WARNING: DISCONNECT POWER TO PUMP AND OPEN VALVE TO

RELIEVE WATER PRESSURE PRIOR TO SERVICING PUMP

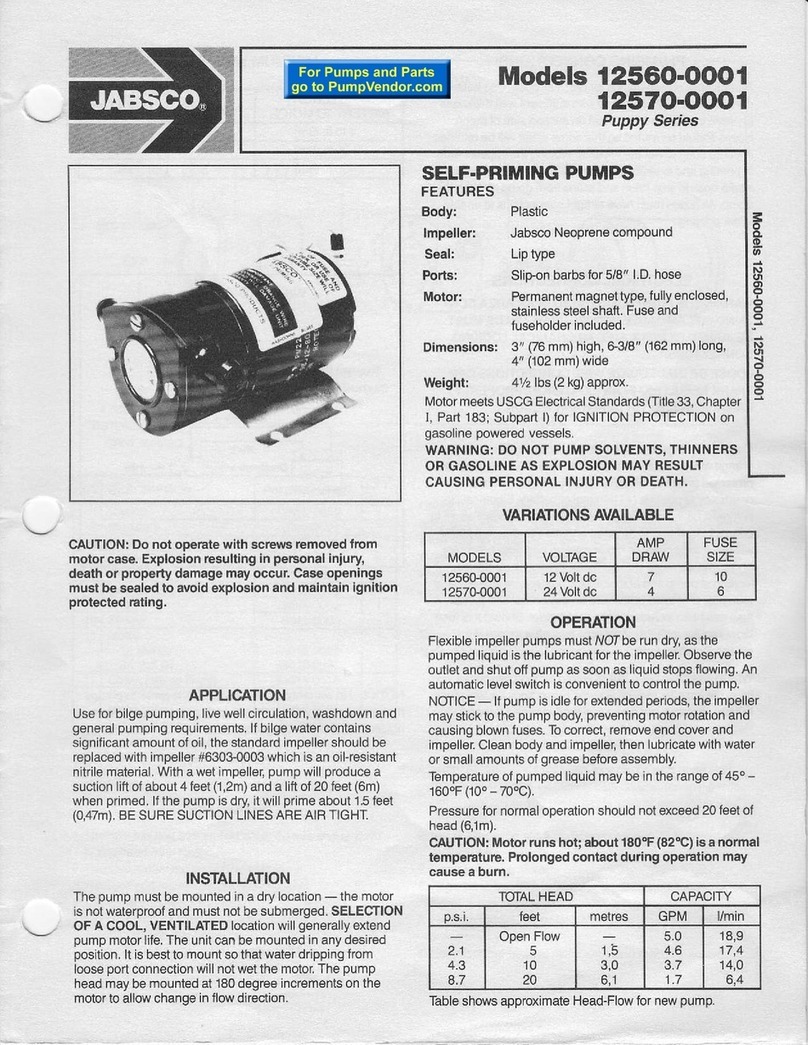

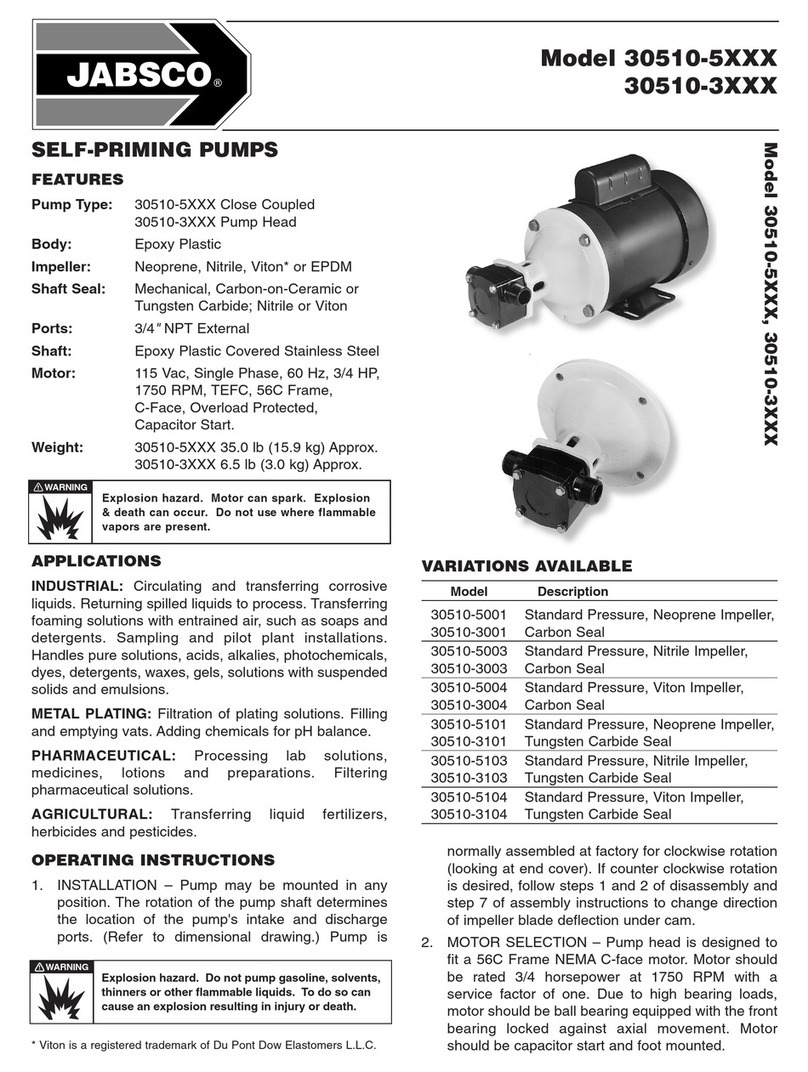

KEY DESCRIPTION

1

2

3

4

5

*

7

8

QTY

1

1

1

2

1

1

1

1

1

1

Pressure switch

Pump head

ValveKit

Slide clips

Motor 12 V

24 V

*PumpgardTM Strainer

*Spray Nozzle US

*Spray Nozzle EC Adapter

*Hose Coil, 25’

18916-1060

18914-1060

18911-1030

30647-1000

18919-0187

18919-1080

46400-9500

30703-1000

30704-1000

31910-3015

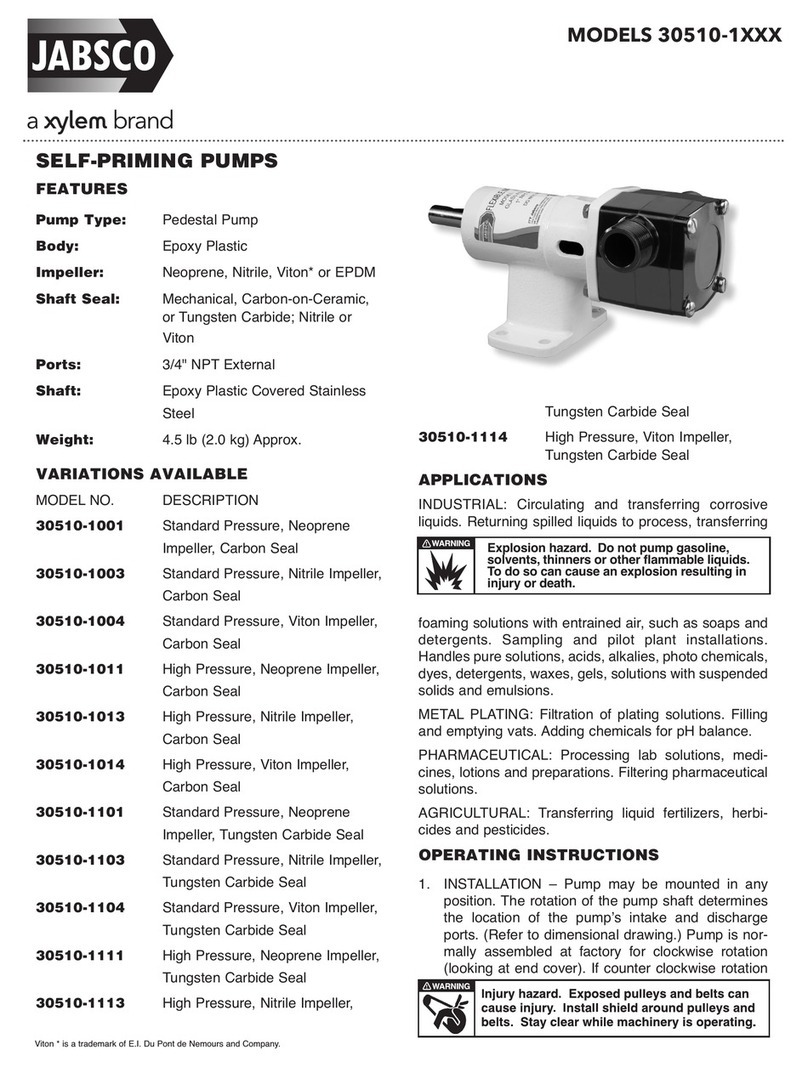

31605-SERIES — PART NO.

EXPLODED VIEW

*Not shown in the above drawing

3.

Reinstall the two wires onto the spade connectors, then install

the switch cover and screw.

Check Valve Assembly

4. Install the o-ring into the o-ring groove located on the

discharge side of the check valve chamber assembly.

5. Install the check valve chamber assembly into the

diaphragm, thus aligning the check valve chamber with the

diaphragm seal walls (push in to secureto the diaphragm).

Upper Housing Assembly

6. With the check valve chamber sub assembly installed on

the diaphragm, place the upper housing assembly onto the

pre-assembled lower housing sub assembly.

7. Align the cam with the motor "D" shaft and motor list, then

slide the cam onto the motor shaft (lube the motor shaft

with a small amount of light grease).

8. Check the discharge location (see arrow on front of port) for

correct port orientation (discharge right is the standard

position).

9. Install the six pump head screws through the upper hous-

ing, 3 screws will engage to lower housing. The other 3

screws will go through the lower housing into the front end

bell assembly aligning the three pins on the front end bell

with the 3 holes on the lower housing and tighten securely.

Motor Assembly

10.

Install the pump head by following steps 6 through 9.

Pump Housing

(For numbers, refer to exploded view)

1. Disconnect power to the pump motor.

2. Remove the pressure switch cover and remove the two

wire leads from the switch spade connectors.

3. Remove the six screws from the upper housing.

4. Remove the upper housing from the check valve and

diaphragm/lower housing assemblies.

Check Valve Assembly

(To replace check valve only follow steps 1 through 6)

5. The check valve chamber and o-ring are located on the

diaphragm/lower housing assembly.

6. Remove the check valve chamber subassembly from the

diaphragm/lower housing subassembly (pull the valve

chamber from the diaphragm).

Motor Replacement

7. To replace the motor only,follow steps 1 and 2, then dis-

connect 3 screws, and pull the pump head out. Replace the

motor with washer and gasket.

REASSEMBLE

PressureSwitch Assembly

1. Install the switch diaphragm into upper housing.

2. Install the switch body over the diaphragm, align the screw

holes and install the two mounting screws.

DISASSEMBLE