BD Sensors DS 4 User manual

www.bdsensors.com

E

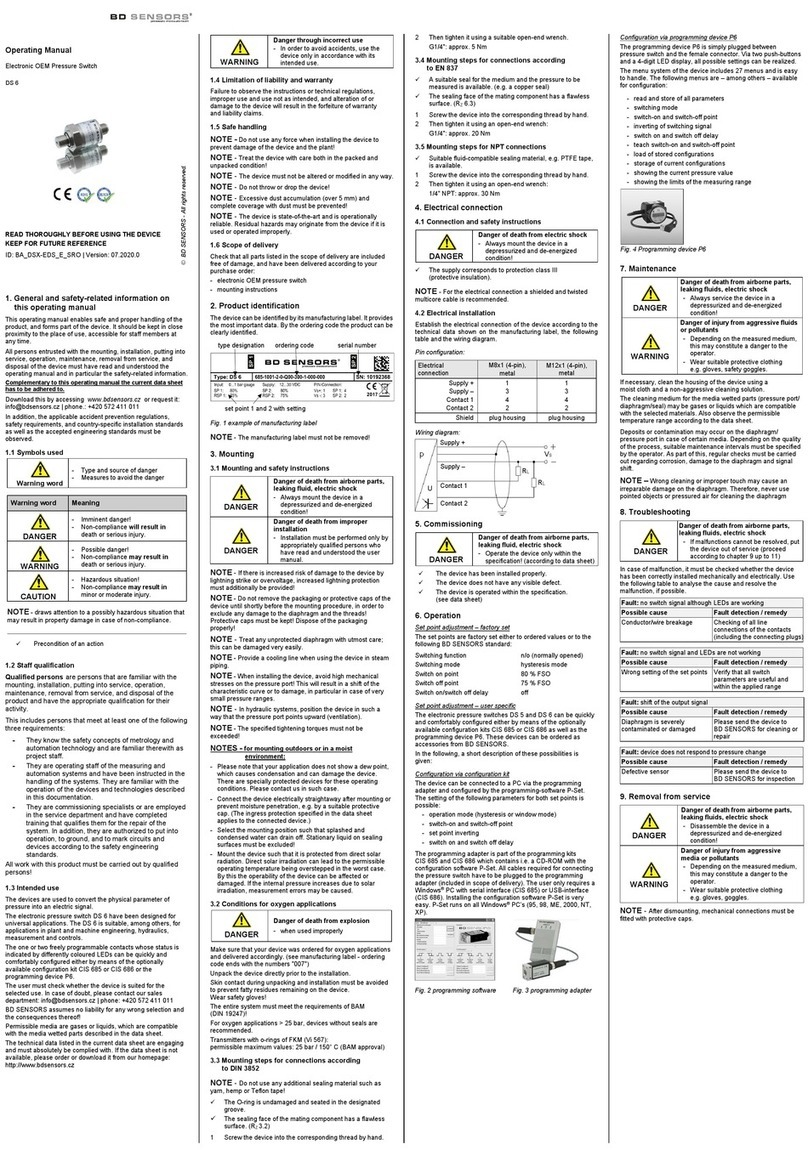

Operating Manual

Electronic Pressure Switch DS 4

Headquarter Western Europe / International

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Germany

Tel: +49 (0) 92 35 / 98 11-0

Fax: +49 (0) 92 35 / 98 11-11

Headquarter Eastern Europe

BD SENSORS s.r.o.

Hradištská 817

CZ - 687 08 Buchlovice

Czech Republic

Tel: +42 (0) 5 72 / 4 11-0 11

Fax: +42 (0) 5 72 / 4 11-4 97

Russia

BD SENSORS RUS

39a, Varshavskoe shosse

RU - Moscow 117105

Russia

Tel: +7 (0) 9 59 81 / 09 63

Fax: +7 (0) 9 57 95 / 07 21

further agencies in:

EUROPE

•Belgium

•Denmark

•France

•Greece

•Italy

•Lithuania

•Luxemburg

•Netherlands

•Norway

•Poland

•Romania

•Sweden

•Switzerland

•Slovakia

•Spain

•Turkey

•UK

•Ukraine

ASIA

•Iran

•Israel

•Kazakhstan

•Taiwan

•Thailand

AUSTRALIA

The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certifi-

cates, as well.

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual

carefully before installing and starting up the pressure meas-

uring device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable

regulations regarding occupational safety, accident preven-

tion as well as national installation standards and engineering

rules must be complied with!

This operating manual is part of the device, must be kept

nearest its location, always accessible to all employees.

This operating manual is copyrighted. The contents of this

operating manual reflect the version available at the time of

printing. It has been issued to our best knowledge. However,

errors may have occurred. BD SENSORS is not liable for any

incorrect statements and their effects.

– Technical modifications reserved –

1.2 Symbols used

DANGER! – dangerous situation, which may result in

death or serious injuries

WARNING! – potentially dangerous situation, which may

result in death or serious injuries

CAUTION! – potentially dangerous situation, which may

result in minor injuries

!

CAUTION! – potentially dangerous situation, which may

result in physical damage

NOTE – tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropriate

use, modification or damage, no liability is assumed and

warranty claims will be excluded.

1.5 Intended use

- The electronic pressure switch DS 4 has been designed

for pneumatics and vacuum applications. Due to the ma-

terials aluminium for the pressure port and silicon for the

pressure sensor, the DS 4 is suited for use with non-

aggressive gases or compressed air. The housing for the

switching electronics consists of PA 6.6. The new micro-

controller switching electronics offer – besides the stan-

dard functions – many additional features for an optimal

adaptation to the measuring requirements. The one or

two freely programmable contacts whose status is indi-

cated by differently coloured LEDs can be quickly and

comfortably configured either by means of the optionally

available configuration kit CIS 680 or CIS 681 or the

programming device P6.

- It is the operator's responsibility to check and verify the

suitability of the device for the intended application. If

any doubts remain, please contact our sales department

in order to ensure proper usage. BD SENSORS is not

liable for any incorrect selections and their effects!

- The technical data listed in the current data sheet are

engaging and must be complied with. If the data sheet is

not available, please order or download it from our

homepage. (http://www.bdsensors.com/products/down-

load/datasheets)

WARNING! – Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your order:

- pressure switch DS 4

- mounting instructions

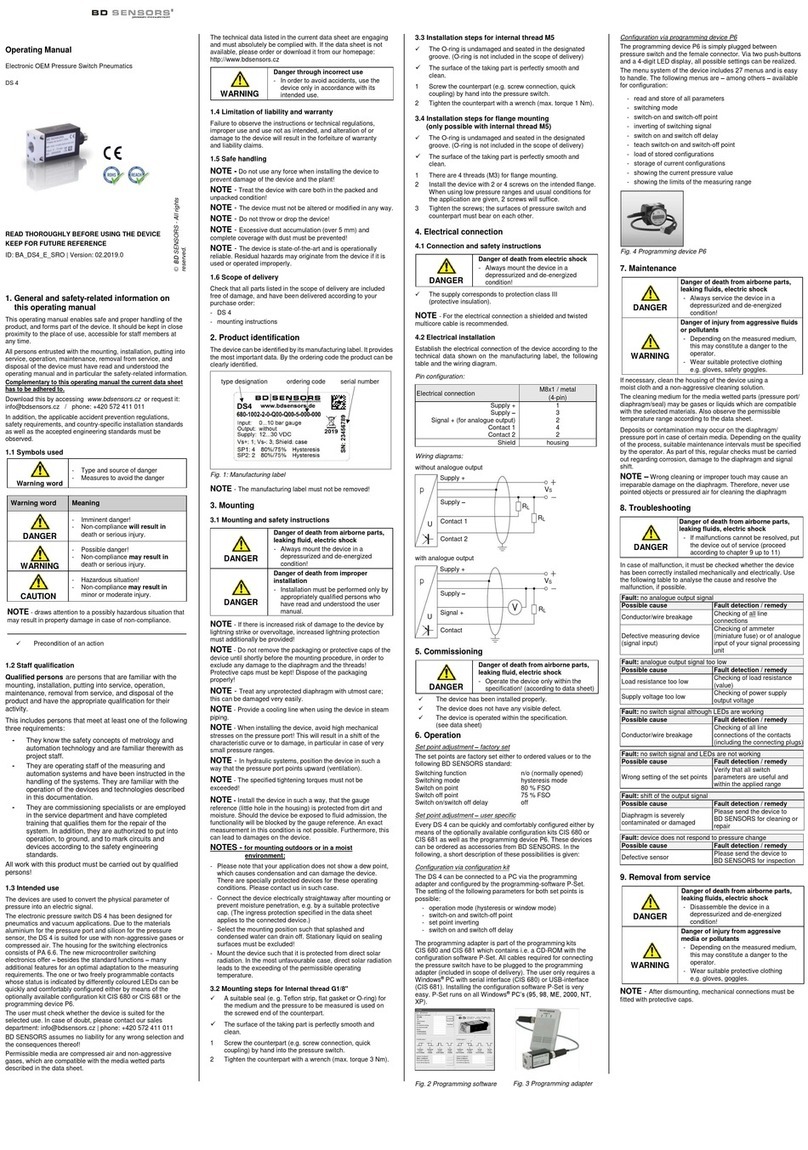

2. Product identification

The device can be identified by its manufacturing label. It

provides the most important data. By the ordering code the

product can be clearly identified.

!

The manufacturing label must not be removed from the

device!

3. Installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be installed by quali-

fied technical personnel who has read and understood

the operating manual!

!

Handle this high-sensitive electronic precision

measuring device with care, both in packed and

unpacked condition!

!

There are no modifications/changes to be made on the

device.

!

Do not throw the package/device!

!

To avoid damaging the diaphragm, remove packaging

directly before starting assembly.

!

Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!

Do not use any force when installing the device to pre-

vent damage of the device and the plant!

Take note that no assembly stress occurs at the

pressure port, since this may cause a shifting of the

characteristic curve.

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

3.2 General installation steps

- Carefully remove the pressure measuring device from

the package and dispose of the package properly.

- Then go ahead as detailed in the specific instructions

below.

3.3 Installation steps for internal thread G1/8"

- Use a suitable seal for sealing, e. g. Teflon strip, flat

gasket or O-ring, on the screwed end of the counterpart.

- Ensure that the surface of the taking part is perfectly

smooth and clean.

- Tighten the counterpart with a wrench (max. torque

3 Nm).

3.4 Installation steps for internal thread M5

- For sealing use an O-ring that fits properly into the

groove. (O-ring is not included in the scope of delivery)

- Ensure that the surface of the counterpart is perfectly

smooth and clean.

- Screw the counterpart (e.g. screw connection, quick

coupling) by hand into the pressure switch.

- Tighten the counterpart with a wrench (max. torque

1 Nm).

3.5 Installation steps for flange mounting (possible with

internal thread M5)

- For sealing use an O-ring that fits properly into the

groove. (O-ring is not included in the scope of delivery)

- Ensure that the surface of the counterpart is perfectly

smooth and clean.

- There are 4 threads (M3) for flange mounting.

- Install the device with 2 or 4 screws on the intended

flange. When using low pressure ranges and usual con-

ditions for the application are given, 2 screws will suffice.

- Tighten the screws; the surfaces of pressure switch and

counterpart must bear on each other.

4. Electrical Installation

WARNING! Install the device in currentless environ-

ments only!

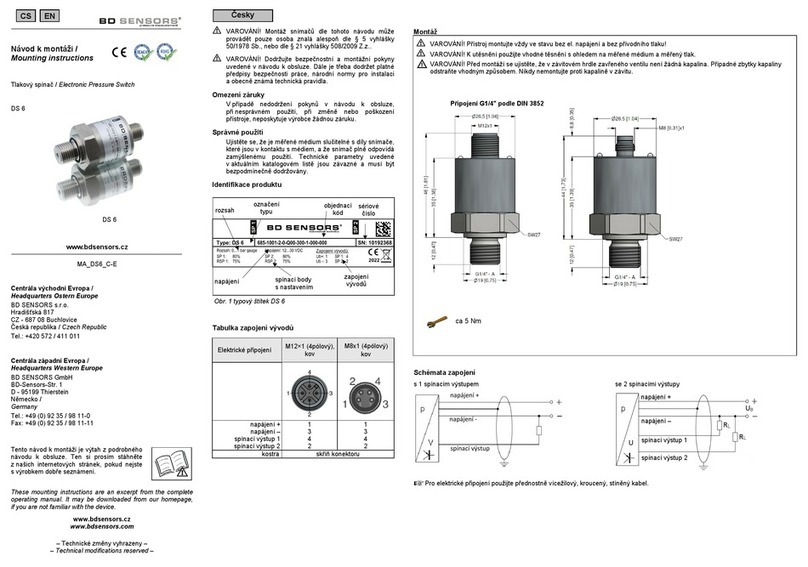

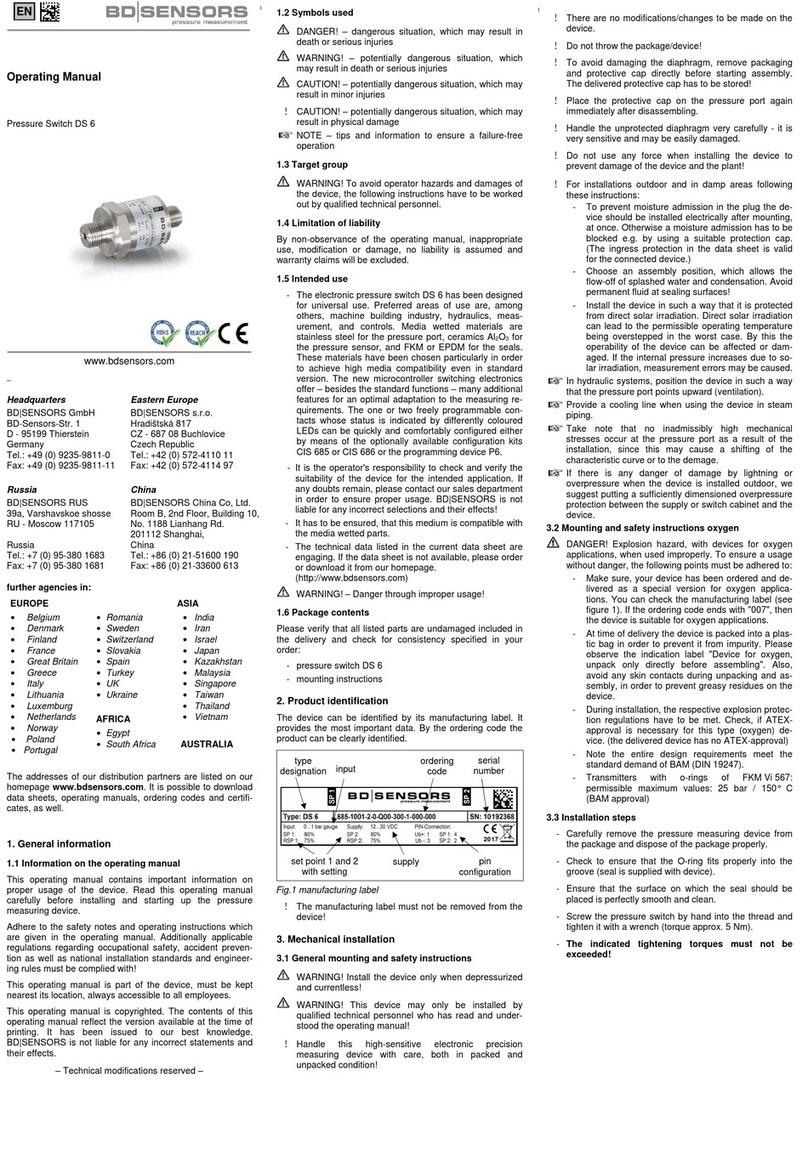

Establish the electrical connection of the device according to

the technical data shown on the manufacturing label, the

following table and the respective wiring diagram.

Wiring diagrams:

without analogue output

with analogue output

Pin configuration:

Electrical connection M8x1 (4-pin)

Supply +

Supply –

Signal + (for analogue output)

Contact 1

Contact 2

1

3

2

4

2

For the electrical connection a shielded and twisted

multicore cable is recommended.

5. Initial start-up

WARNING! Before start-up, the user has to check for

proper installation and for any visible defects.

WARNING! The device can be started and operated by

authorized personnel only, who have read and under-

stood the operating manual!

WARNING! The device has to be used within the

technical specifications, only (compare the data in the

data sheet)!

Supply

+

Supply –

Contact 1

Contact 2

VS

R

L

R

L

U

VS

Supply

+

Supply –

Signal +

Contact

R

L

U

Fig. 1 manufacturing label

Type designation

Ordering code

Nominal pressu

re

range

Serial number

DS4_E_190509

6. Operation

Set point adjustment – factory set

The set points are factory set either to ordered values or to

BD SENSORS standard:

Switching function n/o (normally opened)

Switching mode hysteresis mode

Switch on point 80 % FSO

Switch off point 75 % FSO

Switch on/switch off delay off

Set point adjustment – user specific

Every DS 4 can be quickly and comfortably configured either

by means of the optionally available configuration kits

CIS 680 or CIS 681 as well as the programming device P6.

These devices can be ordered as accessories from

BD SENSORS. In the following, a short description of these

possibilities is given:

Configuration via configuration kit

The DS 4 can be connected to a PC via the programming

adapter and configured by the programming-software P-Set.

The setting of the following parameters for both set points is

possible:

- operation mode (hysteresis or window mode)

- switch-on and switch-off point

- set point negation

- switch on and switch off delay

The programming adapter is part of the programming kits

CIS 680 and CIS 681 which contains i.a. a CD-ROM with the

configuration software P-Set. All cables required for connect-

ing the pressure switch have to be plugged to the program-

ming adapter (included in scope of delivery). The user only

requires a Windows

®

PC with serial interface (CIS 680) or

USB-interface (CIS 681).

Installing the configuration software P-Set is very easy. P-Set

runs on all Windows

®

PC’s (95, 98, ME, 2000, NT, XP).

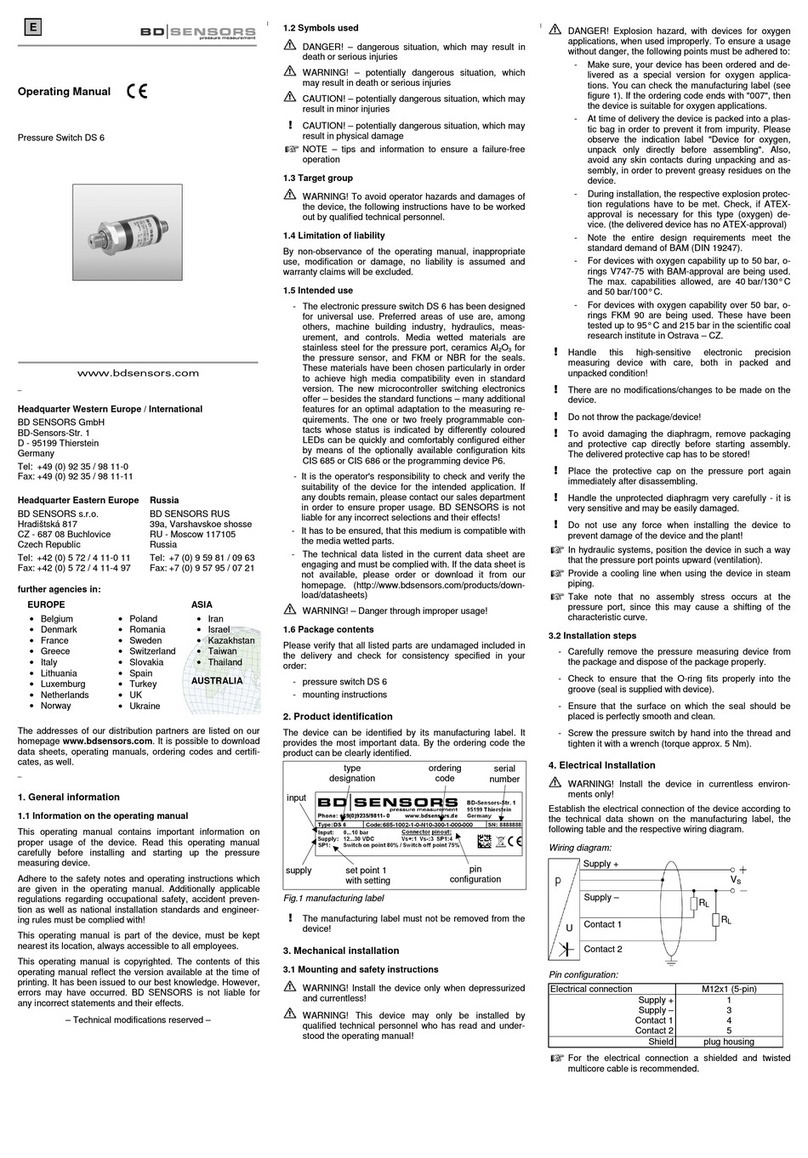

Configuration via hand-held programming device P6

The programming device P6 is simply plugged between DS 4

and the female connector. Via two push-buttons and a 4-digit

LED display, all possible settings can be realized. The menu

system of the device includes 27 menus and is easy to

handle. The following menus are – among others – available

for configuration:

- read all and store all

- operation mode (for both set points)

- switch-on and switch-off point (for both set points)

- set point negation (for both set points)

- switch on and switch off delay (for both set points)

- teach switch-on and switch-off point

(for both set points)

- load of stored configurations

- storage off current configurations

- showing the current pressure value

- showing the limits of the measuring range

7. Placing out of service

WARNING! When dismantling the device, it must always

be done in the depressurized and currentless condition!

Check also if the medium has to be drained off before

dismantling!

WARNING! Depending on the medium, it may cause

danger for the user. Comply therefore with adequate

precautions for purification.

8. Maintenance

In principle, this device is maintenance-free. If desired, the

housing of the device can be cleaned when switched of using

a damp cloth and non-aggressive cleaning solutions.

Depending on the measuring medium, however, the dia-

phragm may be polluted or coated with deposit. If the me-

dium is known for such tendencies, the user has to set

appropriate cleaning intervals. After placing the device out of

service correctly, the diaphragm can usually be cleaned

carefully with a non-aggressive cleaning solution and a soft

brush or sponge. If the diaphragm is calcified, it is recom-

mended to send the device to BD SENSORS for decalcifica-

tion. Please read therefore the chapter “Repair” below.

!

An incorrect cleaning can cause irreparable damages on

diaphragm. Never use spiky objects or pressured air for

cleaning the diaphragm.

9. Return

Before every return of your device, whether for decalcifica-

tion, modifications or repair, it is necessary to contact us to

ensure a fast handling of your request. Please inform us by

number of devices sent and request a RMA. Then clean the

device and pack it shatterproof before send it to

BD SENSORS indicating the RMA.

10. Disposal

The device must be disposed according to the

European Directives 2002/96/EG and

2003/108/EG (on waste electrical and electronic

equipment) Waste of electrical and electronic

equipment may not be disposed by domestic

refuse!

WARNING! Depending on the measuring medium,

deposit on the device may cause danger for the user

and the environment. Comply with adequate precautions

for purification and dispose of it properly.

11. Warranty conditions

The warranty conditions are subject to the legal warranty

period of 24 months from the date of delivery. In case of

improper use, modifications of or damages to the device, we

do not accept warranty claims. Damaged diaphragms will

also not be accepted. Furthermore, defects due to normal

wear are not subject to warranty services.

12. Error handling

13. Declaration of conformity / CE

The delivered device fulfils all legal requirements.

The applied directives, harmonised standards and documents

are listed in the EC declaration of conformity, which is avail-

able online at: http://www.bdsensors.com/products/

download/certificates.

Additionally, the operational safety is confirmed by the CE

sign on the manufacturing label.

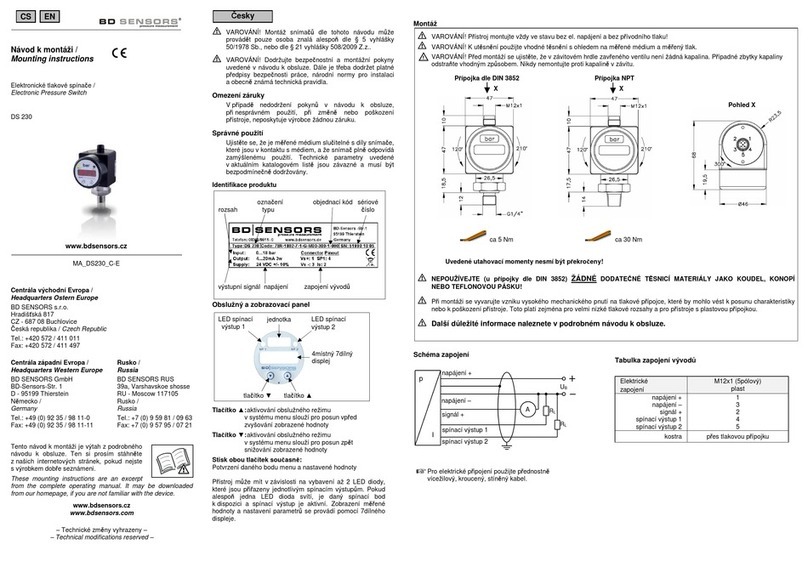

Fig. 2 Programming

Software

Fig. 3 Programming

adapter

Fig. 4 Programming device P 6

Malfunction

Possible cause

Error detection / corrective

no analogue output

signal

line break inspect all connecting lines and the connector plugs

defective ampere meter inspect the ampere meter (fine-wire fuse) or the analogue

input of the following device

analogue output signal too low

load resistance too low verify the value of the load resistance.

supply voltage too low verify the output voltage of the power supply

no switch signal although LEDs

are working line break inspect all connecting lines of the contacts (including the

connecting plugs)

no switch signal and LEDs are

not working wrong setting of the set points

verify that all switch parameters are useful and permitted

(e.g. the set parameters must lie within the applied

pressure range)

device does not respond to

pressure change defective sensor please send the device for inspection to our service

address

little shift of the output signal diaphragm is contaminated if a contamination is suspected, please send the device to

BD SENSORS for repair

large shift of the output signal diaphragm is damaged if damage (e. g. by overpressure) is suspected, please

send the device to BD SENSORS for repair

If you detect an error, please try to eliminate it by using this table or send the device to our service address for repair.

!

Improper action and opening can damage the device. Therefore repairs on the device may only be executed by the

manufacturer!

Other BD Sensors Switch manuals

BD Sensors

BD Sensors DS 6 User manual

BD Sensors

BD Sensors DS 4 User manual

BD Sensors

BD Sensors DS 200 User manual

BD Sensors

BD Sensors DS 6 User manual

BD Sensors

BD Sensors DM01 User manual

BD Sensors

BD Sensors DS 230 User manual

BD Sensors

BD Sensors DS 6 User manual

BD Sensors

BD Sensors DM 200 User manual

BD Sensors

BD Sensors iS4 User manual

BD Sensors

BD Sensors DS 6 User manual