BE-Combi 3500PLUS Operating instructions

User and Maintenance Manual MAN TGE

Page 2 of 31

No part of this document may be reproduced and/or published without written permission from BE-

Combi Systems.

BE-Combi Systems reserves the right to make changes without prior notice.

© Copyright BE-Combi Systems, Vuren, The Netherlands

09-2023 V1.1 EN

User and Maintenance Manual MAN TGE

Page 3 of 31

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................................................3

1INTRODUCTION ...............................................................................................................................4

2USER MANUAL ................................................................................................................................5

2.1 GENERAL........................................................................................................................................5

2.2 MAXIMUM PERMISSIBLE PAYLOAD....................................................................................................6

2.3 TACHOGRAPH................................................................................................................................7

2.4 COMMISSIONING............................................................................................................................7

2.5 CONNECTING AND DISCONNECTING VEHICLE AND TRAILER................................................................8

2.6 SYSTEM DESCRIPTION AND INSTRUCTIONS ........................................................................................ 11

Intelligent Braking System (IBS) operation and display .......................................................................11

Fifth wheel...........................................................................................................................................13

Park and brake valve............................................................................................................................13

Semi-trailer parking brake....................................................................................................................14

Plug connection terminal.....................................................................................................................15

Tail lift controls (optional) ...................................................................................................................16

Trailer height controls (optional) .........................................................................................................16

3MAINTENANCE MANUAL............................................................................................................. 17

3.1 AIR SYSTEM................................................................................................................................. 17

3.2 COUPLING CONNECTION ................................................................................................................ 19

3.3 SEMI-TRAILER AXLE....................................................................................................................... 20

3.4 BRAKE SYSTEM AND BLEEDING........................................................................................................ 21

3.5 AIR SUSPENSION........................................................................................................................... 23

3.6 FUSES......................................................................................................................................... 23

4MALFUNCTIONS........................................................................................................................... 25

4.1 CAUSES AND SOLUTIONS................................................................................................................ 25

4.2 IBS ERROR CODE READOUT ............................................................................................................. 28

APPENDIX A .......................................................................................................................................... 30

User and Maintenance Manual MAN TGE

Page 4 of 31

1INTRODUCTION

This user and maintenance manual describes the operations required to couple a 3500PLUS trailer to

its corresponding truck. Furthermore, this manual provides instructions to perform periodic

maintenance on an entire 3500PLUS System, which is equipped with IBS (Intelligent Braking System).

This manual is applicable for the following models:

•B53DL, wheelbase 3640 mm

•B54DL, wheelbase 4490 mm

Follow the instructions at all times, always adhere to general safety and environmental regulations.

Please contact BE-Combi Systems if you have any questions and/or comments.

User and Maintenance Manual MAN TGE

Page 5 of 31

2USER MANUAL

2.1 General

Features of a 3500PLUS System:

•The towing vehicle is equipped with a subframe, on which a fifth wheel is mounted.

•The 3500PLUS trailer is coupled to this fifth wheel while the trailer rests entirely on the

subframe.

•Through an air compressor on the vehicle, the trailer is supplied with air for brakes and air

suspension.

•The vehicle and trailer are coupled and secured rigidly, so it is not a hinged structure like a

regular trailer / truck combination.

•Driver must have a BE driver’s licence, either from before 19-01-2013 or after 19-01-2013.

•The speed limit is 80 km/h (locally applicable laws and regulations apply).

•The maximum permissible vehicle / trailer combination is always 7000 kg.

3500PLUS trailer

Air compressor

Subframe

Vehicle

Fifth wheel

User and Maintenance Manual MAN TGE

Page 6 of 31

2.2 Maximum permissible payload

The maximum payload for a 3500PLUS System is different for each vehicle/trailer combination. The

example below must be adhered in order to determine the maximum payload.

•Max. gross vehicle / trailer combination weight is always 7000 kg.

•The permissible fifth wheel load is the difference between gross and kerb vehicle weight,

which pushes downwards on the fifth wheel on the vehicle.

•This fifth wheel load is included in the gross trailer weight.

•The kerb weight varies by type of vehicle and trailer. This affects the permissible fifth wheel

load and so maximum payload.

* Use the correct kerb vehicle and trailer weights as specified in the corresponding registration certificate.

Gross vehicle weight 3500kg

Kerb vehicle weight 2400kg* -.

Vehicle fifth wheel load 1100kg

Gross trailer weight 4600kg

Kerb trailer weight 1900kg* - -.

Max payload capacity 2700kg

Max. axle load trailer 3500kg

Vehicle fifth wheel load 1100kg +

Gross trailer weight 4600kg

User and Maintenance Manual MAN TGE

Page 7 of 31

2.3 Tachograph

The vehicle combined with a 3500PLUS System is tachograph-compliant. Refer to the tachograph

instruction book for its correct use in conjunction with local applicable laws and regulations. Make sure

the following actions are carried out:

•On first use, insert the company card into the tachograph to link the company to the vehicle.

When doing so, enter the correct registration number of the towed vehicle.

•Before starting each trip, insert the driver card into the tachograph.

•The tachograph and driver's card are legally required to be read out regularly to check driving

and rest periods. In doing so, always follow the local applicable laws and regulations.

2.4 Commissioning

After the new vehicle has been delivered with the 3500PLUS trailer, the entire combination requires a

short running in period. If there are any problems, contact your dealer.

•The vehicle should run in according to the specifications of the manufacturer in the

corresponding owner's manual.

•First 50 km - Check trailer wheel nuts for correct tightening torque of 320Nm and even tyre

wear.

•First 100 km - It is important to brake the 3500PLUS trailer intensively to allow the brake drum

and brake shoe to wear into each other. Keep general road safety in mind.

User and Maintenance Manual MAN TGE

Page 8 of 31

2.5 Connecting and disconnecting vehicle and trailer

The correct connecting and disconnecting procedure of vehicle and trailer are shown in detail in an

animation, accessible via the QR code or via the URL link below. The trailer is fit for purpose for the type

of vehicle and not exchangeable with any other type of vehicles.

www.be-combi.com/technical-documentation/videos

CAUTION! Images and animations may vary by type of vehicle and trailer.

•Vehicle and trailer are coupled here

•After docking, always check the following

procedures

•After coupling the vehicle and trailer, check

the removal of the left and right trailer support

User and Maintenance Manual MAN TGE

Page 9 of 31

•After coupling, check whether the left and

right guide pins behind the vehicle cab are

correctly positioned in their guide rails

•Check that the fifth wheel lever on the

passenger side is fully retracted and secured

by the locking lever

•Check the left and right rear of the trailer for

correct positioning of hook clamps

User and Maintenance Manual MAN TGE

Page 10 of 31

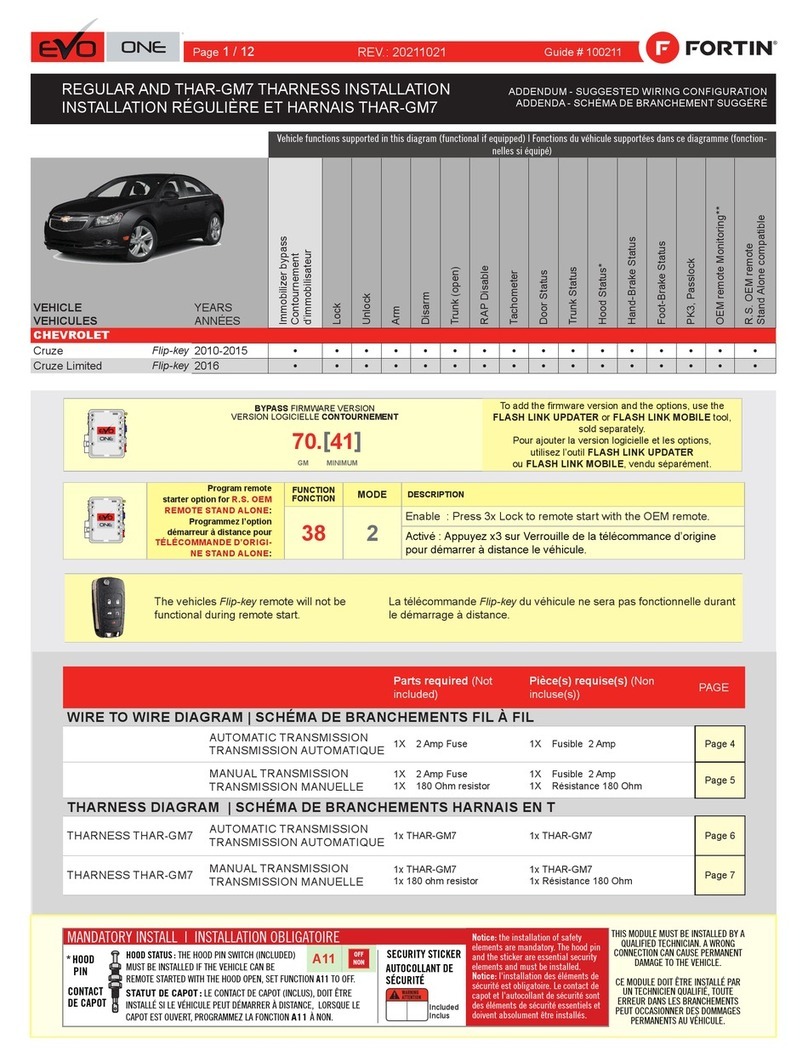

•Visually inspect the left and right trailer

wheels and wheel nuts for any damage or

incorrect mounting

•Visually check the left and right air bellows

and shock absorbers for cracks or leaks

•Check if the trailer parking brake is released,

operated by the spindle on the driver's side

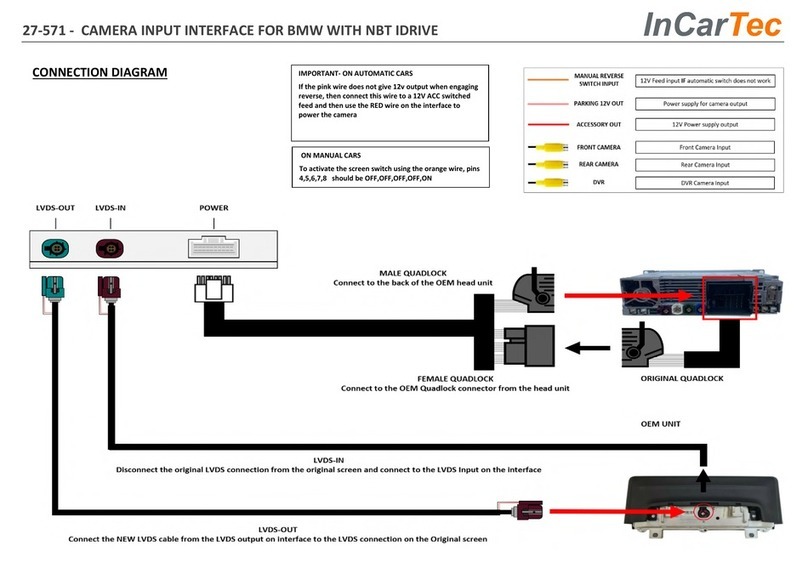

•Check if all plugs are connected to the driver

or passenger side terminal board (depending

on model)

oDuomatic

o13-pin plug

oEBS plug

oTailgate Harrisson plug (optional)

oHeight control plug (optional)

oRear view camera (optional)

User and Maintenance Manual MAN TGE

Page 11 of 31

•Check the cabin dashboard control panel

whether IBS is fault free

•3x LED indicator when ignition switched on

•Short trailer brake operation is audible

•3x LED indicator should go out

•See also section 2.6.1

2.6 System description and instructions

This section describes the various systems with their associated instructions, which are present on the

3500PLUS System.

Intelligent Braking System (IBS) operation and display

The IBS ensures that the ESP, ABS, AEBS and ASR signals from the vehicle are transmitted to the trailer's

braking system for optimum safety. The system complies with the GSR2 regulations, which are in force

as of 07-07-2024.

•The IBS control panel is mounted on the

dashboard as shown.

•The IBS continuously performs a self-

diagnosis upon startup and while driving, any

malfunctions are displayed immediately.

•When ignition is turned on, 3x lights light up

briefly at the same time.

•The right ABS light is the diagnostic check

for the trailer brakes.

•If there is no fault, this light turns off

immediately or after reaching a speed of up to

10 km/h.

User and Maintenance Manual MAN TGE

Page 12 of 31

•The left red and centre orange lights light up

briefly, during this check the air brakes are

audibly operated briefly 1x.

•After this check, the lights go out.

•When operating correctly, all lights are off.

If a light stays on, there is a malfunction in the IBS, see also chapter 4:

•Red light - IBS malfunction where electronic brake control is converted to mechanical emergency

brake control. CAUTION! Semi-trailer remains braked at all times, however, with higher brake pedal

resistance. Consult your dealer immediately.

•Orange light centre - minor malfunction where IBS remains active. Consult dealer at first

opportunity.

•Orange light right - trailer brake failure. Semi-trailer brakes at maximum pressure using the back-

up system. Consult dealer at first opportunity.

User and Maintenance Manual MAN TGE

Page 13 of 31

Fifth wheel

•The fifth wheel provides the mechanical

coupling between the vehicle and trailer.

•The fifth wheel is positioned on the vehicle's

subframe.

•The fifth wheel is equipped with two levers.

oLocking lever - push it down to operate the

coupling lever.

oCoupling lever - pull out the coupling lever in

order to couple the trailer, see also section 2.5.

Park and brake valve

•The valve must be used to park the trailer

braked or unbraked when uncoupled from the

vehicle.

•The valve is positioned at the rear of the

trailer on the passenger’s side

oBlack button out Trailer brake fixed

(happens automatically when uncoupling)

oBlack button in Semi-trailer brake

released

•CAUTION! Never operate the black button if

the trailer is uncoupled on a slope, always use

the parking brake for this, see section2.6.4.

Older types of trailers are equipped with a different valve with an air-operated parking brake,

(additional red button).

oBlack button out Trailer brake fixed (happens automatically when uncoupling)

oBlack button in Semi-trailer brake released

oRed button out Parking brake fixed

oRed button in Parking brake released (must always be done manually with a

coupled and uncoupled trailer)

User and Maintenance Manual MAN TGE

Page 14 of 31

Semi-trailer parking brake

•Under normal operating conditions, the trailer

parking brake must not be used. The vehicle's

handbrake is powerful enough for a 7000 kg

combination on a steep slope.

•Only use the parking brake with the trailer

uncoupled on a steep slope

•The parking brake is positioned at the rear

end of the trailer on the driver’s side

•Turn the crank counterclockwise to activate

the parking brake

•Turn the crank clockwise to deactivate the

parking brake

User and Maintenance Manual MAN TGE

Page 15 of 31

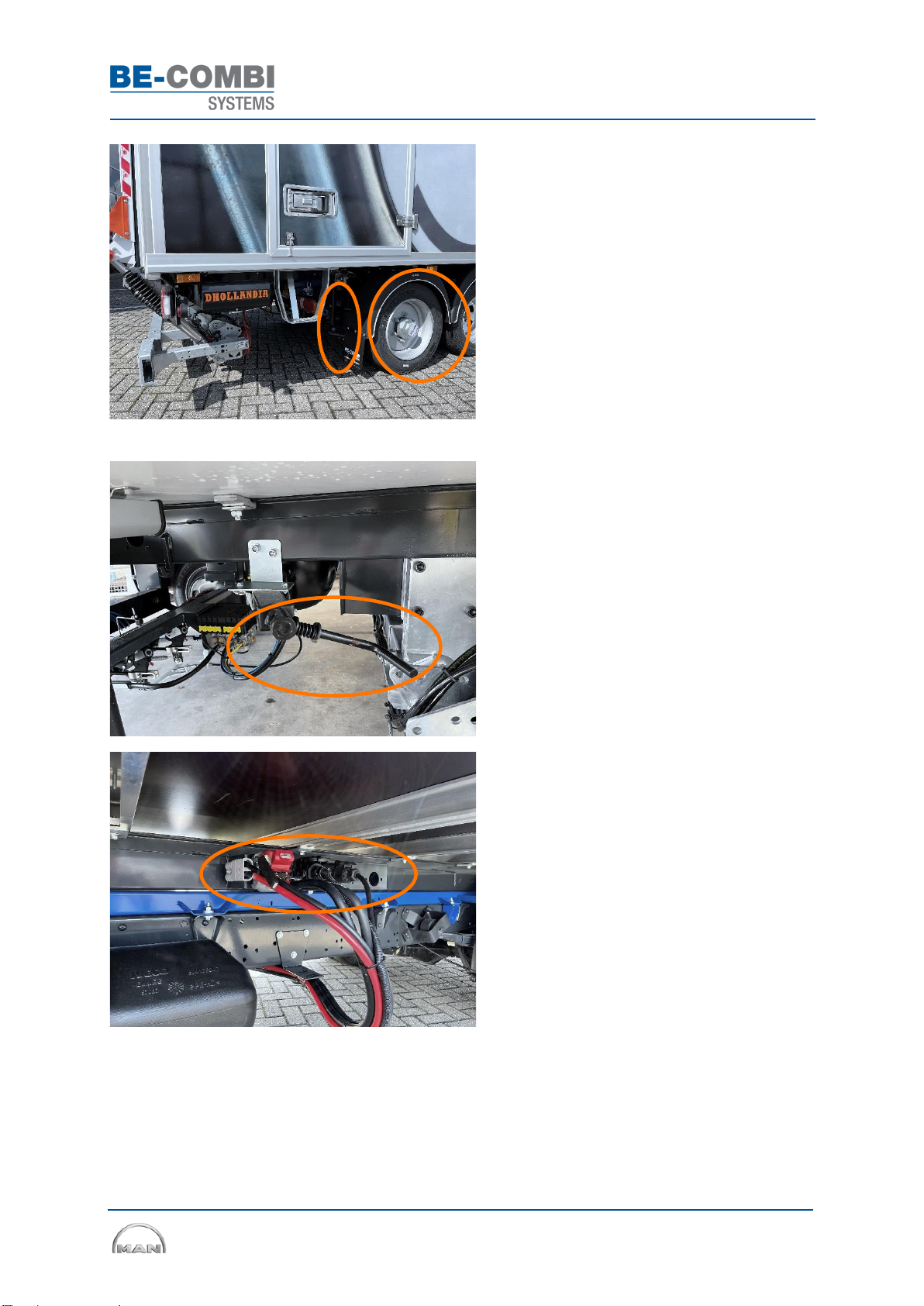

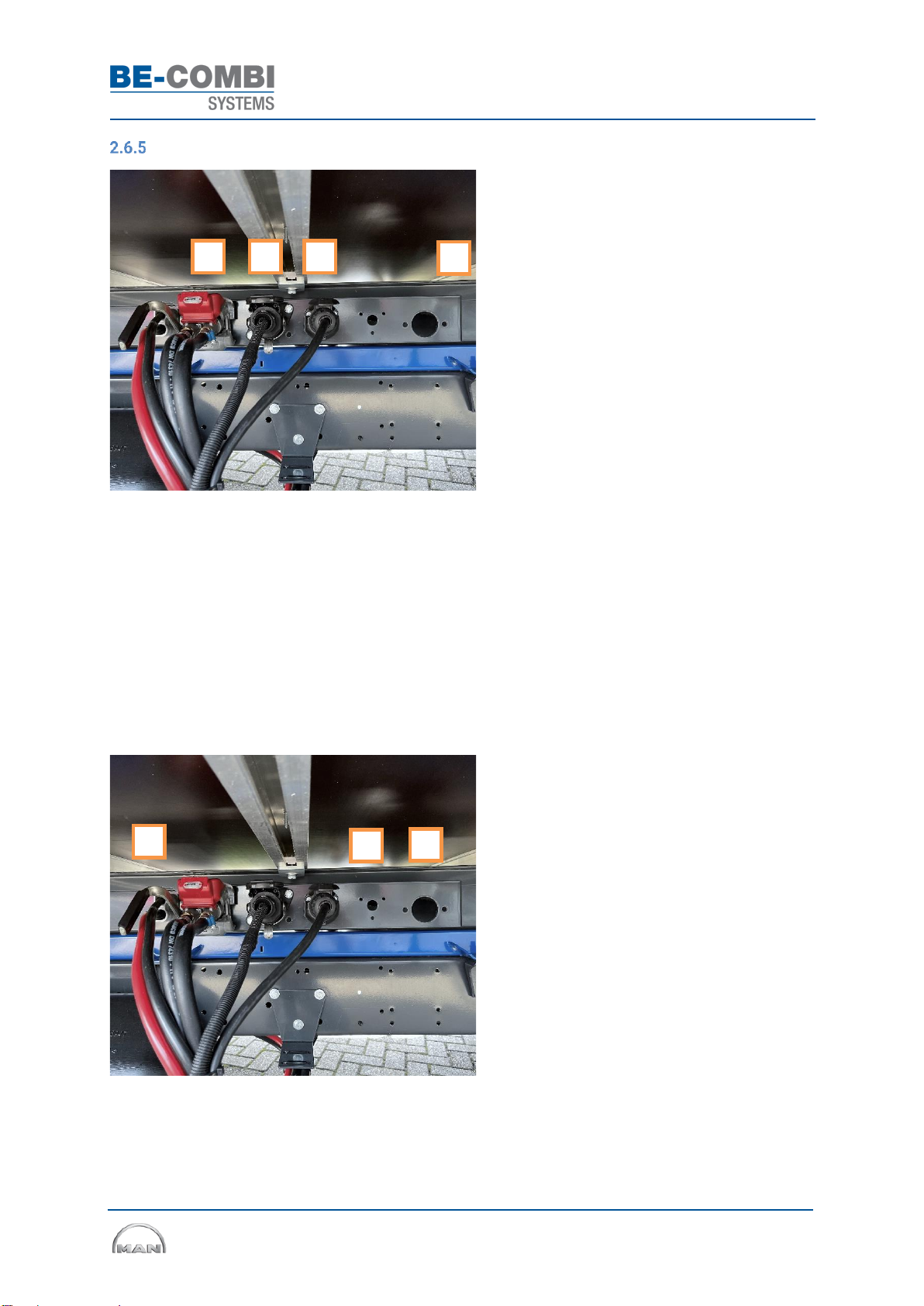

Plug connection terminal

•All plugs between the vehicle and trailer are

connected on the connection terminal on the

front of the trailer.

•Fixed connections:

1. Duomatic –provides supply pressure and

power steering air pressure. Open the red

cover and push the handle down. Then hook

the connection into the connection terminal

block. Check connection properly.

2.EBS plug –controls the anti-lock system.

Open valve and push plug in. Lock by metal

bracket.

3. 13-pin plug –controls the lights

Open the valve and turn the bayonet socket

clockwise until plug is pulled fully into the

socket.

4. Diagnostic EBS plug –is not connected.

Dealer uses this for failure analysis of the EBS

unit

•Optional connections

5. Harrisson plug –high current for e.g. tail

lift. Push plug straight into holder.

6. 3-pin plug –height control is controlled

from the cab. Open cover and push plug into

plug box, form-fitting (not shown in image).

7.Camera plug –power and signal for rear

view camera. Open cover and push plug into

power socket, form-fitting (not shown in

image).

1

2

3

3

5

6

7

4

User and Maintenance Manual MAN TGE

Page 16 of 31

Tail lift controls (optional)

•The tail lift controls are located on the rear

end and passenger side of the trailer

•Refer to the tail lift supplier's manual for the

proper operation

Trailer height controls (optional)

•With the height control, it is possible to vary

the loading floor height

•The height control can also act as a traction

control on slippery surfaces. Reducing the

trailer axle load adds more pressure on the

vehicle's driving axle

•Valve and instructions are positioned at the

rear end of the trailer on the driver’s side

•The vehicle is also equipped with a joystick

for operating height control from the cab

•Position MAN TGE: right side of driver's seat

oJoystick up - trailer axle up

oJoystick down - trailer axle down

•CAUTION! Height control only works while

stationary and up to 10 km/h

•Above 10 km/h, the axle automatically

returns to driving position

User and Maintenance Manual MAN TGE

Page 17 of 31

3MAINTENANCE MANUAL

The maintenance required on the 3500PLUS System is shown below.

•This manual only describes the 3500PLUS System. The vehicle should be serviced as specified by

the manufacturer.

•Regular maintenance should be carried out at least every six months.

•In accordance with local laws and regulations, the vehicle and trailer should be legally inspected at

regular intervals.

•Maintenance must be carried out by qualified personnel in accordance with the general applicable

safety and environmental regulations.

Period

Air system

Coupling

connection

Semi-trailer

axle

Brake

system

Air

suspension

First use

x

Every 6 months

x

x

x

x

x

Every 12 months

x

3.1 Air System

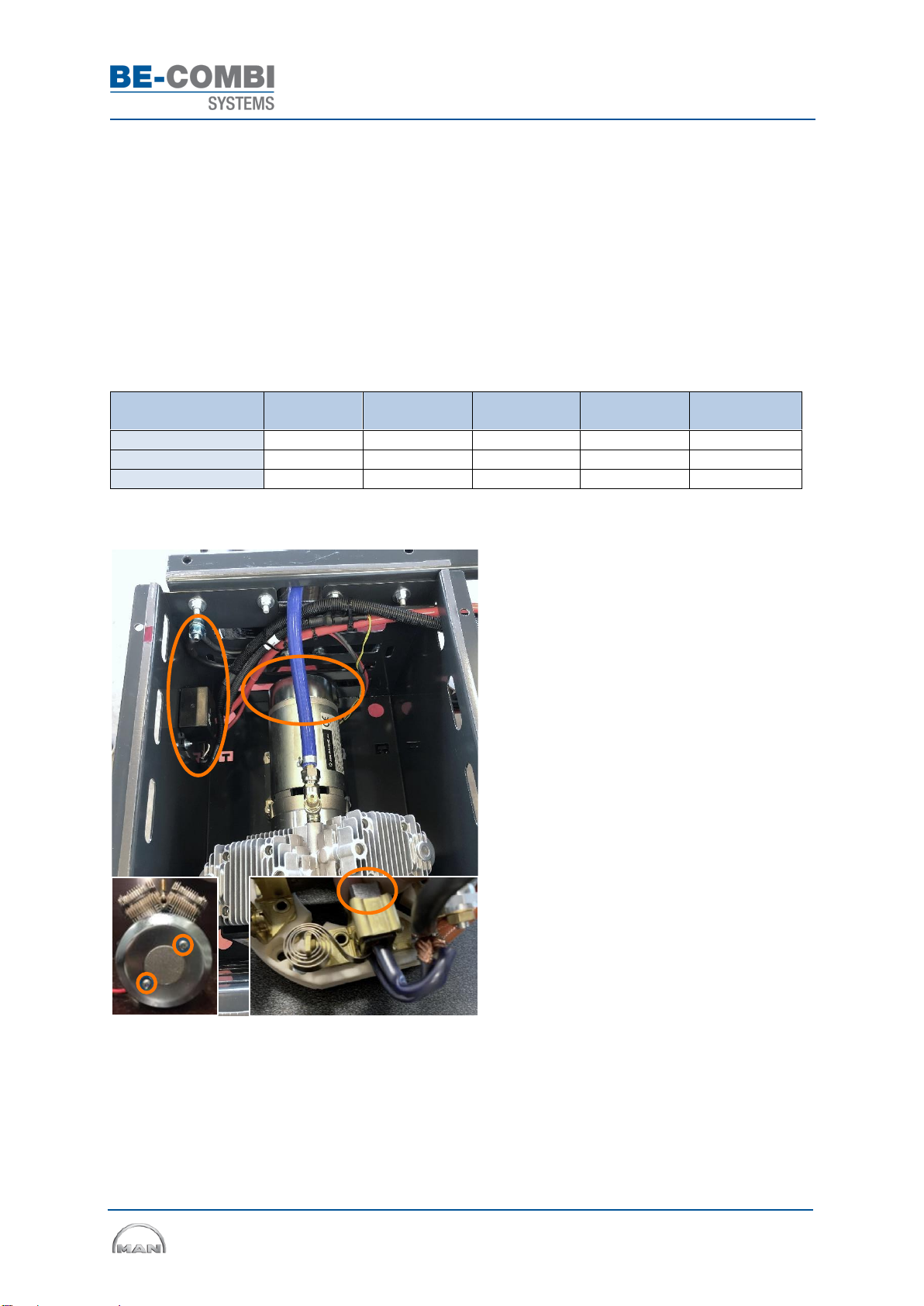

•Remove the cover of the compressor box, by

means of 4 bolts

•Remove the cover of the compressor motor,

by means of 2 screws

•Check the carbon brushes on the

compressor motor. Replace the carbon

brushes if the carbon brush length is the same

as the holder

•Check the wiring to the relay and the earth

point

•Check all air connections for leakages

User and Maintenance Manual MAN TGE

Page 18 of 31

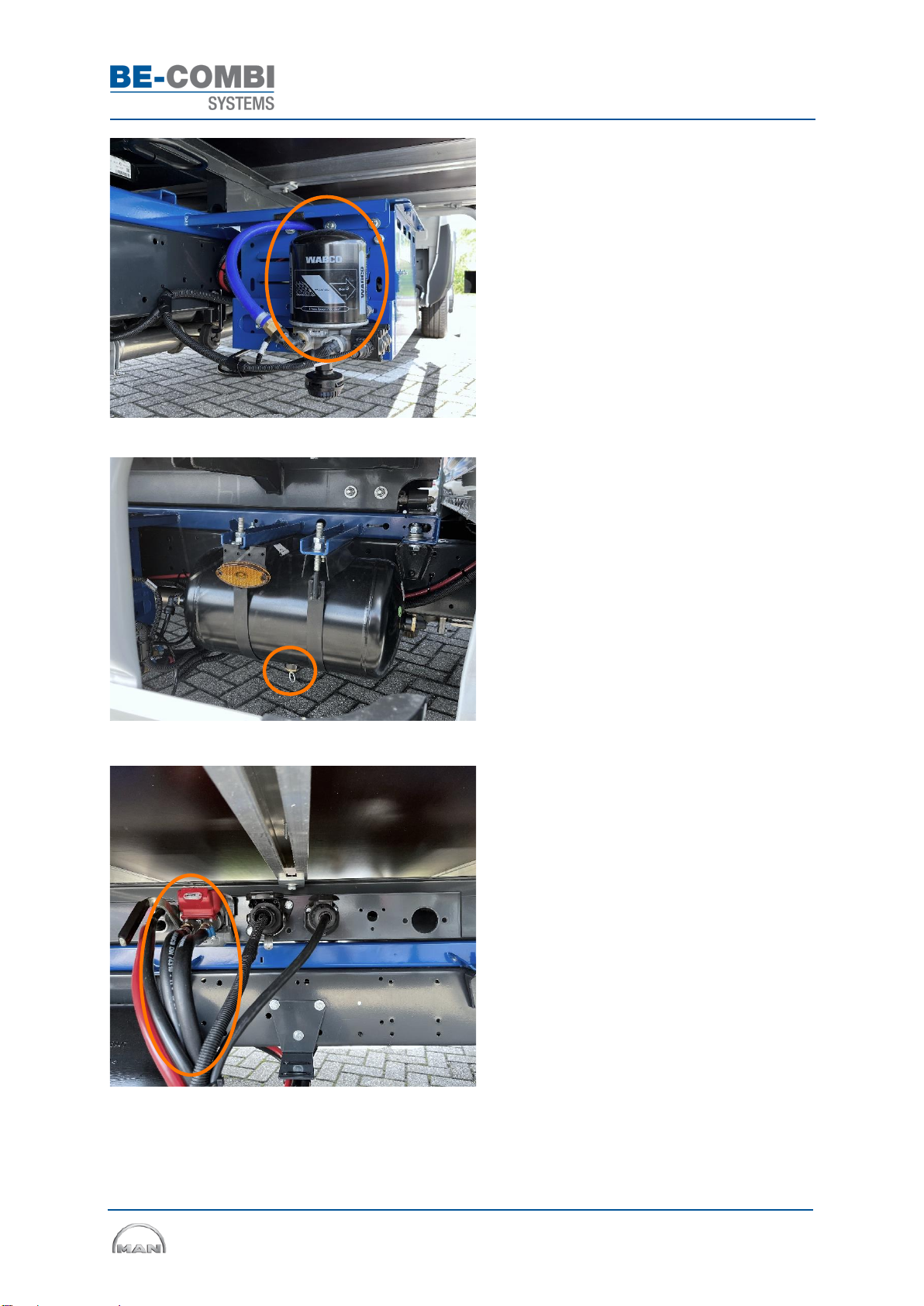

•Replace annually the air dryer filter on the

outside of the compressor bin

•Disconnect the Duomatic to prevent deflation

of the trailer air system

•CAUTION! Remove full air pressure from

vehicle system, via air tank drain valve plug

•Remove the air filter

•Apply grease to the rubber O-ring

•Install new air filter hand-tight (15 Nm)

•Drain water at the 3x air tanks

•Pull ring to the left or right until no more

water comes out

•Check air tanks and brackets for corrosion

and replace if necessary

o2x air tank trailer

o1x air tank vehicle

•Check all rubber air hoses for cracks and

leaks

•Replace if necessary

User and Maintenance Manual MAN TGE

Page 19 of 31

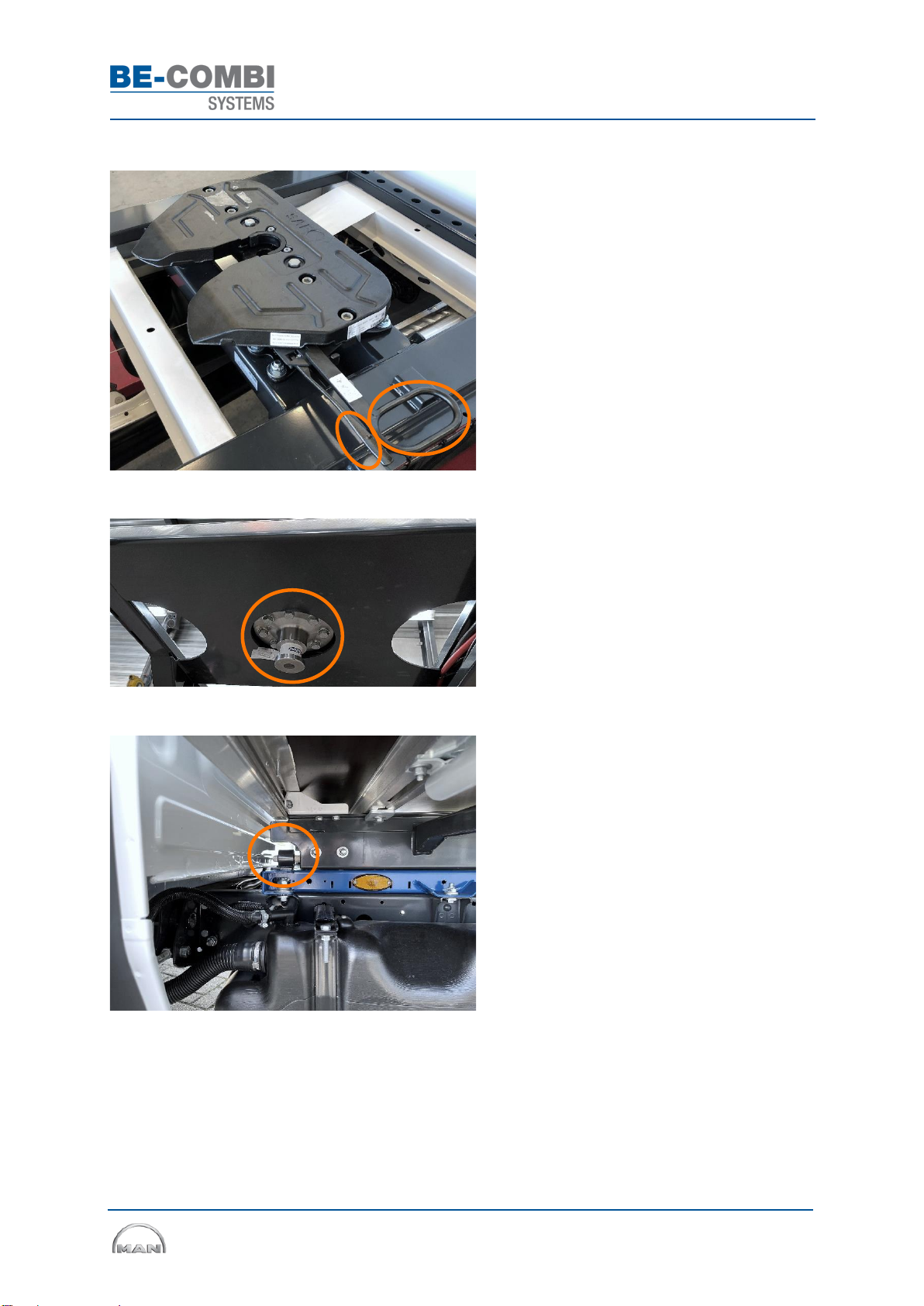

3.2 Coupling connection

•Check the bolt connection of the fifth wheel

on the subframe. Tightening torque 260 Nm

•Apply graphite grease on the entire top side

of the fifth wheel

•Check the kingpin bolt connection.

Tightening torque 130 Nm

•Lubricate the pin on the front left and right

sides of the fifth wheel with ceramic grease

User and Maintenance Manual MAN TGE

Page 20 of 31

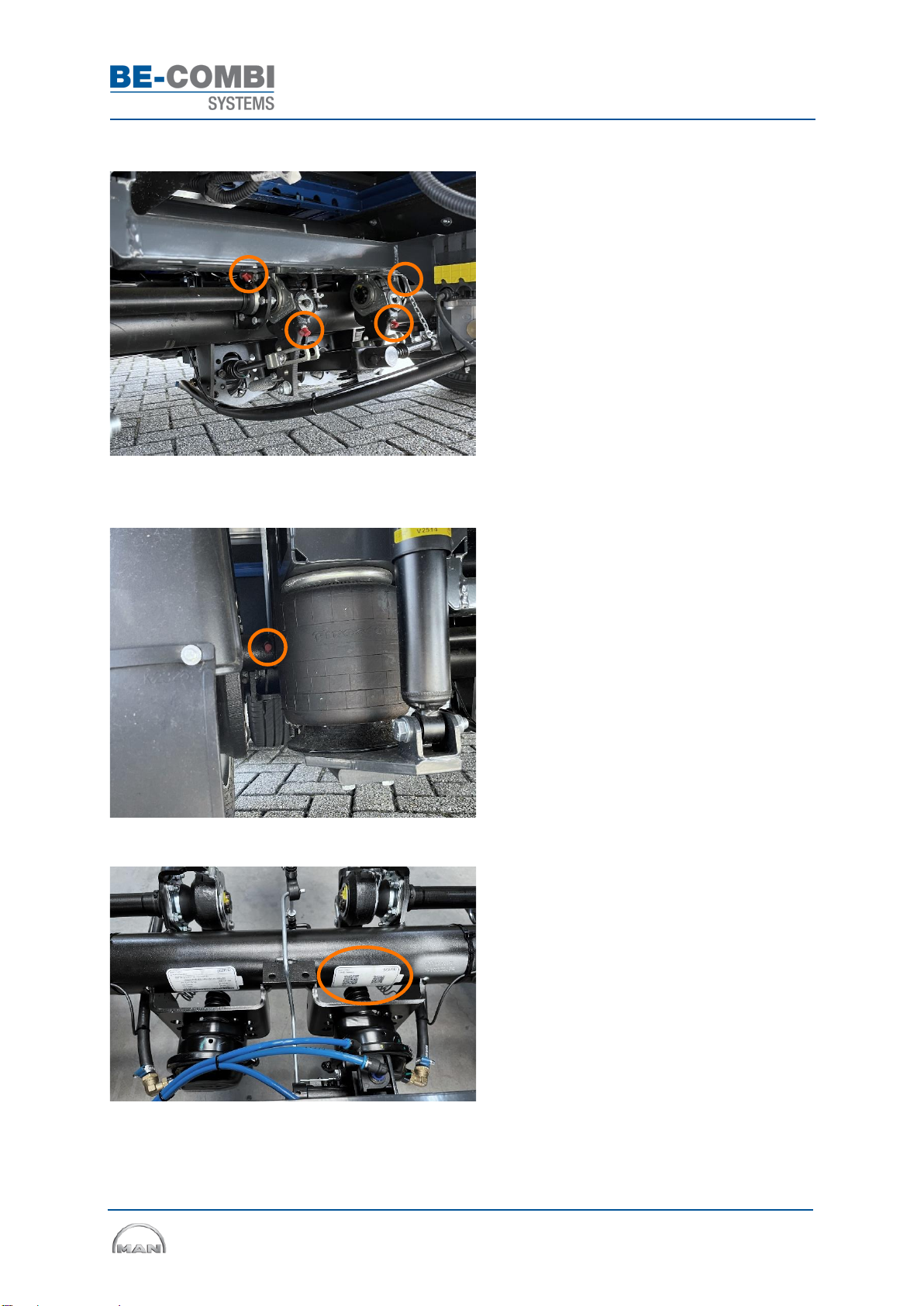

3.3 Semi-trailer axle

•Lubricate the axle with high pressure grease

(EP)

•Pump grease into grease nipple 6x until

grease is flowing out the axle

oAnchor plate, left and right sides (2x)

oSlack adjusters, left and right sides (4x)

•Position of grease nipple on anchor plate, left

and right sides

•Scan the QR code on the Gigant axle for the

correct maintenance manual

This manual suits for next models

2

Table of contents

Popular Automobile Accessories manuals by other brands

Whelen Engineering Company

Whelen Engineering Company Howler installation guide

GMC

GMC AUX-GM3 GM CLASS II Quick start installation guide

Parrot

Parrot SAT-3500 user manual

Hook

Hook E063 quick start guide

ClearView

ClearView EXPANDA EXP-01 Assembly instructions

TEINHOF

TEINHOF B-042 FITTING AND OPERATION MANUAL