Table of Contents

Table of Contents

1. Introduction

1.1. General............................................................................................................ 5

1.2. Scrapping and recycling.................................................................................. 5

1.3. Technical support and spare parts.................................................................. 5

1.4. Product approval............................................................................................. 6

1.4.1. Declaration of Incorporation.....................................................................6

2. Safety

2.1. General............................................................................................................ 7

2.2. Safety features according to 13849-1............................................................. 8

3. Design and function

3.1. DC2..................................................................................................................9

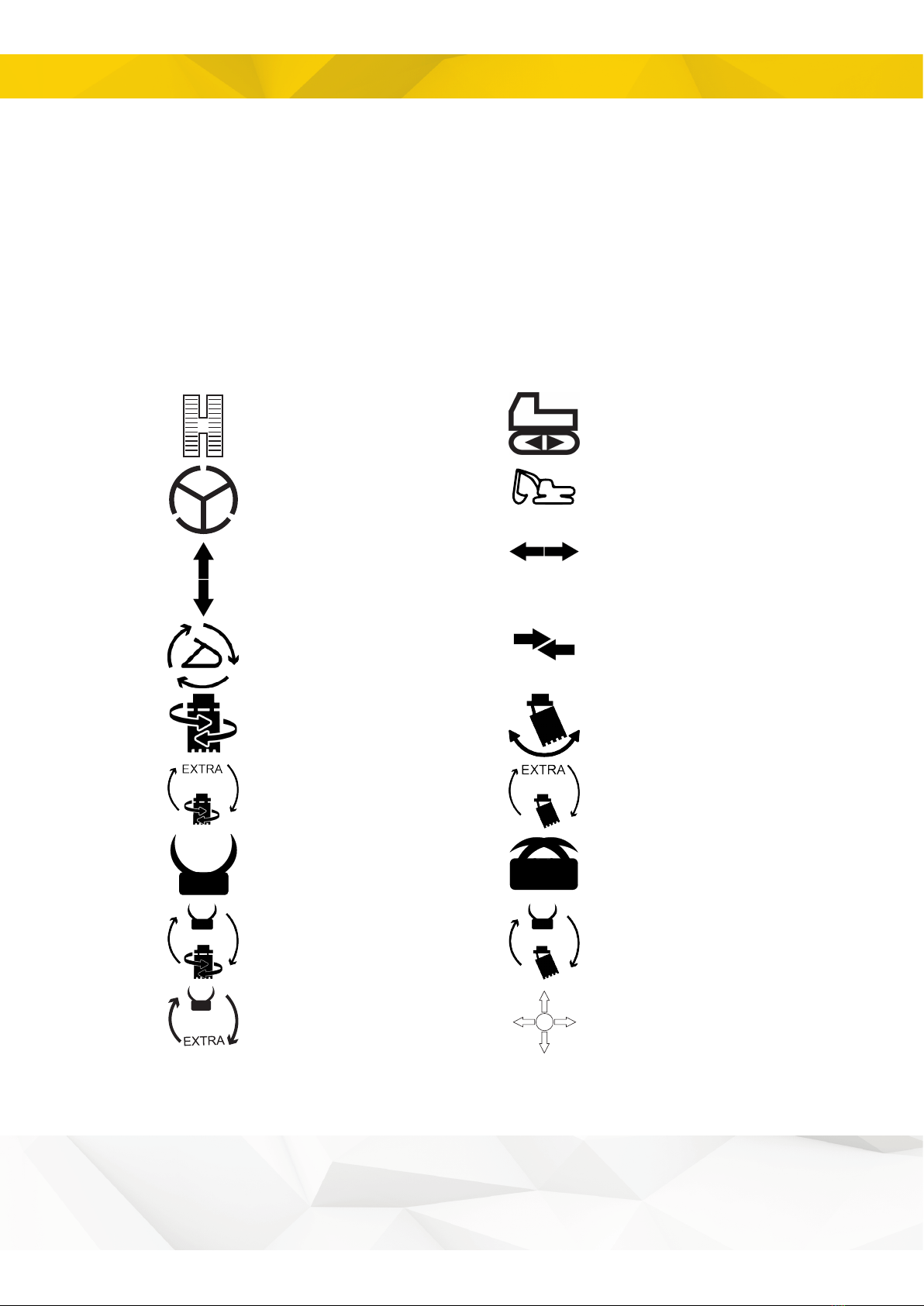

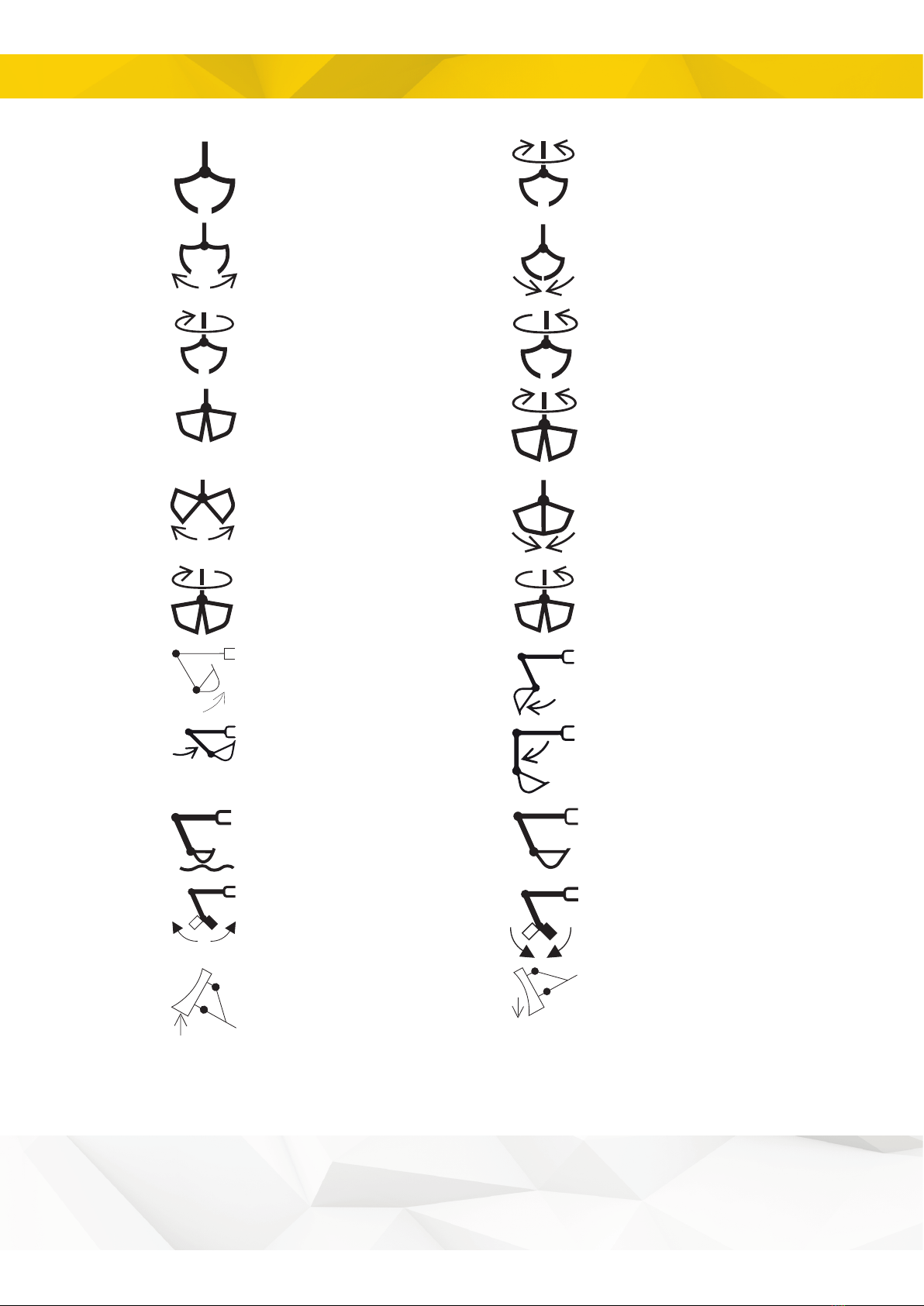

3.2. Symbols........................................................................................................... 9

3.3. Control panel - QPM....................................................................................... 13

3.3.1. Symbols on the Control Panel QPM........................................................13

3.3.2. Functions QPM - buttons.........................................................................13

3.4. Q-Safe electronics module QLM..................................................................... 15

3.4.1. QLM overview.......................................................................................... 15

4. Installation

4.1. System overview............................................................................................. 16

4.1.1. Tiltrotator control...................................................................................... 16

4.1.2. Track control............................................................................................ 17

4.1.3. Wheel control........................................................................................... 18

5. Operation

5.1. Cabin module menu system............................................................................20

5.1.1. Identification............................................................................................. 20

5.1.2. Logging in to the menu............................................................................20

5.1.3. Menu system............................................................................................21

5.1.4. User..........................................................................................................21

5.1.5. Grip.......................................................................................................... 22

5.1.6. System..................................................................................................... 23

5.1.7. Tool...........................................................................................................24

5.2. Tiltrotator quick hitch (QH).............................................................................. 25

5.2.1. Connecting the tool, hydraulic lock..........................................................25

5.2.2. Disconnecting the tool, hydraulic lock..................................................... 31

5.3. Option – slew/lift limitation...............................................................................35

5.4. Wheel control...................................................................................................37

5.5. Track control....................................................................................................37

5.6. Switching users............................................................................................... 37

6. Starting the system

6.1. Download the latest version of MicroConf.......................................................39

6.2. Connect the system to a computer................................................................. 40

3