BBC 7.5HK500 Installation and operating instructions

This manual suits for next models

2

Table of contents

Other BBC Security Sensor manuals

Popular Security Sensor manuals by other brands

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL IR 180 Information

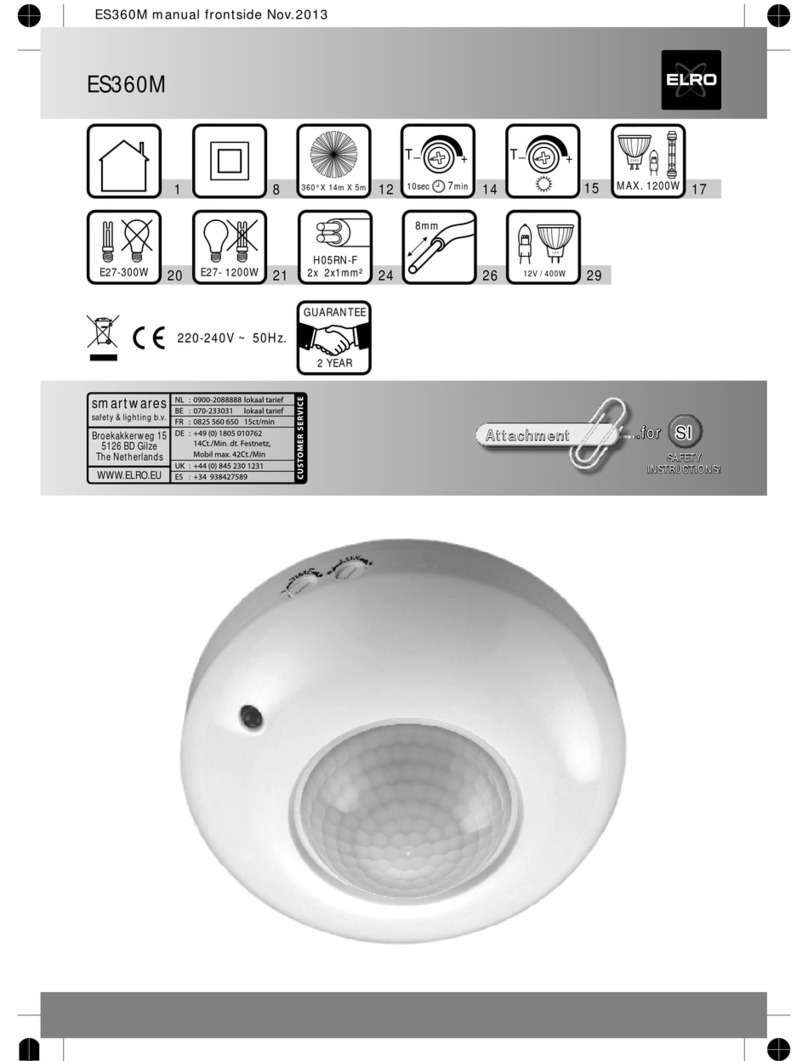

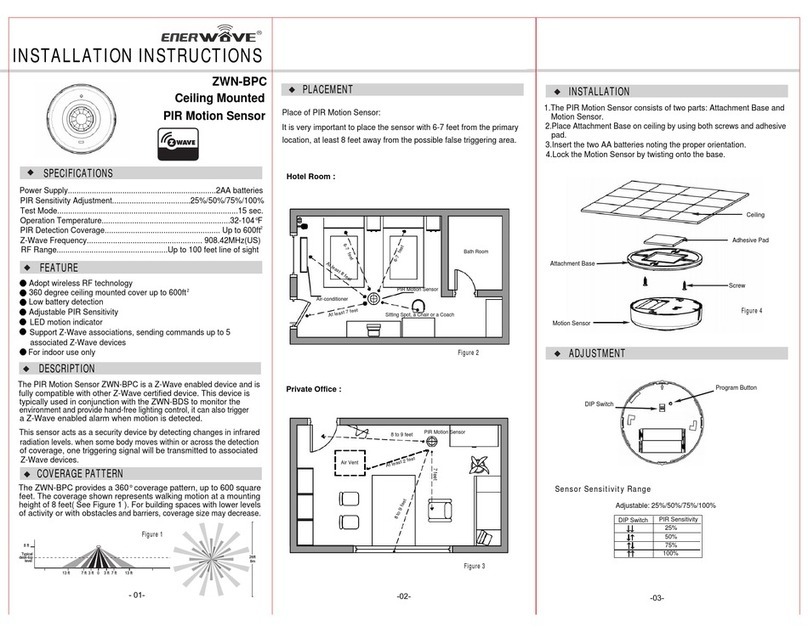

Enerwave

Enerwave ZWN-BPC installation instructions

DBI SALA

DBI SALA Hot Work NANO-LOK SRL Series instruction manual

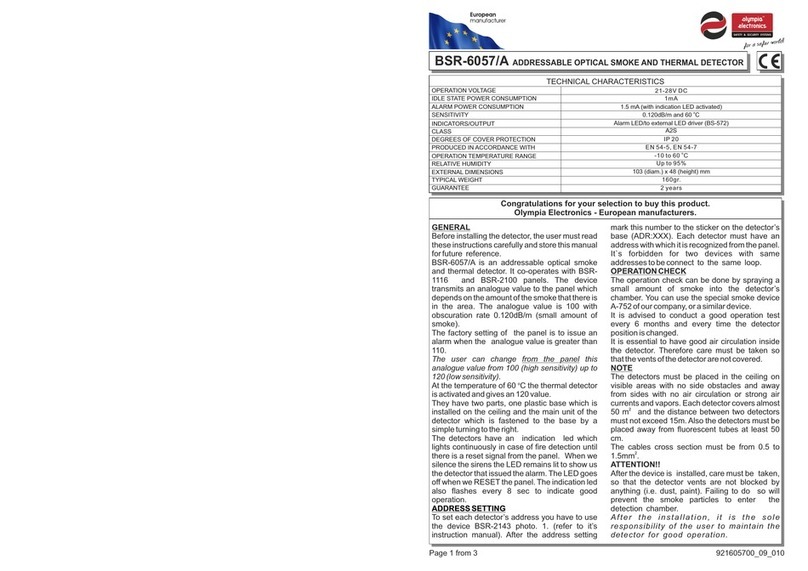

olympia electronics

olympia electronics BSR-6057/A quick start guide

Bosch

Bosch RFPR-ZB installation guide

B.E.G.

B.E.G. LUXOMAT PD2-M-2C-24V Installation and operating instruction

Westfalia

Westfalia 961151 instruction manual

Bircher

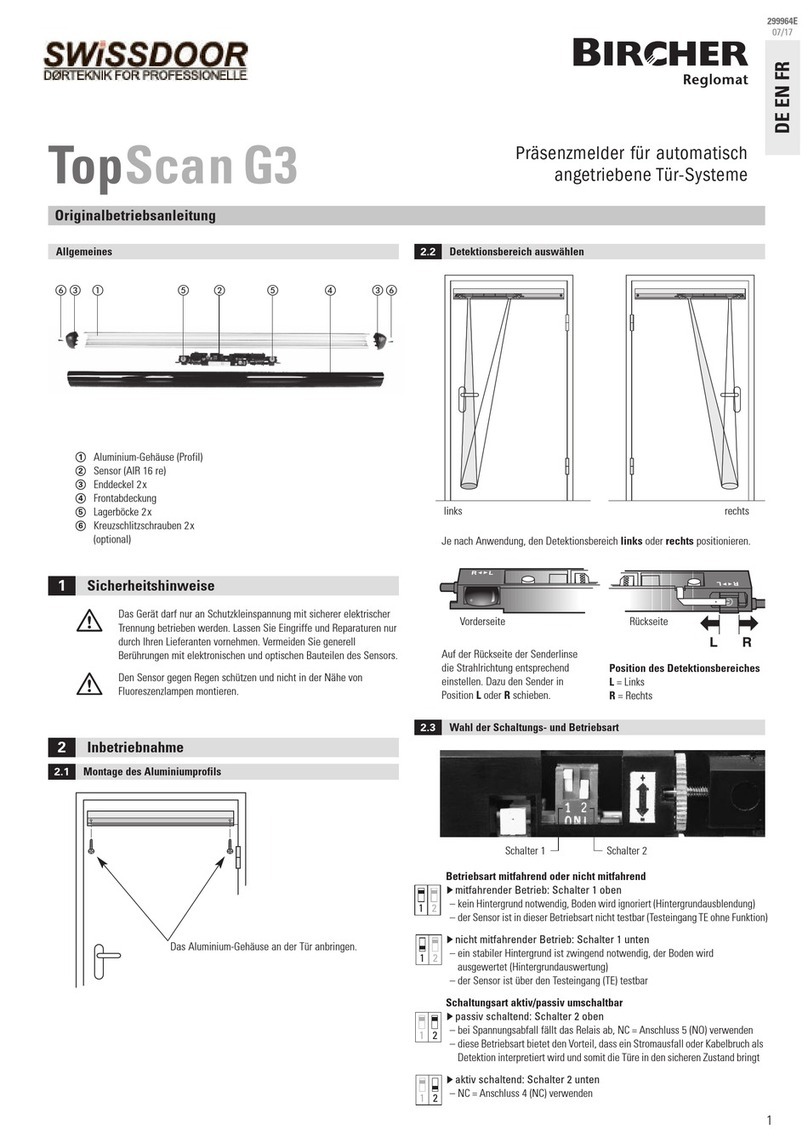

Bircher TopScan G3 Translation of the original instructions

REV Ritter

REV Ritter LED GIGA SENSOR Assembly and operating instructions

AVS Electronics

AVS Electronics BF100 R manual

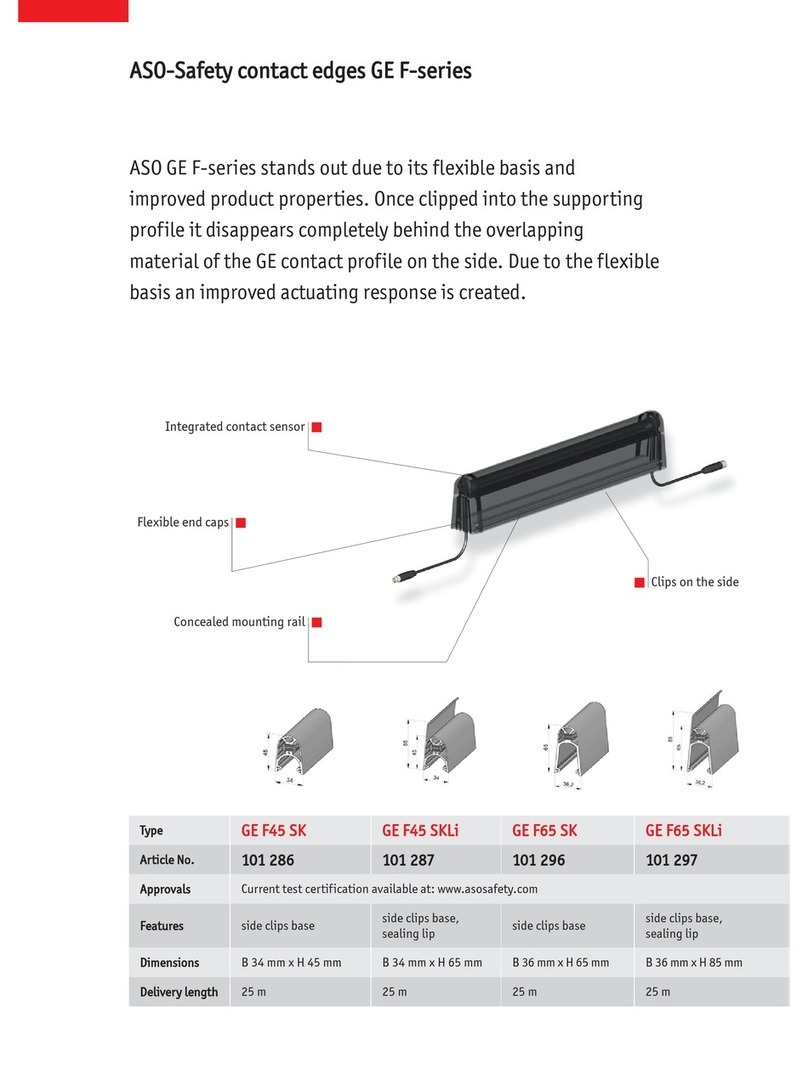

ASO Safety Solutions

ASO Safety Solutions GE F-series manual

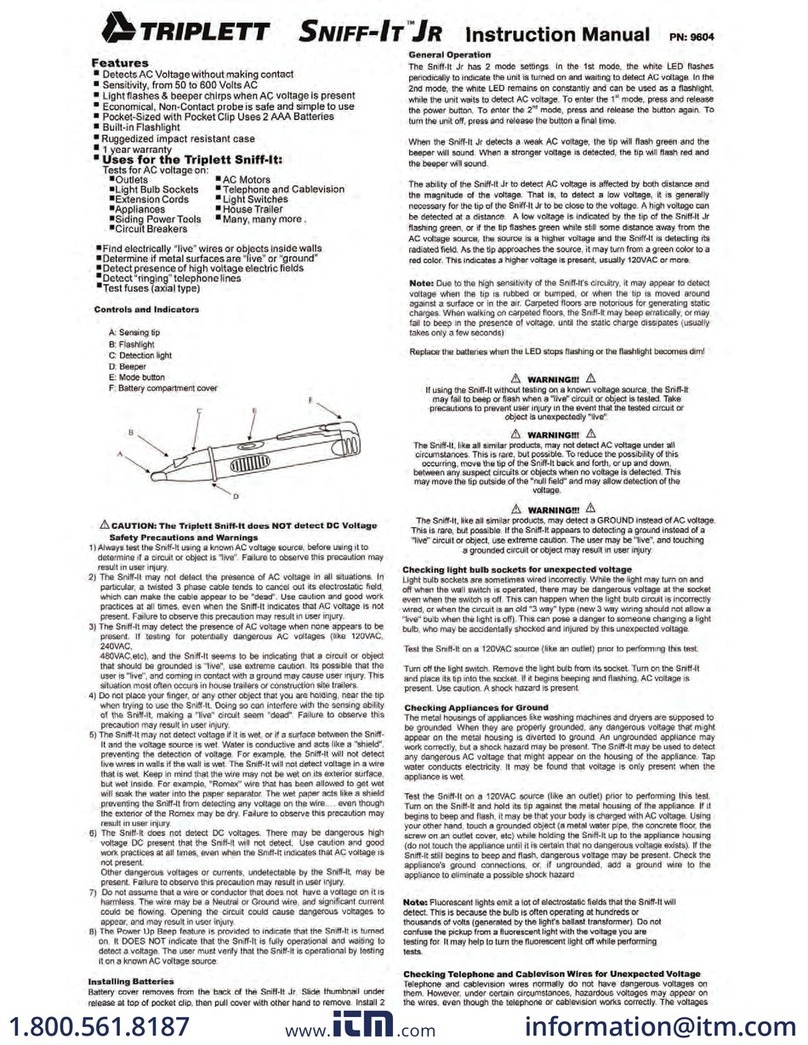

Extech Instruments

Extech Instruments DV690 user manual