possible

leakage problems or destructive vibration.

Pressure Relief

Discharge lines should be fitted with properly sized line pressure relief valves to protect both the pump and the system. Pumps equipped with

integral internal bypass relief valves are intended as a safety device against intermittent overpressurization. They are not designed for

continuous use and can lead to overheating. In these instances, a line pressure relief valve is required. The relief outlet should be piped back

to the suction vessel.

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

Flow By-Pass

When a flow by-pass system is used to control output from the pump, the bypassed fluid should be directed back to the suction vessel to

avoid recirculation heat build-up. In cases where this is not possible, connect to the suction at least 10 pipe diameters length away from the

pump inlet. Provisions for cooling should be made in the event of recirculation heat build-up.

Pump Driver Mounting

Adapter kits (including bracket, coupling components, and hardware) are available for Bronze Close Coupled Gear pumps allowing

connectivity to NEMA and IEC motor frames. Assembly instructions are included with each kit. Adapterless motors, carbonator mounts, and

electric clutches are available for some models. Base mount kits (including baseplate, coupling components, coupling guard, and hardware)

are available for Bronze Pedestal Gear pumps. Contact your Oberdorfer representative for additional information.

OPERATION

Pre-Startup

Prior to start-up, recheck installation as described above. Verify desired rotation by jogging the motor and make corrections if necessary.

Before initial startup, pre-wet the gears and make sure the pump is adequately primed. Failure to do so could cause immediate damage to

pump components. Make sure that discharge valves are open.

Startup

Start pump and check for proper operation. Adjust packing (if applicable) as necessary, allowing adequate time to run in. Do not overtighten

the packing else damage to the packing and the shaft can occur. A properly packed and adjusted packing nut will leak at about 10 drops

every 3 to 5 minutes. Tighten packing nut only while shaft is rotating. Lip and mechanical seal versions require no adjustment. If the pump’s

bearing areas or seal area runs hot, shut the pump down and determine the cause. For units equipped with integral pressure relief valve, the

factory setting is usually 50 psig. It is recommended that the setting should be 5 psig above the operating pressure in the discharge line. To

increase the set point, turn the by-pass valve adjusting screw clockwise. If start-up screens were used, be sure they are removed prior to

placing the system into regular operation. Depending on suction conditions, it may be necessary to reprime the pump for subsequent restarts.

MAINTENANCE

Frequency

Since each installation differs, the frequency and extent of pump maintenance is best established based upon past performance. Keeping

detailed maintenance records of past performance aids in determining future preventative maintenance intervals. During routine operating

inspections, pay particular attention to seal and bearing areas of the pump. Consult the motor manufacturer for motor maintenance

instructions.

Changing Applications

Verify that all wetted parts of the pump are compatible with the new fluid to be handled and that the motor is adequately sized. Check with

your Oberdorfer distributor if in doubt.

Inspect for Wear

If your Bronze Gear Pump exhibits reduced flow, an inability to maintain pressure, is noisy or performs otherwise abnormally, first refer to

the Troubleshooting Matrix on back. If the problem persists, the pump should be inspected for wear or damage. Oberdorfer Bronze Gear

pump internals may be readily inspected in the field usually without removal from the drive or system plumbing. Simply remove the cover

screws to pull the cover. Full pumpremoval and complete disassembly may be needed for a comprehensive inspection. Contact your local

authorized distributor or the Oberdorfer factory.

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

Mechanical Seals

Pumps equipped with mechanical seals are of the standard pusher bellows type or wedge style. They can be expected to provide long and

troublefree service provided:

1) Seal materials are compatible with pumped fluid and properly applied to the service.

2) Adequate cooling and lubrication is provided

3) Dry running is avoided

4) Abrasives are kept away from the seal area

5) Pump and driver are properly aligned

Detailed mechanical seal inspection and replacement instructions are included with Oberdorfer Repair Kits.

Lip Seals

Pumps equipped with lip seals are of the metal cased, spring energized, single lip style. These are intended to provide minimum friction drag

with positive sealing and again should be maintenance free provided the same conditions for mechanical seals are met as well as:

6) Avoid scouring of the shaft in the lip seal area due to contaminated abrasives

7) Avoid excessive seal lip contact pressure on the pump shaft due to excessive pump pressure.

These are readily replaceable by pressing out the old seal and pressing in a new replacement.

Packing

Pumps equipped with teflon or graphoil packing require periodic adjustment as described above in the Startup section to avoid excessive

leakage. Eventually all the packing in the pump will become deteriorated and will have to be replaced.

Recommended Spares

Repair kits are available for all Oberdorfer Bronze Gear Pumps. Each kit comes with detailed instructions. For the proper kit, contact your

Oberdorfer Distributor or the factory.

PRESSURE SWITCH INSTRUCTIONS

SQUARE D

Commercial Pressure Switch

Class 9013, Model FSG29J99

Model FSG29J99

CUT-OUT RANGE 20-60 PSI

ADJUSTABLE RANGE 10-30 PSI

CUT-IN RANGE 10-45 PSI

PRESSURE CONNECTION : ¼” NPT EXTERNAL

T

ECHNICAL

T

ERMS

Operating Points (Settings)

Every pressure switch has two operating points; one on rising pressure and one of falling pressure. The operating point on rising

pressure is referred to as the TRIP POINT or cut out for pumps and compressors and the operating point on falling pressure is

referred to as the RESET POINT or cut in for pumps and compressors. These operating points are called the SETTINGS of the

switch. — TRIP POINT (rising pressure)

— RESET POINT (falling pressure)

Differential

The differential is the difference in pressure between the trip point (cut-out) and the reset point (cut-in). It can be adjustable or

nonadjustable (fixed).

Example: Cut-in 30 psi

Cut-out 50 psi

Differential 20 psi (50-30 psi)

Range

The range is the pressure limits within which the operating points (settings) can be adjusted. The range of the Class 9013

pressure switch is referenced to the operating point on rising pressure (trip point). The differential subtracts from the trip point

setting. During the normal operating cycle, system pressure should never exceed the upper limit of the range when using a

diaphragm actuated switch. This will greatly reduce the life of the diaphragm.

Maximum Allowable Pressure

Maximum allowable pressure is the pressure to which a switch can be subjected without causing a change in operating

characteristics, shift in settings, or damage to the device. Pressure surges may occur in a system during the start up of a

machine or from valve operation. Surges are not normally detrimental to the life of a switch if the surge is within the maximum

allowable pressure rating of the switch. Diaphragm actuated switches should not be subjected to more than 10 surges per day.

More frequent surges will greatly reduce the life of the diaphragm.

PRESSURE SWITCH INSTRUCTIONS continued …..

SET POINT ADJUSTMENTS

The pressure switch is set at the factory to the operating point(s) marked on the outside of the switch housing. Before

readjusting the switch, cyle it to determine actual operating points.

Non-Adjustable Differential

The range adjustment nut ( Item H, Figure 3 ) or knob ( Item C, Figure 3 ) adjusts both setpoints by the same amount.

To adjust the operating points :

1. Place a flat blade screwdriver in a range adjustment nut slot.

2. Rotate the nut to the left to increase the operating points or to the right to decrease the operating set points.

Adjustable Differential

The range adjustment nut or knob determines the decreasing setpoint. The adjusting screw ( Item J, Figure 3 ) determines the

increasing setpoints. To adjust the operating points :

1. Adjust the decreasing setpoint ( see steps 1 and 2 above ).

2. Turn the adjusting screw clockwise ( to raise the increasing setpoint ). This adjustment does not affect the

decreasing setpoint.

FIGURE 3

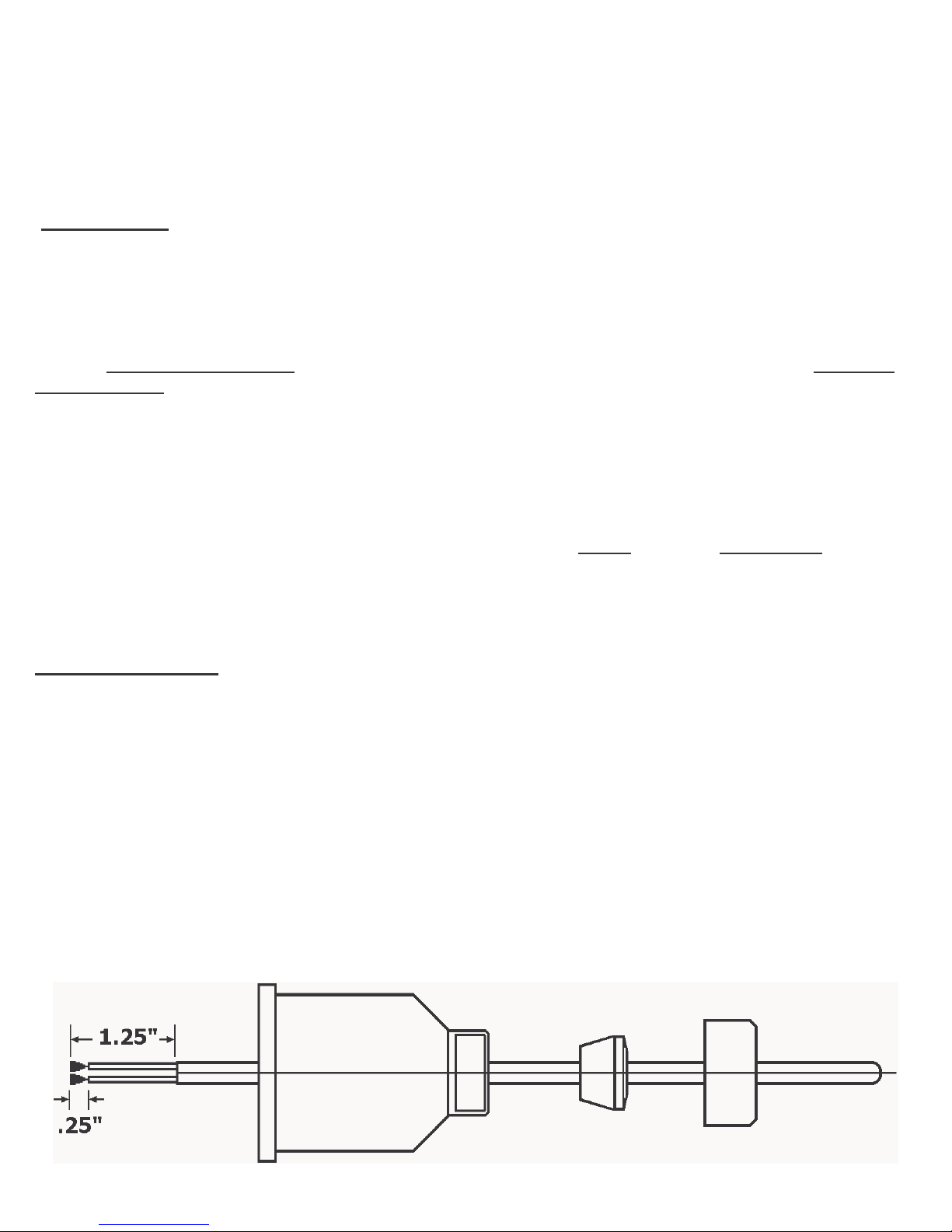

INSTALLATION INSTRUCTIONS LL-3 (L-30N)

LIQUID LEVEL SWITCH

MODEL L30N LIQUID LEVEL SWITCH

INSTALLATION AND OPERATING INSTRUCTIONS

Installation:

The L-30 liquid level switch is supplied with a 1-1/2” or 1-1/4” X 1 bushing threaded in place

with 2 to 3 wraps of teflon tape, which must be intact or renewed if bushing and switch are

separated before assembly in tank. Care must be exercised when threading the bushing

into plastic or metal fittings. Apply a minimurn of 2 to a maximum of 3 wraps of teflon tape

to threads of bushing - this is especially important if unit is to be used in metal fittings where

coarse METAL THREADS could gall plastic if not lubricated. The plastic bushing CAN BE

CRACKED if the main body of the flow switch is tightened into it FIRST. Cracking will not

occur if the bushing is FIRST tightened into the pipe or tank fitting and THEN the L-30 body

is tightened into the bushing.

Thus:

1). Teflon tape thread and tighten plastic bushing into pipe or tank fitting.

2). Teflon tape thread and tighten L-30 switch into PLASTIC bushing by applying wrench to

hexagon section. Repeat steps I and 2 until ARROW on body points to UPWARD and

threads are, leak tight.

Plumbers'tools such as pipe wrenches are not recommended. If possible use a "Ridgid"

type wrench where the smooth jaws closely fit the hexagon section.

Electrical Wiring:

1). Remove gland nut, grommet and switch cover.

2). Strip outerjacket of electrical cord back

3). Slip on terminals are

individual conductors supplied with each switch. approximately 1-1/4". Strip insulation

from back approximately 1/4". Remove from switch terminals and

and crimp on or solder to electrical leads.

4). Feed electrical cable through gland nut, grommet and switch cover as shown.

MODEL L30N LIQUID LEVEL SWITCH

INSTALLATION AND OPERATING INSTRUCTIONS

5). Apply slip on terminals to appropriate contacts of micro switch. Slide cover down

cable and fasten to body of switch with four screws provided. Slide grommet down cable

until outer jacket is level with small end of grommet per illustration page 2. Push

grommet into tapered end of cover. Hold cable jacket to prevent rotation and thread

gland nut firmly on to cover.

Fig. 1: Wiring schematic for power applied to load when liquid level is less than set point

(power to load interrupted when level increases to above set point).

Fig. 2: Wiring schematic for power applied to load when liquid level is greater than set

point (power to load interrupted when level decreases to below set point).

Microswitch actuation point may be monitored by an audible click or with an OHM meter

before connecting line power to the terminal strip or by monitoring the voltage supplied to

the load through the microswitch.

Figure 1 Figure 2

This manual suits for next models

4

Table of contents

Other Neptune Industrial Equipment manuals