BDS_sro_NAMO_DM2XX-DSXXX_CS-EN_290811

English

www.bdsensors.com

Návod k montáži /

Mounting instructions

Elektronické digitální manometry DM 2XX/

Electronic Pressure Gauge DM 2XX

Elektronické tlakové spínače DS 2XX a DS 4XX /

Electronic Pressure Switch DS 2XX or DS 4XX

DM 200, DM 201, DS 200, DS 200 P, DS 201, DS 201 P,

DS 202, DS 210, DS 217, DS 226, DS 400, DS 400 P,

DS 401, DS 401 P

Centrála východní Evropa /

Headquarters Ostern Europe

BD SENSORS s.r.o.

Hradišťská 817

CZ - 687 08 Buchlovice

Česká republika / Czech Republic

Tel.: +420 572 / 411 011

Fax: +420 572 / 411 497

Centrála západní Evropa /

Headquarters Western Europe

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Německo /

Germany

Tel.: +49 (0) 92 35 / 98 11-0

Fax: +49 (0) 92 35 / 98 11-11

Rusko /

Russia

BD SENSORS RUS

39a, Varshavskoe shosse

RU - Moscow 117105

Rusko /

Russia

Tel.: +7 (0) 9 59 81 / 09 63

Fax: +7 (0) 9 57 95 / 07 21

Tento návod k montáži je výtah z podrobného

návodu k obsluze. Ten si prosím stáhněte

z našich internetových stránek, pokud nejste

s výrobkem dobře seznámeni.

These mounting instructions are an excerpt from the complete

operating manual. It may be downloaded from our homepage,

if you are not familiar with the device.

www.bdsensors.cz

www.bdsensors.com

– Technické změny vyhrazeny –

– Technical modifications reserved –

WARNING! In order to avoid hazards to operators and

damages to the device, the following instructions have to

be performed by qualified technical personnel.

WARNING! Adhere to the safety and operating instructions

stated in the operation manual. Effective regulations on

occupational safety, accident prevention as well as national

installation standards and approved engineering tech-

niques must in addition be complied with.

Limitation of liability

If the instructions in the operating manual are not adhered

to or if the device is inappropriately used, modified or da-

maged, liability is not assumed and warranty claims will be

excluded.

Intended use

Ensure that the medium is compatible with the media-

wetted parts and that the device is suitable for the appli-

cation without restrictions. The technical data listed in the

current data sheet is binding and must definitely be obser-

ved.

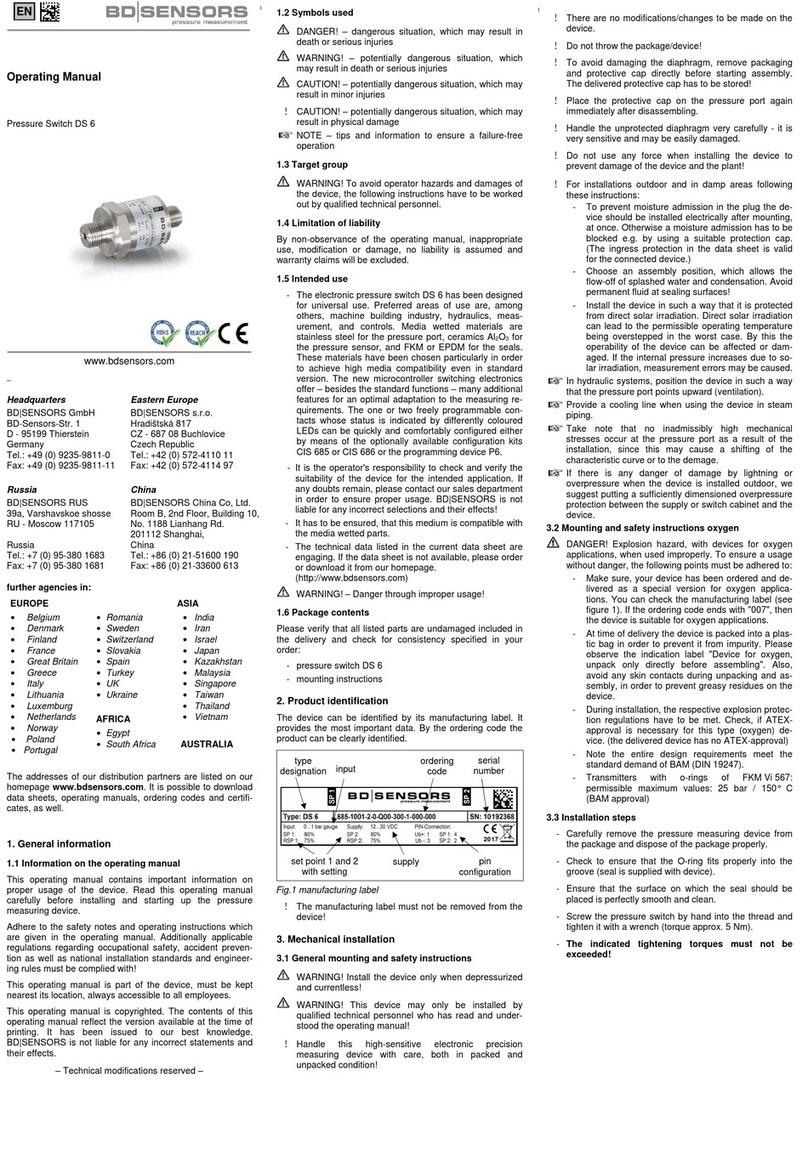

Product identification

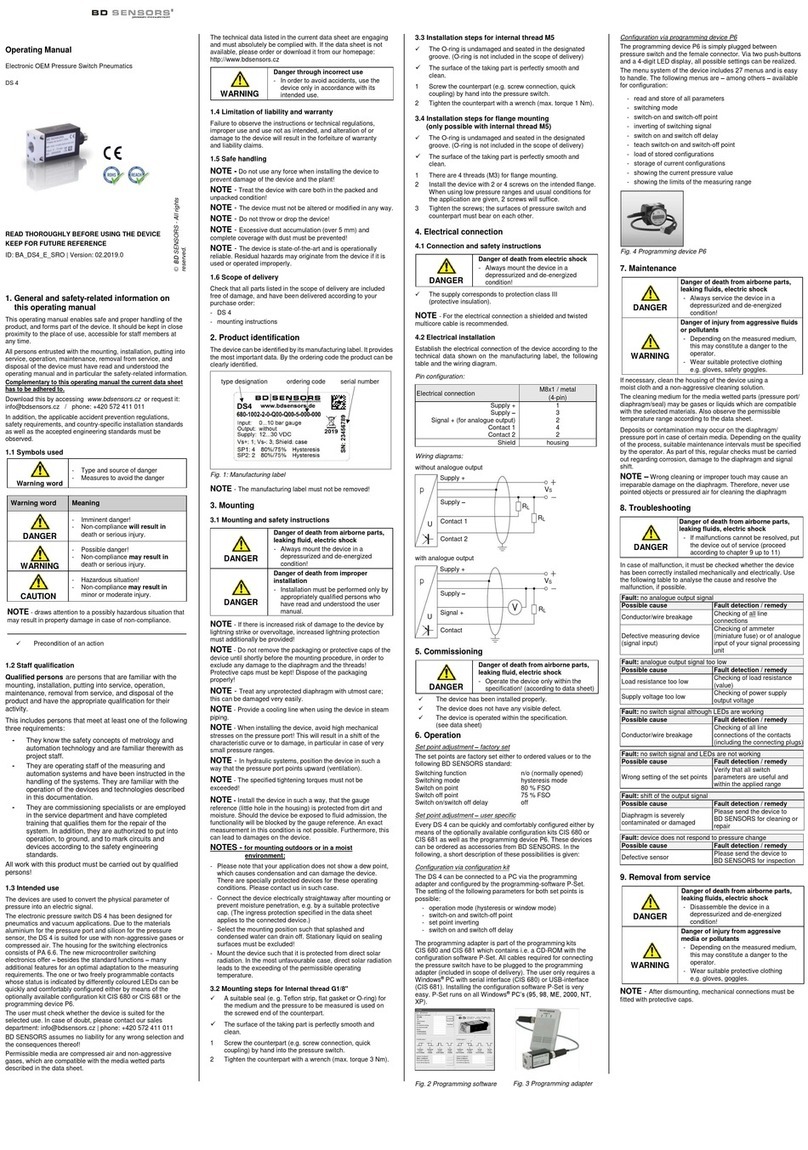

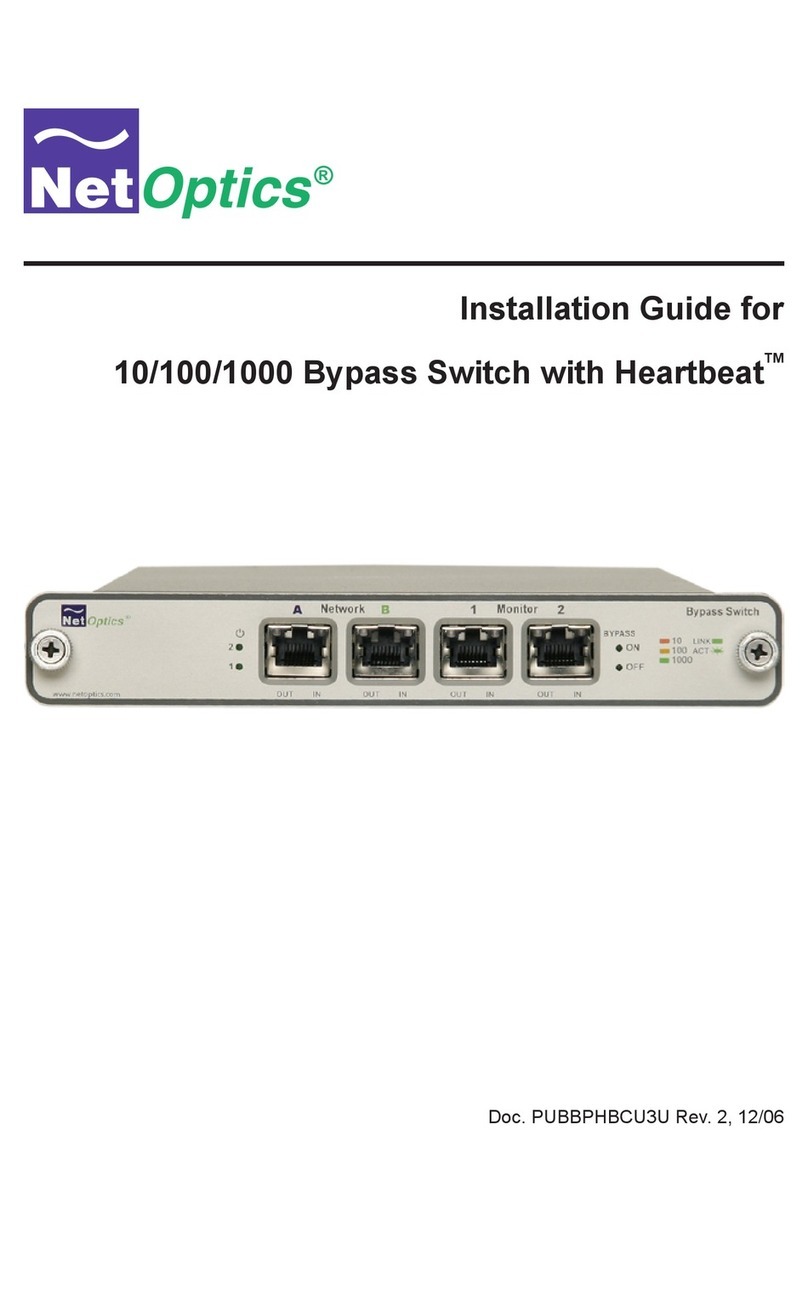

Operating and display elements

(e.g. for DS 2XX with two contacts)

▲-button: enter operating mode

move forward in the menu system

increase the displayed value

▼-button: enter operating mode

move backward in the menu system

decrease the displayed value

both buttons simultaneously:

confirm the menu items and set values

Mounting

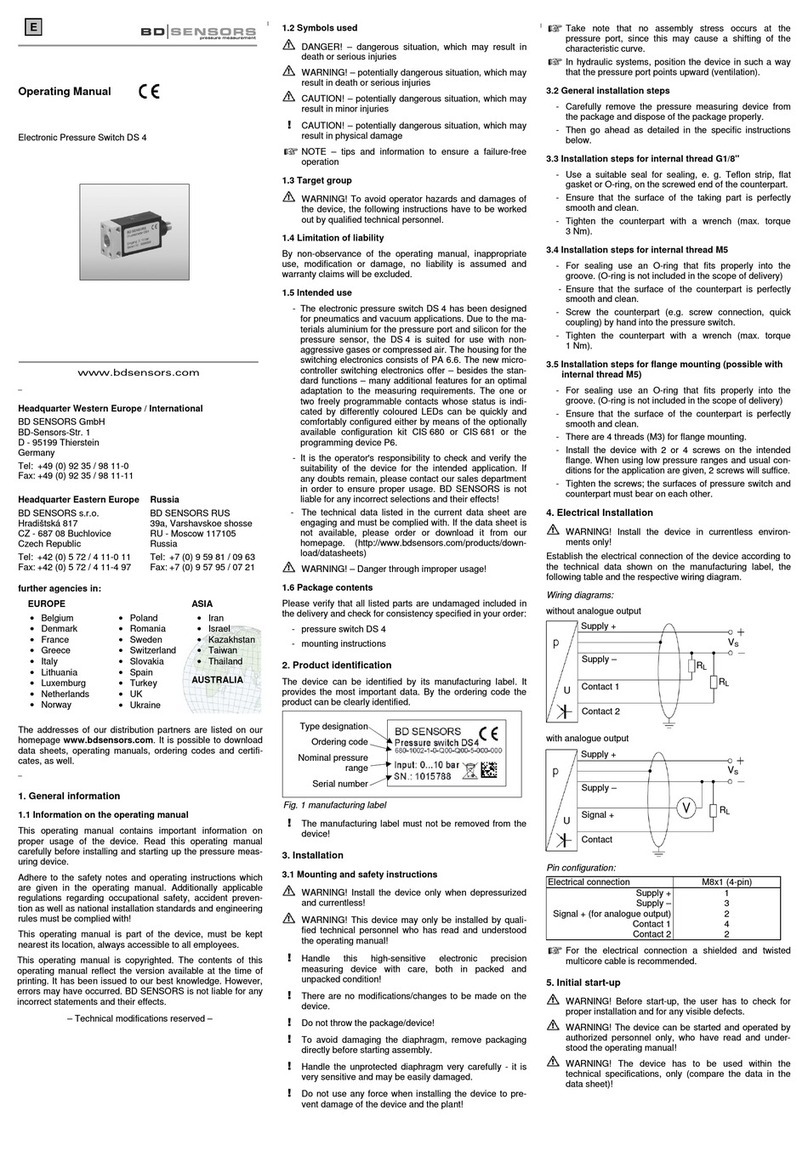

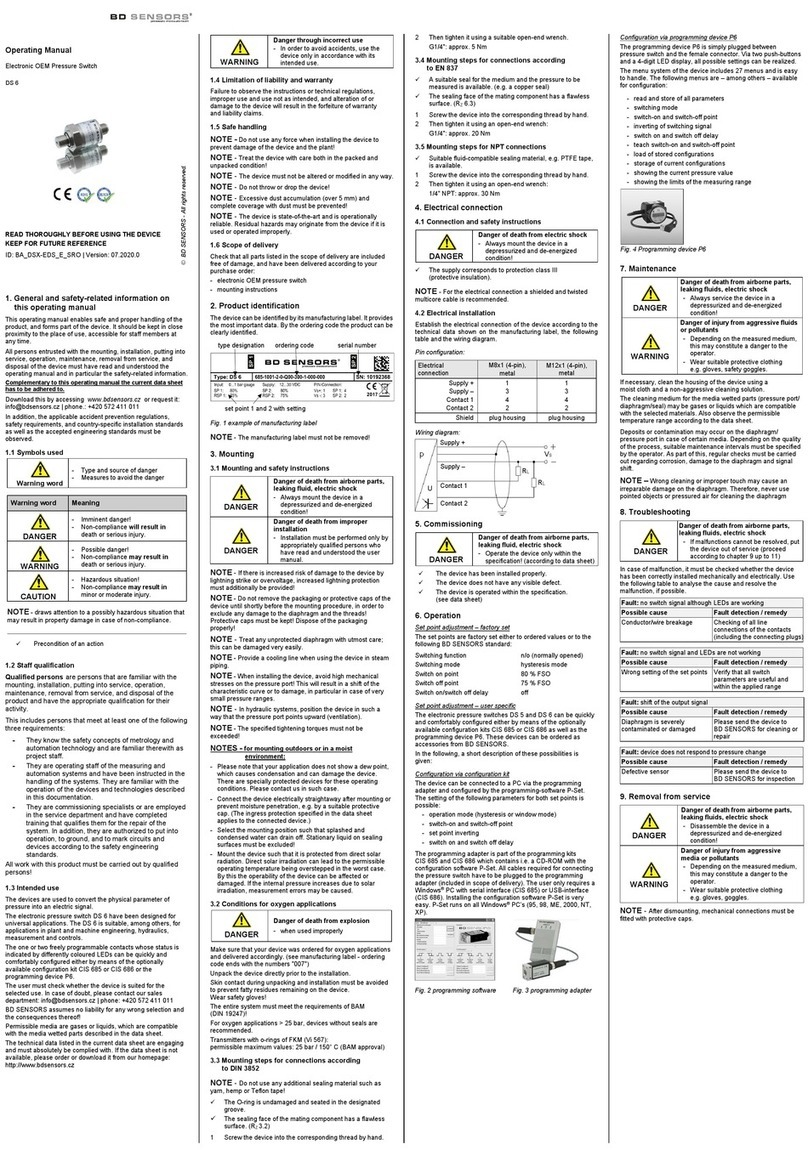

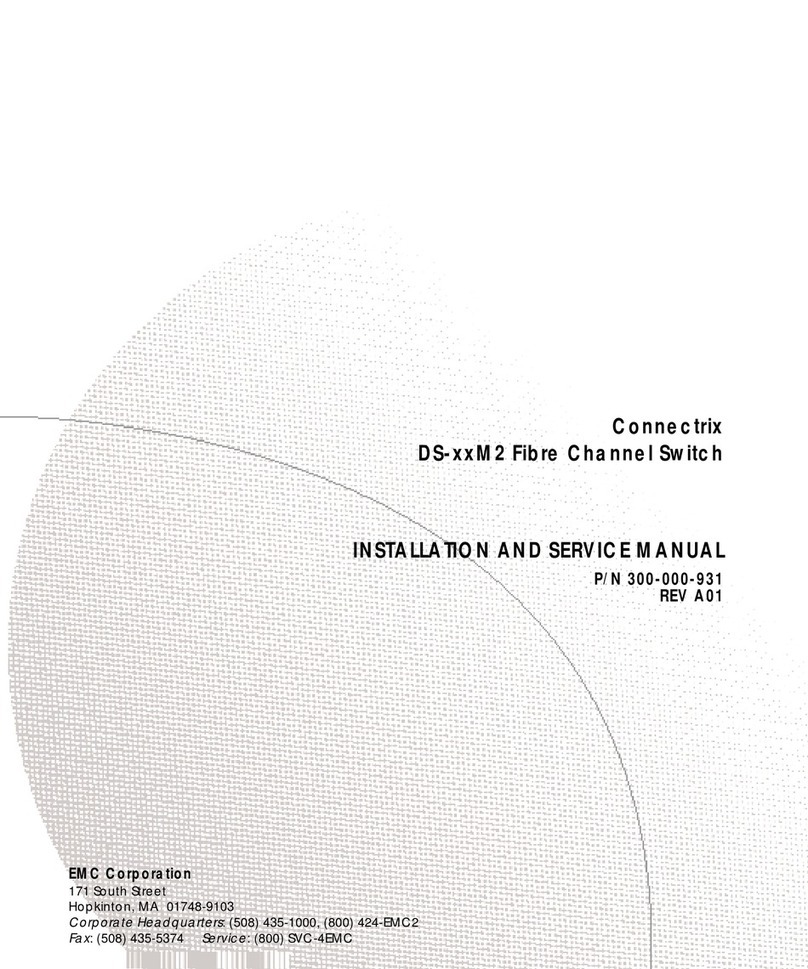

Pin configuration

Electrical

connections

M12x1

plastic

(5-pin)

M12x1

metal

(5-pin)

M12x1

plastic

(8-pin)

Supply +

Supply –

3-wire: Signal +

Contact 1

Contact 2

Contact 3

Contact 4

1

3

2

4

5

-

-

1

3

2

4

5

-

-

1

3

2

4

5

6

7

Shield via

pressure

port

plug-

housing/

pressure port

via

pressure

port

Electrical

connections ISO 4400 cable colours

(DIN 47100)

Supply +

Supply –

3-wire: Signal +

Contact 1

Contact 2

Contact 3

Contact 4

1

2

3

3

-

-

-

wh (white)

bn (brown)

gn (green)

gr (grey)

pn (pink)

-

-

Shield ground contact gn/ye

(green/yellow)

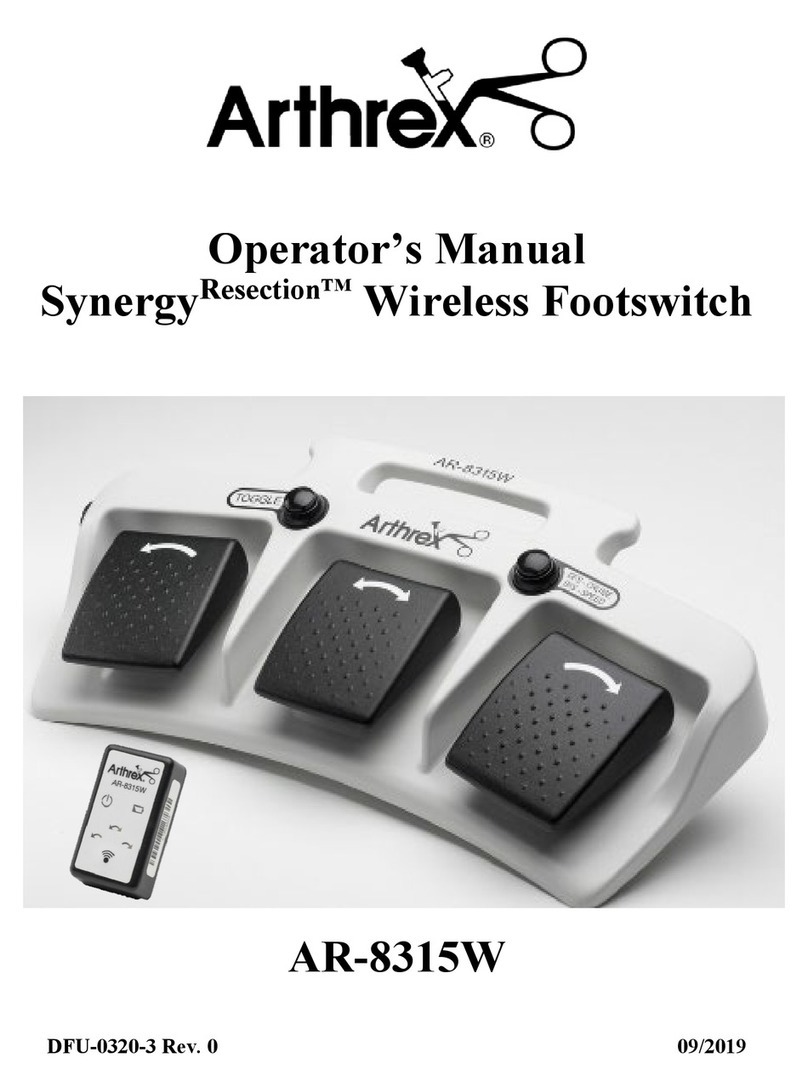

Wiring diagrams

2-wire-system (current)

3-wire-system (current/voltage)

For the electrical connection, a shielded and twisted

multicore cable is recommended.

LED unit LED

contact 1 contact 2

4-digit seven-

segment display

▼-button ▲-button

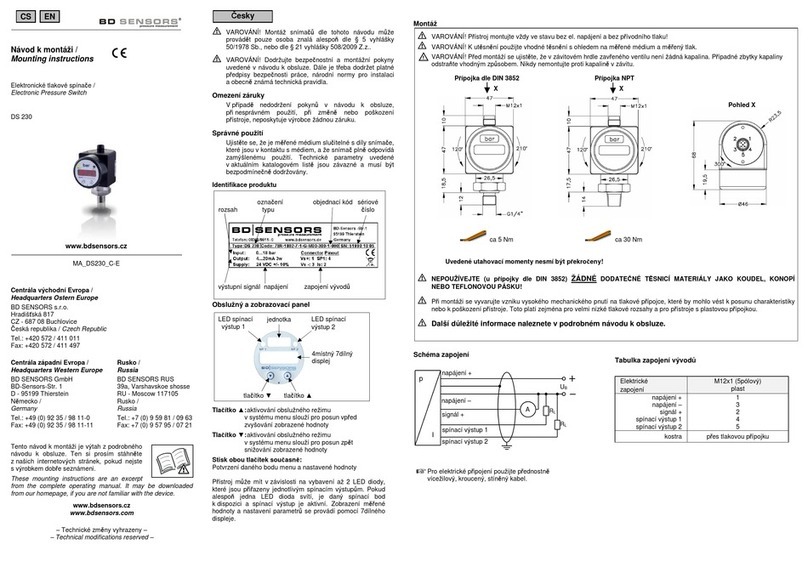

nominal designation ordering serial

pressure code number

range

signal supply connector pinout

supply+

signal +

contact 1

VS

A/V

p

I/U

supply –

contact 2

R

L

R

L

contact 3

contact 4

R

L

R

L

p

I

VS

supply +

supply –

contact 1

contact 2

R

L

R

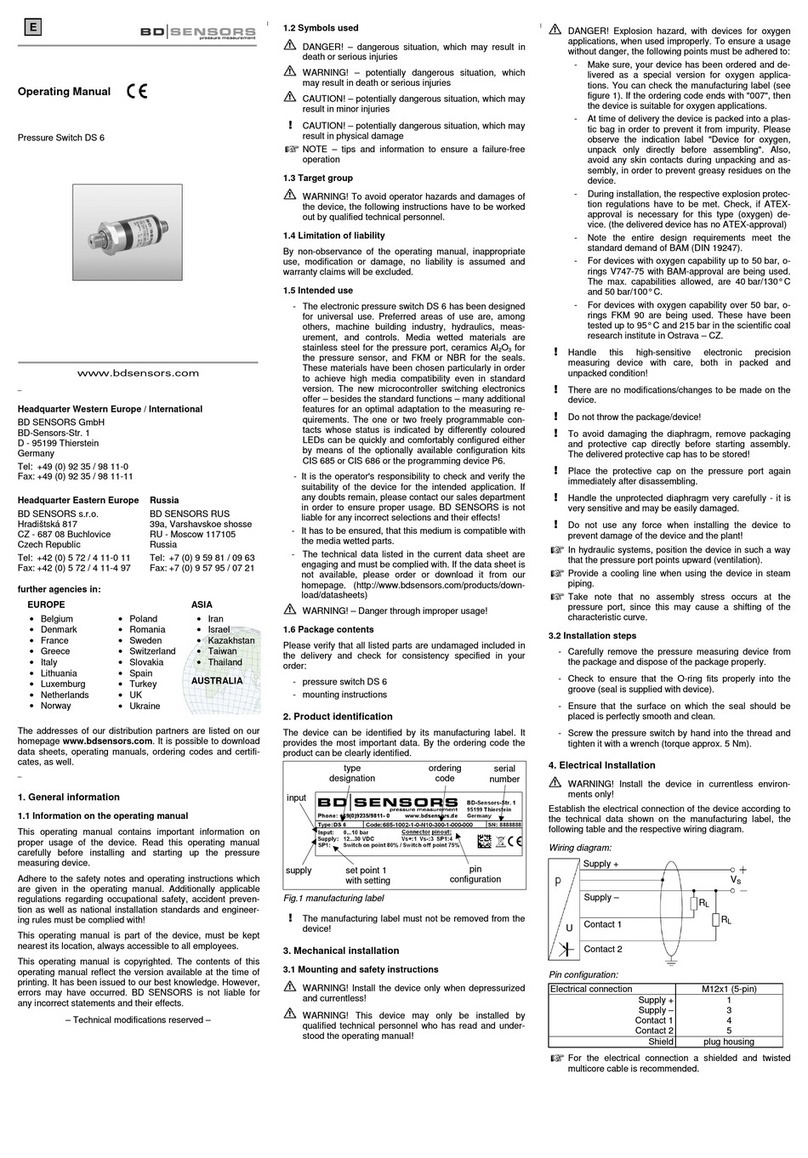

WARNING! Install the device only in depressurized and currentless state!

WARNING! Use a suitable seal, corresponding to the medium and the pressure input.

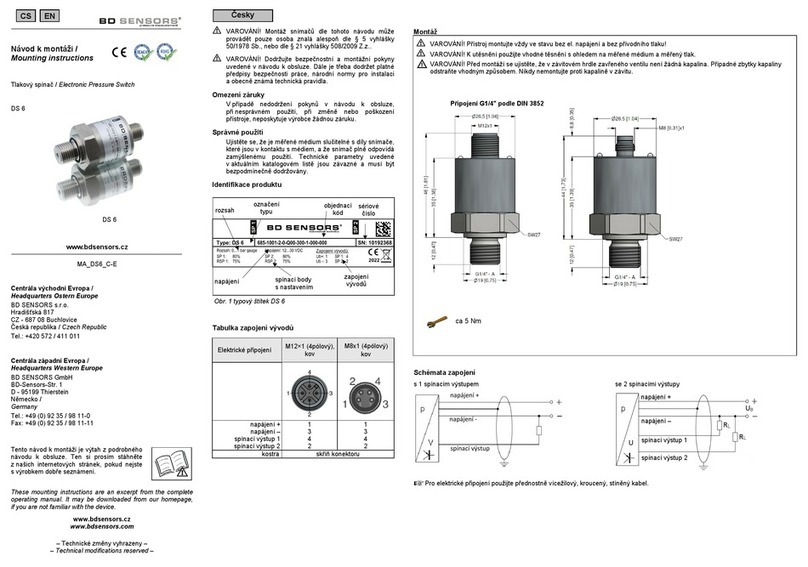

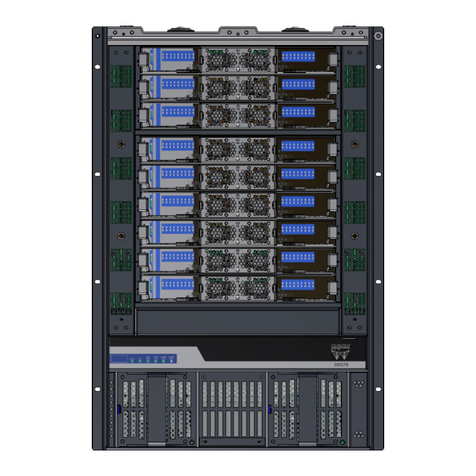

Connection acc. to DIN 3852 Connection acc. to EN 837 NPT connections

knurled ring: tighten by hand only

wrench size of plastic: max. 3 Nm

G1/4" steel: approx. 5 Nm G1/4": approx. 20 Nm 1/4" NPT: approx. 30 Nm

G1/2" steel: approx. 10 Nm G1/2": approx. 50 Nm 1/2" NPT: approx. 70 Nm

G3/4" steel: approx. 15 Nm

G1" steel: approx. 20 Nm

Dairy pipe connection Clamp and Varivent

connection

- Centre the connection - Centre the connection in the

in the mounting part. mounting part.

- Screw the cup nut onto the - Fix the device with a suitable fastening

mounting part. element (e. g. semi-ring or retractable

- Then tighten it with a hook wrench. ring clamp) according to the supplier’s

instructions.