BDS Maschinen MAB 1300 User manual

M A B 1 3 0 0

O r i g i n a l

O p e r a t i n g i n s t r u c t i o n s • In s t r u c c i o n e s d e m a n e j o

M o d e d ‘ e m p l o i

2 2 Ha r b o r A v e n u e , No r w a l k , C T 0 6 8 5 0 U SA

T o l l - F r e e : 8 0 0 - 7 0 0 - 5 9 1 9

Phone:203-853-9522

Fax:203-853-9921

Em a i l : i n f o @ c s u n i t e c . c o m

w w w . c s u n i t e c . c o m

Distributed exclusively by:

BA_MAB1300B_0510_A3 © 2012 BDS Maschinen GmbH

C o n t e n t s P a g e

O p e r a t i n g i n s t r u c t i o n s ..............3

So m m a i r e P a g e

M o d e d ’ e m p l o i ...................6 7

In d i c e P á g i n a

In s t r u c c i o n e s d e m a n e j o ...........3 5

3

M A B 1 3 0 0

ENGLISH

T a b l e o f C o n t e n t s

F o r e w o r d .........................4

In s t r u c t i o n s f o r u s e ................4

Copyright .........................4

Safety warning structure..............5

Intended use.......................6

Liability disclaimer ..................6

Sa f e t y ............................7

Fundamental safety precautions .......7

Danger of electric shock..............8

Risk of injury.......................9

Preventing damage ................10

Transporting the machine............10

Safety installations .................11

Personal protective equipment........12

C o m p o n e n t s / d e l i v e r y c o n t e n t s ......1 3

Machine overview..................13

Delivery contents ..................14

Control panel .....................14

Before using for the rst time .......1 5

Transport inspection................15

P r e p a r a t i o n ......................1 5

Additional safety measures for certain

operations........................15

Check the condition of the substrate ...16

Dismantling/assembling the tool holder .17

Inserting the tool...................18

O p e r a t i o n .......................2 3

Activating/deactivating the magnetic clamp

.23

Switching machine ON/OFF..........23

Selecting the speed range ...........24

Setting the speed ..................25

Setting the torque cut-off ............25

Drilling with the machine ............26

Thread cutting ....................28

Reaming/counter-sinking ............28

El i m i n a t i n g b l o c k a g e s .............2 9

C l e a n i n g ........................2 9

After every use ....................29

M a i n t e n a n c e .....................3 0

Adjusting the guide of the machine slide

. .30

Replacing the carbon brushes ........30

After-sales service/service ...........30

T r o u b l e s h o o t i n g ..................3 1

Faults: causes and remedies .........31

St o r a g e / d i s p o s a l .................3 2

Storage..........................32

Disposal .........................32

A p p e n d i x ........................3 3

Technical data ....................33

EC Declaration of Conformity.........34

4

F o r e w o r d

M A B 1 3 0 0

ENGLISH

F o r e w o r d

With the purchase of this machine you have decided in favor of

a quality product whose engineering and sturdiness have been

designed to meet the high demands of day-to-day professional

use.

Read all the information contained here to quickly familiarize

yourself with the machine and to be able to make full use of its

functions.

This machine will serve you for many years to come if you handle

and treat it properly.

In s t r u c t i o n s f o r u s e

These operating instructions form an integral part of the Magnetic

Core Drilling Machine MAB 1300 (hereinafter referred to as

"machine") and contains important information for commissioning,

safety, intended use and care of the machine.

These operating instructions must always be kept in the vicinity

of the machine. They must be read and observed by all persons

entrusted with operation, troubleshooting and/or cleaning of the

machine.

Keep these operating instructions and pass them onto the next

owner of the machine.

C o p y r i g h t

This document is protected by copyright.

Any duplication or reprinting, in whole or in part, as well as

reproduction of the illustrations even in modied form is only

permitted with the written approval of the manufacturer.

5

In s t r u c t i o n s f o r u s e

M A B 1 3 0 0

ENGLISH

Sa f e t y w a r n i n g s t r u c t u r e

The following warnings are used in operating instructions:

D A NGER

A w a r n i n g o f t h i s c a t e g o r y i n d i c a t e s a n i m p e n d i n g

d a n g e r o u s s i t u a t i o n .

If the dangerous situation is not avoided, it may lead to serious

injury or even death.

►Follow the instructions in this warning to avoid the danger of

serious injury or even death.

W A R NING

A w a r n i n g o f t h i s c a t e g o r y i n d i c a t e s a p o t e n t i a l l y

d a n g e r o u s s i t u a t i o n .

If the dangerous situation is not avoided, it may lead to injuries.

►Follow the instructions in the warning message to prevent

injuries to persons.

CAUTION

A w a r n i n g o f t h i s c a t e g o r y i n d i c a t e s p o t e n t i a l m a t e r i a l

d a m a g e .

If the situation is not avoided, it may lead to material damage.

►Follow the instructions in this warning to avoid material

damage.

NOTE

►A note indicates additional information that simplies the use

of the machine.

6

In s t r u c t i o n s f o r u s e

M A B 1 3 0 0

ENGLISH

In t e n d e d u s e

The machine is intended solely for drilling operations in magnetic

and non-magnetic metals, and for cutting threads, countersinking

and reaming within the limits specied in the technical data.

Any other use other than previously stated is considered as

improper use.

W A R NING

D a n g e r r e s u l t i n g f r o m i m p r o p e r u s e !

If not used for its intended purpose and/or used in any other

way, the machine may be or become a source of danger.

►Use the machine only for its intended purpose.

►Observe the procedures described in these operating

instructions.

No claims of any kind will be accepted for damage or injury

resulting from use of the machine for other than its intended

purpose.

The risk has to be borne solely by the machine owner.

NOTE

►If used commercially, pay attention to compliance with the

accident prevention and safety at work regulations.

Li a b i l i t y d i s c l a i m e r

All technical information, data and instructions for commissioning,

operation and maintenance of the machine contained in these

operating instructions represent the latest status at the time of

printing.

The manufacturer assumes no liability for damage or injury

resulting from failure to observe the operating instructions, use

for other than the intended purpose, unprofessional repairs,

unauthorized modications or use of non-approved spare parts

and accessories, tools and lubricants.

7

Sa f e t y

M A B 1 3 0 0

ENGLISH

Sa f e t y

C A U T IO N

W h e n u s i n g e l e c t r i c a l t o o l s , t h e f o l l o w i n g f u n d a m e n t a l

p r e c a u t i o n s m u s t b e t a k e n t o p r o t e c t a g a i n s t e l e c t r i c s h o c k

and the risk of injury and re!

F u n d a m e n t a l s a f e t y p r e c a u t i o n s

■Do not use the machine in ammable or potentially explosive

environments.

■Persons who due to their physical, mental or motor response

abilities are unable to operate the machine safely may

only use the machine under supervision or instruction by a

responsible person.

■Persons with heart pacemakers or other medical implants

must not use this machine.

■Children must not be allowed to use the machine.

■Inspect the machine for visible signs of damage before use.

Do not use a visibly damaged machine.

■Before beginning work, check the condition of the safety belt

and the function of the switches on the machine.

■Repairs to the mains cable may only be carried out by a

qualied electrician.

■Repairs to the machine may only be carried out by an

authorized workshop or by the works after-sales service.

Unqualied repairs can lead to considerable danger for the

user.

■Repairs to the machine during the warranty period may

only be carried out by a service centre authorized by the

manufacturer, as otherwise the warranty will be voided.

■Defective parts may only be replaced with original spare parts.

Only these parts guarantee that the safety requirements are

satised.

8

Sa f e t y

M A B 1 3 0 0

ENGLISH

■Do not leave the machine unsupervised during operation.

■Store the machine in a dry, temperate location out of the reach

of children.

■Do not leave the machine standing outdoors and do not

expose it to moisture.

■Make sure that your work area is sufciently lit (>300 Lux).

■Do not use low power machines for heavy working.

■Make sure that your workplace is clean.

■Keep the machine clean, dry and free of oil and grease.

■Follow the instructions on lubricating and cooling the tool.

D a n g e r o f e l e c t r i c s h o c k

D A NGER

D a n g e r t o l i f e b y e l e c t r i c s h o c k !

C o n t a c t w i t h l i v e w i r e s o r c o m p o n e n t s c o u l d l e a d t o

s e r i o u s i n j u r y o r e v e n d e a t h !

Observe the following safety precautions to avoid electric

shocks:

►Do not open the housing of the machine. Risk of electric

shock if live terminals are touched.

►Never immerse the machine or the plug into water or other

liquids.

►Use only extension leads or cable drums with a cable cross-

section of 1.5 mm² (1/16 inch2).

►Only use extension leads that are approved for the place of

work.

►Check the condition of the extension lead regularly and

replace if damaged.

►Avoid direct body contact with grounded parts (e.g., tubes,

radiators, steel girders) to reduce the risk of electric shock in

the event of a defect.

9

Sa f e t y

M A B 1 3 0 0

ENGLISH

R i s k o f i n j u r y

W A R NING

Im p r o p e r h a n d l i n g o f t h e m a c h i n e i n c r e a s e s t h e r i s k o f

i n j u r y !

Observe the following safety precautions to avoid injuring

yourself and/or others:

►Operate the machine only with the protective equipment

stipulated in these operating instructions (see section

Personal protective equipment).

►Do not wear protective gloves when the machine is running.

A glove can be caught by the drilling machine and torn off

the hand. Risk of losing one or more ngers.

►Remove loose jewellery before beginning work. Wear a hair

net if you have long hair.

►Always switch off the machine before changing tools,

performing maintenance or cleaning. Wait until the machine

has come to a complete standstill.

►Always remove the plug from the mains socket before

changing tools, cleaning or performing maintenance, in

order to avoid unintentional starting of the machine.

►Do not put your hand into the machine while it is in

operation. Remove shavings only when the machine is at a

standstill. Wear protective gloves when removing swarf.

►When working on scaffolding, the operator must be secured

with a safety belt as the machine can oscillate dangerously

in the event of interruption to the power supply.

►Check for secure clamping of the electromagnets on the

substrate before every use (see section Preparing).

►Secure the machine with the safety belt supplied when

working from an inclined or vertical position or during

overhead work. The machine could fall down if the magnet is

loosened or the power fails.

►Check that the tool is tightened securely before using (see

section Inserting the tool).

►Do not allow the connecting cable to hang over edges

(danger of tripping).

1 0

Sa f e t y

M A B 1 3 0 0

ENGLISH

P r e v e n t i n g d a m a g e

CAUTION

P o t e n t i a l d a m a g e t o p r o p e r t y i f t h e m a c h i n e i s i m p r o p e r l y

u s e d !

Observe the following instructions to avoid damage:

►Before connecting the machine, compare the connection

data (voltage and frequency) on the rating plate with those

of your mains power supply. The data must correspond in

order to avoid damage to the machine.

►Always use the handle to carry the machine and not the

connecting cable.

►Do not pull the mains cable to remove the plug from the

mains socket.

►Do not crush the connecting cable.

►Do not expose the connecting cable to heat or chemical

liquids.

►Do not pull the connecting cable across sharp edges or hot

surfaces.

►Lay the connecting cable in such a way that it cannot be

caught and wound up in the rotating part of the machine.

T r a n s p o r t i n g t h e m a c h i n e

W A R NING

D a n g e r r e s u l t i n g f r o m h e a v y w e i g h t o f t h e m a c h i n e !

Due to the heavy weight of the machine, observe the following

instructions

►Transport the machine only with suitable transport material.

►Lifting the machine manually should be carried out by two

persons.

►When transporting the machine with a crane, use suitable

lifting devices. Pay attention to the carrying capacity of the

lifting device.

1 1

Sa f e t y

M A B 1 3 0 0

ENGLISH

Sa f e t y i n s t a l l a t i o n s

R e s t a r t p r o t e c t i o n

NOTE

►The machine stops automatically when the magnetic clamp

is switched off or in the event of interruption to the power

supply.

In order to prevent the machine from starting unexpectedly after

switching the magnetic clamp on again or after reconnection

following interruption to the power supply ("restart protection"), the

machine must be switched on again using the ON/OFF switch.

M a g n e t i n d i c a t o r

The magnet indicator provides a visual control of the magnet's

clamping force.

■Magnet indicator lights up GR EEN:

The magnet's clamping force satises the minimum

requirements. The machine cane used.

■Magnet indicator lights up RED:

Insufcient magnet clamping force. Do not operate the

machine. This can be the case if the material is too thin, the

surface is uneven or if coated with paint, scale or zinc.

T h e r m a l o v e r l o a d p r o t e c t i o n

The machine is also protected against overheating. If the machine

becomes too hot, it switches off automatically.

Perform the following steps before continuing to work with the

machine:

Remove any blockages that may have occurred.

Allow the machine to run at idle for approx. 2 minutes.

The machine is then ready for operation again.

Sl i p c l u t c h

In the event of the drill blocking, the gearbox is protected by a slip

clutch.

1 2

Sa f e t y

M A B 1 3 0 0

ENGLISH

Sy m b o l s o n t h e m a c h i n e

The symbols on the machine have the following meaning:

Sy m b o l M e a n i n g

Electric shock hazard!

Read the operating instructions before beginning

work!

Wear protective goggles and ear protection!

P e r s o n a l p r o t e c t i v e e q u i p m e n t

Wear the following protective equipment at all times when working

with the machine:

Sy m b o l M e a n i n g

Close-tting work protection clothing with a low

tearing resistance

Goggles for protecting eyes against ying parts and

liquids and ear protection in areas with noise emission

>80 dB(A)

Safety shoes to protect the feet from falling objects

Wear the following additional protective equipment during special

operations:

Sy m b o l M e a n i n g

Helmet to protect your head from falling objects

Wear a safety belt where there is a danger of falling

Working gloves as protection against injury

1 3

C o m p o n e n t s / d e l i v e r y c o n t e n t s

M A B 1 3 0 0

ENGLISH

C o m p o n e n t s / d e l i v e r y c o n t e n t s

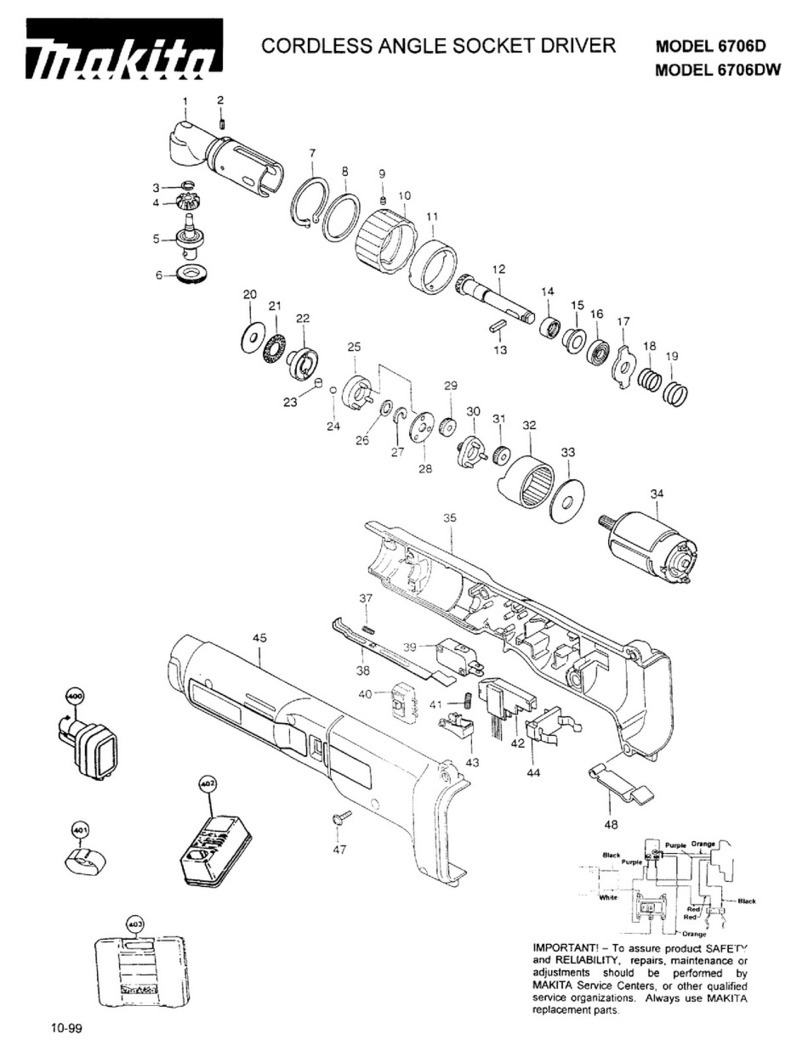

M a c h i n e o v e r v i e w

1 2

1 0

9

8

7

5

3

1 5

4

2

1 1

1

6

1 3

1 4

1 Core drill (not supplied as standard) 8 Speed and torque controller

2 Tool holder 9 Drive motor

10 Transport lug

3 Support strut 11 Hand lever

4 Internal lubrication 12 Handle

5 Morse taper MK4 13 Control panel

6 Opening for ejector pin 14 Machine slide and guide

7 4-speed gearbox with selector 15 Magnetic foot

1 4

C o m p o n e n t s / d e l i v e r y c o n t e n t s

M A B 1 3 0 0

ENGLISH

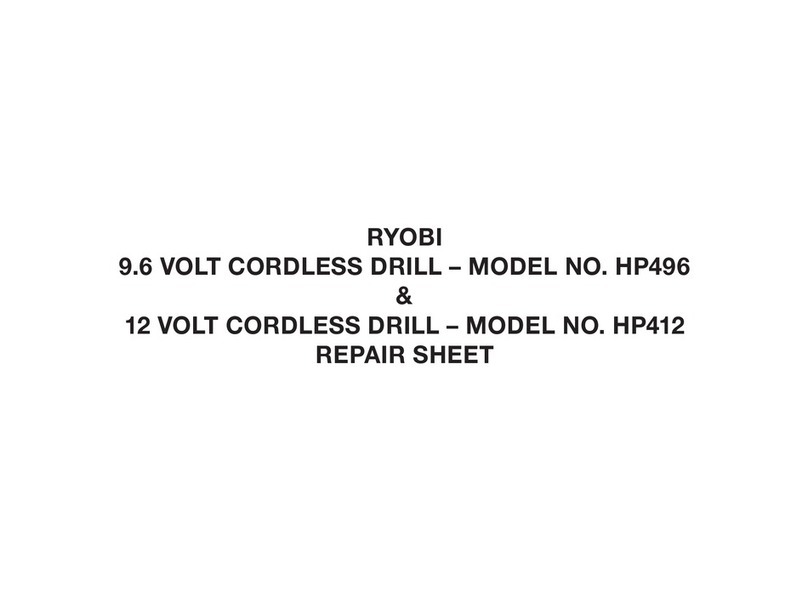

D e l i v e r y c o n t e n t s

A B , C , D , E F H

G

MAB 1300 machine (not illustrated) E ZAK 120 ejector pin

A ZAP 200 reducing ring

(11/4" [32 mm] Weldon to 3/4" [19 mm]

Weldon)

F Safety belt

G MK4 ejector pin

B ZAK 075 ejector pin H WAF6 Allen key

C ZAK 090 ejector pin Operating instructions/guarantee card

(not illustrated)

D ZAK 100 ejector pin Metal transport case

(not illustrated)

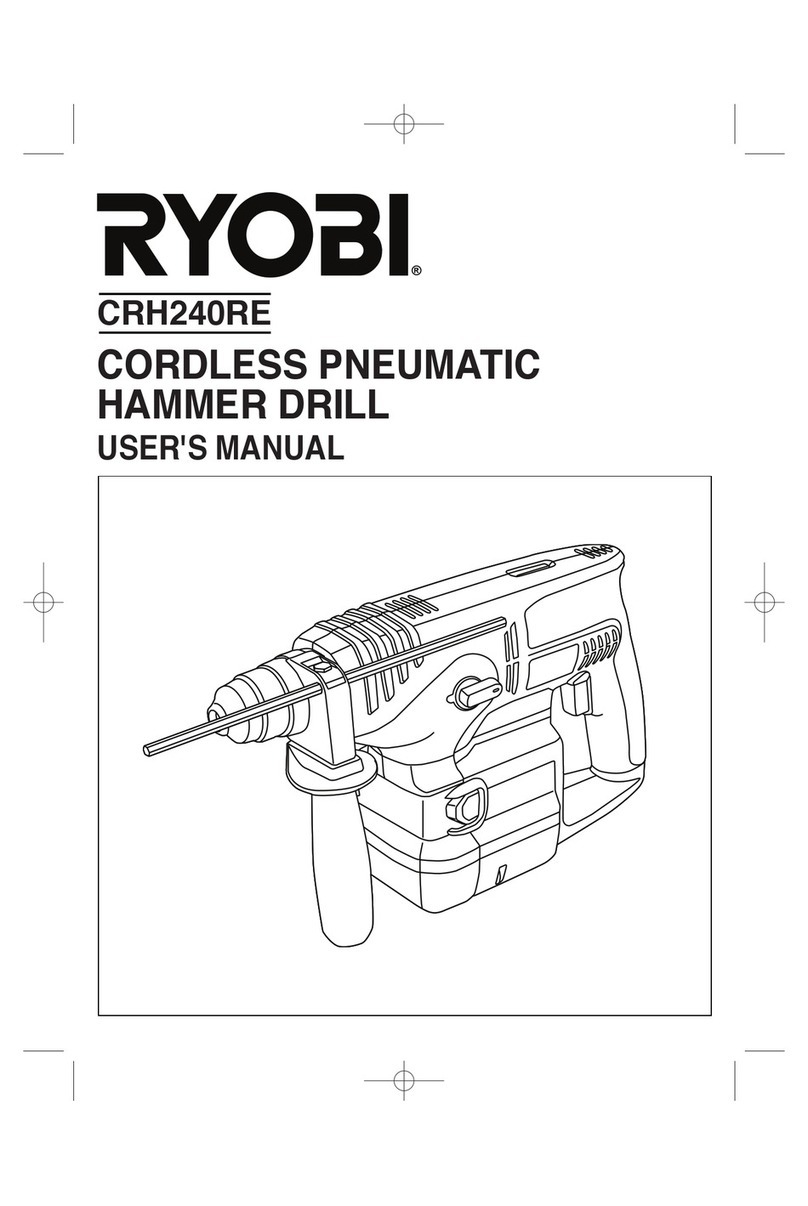

C o n t r o l p a n e l

2 1

2 2

3 1

3 2

2 4

2 3

21 Motor ON/OFF switch 31 Speed setting

22 Magnet ON/OFF switch

23 Direction of rotation switch 32 Torque setting

24 Magnet indicator

1 5

Before using for the rst time

M A B 1 3 0 0

ENGLISH

Before using for the rst time

T r a n s p o r t i n s p e c t i o n

As standard, the machine is supplied with the components

indicated in section Components/delivery contents.

NOTE

►Inspect the delivery for completeness and obvious signs of

damage. Report an incomplete or damaged delivery to your

supplier/retailer immediately.

P r e p a r a t i o n

This section contains important instructions on required

preparation before starting work.

A d d i t i o n a l s a f e t y m e a s u r e s f o r c e r t a i n o p e r a t i o n s

Additional safety precautions must be taken when performing the

following operations with the machine:

No n - h o r i zo n t a l w o r k i n g p o s i t i o n

W A R NING

R i s k o f i n j u r y f r o m a f a l l i n g m a c h i n e .

When working in an inclined or vertical position or during

overhead work, the machine must be secured using the safety

belt (D) supplied to prevent it from falling.

►Check the safety belt for correct function before using. A

damaged safety belt must not be used. Replace a damaged

safety belt immediately.

►Attach the safety belt in such a way that the machine can fall

away from the operator if it slips.

►Lay the safety belt as taught as possible around the handle

of the machine.

►Check the secure tting of the safety belt and lock before

starting work.

►Use the protective equipment stipulated in the section

Personal protective equipment.

1 6

P r e p a r a t i o n

M A B 1 3 0 0

ENGLISH

W o r k o n s c a f f o l d i n g

W A R NING

R i s k o f f a l l i n g f r o m s u d d e n o s c i l l a t i n g m o v e m e n t s o f t h e

m a c h i n e .

When working on scaffolding, the machine can make a sudden

oscillating movement on starting or in the event of interruption to

the power supply.

►Secure the machine with the safety belt (F) supplied.

►Wear a safety belt to protect yourself against falling.

C h e c k t h e c o n d i t i o n o f t h e s u b s t r a t e

The magnet clamping force is dependent on the condition of the

substrate. The clamping force is signicantly reduced by paint,

zinc and scale coatings and rust.

The substrate must satisfy the following conditions in order to

achieve sufcient magnet clamping force:

■The substrate must be magnetic.

■The clamping surface and the magnetic foot (15) must be

clean and grease-free.

■The clamping surface must be completely smooth and level.

NOTE

►Clean the substrate and the magnetic foot (15) of the

machine before use.

►Remove any unevenness and loose rust from the substrate.

►CS Unitec offers special holding devices in its range of

accessories.

The best clamping effect is obtained on low-carbon steel substrate

with a thickness of at least 3/4" (20 mm).

1 7

P r e p a r a t i o n

M A B 1 3 0 0

ENGLISH

St e e l w i t h l o w t h i c k n e s s

When drilling into steel of low thickness, an additional steel plate

(minimum dimensions: 4" x 77/8" x 3/4" [100 x 200 x 20 mm]) must

be placed under the workpiece. Secure the steel plate to prevent

it from falling.

NF m e t a l s o r w o r k p i e c e s w i t h a n u n e v e n s u r f a c e

A special holding device must be used when drilling into NF

metals or into workpieces with an uneven surface.

NOTE

►CS Unitec offers special clamping devices for tubes and

non-magnetic materials in its range of accessories.

D i s m a n t l i n g / a s s e m b l i n g t h e t o o l h o l d e r

D i s m a n t l i n g t h e t o o l h o l d e r

Unscrew and remove the screws of the retainer (3) on the

magnetic foot.

Push the tool holder (2) out of the morse taper with the

ejector pin (G).

Remove the tool holder with the retainer.

NOTE

►Keep the tool holder with retainer and screws in the

transport case for later use.

A s s e m b l e t h e t o o l h o l d e r

Insert the tool holder (2) from below into the morse taper (5)

of the machine.

Put the retainer into the guide on the magnetic foot and

secure it with the screws.

1 8

P r e p a r a t i o n

M A B 1 3 0 0

ENGLISH

In s e r t i n g t h e t o o l

The machine is equipped with an MK tool holder. Depending

on the type of tool to be used, corresponding tool holders, drill

chucks or adapters must be employed.

T o o l t o o l h o l d e r t o b e u s e d

Tools with

11/4" (32mm)

Weldon shank

Use MT4 (MK4) / Weldon 11/4" (32mm)

tool holder with retainer (delivery

condition).

Tools with

3/4" (19mm) Weldon

shank

Use ZAP 200 reducing ring.

Tool with

MK4 taper

Insert the tool directly into the morse taper

(5). Dismantle the tool holder with the

retainer.

Tool with

MK3 taper

Use adapter sleeve (available as an

accessory). Dismantle the tool holder with

the retainer.

Tools with

straight shank

Use drill chuck with tapered mandrel

(available as an accessory). If necessary,

use an adapter sleeve.

drill taps

Use industrial tool holder with Weldon

Shank and matching ZGA adapter for drill

taps (available as an accessory).

Sa f e t y p r e c a u t i o n s

W A R NING

R i s k o f i n j u r y !

►Do not use damaged, soiled or worn tools.

►Carry out tool changes only when the machine is switched

off and at a standstill. Remove plug from the mains socket.

►After inserting, check that the tool is engaged securely.

►Only use tools, adapter and accessories that match the

machine.

1 9

P r e p a r a t i o n

M A B 1 3 0 0

ENGLISH

W e l d o n i n d u s t r i a l t o o l h o l d e r

NOTE

►When using tools with Weldon shank, the tool holder with

retainer must be assembled (delivery condition).

For further information, see the section Dismantling/

assembling the tool holder.

In s e r t i n g t h e t o o l

Before inserting, clean the Weldon shank of the tool and the

tool holder.

Loosen both Allen screws in the tool holder with the Allen key

(H) supplied.

Insert the tool into the tool holder.

NOTE

►Use the ZAP 200 (A) reducing ring for tools with 3/4" (19mm)

Weldon shank.

►Insert the appropriate ejector pin (B,C,D,E) before inserting

a core drill.

Tighten both Allen screws in the tool holder using the Allen

key (H) supplied.

R e m o v i n g t h e t o o l

Loosen both Allen screws in the tool holder using the

Allen key (H) supplied and remove the tool by pulling it

downwards.

Remove the ZAP 200 reducing ring (A), if necessary.

2 0

P r e p a r a t i o n

M A B 1 3 0 0

ENGLISH

M K t o o l / i n d u s t r i a l t o o l h o l d e r

NOTE

►When using tools with MK4 taper, the toolholder with

retainer must be dismantled.

For further information, see the section Dismantling/

assembling the tool holder.

F i t t i n g t h e t o o l / i n d u s t r i a l t o o l h o l d e r

Before tting, clean the shank of the tool, adapter or

industrial tool holder and the morse taper (5) of the machine.

Insert the tool from below into the morse taper (5) of the

machine.

NOTE

►When using tools/adapters with MK3 taper, use MK4:3

adapter sleeve.

R e m o v i n g t h e t o o l

Turn the tool until the ejector pin (6) slips into the opening.

Lever the tool out using the ejector pin or loosen the tool by

tapping the ejector pin.

Other manuals for MAB 1300

1

Table of contents

Languages:

Other BDS Maschinen Drill manuals

BDS Maschinen

BDS Maschinen MAB 800 User manual

BDS Maschinen

BDS Maschinen MAB 450 User manual

BDS Maschinen

BDS Maschinen MAB 500 User manual

BDS Maschinen

BDS Maschinen AutoMAB 350 User manual

BDS Maschinen

BDS Maschinen MAB 1300 User manual

BDS Maschinen

BDS Maschinen MAB 825 KTS User manual

BDS Maschinen

BDS Maschinen MAB 825 User manual