BBH SCU Series User manual

Installation Manual

English

SCU Series

FSoE Master and Slaves

Read and observe installation manual before initial

commissioning/initial startup/ integration of the module!

Observe safety instructions!

Keep for future use!

i

Information

Man

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 2 of 303

Status: 29.04.2022

Installation manual for SCU series devices

Status: 06/2022

INFORMATION

The German version is the original Version of the installation manual.

Contact the manufacturer immediately if the instructions are missing!

Always keep the manual at hand!

Make sure that the manual is complete!

Obtain this document only through the original publisher!

Subject to technical changes!

The content of this documentation has been compiled with the utmost

carefulness, and corresponds to our current state of information.

Nevertheless, we point out that the technical update of this

documentation cannot always be carried out simultaneously with the

technical evolution of our products.

Information and specifications can always be changed. For the current

version, please refer to www.bbh-products.de.

Manufaturer BBH Products

BBH Products GmbH

Böttgerstraße 40

92637 Weiden

GERMANY

i

Information

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 3 of 303

Status: 09.06.2022

Man

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 4 of 303

Status: 09.06.2022

Man

1. Inventories

1.1. Table of contents

1. Inventories .................................................................................................4

1.1. Table of contents 4

1.2. Table of illustrations 10

1.3. List of tables 12

2. Basic information ......................................................................................13

2.1. Identification 13

2.2. Important information for use 13

2.3. Warranty claims 14

2.4. Liability exclusion 14

2.5. Copyright 14

2.6. Brands 14

2.7. Supplied documents 15

2.8. Symbols and signal words 16

2.8.1. Safety information 16

3. Safety .......................................................................................................17

3.1. General safety information 17

3.2. Target group 18

3.3. Terms 20

3.4. Relevant standards and directives 21

3.5. Intended use 22

3.6. Storage and transport 23

3.7. Placement 24

3.8. Electrical connection 25

3.9. Behaviour in case of emergencies 26

3.10. Safe status 26

3.11. Scope of delivery SCU 27

3.12. Labelling / rating plate SCU 28

3.12.1. Rating plate SSB-x-x-x 29

4. Use............................................................................................................30

4.1. Device description 30

4.1.1. Function 30

4.1.2. Embedding into the EtherCAT network and into FSoE 31

4.1.2.1. FSoE data transfer 31

4.1.2.2. EtherCAT network 31

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 5 of 303

Status: 09.06.2022

Man

4.1.2.3. EtherCAT data transfer 32

4.1.2.4. FSoE and EtherCAT 32

4.1.3. The principle of safe monitoring with SCU 34

4.2. Operation and service 34

5. General structure of the SCU assemblies ..................................................35

5.1. FSoE Master (SCU) 35

5.2. FSoE-Slaves (SDU, SIO, SSB) 36

5.2.1. SDU-x 36

5.2.2. SIO-x 38

5.2.3. SSB-x-x-x 39

5.3. Encoder specifications 40

6. Technical specifications of the SCU series.................................................42

6.1. SCU Master 42

6.1.1. SCU-0-EC/x 42

6.1.2. SCU-1-EC/x 42

6.1.3. SCU-2-EC/x 42

6.2. SCU Slaves 42

6.2.1. SDU-11 42

6.2.2. SDU-11/NM 42

6.2.3. SDU-11-PXV 42

6.2.4. SDU-12 42

6.2.5. SDU-21 43

6.2.6. SDU-21A 43

6.2.7. SDU-22 43

6.2.8. SDU-22A 43

6.2.9. SIO-1 43

6.2.10. SIO-2 43

6.2.11. SSB-x-x-x 43

6.3. Additional information 44

6.3.1. Cable lengths 44

6.3.2. Derating outputs 44

7. Connection and installation.......................................................................45

7.1. General notes on installation 45

7.2. Installation / mounting 47

7.2.1. Mounting 47

7.3. Wiring 48

7.4. Terminal schemes 49

7.4.1. SCU Master 49

7.4.2. SCU Slaves 49

7.5. External DC 24 V –voltage supply 50

7.6. Connection of the external encoder supply 52

7.6.1. Incremental, HTL, SIN/COS, SSI 52

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 6 of 303

Status: 09.06.2022

Man

7.6.2. Resolver 53

7.7. Connection of digital inputs 54

7.8. Connection of analog inputs 55

7.9. Connection of position and speed sensors 56

7.9.1. General information 56

7.9.2. Assignment of encoder interface 58

7.9.2.1. ENC 1.1 / ENC 2.11) 58

7.9.2.2. ENC 1.2 / ENC 2.22) 58

7.9.3. Connection varaints 59

7.9.3.1. Connection of an absolute encoder as master 59

7.9.3.2. Connection of an absolute encoder as slave 60

7.9.3.3. Connecting an incremental encoder with TTL-Signal level 61

7.9.3.4. Connection of a SIN/COS encoder 62

7.9.3.5. Connection of a resolver as master 63

7.9.3.6. Connection of a resolvers as slave 64

7.9.3.7. Connection of proximity switch SDU-1x/-2x 65

7.9.3.8. Connection of HTL/proximity switch SDU12/SDU22x 65

7.9.3.8.1. HTL-encoder with A+/A- or B+/B- signal 65

7.9.3.8.2. HTL-encoder with A+ or B+- signal 66

7.10. Configuration of measuring distances 67

7.10.1. Genreal description of encoder configuration 67

8. Sensor type diagnoses ..............................................................................68

8.1. Absolute encoder: 68

8.2. Incremental encoder: 70

8.3. SinusCosinus encoder –Standard mode 70

8.4. SinusCosinus encoder –High resolution mode: 71

8.5. Proxi –Switch 71

8.6. Extended monitoring Proximity switch / proximity switch 72

8.7. HTL –Sensor 73

8.8. Resolver 74

9. Reaction time............................................................................................75

9.1. Response time at standstill: 75

9.2. Response time of FSoE in Fastchannel operation: 79

9.3. Response times for error distance monitoring 80

10. Safety-related characteristics ................................................................83

10.1. Internal architecture 83

10.2. Safety related characteristic data and wiring for the connected

sensors 85

10.2.1. Digital sensors 85

10.2.1.1. Charakteristics of sensors / input elements 85

10.2.1.2. DC of digital sensors / inputs 86

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 7 of 303

Status: 09.06.2022

Man

10.2.1.3. Classification of digital inputs 90

10.2.1.3.1.Digital inputs I00 … I13 90

10.2.1.3.2.Digital inputs I/Os (IQIx) 91

10.2.1.4. Exemplary connections of digital sensors 92

10.2.1.4.1.Single-channel sensor, without cross-shorting test 92

10.2.1.4.2.Single-channel sensor with cross-shorting test 92

10.2.1.4.3.Dual-channel sensor without time-out and without cross-shorting 94

10.2.1.4.4.Dual-channel sensor with time-out and cross-shorting test 96

10.2.1.5. Overview of achievable PL for digital safety inputs 97

10.2.2. Sensors for speed and/or position detection 99

10.2.2.1. General safety related structure of sensor interface for position

and/or speed 99

10.2.2.2. General diagnostic measures for encoder interface 100

10.2.2.3. Encodertypen und deren Kombination, Diagnosekenndaten 101

10.2.2.4. Specific diagnostic measures with regard to the encoder type used 104

10.2.2.5. Safety-related switch-off threshold encoder systems for position

and speed detection 105

10.2.2.6. Safety-related evaluation of encoder systems, resolvers or their

combination 108

10.2.3. Analog sensors 110

10.2.3.1. Exemplary connection of analog sensors 111

10.2.3.1.1.Voltage and current sensor 111

10.2.3.1.2.Voltage sensor with test pulse 112

10.2.3.1.3.Current sensor with test pulse 112

10.3. Safety related characteristic data and wiring of the outputs 113

10.3.1. Charakteristic of output elements 113

10.3.2. Diagnoses in the cut-off circuit 115

10.3.2.1. Diagnostic functions 115

10.3.2.2. Overview DC with respect to the chosen diagnostic functions 116

10.3.3. Permissable capacitive and inductive load at safe outputs 117

10.3.4. Digital outputs 118

10.3.4.1. Characteristic data of the basic outputs 118

10.3.4.2. Wiring examples basic outputs 120

10.3.4.2.1.Single-channel switching relay or semi-conductor output

without test 120

10.3.4.2.2.Single-channel switching relay or semi-conductor output

with external switching amplifier and testing 121

10.3.4.2.3.Single-channel switching relay or semi-conductor output

with dual-channel external circuit with testing 122

10.3.4.2.4.Dual-channel switching relay output with external monitoring

- group feedback 124

10.3.4.2.5.Dual-channel output with relay output and semi-conductor output

–external control circuit with monitoring 125

10.3.4.2.6.Dual-channel output with relay output and external control

circuit in PL e 126

10.3.4.2.7.Dual-channel output with semi-conductor output and external control

circuit in PL e 126

10.3.4.2.8.Wiring of a auxiliary output 127

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 8 of 303

Status: 09.06.2022

Man

10.3.5. Digital outputs I/Os (IQx) 128

10.3.5.1. Classification of the I/Os (IQx) when used as output 128

10.3.5.2. Wiring examples for safe digital outputs I/O ‘s (IQx) 129

10.3.5.2.1.Wiring single-channel without testing 129

10.3.5.2.2.Wiring single-channel with testing 130

10.3.5.2.3.Wiring with safe cut-off circuit 131

10.3.5.2.4.Wiring in connection with two-channel switching cut-off 131

10.3.5.2.5.Redundant two-channel output 132

10.3.5.2.5.1.Wiring dual-channel in the same group 132

10.3.5.2.5.2.Wiring dual-channel in diffrent groups 133

10.3.5.3. Overview of achievable PL for digital safety outputs 134

11. Commissioning and start......................................................................137

11.1. Switch-on sequence 137

11.2. Reset behaviour 138

11.2.1. Types of Reset and triggering events 138

11.2.2. Timing of Reset 139

11.2.3. Reset functions 140

11.3. LED displays 142

11.4. Parametrization 143

11.5. Regular function test 143

11.6. Validation 143

11.6.1. Process 144

11.6.2. Configuration report 145

11.6.2.1. Structure of the configuration report 145

11.6.2.2. Creating a configuration report 145

11.6.2.3. Filling in the configuration report 145

12. Safety inspection .................................................................................147

13. Maintenance.........................................................................................148

14. Failure and troubleshooting .................................................................148

15. Replacing an assembly.........................................................................148

16. Decommissioning / disassembly / disposal .........................................149

17. Setting as EtherCAT Slave with TwinCAT3............................................150

17.1. Installing the program 150

17.2. Creating a new project / Creating a new EtherCAT network 150

17.3. EoE settings in TwinCAT (EtherCAT settings) 159

18. Information for design, programming, validation and test...................161

18.1. Risk analysis 161

18.2. Necessary technical documents 164

18.3. Necessary steps –design, realization and test 165

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 9 of 303

Status: 09.06.2022

Man

18.3.1. Specification of the safety requirements 167

18.3.2. Specification of the safety system 169

18.3.3. Software specification 171

18.3.4. Hardware specification 171

18.3.5. Selection of the SRP/CS and selection of the equipment 171

18.3.6. Consideration of systematic failures 172

18.3.7. Fault exclusions 173

18.3.8. Hardware design and software design 174

18.3.8.1. Testing of the hardware design 174

18.3.8.2. Analysis of the circuit diagram 174

18.3.8.3. Iterative test of the achieved safety level 175

18.3.8.4. Verification of the software and parameters 175

18.3.8.5. Validation of the functional scheme against the Instruction List (AWL)

and parameters via a validation report 175

18.3.8.6. Execution of system tests / FIT (Fault Injection Test) 175

19. List of abbreviaions..............................................................................176

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 10 of 303

Status: 09.06.2022

Man

1.2. Table of illustrations

Fig. 1: rating plated SCU-2-EC/NM............................................................................ 28

Fig. 2:Network EtherCAT ......................................................................................... 32

Fig. 3:example FSoE Netzwerk FSoE ......................................................................... 33

Fig. 4: strucutre of SCU-2-EC/NM ............................................................................ 35

Fig 5: structure of SCU-1-EC ................................................................................... 35

Fig. 6: structure of SDU-11-PXV ............................................................................... 36

Fig. 7: structure of SDU-22A .................................................................................... 37

Fig. 8: structure SIO-2 ............................................................................................ 38

Fig. 9: structure of SSB-6-x* ................................................................................... 39

Fig. 10: mounting of the top-hat rail ......................................................................... 47

Fig. 11: 2-channel architecture................................................................................. 83

Fig. 12: total architecture ........................................................................................ 83

Fig. 13: Digital sensor 2-channel parallel ................................................................... 85

Fig. 14: Digital sensor 2-channel serial...................................................................... 85

Fig. 15: digital sensor one-channel ........................................................................... 86

Fig. 16: Single-Channel sensor, without cross-shorting test ......................................... 92

Fig. 17: Single-channel sensor with cross-shorting test ............................................... 92

Fig. 18: dual-channel sensor homogenous without cycling, with positive disconnection.... 94

Fig. 19: dual-channel input element heterogeneous, without cycling ............................. 94

Fig. 20 dual-channel sensor homogenous with clock.................................................... 96

Fig. 21: dual-channel sensor system with separate signal processing ............................ 99

Fig. 22: Sensor system with single-/dual-channel partial system .................................. 99

Fig. 23 Course of fault in V-detection .......................................................................105

Fig. 24: Single-channel switching P-output................................................................120

Fig. 25: Single-channel switching relay output...........................................................120

Fig. 26: Single-channel relay output with testing .......................................................121

Fig 27: Single-channel switching outout QX00_PP with dual-channel external circuit

and monitoring at output 13 as group feedback.........................................................122

Fig. 28: Single-channel switching output QX00_PP with dual-channel external circuit as

combination of electro-mechanical element and hydraulic/pneumatic valve and

monitoring at two inputs.........................................................................................123

Fig. 29: Two-channel switching relay output with external monitoring –group feedback.124

Fig. 30: Dual-channel output with relay output and semi-conductor output –external

control circuit with monitoring .................................................................................125

Fig. 31: Dual-channel output with relay output –external control circuit in PL e ............126

Fig. 32: Dual-channel output with semi-conductor output and external control

circuit in PL e ........................................................................................................126

Fig. 33 wiring of a notification output .......................................................................127

Fig. 34: Two-channel output with single-channel wiring without testing ........................129

Fig. 35: Two-channel output with single-channel wiring with testing.............................130

Fig. 36: two-channel output in connection with a device with examined disconnection....131

Fig. 37: two-channel output in connection with two-channel cut-off circuit with testing ..131

Fig. 38: Redundant two-channel outputs in the same group in connection with

two-channel cut-off circuit ......................................................................................132

Fig. 39: Redundant two-channel outputs in different groups in connection with

two-channel switching-off circuit..............................................................................133

Fig. 40: Timing of Reset .........................................................................................139

Fig. 41: Reset function 1 ........................................................................................140

Fig. 42: Reset function 2 ........................................................................................140

Fig. 43: Reset function 3 ........................................................................................141

Fig. 44: starting TwinCAT .......................................................................................151

Fig. 45: TwinCAT –Geräte einfügen [TwinCAT - insert devices] ...................................151

Fig. 46: TwinCAT - Master einfügen [TwinCAT –insert Master] ....................................152

Fig..47: TwinCAT –SCU einfügen [TwinCAT - insert SCU] ...........................................152

Fig .48: TwinCAT –IO devices.................................................................................153

Fig. 49: TwinCAT –IO devices.................................................................................154

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 11 of 303

Status: 09.06.2022

Man

Fig. 50: TwinCAT –setting Slaves ...........................................................................154

Fig. 51: TwinCAT - linking.....................................................................................155

Fig. 52: TwinCAT –insert SDC.................................................................................156

Fig. 53: TwinCAT - Task .........................................................................................156

Fig .54: TwinCAT connection ..................................................................................157

Fig. 55: TwinCAT –time parameters ........................................................................158

Fig. 56: TwinCAT –RUN .........................................................................................158

Fig 57: TwinCAT –EoE settings ...............................................................................159

Fig 58: TwinCAT –IP ports .....................................................................................159

Fig 59: TwinCAT –pinging of the Slaves ...................................................................160

Fig 60: TwinCAT + SafePLC2...................................................................................160

Fig 61: risk analysis ...............................................................................................161

Fig 62: risk graph according to EN 13849-1 ..............................................................162

Fig. 63: technical documents according to the Machine Directive .................................164

Fig. 64: V model....................................................................................................165

Fig. 65: safety requirements ...................................................................................169

Fig. 66: decision pathway according to SISTEMA .......................................................170

Fig. 67: Systematic failurese ...................................................................................172

1

Inventories

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 12 of 303

Status: 09.06.2022

Man

1.3. List of tables

Table 1: reaction time ............................................................................................ 77

Table 2: calculation of response time without Overspeed ............................................ 82

Table 3: calculation of response time with Overspeed................................................. 82

Table 4: 7-segment display....................................................................................138

Table 5: types of Reset..........................................................................................139

Table 6: Reset functions ........................................................................................140

Table 7: LED displays ............................................................................................142

Table 8: Phases of the V model ..............................................................................166

Table 9: Abbreviations...........................................................................................177

2

Basic information

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 13 of 303

Status: 09.06.2022

Man

2. Basic information

2.1. Identification

Units of SCU series: SCU-x-EC/x, SDU-x, SIO-x and SSB-x-x-x

Firmware Version: The firmware version is indicated on the

device rating plate.

Hardware Version: The hardware version is indicated on the

device rating plate.

BBH Products GmbH

Böttgerstraße 40

92637 Weiden

Germany

phone:

+49 961 / 4 82 44 0

fax:

e-Mail:

2.2. Important information for use

The documentation is part of the product and contains important information on the

integration of the module into devices as well as on their operation and service. The

programming and parameterization of the devices are described in the programming

manual. Their exact knowledge and understanding is a mandatory prerequisite for

installation or modification of the device function or device parameters.

The documentation is intended for all persons involved in integration and installation

planning and who perform assembly, installation, commissioning and service work on the

product.

The documentation must be made available to this group of persons in a legible condition.

Make sure that the persons responsible for planning and integration, plant and operation,

as well as persons who work with the modules under their own responsibility, have read

and understood the documentation in full.

In case of ambiguities or further information requirements, please contact BBH Products

GmbH.

2

Basic information

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 14 of 303

Status: 09.06.2022

Man

2.3. Warranty claims

Compliance with the following documentation is a prerequisite for trouble-free

operation and the fulfillment of any warranty claims. Therefore, read the

documentation first before you start planning the integration and/or work with

the connected devices from BBH Products GmbH!

Make sure that the documentation is made available in a legible condition to

integration and installation planners, employees and persons who carry out

assembly, installation, commissioning and service work on the product, to

persons responsible for the system and its operation, and to persons who work

on the devices under their own responsibility.

2.4. Liability exclusion

Observance of this documentation and the documentation on the connected

devices from BBH Products GmbH is a basic prerequisite for safe operation and

for achieving the specified product properties and performance characteristics.

BBH Products GmbH assumes no liability for personal injury, property damage or

financial loss resulting from non-observance of the documentation.

Liability for material defects is excluded in such cases.

2.5. Copyright

© 2022 - BBH Products GmbH. All rights reserved.

This document is subject to German copyright law. Copying, editing, distribution,

and every kind of processing outside the limits require the written consent of the

respective author, or rather, of the respective creator.

2.6. Brands

The product names mentioned in this documentation are brands or registered

trademarks of the respective titleholders.

EtherCAT is a technological standard for

fieldbus systems.

EtherCAT® is a registered trademark and a

patented technology, licensed by

Beckhoff Automation GmbH, Germany,

Deutschland.

2

Basic information

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 15 of 303

Status: 09.06.2022

Man

2.7. Supplied documents

The following documents must be read carefully andmust be considered during

installation.

•Programming manual SafePLC²:

➔

HB-37480-820-01-xxF-DE programming Manual SafePLC2

•Programming manual SCU:

➔HB-37500-820-10-xxF-EN SCU programming manual

➔HB-37500-820-10-xxF-EN SCU programming manual-SARC

•Error list SCU series:

➔HB-37500-813-02-xxF-EN error list SCU

-Error list SDU devices:

➔HB-37500-813-03-xxF-EN error list SCU- SDU-modules

•Validation report (validation according to SafePLC² print):

➔Print of programming software

•Inspection report (TÜV inspection report for type release of the assemblies SCU, etc.):

➔Inspeciton report SCU series.

•Manufacturer documentation of the components integrated via the bus, and of the

directly integrated components.

➔External Documents

xx = Placeholder for the currently valid version

Always use the latest version of the documentation and software.

In case of ambiguities or further information requirements, contact the publisher directly.

If required, you can also request the documentation in printed form from

BBH Products GmbH

2

Basic information

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 16 of 303

Status: 09.06.2022

Man

2.8. Symbols and signal words

The following symbols and signal words are used in this documentation.

The combination of a pictogram and a signal word classifies the respective

safety note. The symbol may vary depending on the type of hazard.

Symbol

Signal word

Description

Death

DANGER

Draws yout attention to a dangerous situation

that will cause death or severe injury if it is not

avoided.

Injury + property

damage

WARNING

Draws wour attention to a dangerous situation

that can cause death or severe injury if it is not

avoided

CAUTION

Draws your attention to a dangerous situation

that can cause minor to moderate injury, if it is

not avoided.

Material

damage

ATTENTION

Draws your attention to possible malfunctions and

material damage.

No damage

NOTICE

Draws your attention to useful hints and tips that

can facilitate handling and operation.

SAFETY NOTE

Draws your attention to the use and the effects of

safety information.

2.8.1. Safety information

The safety information applies not only to one specific action, but to several

actions within a topic. The pictograms used indicate either a general or

specific hazard.

Structure of a safety notice:

SIGNALWORD

Description of the hazard source

Type and danger of the source.

Possible consequences in case of disregard.

3

Safety

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 17 of 303

Status: 09.06.2022

Man

3. Safety

The following general safety instructions are intended to prevent personal

injury and damage to property. The operator must ensure that the basic

safety instructions are observed and complied with.

Make sure that the persons responsible for planning and integration, the

persons responsible for the plant and its operation, as well as persons who

work on the device under their own responsibility have read and understood

the operating instructions completely.

In case of ambiguities or further information requirements, please contact

BBH Products.

3.1. General safety information

Never install, commission or start damaged products. Please complain

immediately to transport company about any damage.

Never open the device housing and / or never carry out modifications

arbitrarily. Mortal danger due to the loss of safety functions.

In case of improper use, incorrect installation or operation, there is a risk

of serious personal injury or property damage.

Further information can be found in the documentation.

DANGER

Working on the wiring or on the electric system can cause electric shock.

Electric shock can cause death or severe injuries due to electric current.

Therefore, work on the electric system may only be carried out by qualified

persons in according to TRBS 1203.

(For qualified persons, knowledge of valid regulations and standards as well

as oft he valid accident prevention rules is presumed).

NOTICE

Work may only be carried out after the Installation manual has been read

carefully and if the installation manual is strictly observed.

The device data (technical data) must be considered.

NOTICE

The content of this Installation manual is restricted to the basic function of

the devices. Programming and parametrizing of the devices is described in

the Programming manual. Exact knowledge and understanding of

programming and parametrization is the prerequisite for the installation and

the modification of both, the device function and the device parameters.

NOTICE

The devices may only be started (i. e. the start of an appropriate operation)

is only permitted in compliance with the specifications of the EMC Directive.

3

Safety

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 18 of 303

Status: 09.06.2022

Man

The underlying regulations are the EMC test regulations EN 55011 and

EN 61000-5-2.

NOTICE

The valid VDE regulations and other special safety regulations must be

observed.

NOTICE

The configured monitoring functions, as well as their parameters and their

links must be proved by a validation report.

WARNING

Inputs and outputs for standard functions, as well as digital data and

analogue data transmitted by communication units must not be used for

safety-related applications. Data errors can cause failures that can also

provoke unexpected start-up of the whole plant.

3.2. Target group

The persons involved in the planning for the integration of the assembly in

devices as well as for their use in applications must have sufficient

qualifications. This usually consists of a university or technical education

for electrical / electronic systems in combination with special knowledge of

the laws, regulations, standards and guidelines for the protection of

persons and property when dealing with machines and plants.

All installation, commissioning, troubleshooting and maintenance work

must be carried out by a qualified electrician (IEC 60364 or CENELEC

HD 384 or DIN VDE 0100 and IEC 60664 or DIN VDE 0110 and observe

national accident prevention regulations).

Qualified electricians in the sense of these basic safety instructions are

persons who are acquainted They must also be conversant with the

applicable safety regulations and laws, in particular the requirements of

EN ISO 13849-1 and the other standards, directives and laws mentioned

in this documentation.

The aforementioned persons must have the authorization explicitly

granted by the company to commission, program, parameterize, label and

ground devices, systems and circuits in accordance with the standards of

safety technology.

All work in the other areas of transport, storage, operation and disposal

must be carried out by persons who have been suitably instructed.

3

Safety

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 19 of 303

Status: 09.06.2022

Man

The following table explains the competencies of the target groups in detail:

Target group

Requirement and knowledge

project developer

Basic technical education (technical college, engineering

education or equivalent work experience).

Knowledge of:

▪the operation of a PLC,

▪safety regulations,

▪the application,

▪Project planning and validation of safety controls,

▪Project planning of EMC-compliant system

structures

Electrician

Specialized electrical training (in accordance with

industry training guidelines).

Knowledge of:

▪Safety regulations,

▪wiring guidelines,

▪circuit diagrams,

▪professional making of electrical connections

Commissioning

engineer

Basic technical education (university of applied

sciences, engineering education or corresponding

professional experience).

knowledge of:

▪safety regulations,

▪the operation of the machine or system,

▪basic functions of the application,

▪system analysis and troubleshooting,

▪the adjustment possibilities on the operating

devices.

▪Validation of safety controls

Service

technician

Basic technical education (university of applied

sciences, engineering education or corresponding

professional experience).

Knowledge of:

▪the operation of a PLC,

▪safety regulations,

▪the operation of the machine or plant,

▪diagnostic possibilities,

▪systematic error analysis and elimination

i

Information

Man

HB-37500-810-11-16F-EN SCU Installation Manual - Master and Slaves - SARC Page 20 of 303

Status: 29.04.2022

3.3. Terms

The SCU assemblies manufactured by BBH Products GmbH serve to implement

safety-relevant functions by safe communication via FSoE and non-safe communication by

means of EtherCAT. These are always having a two-channel design: systen A and

system B.

▪The term “safe” is used in accordance with the following standards: DIN EN ISO

13849-1, DIN EN 61508-1:2011-02 (cf, the chapter “Relevant standards”).

▪The term “Safe function for applications up to PL e or SIL 3“indicates

functions in line with the above standards with appropriate integrity (reliability).

▪The term "non-safe" refers to functions and data interfaces that do not or not

completely fulfill the requirements according to the aforementioned standards.

▪The system software “SafePLC2“serves for programming and configuration of the

SCU-assemblies manufactured by BBHProducts GmbH.

▪In this document, the abbreviation “SCU” refers to the FSoE Master assemblies

SCU-0-EC/x, SCU-1- EC/x and SCU-2-EC/x.

▪The abbreviations SDU, SIO and SSB refer to the FSoE slave assemblies of the

SCU series.

▪The -S variants of the assemblies are identical to the standard devices

Other manuals for SCU Series

1

Table of contents

Other BBH Controllers manuals

Popular Controllers manuals by other brands

Flycolor

Flycolor Raptor390 Tower F3 FC user manual

Danfoss

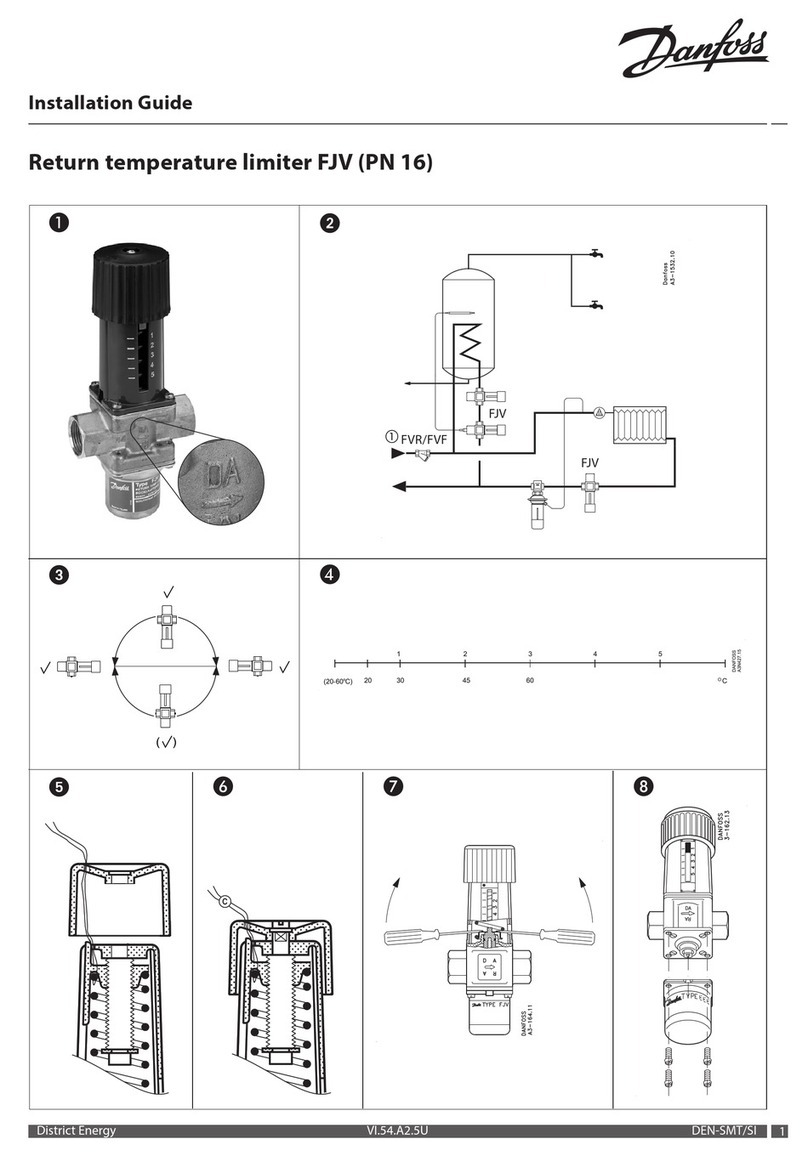

Danfoss FJV Series installation guide

Conductix-Wampfler

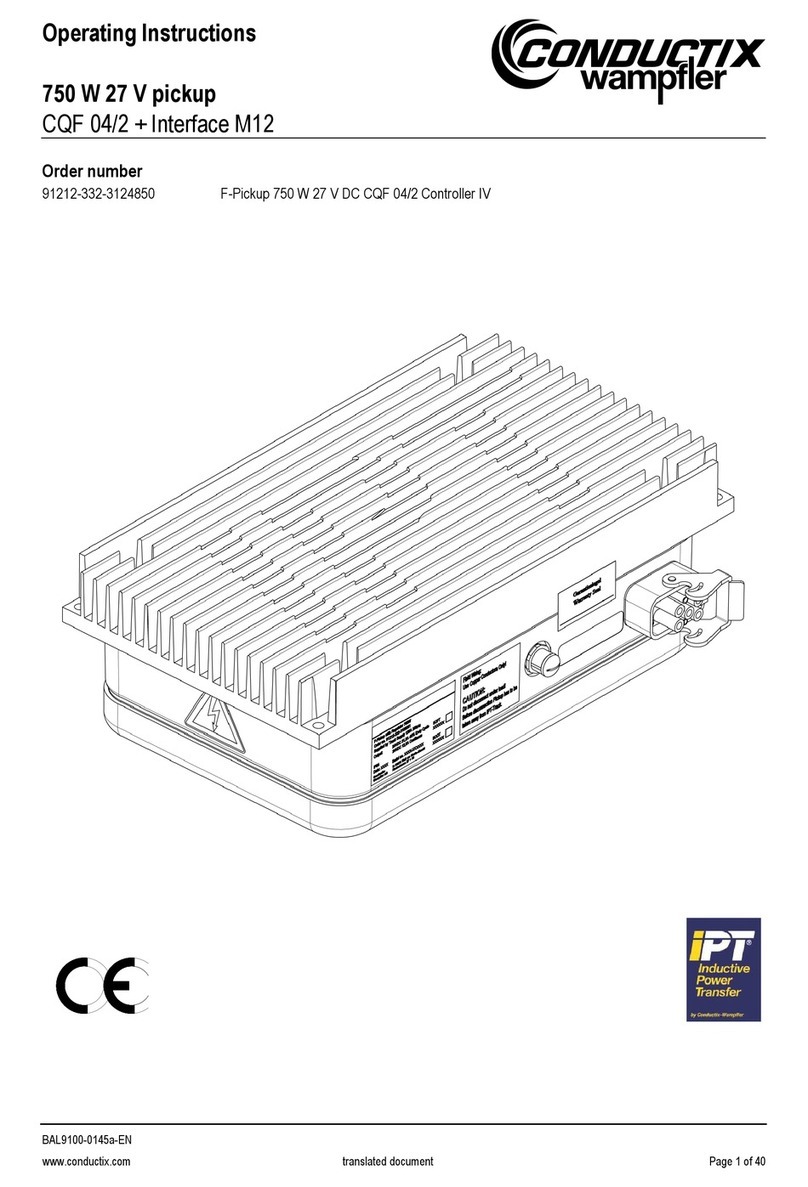

Conductix-Wampfler CQF 04/2 + Interface M12 operating instructions

Tropos Networks

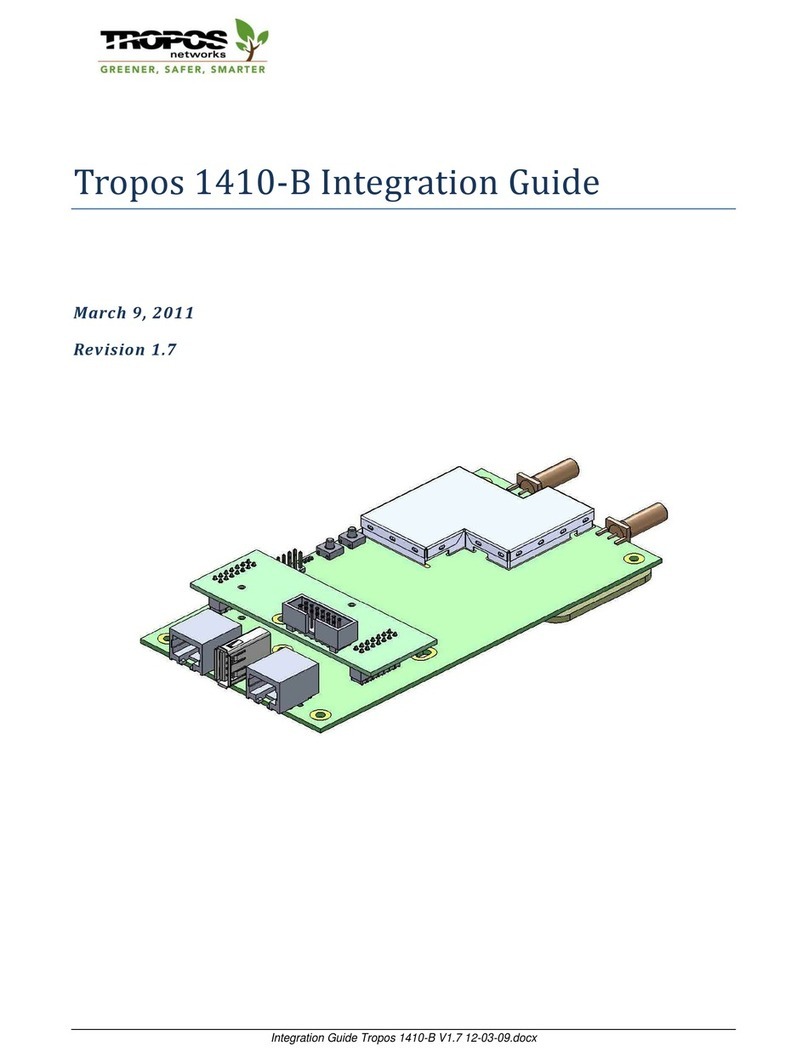

Tropos Networks 1410-B Integration guide

kayse

kayse LS30 Nstallation and operation guide

Compac

Compac C4000 Futra manual