4

1. General safety instructions

This operating manual contains basic instructions that must be

complied with for installation, commissioning, operation, and

maintenance. Consequently this operating manual must always

be read by the fitter as well as the responsible owner prior to

installation and commissioning, and must be accessible to

every user of the device. In addition, all other safety

instructions in this document must be strictly complied with.

Read and comply with all instructions.

To reduce the danger of injury, do not allow children to use this

product.

Dangers due to failure to comply with the safety

instructions

Failure to comply with the safety instructions can result in

hazards for personnel as well as for the environment and the

device.

Failure to comply with the safety instructions can result in loss

of all claims for damage compensation.

Inadequate qualification of personnel

Dangers due to inadequate qualification of

personnel!

Possible consequence: Death or severe injury,

significant damage to material assets.

The system owner must ensure compliance

with the required qualifications.

All activities must only be carried out by

personnel who are qualified to perform such

activities.

Access to the system must be prevented for

inadequately qualified personnel..

Compliance with the applicable accident

prevention regulations and the other statutory

regulations and the generally acknowledged

safety regulations must be ensured by the system

owner!

Only liquid flocculants from the company

BAYROL may be dosed with the Flockmatic. The

use of flocculants or other products from other

manufacturers results in loss of all damage

compensation claims!

Compliance with the protection rating

After tasks on the Flockmatic, if the housing or

individual cable glands are not properly closed, so

that a reliable seal is ensured, moisture can

penetrate into the device.

Possible consequences: Damage or

destruction of the Flockmatic, malfunctions.

After all tasks performed on the device,

ensure a safe seal.

2. General

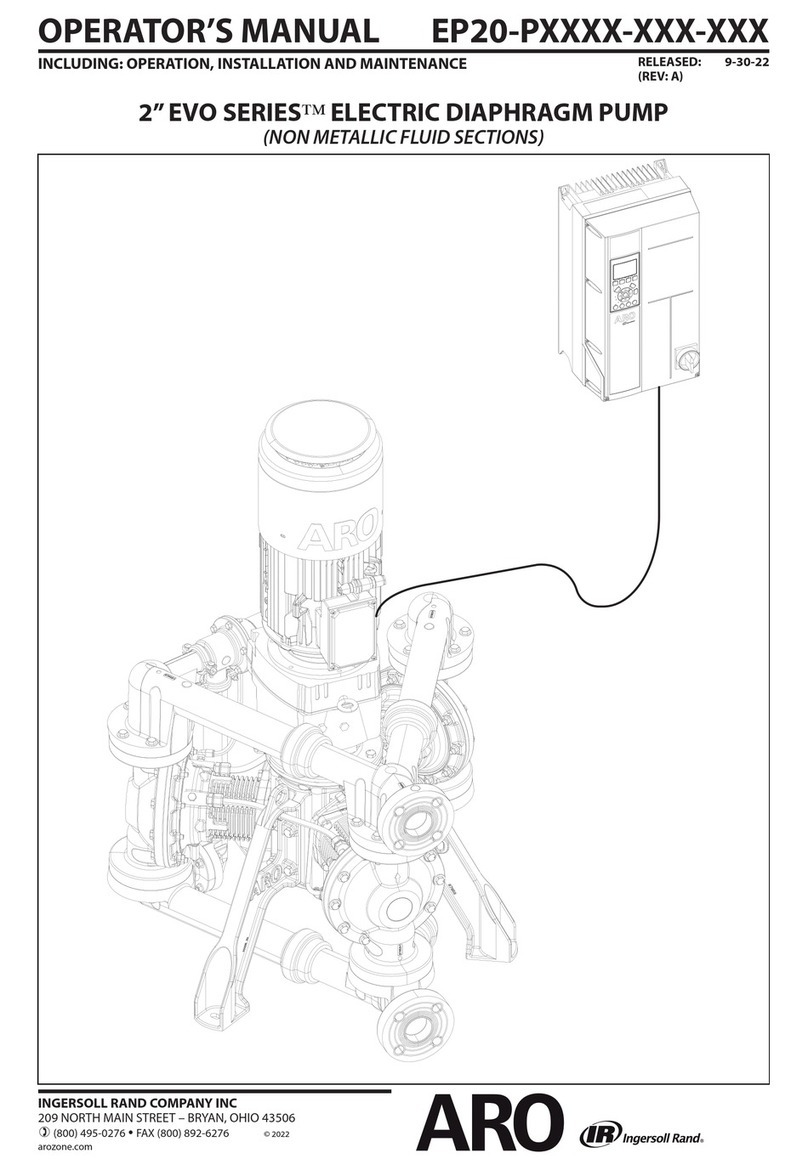

The Flockmatic is a high quality peristaltic pump for dosing of

flocculant (Quickflock Automatic Plus) in to the circulation

system of a swimming pool.

The pool must be equipped with a properly sized sand/glass

filter.

Technical data:

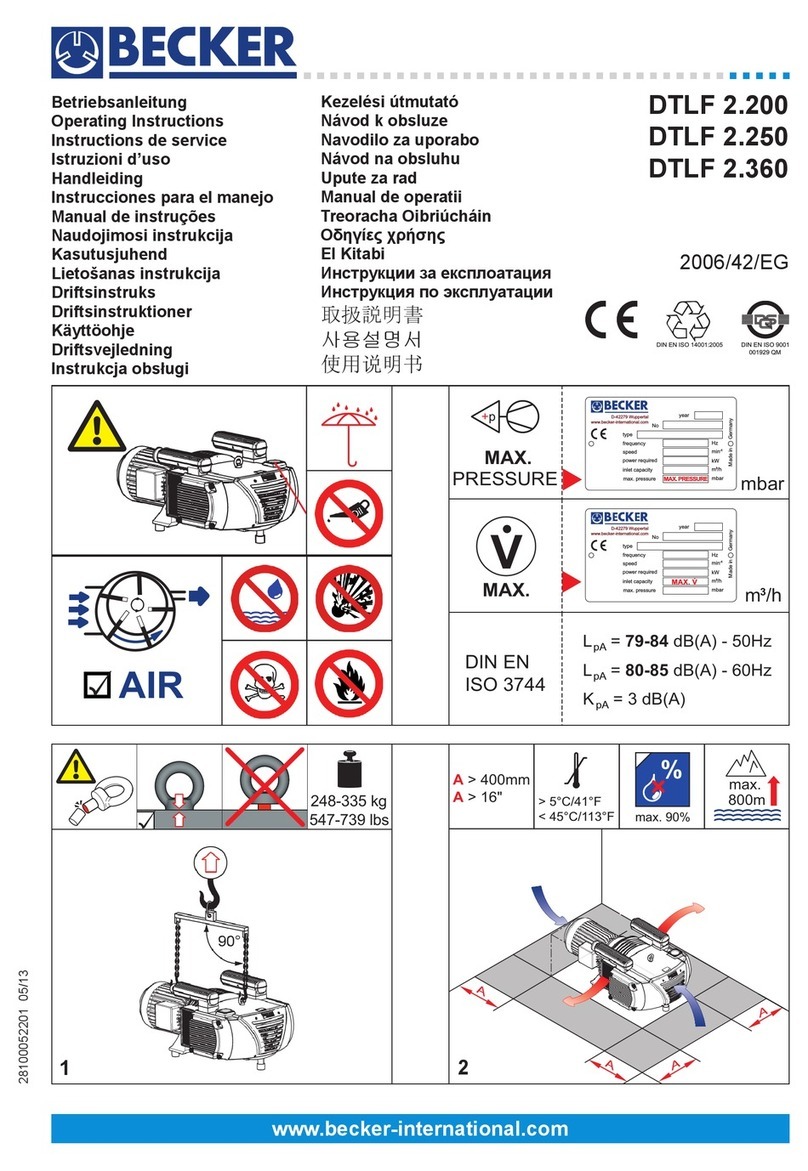

The Flockmatic is a high quality stepper motor that requires no

gears.

With the supplied hose, the capacity is - 0.01 l / (10ml / h).

Max. pressure: 1.5 bar

Flow rate: 0,01 l/h (10ml/h)

Protection class housing: IP65

Dimension

(without wall mounting panel,mm): approx. 93x150x130

(BxHxT)

Electric power supply: 230 V / 50 Hz

3. Electrical connection

The Flockmatic pump must be connected in a way that it only

works when the circulation pump is running.

The Flockmatic must be isolated when carrying out a backwash

of the sand/glass filter. The Flockmatic must be installed in

such a way to ensure that it is switched off during Backwashing

of the filter.

The Flockmatic can easily be connected to the PoolManager®.

Please refer to the operating instructions of the PoolManager®.

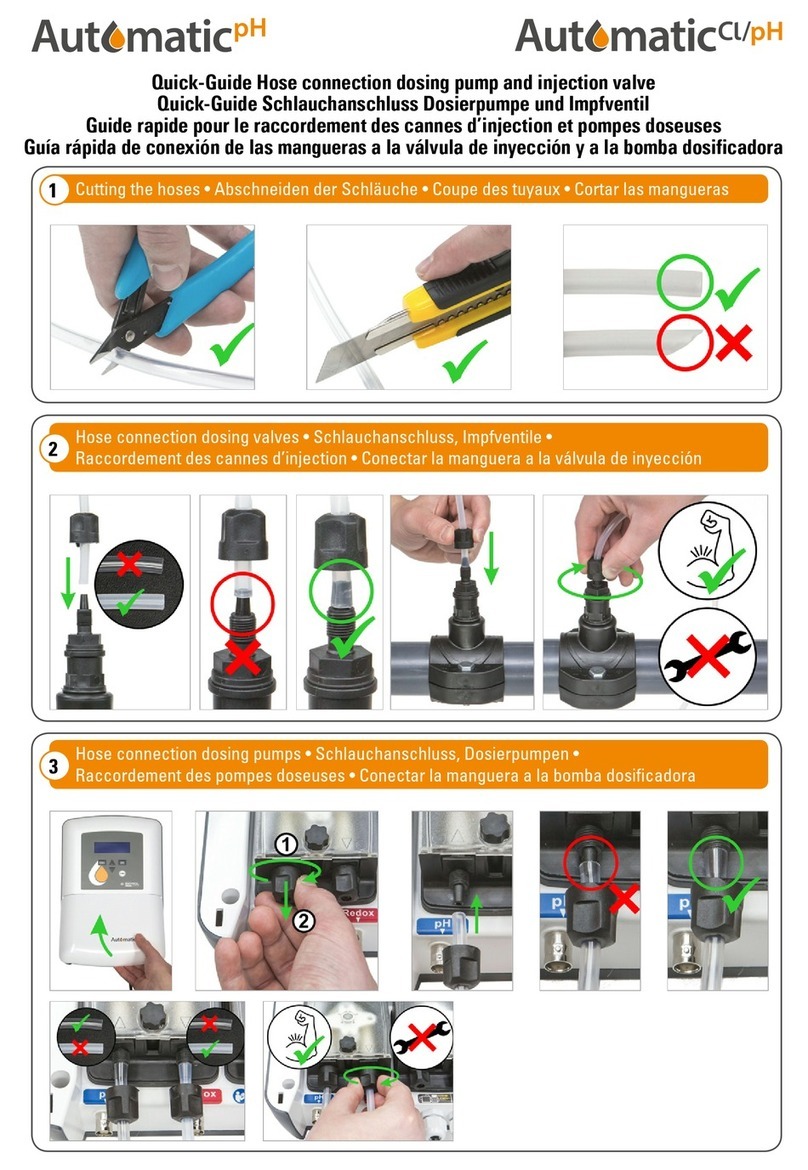

4. Installation in the circulation

system

The Flockmatic is supplied ready for installation on a panel for

wall mounting. The pump is preferably mounted at a height of

about 1.5 m on the wall. The container with

Quickflock Automatic Plus is placed directly under the

Flockmatic pump in order to keep the Suction tube as short as

possible. Read the safety instructions on the label of the

container of Quickflock Automatic Plus. Do not dispense any

liquids other than liquid flocculant with this pump!