10 11

CAUTION

Excessively high operating speeds increase risk of injury and damage to

water pump.

Excessively low speeds impose a heavy load.

• DO NOT tamper with the governed speed.

• DO NOT modify the water pump.

• DO NOT allow unqualified persons or children to operate or service

water pump.

NOTICE

Improper treatment of water pump can damage it and shorten its life.

• If you have questions about intended use, ask dealer or contact

nearest authorized dealer.

• Be sure pump chamber is filled with water before starting the engine.

Never run pump without priming.

• Use a non-collapseable hose on the suction side of the hose.

• Use water pump only for intended uses.

• Pumping sea water, beverages, acids, chemical solutions, or any other

liquid that promotes corrosion can damage the pump.

• Ensure all connections are air tight.

• DO NOT obstruct the suction or discharge hose in any way.

• NEVER operate pump without strainer basket connected to end of

suction hose.

• NEVER allow vehicles to drive over hoses. If a hose must be

positioned across a roadway, use planking on each side of hose to

allow vehicles to pass over without obstructing or collapsing hose.

• Anchor pump to avoid equipment movement.

• Keep equipment away from edge of river or lake where it could cause

the bank to collapse.

• DO NOT insert any objects through cooling slots.

• NEVER operate units with broken or missing parts, or without

protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• NEVER move machine by pulling on hoses. Use frame on unit.

• Check fuel system for leaks or signs of deterioration, such as chafed

or spongy hose, loose or missing clamps, or damaged tank or cap.

Correct all defects before operating water pump.

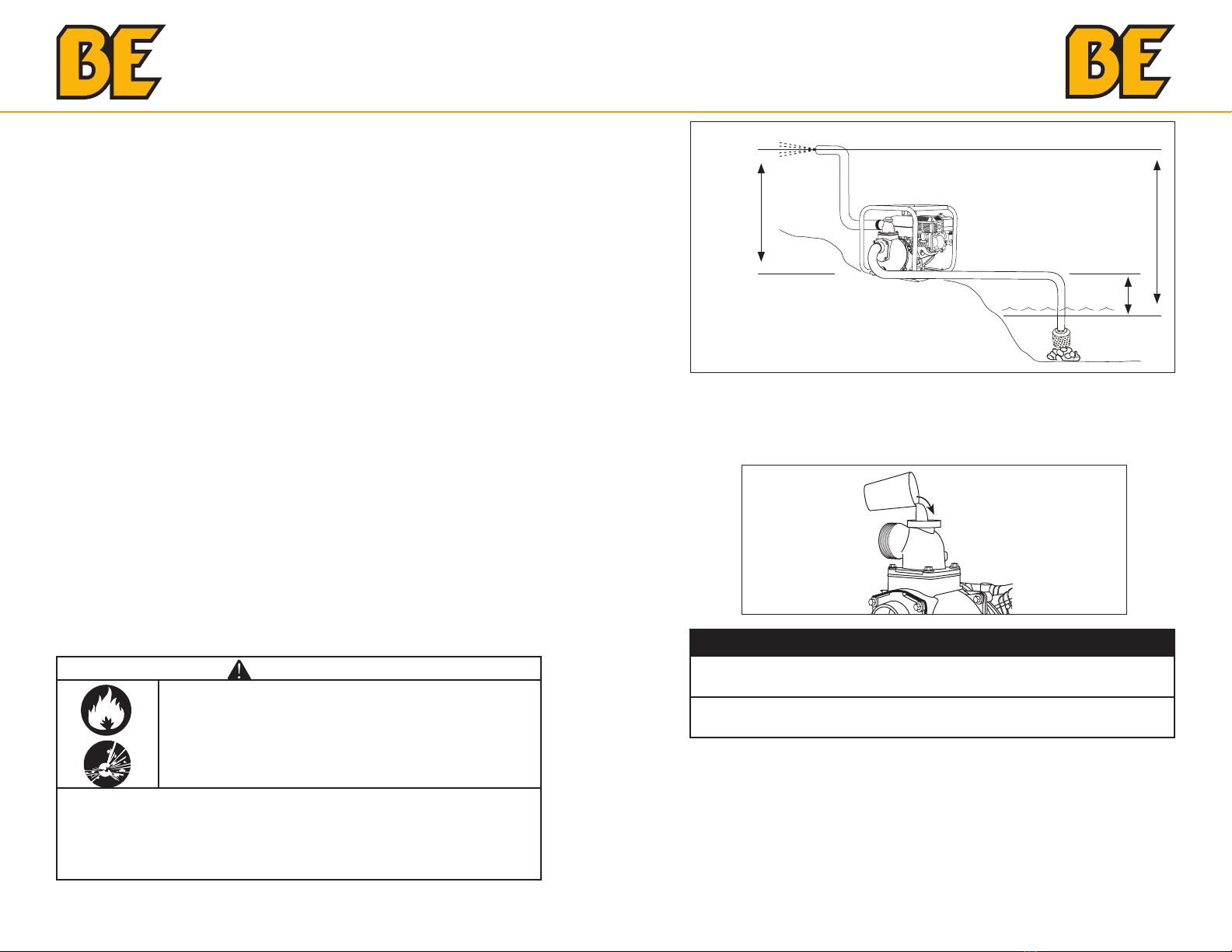

SAFETY

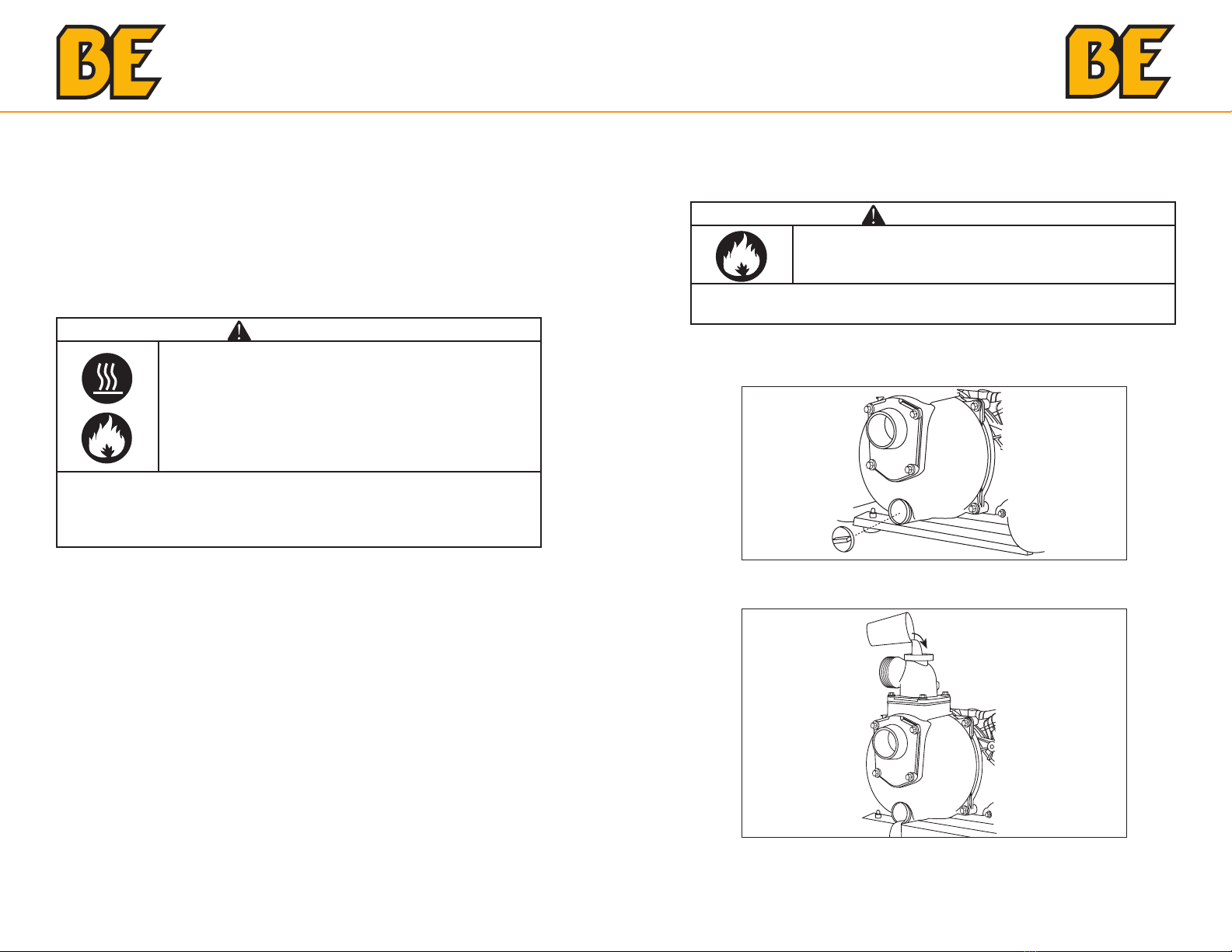

Your unit may dier from the model shown

below. For specific model information, please

visit our website: BEPOWEREQUIPMENT.COM

1. Fuel Tank Fill tank with regular unleaded fuel. Always leave room for fuel

expansion.

2. Priming Plug Fill pump with water here to prime pump before starting.

3. Discharge Outlet Connect discharge hose here.

4. Choke Lever Prepares a cold engine for starting.

5. Air Cleaner Protects engine by filtering dust and debris out of intake air.

6. Recoil Starter Used for starting the engine manually.

7. Engine Speed Lever Used to adjust engine speed to control pump output.

8. On/O Switch Set this switch to “On” before using recoil starter. Set switch to

“O” to stop a running engine.

9. Oil Drain Drain engine oil here.

10. Oil Fill Check and add engine oil here.

11. Suction Inlet Connect reinforced suction hose here.

12. Water Drain Plug Remove to drain water from pump and flush internal

components with clean water.

13. Pump Chamber Be sure to fill with water before starting.

14. Fuel Shuto Valve Used to turn fuel supply on and o to engine.

Item Not Shown:

Strainer Basket Used to limit passage of abrasive materials into the pump.

WATER PUMP COMPONENTS

1.

2.

3.

12.

11.

7.

6.

13.

14.

9.

11.

4.

10.

8.