www.bdsensors.com

Operating Manual

Pressure Switch DS 6

Headquarter Western Europe / International

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Germany

Tel: +49 (0) 92 35 / 98 11-0

Fax: +49 (0) 92 35 / 98 11-11

Headquarter Eastern Europe

BD SENSORS s.r.o.

Hradištská 817

CZ - 687 08 Buchlovice

Czech Republic

Tel: +42 (0) 5 72 / 4 11-0 11

Fax: +42 (0) 5 72 / 4 11-4 97

Russia

BD SENSORS RUS

39a, Varshavskoe shosse

RU - Moscow 117105

Russia

Tel: +7 (0) 9 59 81 / 09 63

Fax: +7 (0) 9 57 95 / 07 21

further agencies in:

•Belgium

•Denmark

•France

•Greece

•Italy

•Lithuania

•Luxemburg

•Netherlands

•Norway

•Poland

•Romania

•Sweden

•Switzerland

•Slovakia

•Spain

•Turkey

•UK

•Ukraine

•Iran

•Israel

•Kazakhstan

•Taiwan

•Thailand

AUSTRALIA

The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certifi-

cates, as well.

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual

carefully before installing and starting up the pressure

measuring device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable

regulations regarding occupational safety, accident preven-

tion as well as national installation standards and engineer-

ing rules must be complied with!

This operating manual is part of the device, must be kept

nearest its location, always accessible to all employees.

This operating manual is copyrighted. The contents of this

operating manual reflect the version available at the time of

printing. It has been issued to our best knowledge. However,

errors may have occurred. BD SENSORS is not liable for

any incorrect statements and their effects.

– Technical modifications reserved –

1.2 Symbols used

DANGER! – dangerous situation, which may result in

death or serious injuries

WARNING! – potentially dangerous situation, which

may result in death or serious injuries

CAUTION! – potentially dangerous situation, which may

result in minor injuries

!

CAUTION! – potentially dangerous situation, which may

result in physical damage

NOTE – tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropriate

use, modification or damage, no liability is assumed and

warranty claims will be excluded.

1.5 Intended use

- The electronic pressure switch DS 6 has been designed

for universal use. Preferred areas of use are, among

others, machine building industry, hydraulics, meas-

urement, and controls. Media wetted materials are

stainless steel for the pressure port, ceramics Al

2

O

3

for

the pressure sensor, and FKM or NBR for the seals.

These materials have been chosen particularly in order

to achieve high media compatibility even in standard

version. The new microcontroller switching electronics

offer – besides the standard functions – many additional

features for an optimal adaptation to the measuring re-

quirements. The one or two freely programmable con-

tacts whose status is indicated by differently coloured

LEDs can be quickly and comfortably configured either

by means of the optionally available configuration kits

CIS 685 or CIS 686 or the programming device P6.

- It is the operator's responsibility to check and verify the

suitability of the device for the intended application. If

any doubts remain, please contact our sales department

in order to ensure proper usage. BD SENSORS is not

liable for any incorrect selections and their effects!

- It has to be ensured, that this medium is compatible with

the media wetted parts.

- The technical data listed in the current data sheet are

engaging and must be complied with. If the data sheet is

not available, please order or download it from our

homepage. (http://www.bdsensors.com/products/down-

load/datasheets)

WARNING! – Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your

order:

- pressure switch DS 6

- mounting instructions

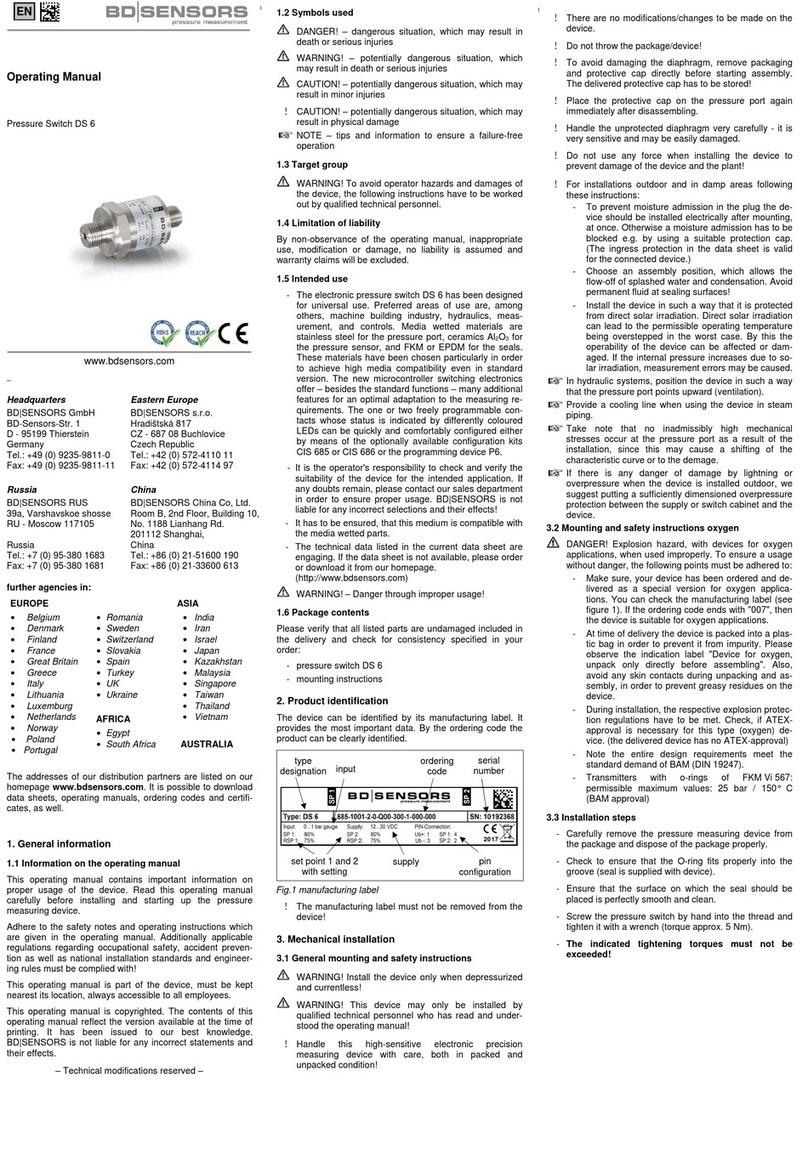

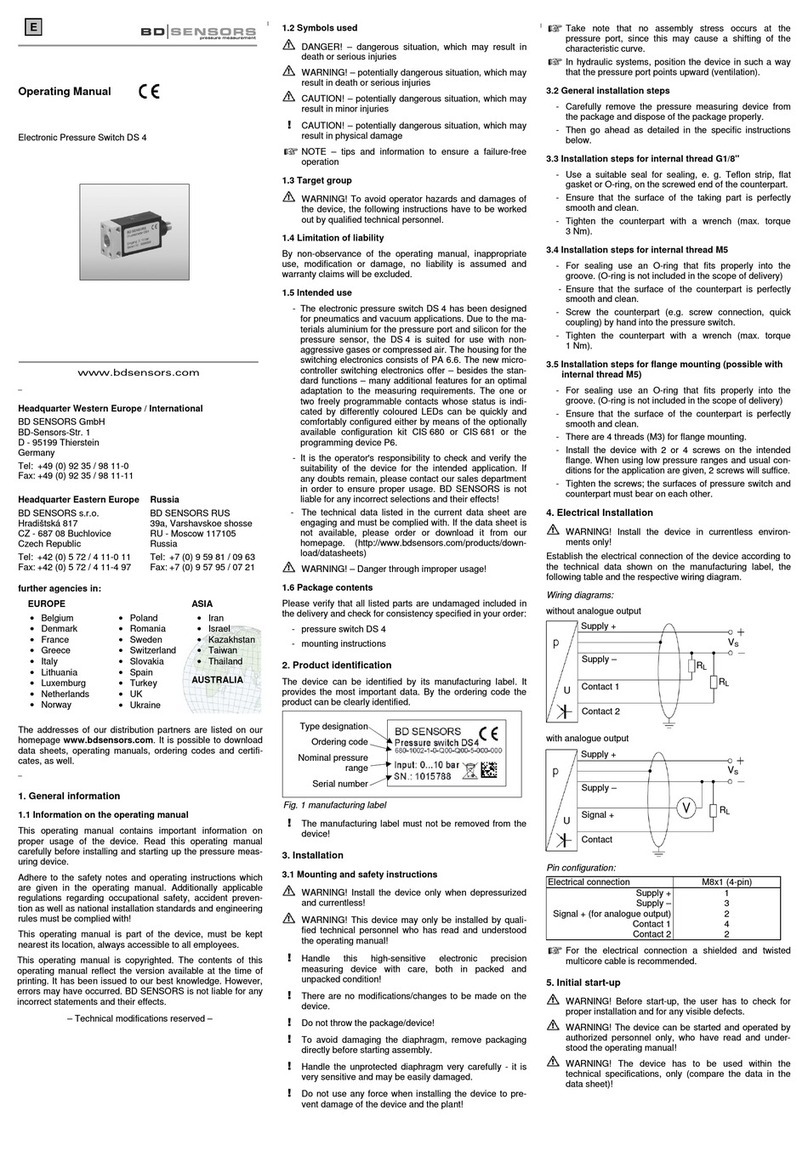

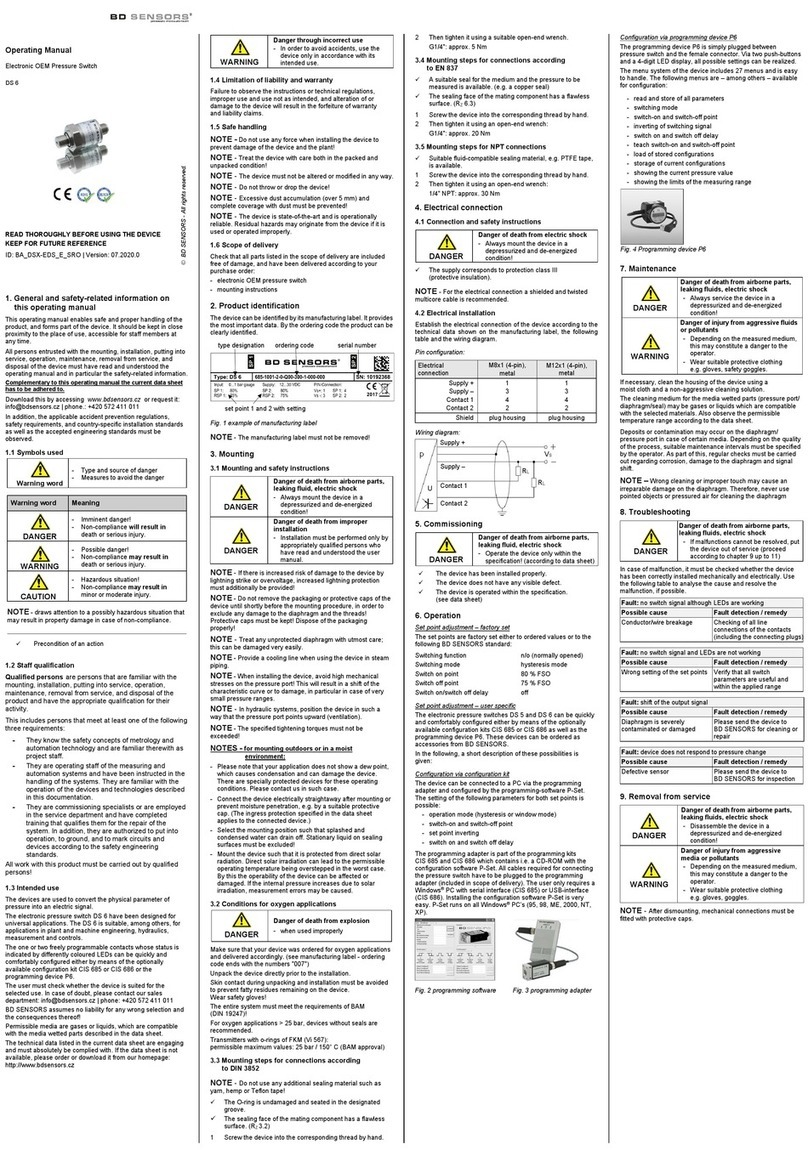

2. Product identification

The device can be identified by its manufacturing label. It

provides the most important data. By the ordering code the

product can be clearly identified.

!

The manufacturing label must not be removed from the

device!

3. Mechanical installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be installed by

qualified technical personnel who has read and under-

stood the operating manual!

DANGER! Explosion hazard, with devices for oxygen

applications, when used improperly. To ensure a usage

without danger, the following points must be adhered to:

- Make sure, your device has been ordered and de-

livered as a special version for oxygen applica-

tions. You can check the manufacturing label (see

figure 1). If the ordering code ends with "007", then

the device is suitable for oxygen applications.

- At time of delivery the device is packed into a plas-

tic bag in order to prevent it from impurity. Please

observe the indication label "Device for oxygen,

unpack only directly before assembling". Also,

avoid any skin contacts during unpacking and as-

sembly, in order to prevent greasy residues on the

device.

- During installation, the respective explosion protec-

tion regulations have to be met. Check, if ATEX-

approval is necessary for this type (oxygen) de-

vice. (the delivered device has no ATEX-approval)

- Note the entire design requirements meet the

standard demand of BAM (DIN 19247).

- For devices with oxygen capability up to 50 bar, o-

rings V747-75 with BAM-approval are being used.

The max. capabilities allowed, are 40 bar/130°C

and 50 bar/100°C.

- For devices with oxygen capability over 50 bar, o-

rings FKM 90 are being used. These have been

tested up to 95°C and 215 bar in the scientific coal

research institute in Ostrava – CZ.

!

Handle this high-sensitive electronic precision

measuring device with care, both in packed and

unpacked condition!

!

There are no modifications/changes to be made on the

device.

!

Do not throw the package/device!

!

To avoid damaging the diaphragm, remove packaging

and protective cap directly before starting assembly.

The delivered protective cap has to be stored!

!

Place the protective cap on the pressure port again

immediately after disassembling.

!

Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!

Do not use any force when installing the device to

prevent damage of the device and the plant!

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

Provide a cooling line when using the device in steam

piping.

Take note that no assembly stress occurs at the

pressure port, since this may cause a shifting of the

characteristic curve.

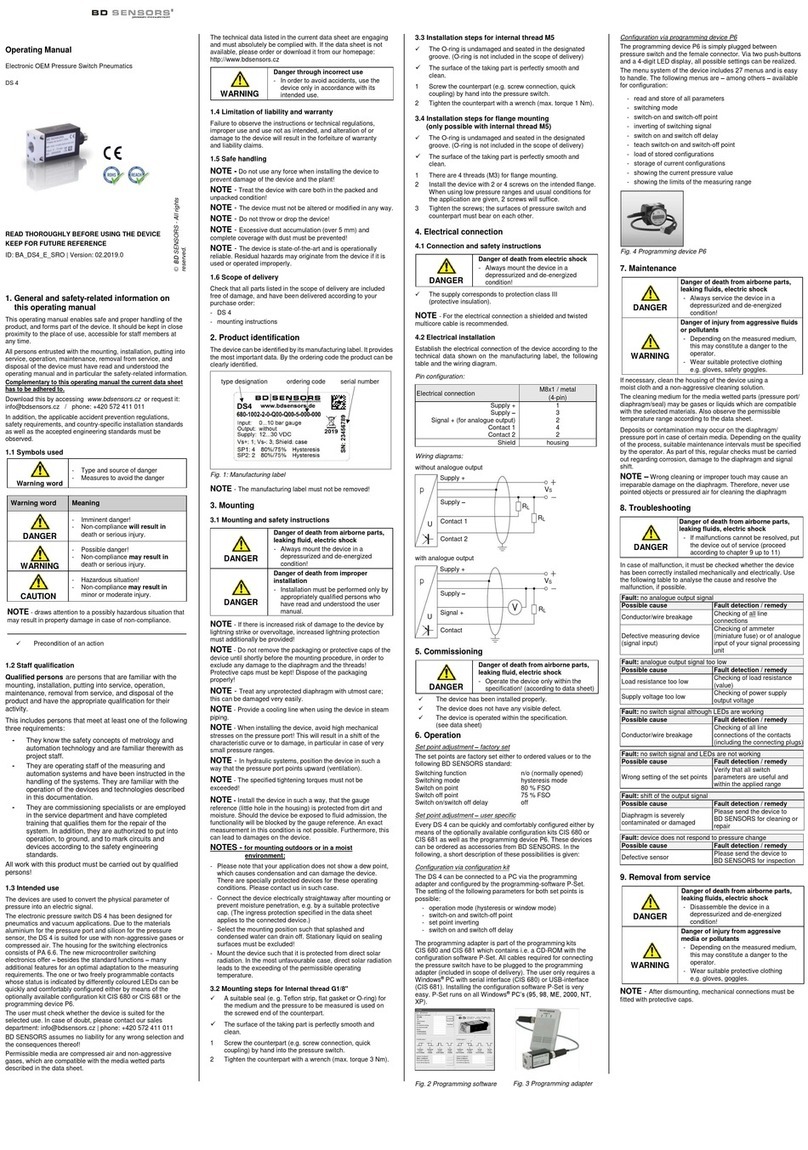

3.2 Installation steps

- Carefully remove the pressure measuring device from

the package and dispose of the package properly.

- Check to ensure that the O-ring fits properly into the

groove (seal is supplied with device).

- Ensure that the surface on which the seal should be

placed is perfectly smooth and clean.

- Screw the pressure switch by hand into the thread and

tighten it with a wrench (torque approx. 5 Nm).

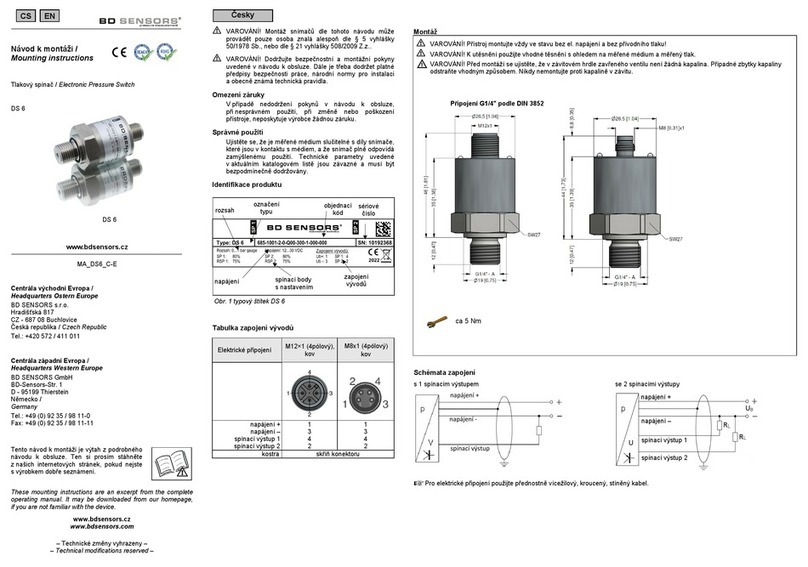

4. Electrical Installation

WARNING! Install the device in currentless environ-

ments only!

Establish the electrical connection of the device according to

the technical data shown on the manufacturing label, the

following table and the respective wiring diagram.

Wiring diagram:

Pin configuration:

Electrical connection M12x1 (5-pin)

Supply +

Supply –

Contact 1

1

3

4

5

Shield

plug housing

For the electrical connection a shielded and twisted

multicore cable is recommended.

Supply –

Contact 1

Contact 2

VS

R

L

R

L

U

pin

configuration

ordering

code

type

designation

supply

input

set point 1

serial

number

Fig.1 manufacturing label