Beamax PSCHP1399 User manual

Made by Adeo Screen sp. Z o.o. (Polska) for Home Cinema Modules

Specifications are subject to change without notice. E&OE

Doc: M Series – HOME CINEMA MODULES Installation Manual rev1 | 10.01. 2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Manuale d’uso schermo avvolgibile

Projection screen user manual

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsugi ekranu

Mod. M-SERIES

Code MS0100MS0199

Mod. M-TENSIONED

Code MT0500MT0599

Made by Adeo Screen sp. Z o.o. (Polska) for Home Cinema Modules

Specifications are subject to change without notice. E&OE

Doc: M Series – HOME CINEMA MODULES Installation Manual rev1 | 10.01. 2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Manuale d’uso schermo avvolgibile

Projection screen user manual

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsugi ekranu

Mod. M-SERIES

Code MS0100MS0199

Mod. M-TENSIONED

Code MT0500MT0599

Made by Adeo Screen sp. Z o.o. (Polska) for Home Cinema Modules

Specifications are subject to change without notice. E&OE

Doc: M Series – HOME CINEMA MODULES Installation Manual rev1 | 10.01. 2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Manuale d’uso schermo avvolgibile

Projection screen user manual

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsugi ekranu

Mod. M-SERIES

Code MS0100MS0199

Mod. M-TENSIONED

Code MT0500MT0599

Made by Adeo Screen sp. Z o.o. (Polska) for Home Cinema Modules

Specifications are subject to change without notice. E&OE

Doc: M Series – HOME CINEMA MODULES Installation Manual rev1 | 10.01. 2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Manuale d’uso schermo avvolgibile

Projection screen user manual

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsugi ekranu

Mod. M-SERIES

Code MS0100MS0199

Mod. M-TENSIONED

Code MT0500MT0599

Made by Adeo Screen sp. Z o.o. (Polska) for Home Cinema Modules

Specifications are subject to change without notice. E&OE

Doc: M Series – HOME CINEMA MODULES Installation Manual rev1 | 10.01. 2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Manuale d’uso schermo avvolgibile

Projection screen user manual

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsugi ekranu

Mod. M-SERIES

Code MS0100MS0199

Mod. M-TENSIONED

Code MT0500MT0599

INCEEL Installation Manual

Made by Adeo Screen sp. Z o.o. (Polska)

Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Rohs Compliant

Mod. INCEEL

Code PSCHP01300PSCHP1399

Mod. INCEEL TENSIO CLASSIC

Code PSCHP1400PSCHP1499

Manuale d’uso schermo avvolgibile

Roller screen user manual

Manuel d’instructions écran

Betriebsanleitung Projektionswand

Manual de uso de la pantalla enrollable

Instrukcja obsługi ekranu

Rohs Compliant

IN-CEILING TENSIONED

IN-CEILING

IN-CEILING

ENGLISH – Motorized screen user manual

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

7

01 INTRODUCTION

This manual is an integral part of the product and must be read and understood in all its parts for safety reasons. It contains norms and directions for correct and safe use of the screen.

The manual should never be separated from the product; it must be stored in a suitable place to ensure its integrity, and in such a way as to be easily consulted by authorised personnel.

Product user shall be responsible for the manual’s safekeeping. User shall also be responsible for checking the screen’s functionality and for the repair or replacement of any damaged

parts that could pose a hazard.

Images contained in this manual are intended to provide a detailed description of the product’s functions, characteristics and procedures. Any slight difference, depending on the model

represented, will not change the meaning that the images convey.

02 GENERAL CHARACTERISTICS OF THE PRODUCT

T

he screen product is manufactured in compliance with the provisions of the following EC directives 2006-95-CE LDV

2004-108-CE EMC

1999-05-CE R&TTE

2005-32-CE Eco design

2011-65-CE ROHS

2002-96-CE RAEEi

2001-95-CE SAFETY

T

he screen described in this manual must be used exclusively as a support for video projection.

Any other use not covered by this manual, it is not consented.

T

he screen contains one or more Fabric of projection.

The Fabric of projection is a cadmium-free plastic pvc sheet or Glass wire (continuos filament) plastified PVC impregnated, any fabric

can be classified in

category:

- M1 and M2 fire classification under French standards (LNE Laboratoire national de métrologie et d’essais – SME Centre de recherches du Bouchet - WARRINGTONFIRE GENT Laboratoire de

métrologie et d’essais – IFTH Laboratoire accreditè

- B1 and B2 fire classification under German standards (LNE Laboratoire national de métrologie et d’essais – SME Centre de recherches du Bouchet - WARRINGTONFIRE GENT Laboratoire

national de métrologie et d’essais)

- UL94HB fire classification under USA standards (THE GOVMARK Organization, Inc.)

In the absence of a standardisation at a European level of the various national classification norms, it should be noted that the French M1 class corresponds to non flammable material and that M2 class

corresponds to flame retardant material.

03 UNPACKING AND HANDING THE SCREEN

Ensure that the screen has suffered no damage during transport. Should any fault be detected, promptly notify your dealer. Verify that all screen accessories have been included

-(2) n°8 threaded bars M8

-(3) n°4 Spacer nuts M8x30

-(4) n°4 Washers

-(5) n°4 Nuts M8

-(6) n°4 Thread stops M8

-(7) n°4 Base plates M8

-(8) n°2 Ceiling plugs

-(9) n°1 Plastic hex wrench

(only for standard motor screen models)

-(10) n° 1 unipolar selector switch (only for standard motor screen models)

-(11) n° 1 RF transmitter (Only for integrated radio screen models

-n°1 instructions booklet

(screws and plugs for wall mount are not included)

CAUTION do not use cutters or sharp objects to open the wrapping, always use protection gloves when unpacking, handling and installing the product. Depending on the product’s weight (reference load: 25

Kg male – 15 Kg female), handling and installing operations should be performed by two, three or four people at least. For heavier loads we recommend the use of specific lifting equipment.

04 GENERAL SAFETY NORMS

Always read the instructions and warnings set out in this manual very carefully before using the product or before performing any maintenance interventions.

Installation of the screen above passageway is strictly forbidden.. Before and during use, check that the screen poses no risk of hazard.

Do not tamper with, remove or damage any part or component of the screen.

Never perform screen maintenance operations when the motor is on (for maximum safety, remove power supply).

Not children safe. It is mandatory to keep children away during operations with the screen.

All our screens are covered by guarantee; validity of the same shall be subject to user’s full compliance with the instructions contained in this manual.

WARNING: Faulty installation may compromise the safety of the product’s operators; manufacturer shall not be held liable for damages to persons or things resulting from faulty

installation, improper use, insufficient or inadequate maintenance of the screen.

Manufacturer shall not be held responsible for problems associated with installation errors.

Screen installation, electrical connections and verifications in case of malfunction of motorised rolling screens must be performed by authorised vendor or by personnel that is

informed and trained in electrical hazards. The connection cable cannot be replaced. If the cable is damaged the screen must be replaced. Tampering with end stops or piercing

the seal placed over holes shall entail the forfeiture of the guarantee. For any necessary clarifications please contact our technical office.

N.B.ONCE THE SCREEN HAS BEEN MOUNTED ON THE BRACKETS, AND PRIOR TO USING IT, USER IS MANDATORILY REQUIRED TO ENSURE THAT THE SCREEN’S POSITION IS

PERFECTLY HORIZONTAL.

IN-CEILING

ENGLISH – Motorized screen user manual

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

8

05 WARNINGS AND RECOMMENDATIONS FOR CORRECT USE

Our screens are suitable for indoor use at normal temperature (20 - 25 °C) and humidity conditions. Special precautions are necessary for outdoor use, especially as regards

temperature levels and the presence of dust. Exposure to temperatures of over 50 °C can cause permanent deformation of the screen’s flatness, or the screen to come away

from the roller.

Avoid prolonged exposure of the projection screen to solar light to prevent yellowing of the same (ensure that exposure to solar light does not cause the screen to reach said

temperature level).

Since electrostatic charge tends to accumulate on the projection screen (which is made of PVC), attracting dust, excessive dustiness in the projection environment can

deteriorate the optical quality of the screen (see projection screen cleaning instructions).

WARNING: Do not manually force the screen’s unrolling: this could result in the motor being damaged or the screen’s case to come away from the wall mount brackets.

Do not allow children to play with the screen’s control panel. Keep remote control out of children’s reach.

Monitor screen movement and allow no-one near it until it is completely closed.

The following operations: blocking, preventing or forcing the screen’s movement, hanging or swinging from it, adding or applying any object to the screen or backdrop,

modifying the screen’s structure – are strictly forbidden and could result in damages to the screen’s rolling system and ensuing hazard to persons and things.

06 CLEANING AND MAINTENANCE

Screens and their projection surfaces are delicate and must be cleaned with great care, according to the following instructions:

Never use solvents, chemical or abrasive products, or pointed tools to clean the surface.

Avoid contact with other materials (varnishes, inks etc) as they might be impossible to remove from the canvas.

FABRIC VISION, REFERENCE, HELIOS: Remove dust from the case with a soft, clean cloth and a non aggressive detergent as necessary.

Clean the projection screen with a soft, clean, damp cloth, and a neutral or alcohol-base detergent as necessary. Since rubbing the screen with a cloth during cleaning operations can cause electrostatic

charge to accumulate, we recommend the subsequent application of an antistatic liquid with a clean cloth, to avoid dust being attracted again

GENERIC PROFILE: Remove dust from the case with a soft, clean cloth and a non aggressive detergent as necessary

VELVET PROFILE: Clean profile with a soft clean cloth, or a brush with soft, antistatic bristles. A vacuum-cleaner brush may be used, provided its bristles are soft and perfectly clean.

STRUCTURE and ANCHORING BRACKETS:

The state of the product and the anchoring capacity of its brackets must be checked regularly. In case of canvas deformation or rips, or loosening of structural

components such as brackets or screws, action must be taken immediately to clear the area around the screen and avoid hazard to people and things, replace the defective component and restore the

product's functionality.

07 INSTALLATION INSTRUCTIONS

WARNING: When installing the screen use plugs and screws suitable for the screen’s weight and for the type of wall or ceiling on which the mount brackets are to be fixed, based on the

following criteria

Screen width up to cm 160

200

250

300

360 410 520 620

Overall weight Kg 20

Kg 25

Kg 30

Kg 35

Kg 45 Kg 50 Kg 100

Kg 150

1. Prepare a hole for the screen as described in Fig. 1.

2. Install brackets as described in Fig. 2, adhering to distances given in Fig. 1.

3. Install screen as described in Fig. 3 to 7 of next page.

5. Finish installation by applying plugs as per Fig. 10 and 11.

IN-CEILING

ENGLISH – Motorized screen user manual

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

8

05 WARNINGS AND RECOMMENDATIONS FOR CORRECT USE

Our screens are suitable for indoor use at normal temperature (20 - 25 °C) and humidity conditions. Special precautions are necessary for outdoor use, especially as regards

temperature levels and the presence of dust. Exposure to temperatures of over 50 °C can cause permanent deformation of the screen’s flatness, or the screen to come away

from the roller.

Avoid prolonged exposure of the projection screen to solar light to prevent yellowing of the same (ensure that exposure to solar light does not cause the screen to reach said

temperature level).

Since electrostatic charge tends to accumulate on the projection screen (which is made of PVC), attracting dust, excessive dustiness in the projection environment can

deteriorate the optical quality of the screen (see projection screen cleaning instructions).

WARNING: Do not manually force the screen’s unrolling: this could result in the motor being damaged or the screen’s case to come away from the wall mount brackets.

Do not allow children to play with the screen’s control panel. Keep remote control out of children’s reach.

Monitor screen movement and allow no-one near it until it is completely closed.

The following operations: blocking, preventing or forcing the screen’s movement, hanging or swinging from it, adding or applying any object to the screen or backdrop,

modifying the screen’s structure – are strictly forbidden and could result in damages to the screen’s rolling system and ensuing hazard to persons and things.

06 CLEANING AND MAINTENANCE

Screens and their projection surfaces are delicate and must be cleaned with great care, according to the following instructions:

Never use solvents, chemical or abrasive products, or pointed tools to clean the surface.

Avoid contact with other materials (varnishes, inks etc) as they might be impossible to remove from the canvas.

FABRIC VISION, REFERENCE, HELIOS: Remove dust from the case with a soft, clean cloth and a non aggressive detergent as necessary.

Clean the projection screen with a soft, clean, damp cloth, and a neutral or alcohol-base detergent as necessary. Since rubbing the screen with a cloth during cleaning operations can cause electrostatic

charge to accumulate, we recommend the subsequent application of an antistatic liquid with a clean cloth, to avoid dust being attracted again

GENERIC PROFILE: Remove dust from the case with a soft, clean cloth and a non aggressive detergent as necessary

VELVET PROFILE: Clean profile with a soft clean cloth, or a brush with soft, antistatic bristles. A vacuum-cleaner brush may be used, provided its bristles are soft and perfectly clean.

STRUCTURE and ANCHORING BRACKETS:

The state of the product and the anchoring capacity of its brackets must be checked regularly. In case of canvas deformation or rips, or loosening of structural

components such as brackets or screws, action must be taken immediately to clear the area around the screen and avoid hazard to people and things, replace the defective component and restore the

product's functionality.

07 INSTALLATION INSTRUCTIONS

WARNING: When installing the screen use plugs and screws suitable for the screen’s weight and for the type of wall or ceiling on which the mount brackets are to be fixed, based on the

following criteria

Screen width up to cm 160

200

250

300

360 410 520 620

Overall weight Kg 20

Kg 25

Kg 30

Kg 35

Kg 45 Kg 50 Kg 100

Kg 150

1. Prepare a hole for the screen as described in Fig. 1.

2. Install brackets as described in Fig. 2, adhering to distances given in Fig. 1.

3. Install screen as described in Fig. 3 to 7 of next page.

5. Finish installation by applying plugs as per Fig. 10 and 11.

ENGLISH – Motorized screen user manual

Specifications are subject to change without notice. E&OE

Doc: M Screen – HOME CINEMA MODULES Installation Manual rev1 |10.01.2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

11

09 MOTOR TYPE IDENTIFICATION –CHARACTERISTICS – ELECTRICAL CONNECTION

The type of motor installed on the product is identified by a label applied on each product showing the CE logo. When unwrapping the product please check the model type indicated on the label in order to

perform the installation and cable connections correctly. Should the power of the motor be different from that of the supply network of the installation place, please contact an electrician to have a current and

Hz transformer installed.

ELECTRICAL CONNECTION:

electric cabling must be conformant with applicable IEC standards. IEC norm EN 60335-1 requires that supply

network be fitted with an omnipolar selector switch with contact opening distance of at least 3 mm. For the screen’s

control use only the selector switch provided by manufacturer, or equivalent model, and follow the instructions of the

connection diagram shown on left (if the motor is mounted on the left, the colours of the wires must be inverted, i.e.

descending = brown, ascending = black). The selector switch must be mounted within sight distance of the product,

at a 1.5 - 1.8 m height from the floor. To connect the wires to the supplied switch, remove the plastic front plates to

access the lock/unlock buttons

WARNING:

Correctly performed, state-of-the-art, norm-compliant electrical connections are important to prevent accidents and

to ensure the screen’s optimal and unaltered performance over time. Prior to carrying out any operation on electrical

parts ensure that power supply is disconnected. In screens fitted with cases the motor is positioned on the right-hand

side of the screen as seen from the front (upon request it can be located on the left). Never connect two or more

motors to the same selector switch without a control unit or two switches to the same motor..

230V 50Hz

Motor characteristics:

Frequency: ~Hz50

Power: 90W

Torque: 6Nm

Speed: 12Rpm

Max no. of cycles: 2

Cable length: 3mt

Mechanical strength:

EN14202 conformant

Operating T°:

from –20 to +55 °C

Connection for each motor:

Blue (Common)

Brown (Up)

Black (Down)

Yellow Green (Ground 230V)

120V 60Hz

Motor characteristics:

Frequency: ~Hz60

Power: 80W

Torque: 88in.lb

Speed: 14r/min

Max no. of cycles: 2

Cable length: 2.5 mt

Mechanical strength:

EN14202 conformant

Operating T°:

from –20 to +55 °C

Connection for each motor:

White(Common)

Black (Down)

Red (Up)

Giallo verde (Terra 120V)

ELECTRICAL CONNECTION:

electric cabling must be conformant with applicable IEC standards. IEC norm EN 60335-1 requires that supply

network be fitted with an omnipolar selector switch with contact opening distance of at least 3 mm. For each motor

(e.g. plug switch etc.). In case of need, this device ensures that the power supply is safely and quickly cut off. Use the

wires as described in the figure.

ATTENTION:

This product contains two motors, which must both be wired in the same manner.

Bus cables must be insulated if not used for the push-button command.

WARNING:

Correctly performed, state-of-the-art, norm-compliant electrical connections are important to prevent accidents and

to ensure the screen’s optimal and unaltered performance over time. Prior to carrying out any operation on electrical

parts ensure that power supply is disconnected.

Bus cables (black white orange) must be insulated if not used for the push-button command.

In screens fitted with cases the motor is positioned on the right-hand side of the screen as seen from the front.

Operates with standard radio control (supplied).

Nice RF 230V 50Hz

Technical characteristics:

Frequency: ~Hz50

Power: 108W

Torque: 8Nm

Speed: 17Rpm

Max no. of cycles:

2

Cable length:

3mt

Mechanical strength: EN14202

conformant

Operating T°:

from –20 to +55 °C

Frequency: 433.92 MHz

Trans. range: 150mt

Connection for each motor:

White orange (BUS)

White (BUS)

White Black (common BUS)

Brown (Phase 230V)

Blue (Neutral 230V)

Yellow Green (Ground 230V)

Nice RF 120V 60Hz

Technical characteristics:

Frequency: ~Hz60

Power: 105W

Torque: 7.1 in.lb

Speed: 20r/min

Max no. of cycles:

2

Cable length:

2.5mt

Mechanical strength: EN14202

conformant

Operating T°:

from –20 to +55 °C

Frequency: 433.92 MHz

Trans. range: 150mt

Connection for each motor:

Orange (BUS)

Violet (BUS)

Pink (common BUS)

White (Neutral 120V)

Black (Phase 120V)

Yellow Green (Ground 120V)

ENGLISH – Motorized screen user manual

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: PROFESSIONAL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

11

09 MOTOR TYPE IDENTIFICATION –CHARACTERISTICS – ELECTRICAL CONNECTION

The type of motor installed on the product is identified by a label applied on each product showing the CE logo. When unwrapping the product please check the model type indicated on the label in order to

perform the installation and cable connections correctly. Should the power of the motor be different from that of the supply network of the installation place, please contact an electrician to have a current and

Hz transformer installed.

ELECTRICAL CONNECTION:

electric cabling must be conformant with applicable IEC standards. IEC norm EN 60335-1 requires that supply

network be fitted with an omnipolar selector switch with contact opening distance of at least 3 mm. For the screen’s

control use only the selector switch provided by manufacturer, or equivalent model, and follow the instructions of the

connection diagram shown on left (if the motor is mounted on the left, the colours of the wires must be inverted, i.e.

descending = brown, ascending = black). The selector switch must be mounted within sight distance of the product,

at a 1.5 - 1.8 m height from the floor. To connect the wires to the supplied switch, remove the plastic front plates to

access the lock/unlock buttons

WARNING:

Correctly performed, state-of-the-art, norm-compliant electrical connections are important to prevent accidents and

to ensure the screen’s optimal and unaltered performance over time. Prior to carrying out any operation on electrical

parts ensure that power supply is disconnected. In screens fitted with cases the motor is positioned on the right-hand

side of the screen as seen from the front (upon request it can be located on the left). Never connect two or more

motors to the same selector switch without a control unit or two switches to the same motor..

230V 50Hz

Motor characteristics:

Frequency: ~Hz50

Power: 90W

Torque: 6Nm

Speed: 12Rpm

Max no. of cycles: 2

Cable length: 2.5m

Mechanical strength:

EN14202 conformant

Operating T°:

from –20 to +55 °C

Connection for each motor:

Blue (Common)

Brown (Up)

Black (Down)

Yellow Green (Ground 230V)

120V 60Hz

Motor characteristics:

Frequency: ~Hz60

Power: 80W

Torque: 88in.lb

Speed: 14r/min

Max no. of cycles: 2

Cable length: 2.5 m

Mechanical strength:

EN14202 conformant

Operating T°:

from –20 to +55 °C

Connection for each motor:

White(Common)

Black (Down)

Red (Up)

Giallo verde (Terra 120V)

ELECTRICAL CONNECTION:

electric cabling must be conformant with applicable IEC standards. IEC norm EN 60335-1 requires that supply network be fitted with an omnipolar selector switch

with contact opening distance of at least 3 mm. For each motor (e.g. plug switch etc.). In case of need, this device ensures that the power supply is safely and quickly

cut off. Use the wires as described in the figure.

WARNING:

Correctly performed, state-of-the-art, norm-compliant electrical connections are important to prevent accidents and to ensure the screen’s optimal and unaltered

performance over time. Prior to carrying out any operation on electrical parts ensure that power supply is disconnected.

Bus cables (black white orange) must be insulated if not used for the push-button command.

In screens fitted with cases the motor is positioned on the right-hand side of the screen as seen from the front.

Operates with standard radio control (supplied).

Somfy RTS 230V 50Hz

Technical characteristics:

Frequency: ~Hz50

Power: 120W

Torque: 10Nm

Speed: 17Rpm

Max no. of cycles:

2

Cable length:

3m

Operating T°:

from –20 to +55 °C

Frequency: 433.92 MHz

Trans. range: 150m

Connection for each motor:

Brown (Phase 230V)

Blue (Neutral 230V)

Yellow Green (Ground 230V)

IN-CEILING

ENGLISH – Motorized screen user manual

Specifications are subject to change without notice. E&OE

Doc: M Screen – HOME CINEMA MODULES Installation Manual rev1 |10.01.2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

12

10 END STOP MOTOR ADJUSTMENT

WARNING - READ CAREFULLY BEFORE PERFORMING ADJUSTMENTS

Adjustments shown in the following table must be performed by authorised and specialised personnel only. Incorrect performance of the procedures described may result in

damages to the product which will not be covered by guarantee. End stops adjustment varies depending on the motor’s position (left side A column - right side B column) or on

drop of the curtain (rear line C – front line D). Adjustment is performed with a 4 mm hex wrench (included).

END STOPS ADJUSTMENT SCREWS ARE POSITIONED IN THE BOTTOM PART OF THE SCREEN, AND NOT IN THE RIGHT OR LEFT HAND SIDES. DO NOT ADJUST THE END STOPS

WHEN UP OR DOWN BUTTON IS ACTIVATED.

WARNING

“UPPER END STOP MUST ALWAYS BE ADJUSTED AT 2mm FROM THE CASE” see picture on the right.

End stop is adjusted so as to allow the projection sheet to wind around the roller at least 1.5 times to avoid the sheet coming loose. Special attention must be paid when end

stops are adjusted in such a way that projection sheet unwinds beyond the factory setting. This is allowed within a limit of 3 cm without posing a risk to the product. Incorrect

adjustment of end stops can cause:

-Projection sheet coming away from the roller

-Projection sheet winding the wrong way, with ensuing damage to flatness of the projection surface and to winding mechanisms

-Breaking of bottom end black frame welding (framed screens)

-Excessive strain on motor with possible ensuing damage and activation of motor’s thermal resistance

-Excessive winding of the end stop adjustment system with ensuing breaking of the mechanical part

WARRANTY

Operators are reminded that in cases where seals have been tampered with and where any damages have resulted from incorrect adjustment, repair interventions shall not be

covered by guarantee.

A – Left Motor B –

Right Motor (standard)

Back fall – C

Frontal fall -(Standard) D

IN-CEILING

ENGLISH – Motorized screen user manual

Specifications are subject to change without notice. E&OE

Doc: M Screen – HOME CINEMA MODULES Installation Manual rev1 |10.01.2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

13

PROGRAMMING END STOPS MOTOR NICE RF 230V 50Hz/NICE RF 120V 60Hz (procedures already carried out in factory, SHOULD NOT be performed by unauthorised personnel)

Each programming procedure consists of several steps; at the end of each step, the operator has 60 seconds to start the next step; this system is devised to prevent the risk of performing operations other

than those desired. Therefore, if the motor does not perform the operation exactly as indicated in the instructions, wait 60 seconds, then exit programming, or cancel the procedure as indicated at specific

point, and start the procedure all over again.

END STOP MOVEMENT (SHOULD NOT be performed by unauthorised personnel)

The motor’s settings follow an overwriting logic: therefore, once the end stop positions have been memorised they cannot be cancelled, but only overwritten by following the above-mentioned procedure from

the start.

TO CANCEL THE PROGRAMMING IN COURSE

In order to cancel the procedure in course, simultaneously press

and

at any time,

until the motor

has executed

6 movements.

PRODUCT’S DISPOSAL

As is the case for installation procedures, when the product reaches the end of its useful life, disposal operations must be carried out by qualified personnel.

The product is made up of various types of material: some can be recycled, others have to be disposed of. You must follow applicable recycling or disposal regulations in

force in your area for this product category.

As shown in the picture on the left, you must not throw the product into a domestic litter bin. Either dispose of the various components separately, pursuant to the

regulations applicable in your territory, or hand the product over to a vendor upon purchasing a similar new product.

Warning: local regulations can foresee heavy fines in case of unlawful disposal of this product.

GUARANTEE

1.GUARANTEE LIMITATIONS The Manufacturer guarantees that all the products it distributes are free of production-, material- and processing-related defects, without prejudice to the following terms and

conditions:

* The product is guaranteed for a period of twenty-four (24) months

* Mechanical parts are guaranteed for a period of thirty-six (36) months

* The motors and remote controls (excluding batteries) are guaranteed for a period of sixty (60) months

as from the date of the purchase invoice/receipt released to the end user

2.CONDITIONS AND LIMITATIONS This guarantee is subject to the following conditions and limitations:

the guarantee shall be deemed null and void if: the product has been used or manipulated in any manner other than those indicated in the user manual’s instructions; or damaged as a result of improper use,

or owing to accident or negligence during transport; or if the product’s defect is the result of repair or manhandling on the part of anyone other than personnel authorized by our Customer Care office.

T

he product must be installed by trained and experienced insider professionals, following the instructions provided for the installation and maintenance procedures.

3.RETURNS No product shall be returned and accepted without an authorization (RMA) released by Customer Care.

Products must be returned in their original (or equivalent) packaging to avoid being damaged during transport. Any transport damages resulting from inappropriate packaging shall not be covered by this

guarantee.

T

he returned product shall be accompanied by a detailed description of the defect and by a photocopy of the original purchase invoice/receipt.

T

he purchase invoice/receipt shall clearly indicate the following: Model – Serial number – Purchase date – Name and address of the purchaser and authorized dealer.

5

ENGLISH – Motorized screen user manual

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: PROFESSIONAL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

13

PROGRAMMING END STOPS MOTOR SOMFY RTS 230V 50Hz/120V 60Hz (procedures already carried out in factory, SHOULD NOT be performed by unauthorised personnel)

Down limit switch

1

Move the

screen surface

to down limit

switch.

2

Press both

and at the

same time until you will see

a brief up and down motion

of screen surface.

3

Move the screen with

buttons

and

to reach the desired

down limit position.

4

Press button until you

will see a brief up and down

motion of screen surface to

memorize the new position

Up limit swicht

1.

Move the

screen surface

to up limit

switch.

2

Press both

and at the

same time until you will see

a brief up and down motion

of screen surface.

3

Move the screen with

buttons

and

to reach the desired up

limit position.

4

Press button until you

will see a brief up and down

motion of screen surface to

memorize the new position

PRODUCT’S DISPOSAL

As is the case for installation procedures, when the product reaches the end of its useful life, disposal operations must be carried out by qualified personnel.

The product is made up of various types of material: some can be recycled, others have to be disposed of. You must follow applicable recycling or disposal regulations in

force in your area for this product category.

As shown in the picture on the left, you must not throw the product into a domestic litter bin. Either dispose of the various components separately, pursuant to the

regulations applicable in your territory, or hand the product over to a vendor upon purchasing a similar new product.

Warning: local regulations can foresee heavy fines in case of unlawful disposal of this product.

GUARANTEE

1.GUARANTEE LIMITATIONS The Manufacturer guarantees that all the products it distributes are free of production-, material- and processing-related defects, without prejudice to the following terms and

conditions:

* The product is guaranteed for a period of twenty-four (24) months

* Mechanical parts are guaranteed for a period of thirty-six (36) months

* The motors and remote controls (excluding batteries) are guaranteed for a period of thirty-six (36) months

as from the date of the purchase invoice/receipt released to the end user

2.CONDITIONS AND LIMITATIONS This guarantee is subject to the following conditions and limitations:

the guarantee shall be deemed null and void if: the product has been used or manipulated in any manner other than those indicated in the user manual’s instructions; or damaged as a result of improper use,

or owing to accident or negligence during transport; or if the product’s defect is the result of repair or manhandling on the part of anyone other than personnel authorized by our Customer Care office.

T

he product must be installed by trained and experienced insider professionals, following the instructions provided for the installation and maintenance procedures.

3.DIMENSIONAL TOLERANCE Projection Fabric +/-20mm, Structure and components up to 2500mm +/-2mm - up to 6120mm +/-5mm.

4.RETURNS No product shall be returned and accepted without an authorization (RMA) released by Customer Care.

Products must be returned in their original (or equivalent) packaging to avoid being damaged during transport. Any transport damages resulting from inappropriate packaging shall not be covered by this

guarantee.

T

he returned product shall be accompanied by a detailed description of the defect and by a photocopy of the original purchase invoice/receipt.

T

he purchase invoice/receipt shall clearly indicate the following: Model

–

Serial number

–

Purchase date

–

Name and address of

the

purchaser and authorized dealer.

IN-CEILING

IN-CEILING

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

32

2

3 4

5 6

7

Made by Adeo Screen sp.

Z o.o. (Polska) Specifications are subject to change without notice. E&OE

Doc: INCEEL Installation Manual rev4 | 17.09.2014

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

33

8

9

10

11

IN-CEILING

Specifications are subject to change without notice. E&OE

Doc: M Screen – HOME CINEMA MODULES Installation Manual rev1 |10.01.2013

Please verify that you are working with the latest revision of this document before specifying your screen.

Page

38

Dear User,

Thank you for purchasing a Beamax® projection screen.

This projection screen is hand built using the finest quality materials with meticulous attention to detail.

Therefore we trust this screen will offer you the utmost. Whether you use it for home cinema or business purposes, it

will give you the ultimate experience.

Most kind regards,

The Beamax® Team

De Dolfijn 20-22

1601 MG Enkhuizen

The Netherlands

+31228 – 748100

UK: 0845 52 800 96

www.beamax.com

6

IN-CEILING

This manual suits for next models

8

Other Beamax Projection Screen manuals

Popular Projection Screen manuals by other brands

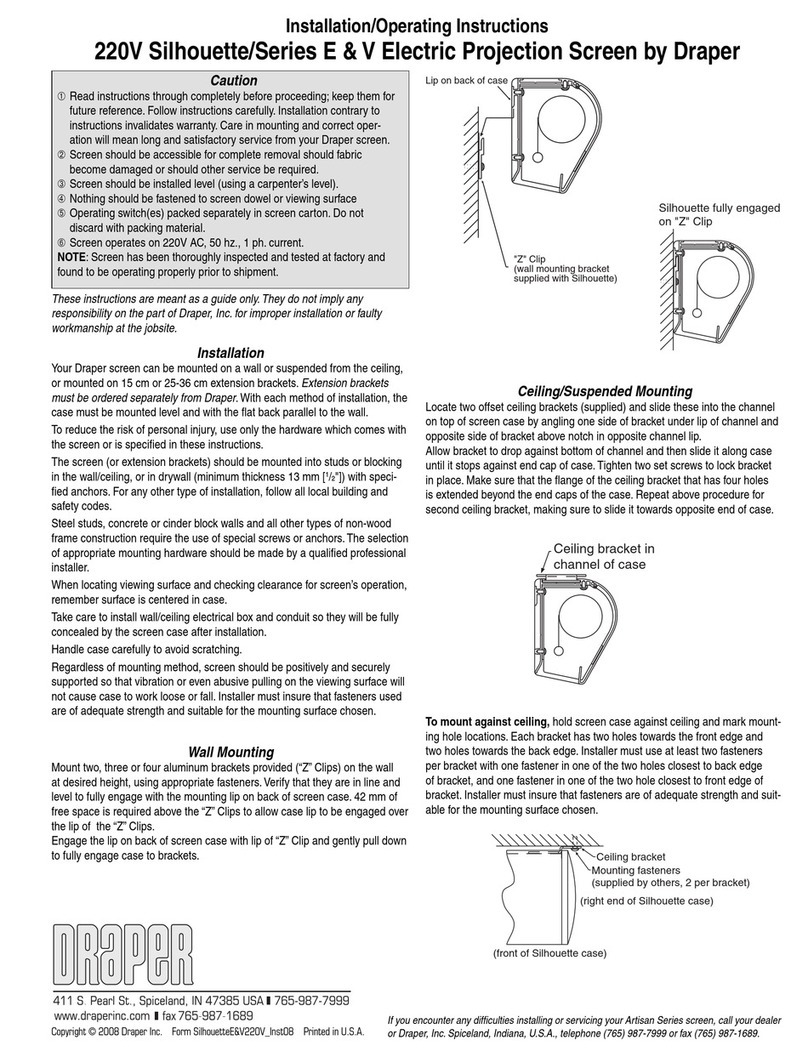

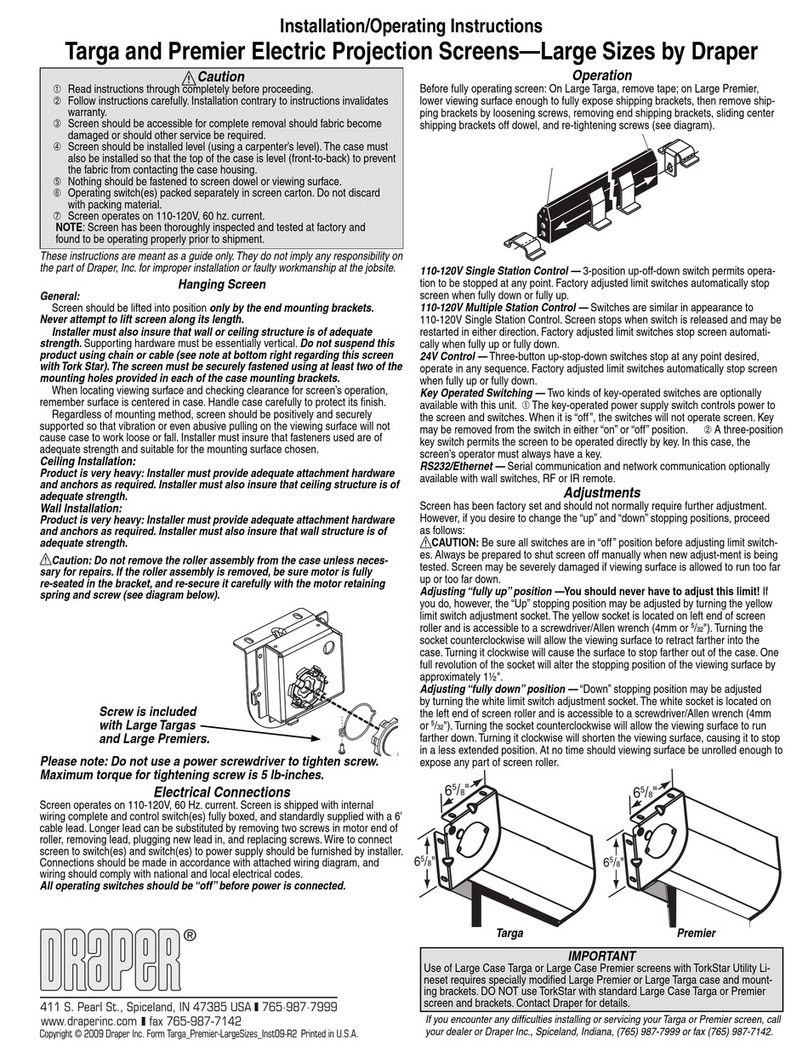

Draper

Draper Targa Installation & operating instructions

Screen Excellence

Screen Excellence True Aspect Masking TAM 2 L Assembly instructions

Barco

Barco R9001309 owner's manual

Celexon

Celexon Expert operating instructions

Draper

Draper Clarion Assembly/mounting instructions

Da-Lite

Da-Lite Large Dual Masking Electrol Instruction book

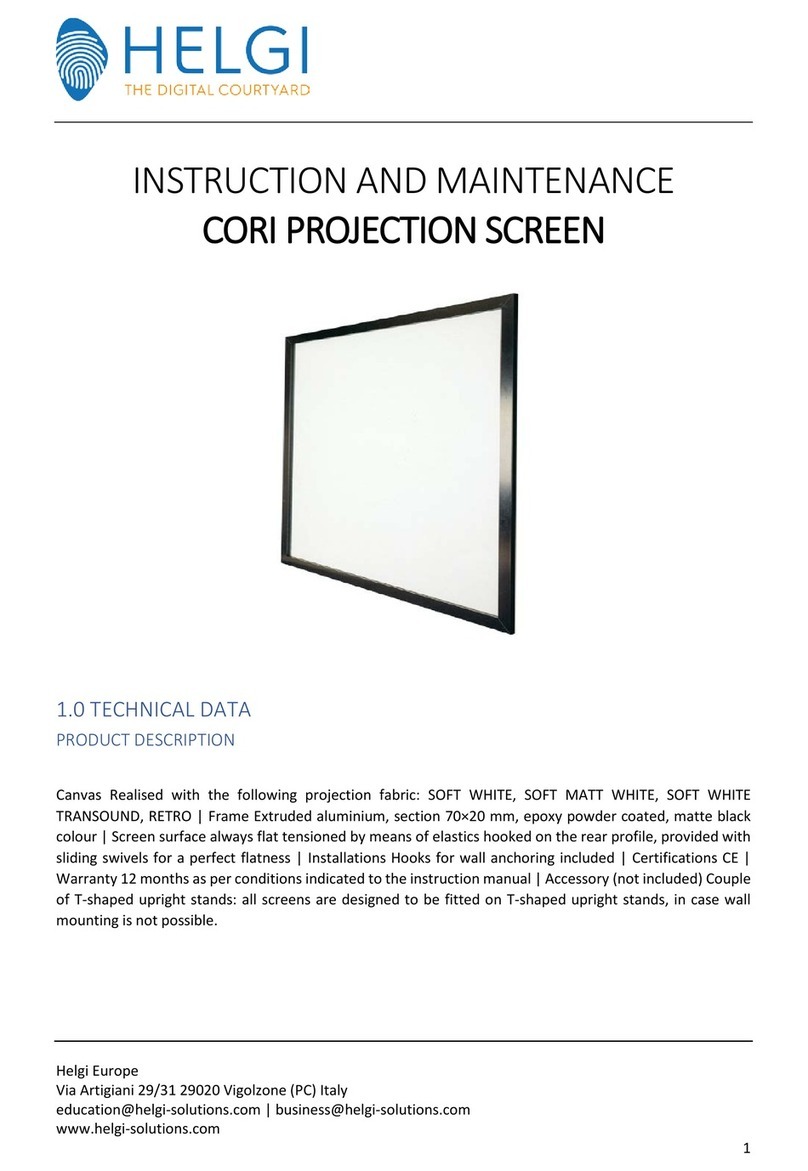

HELGI

HELGI CORI Instruction and maintenance

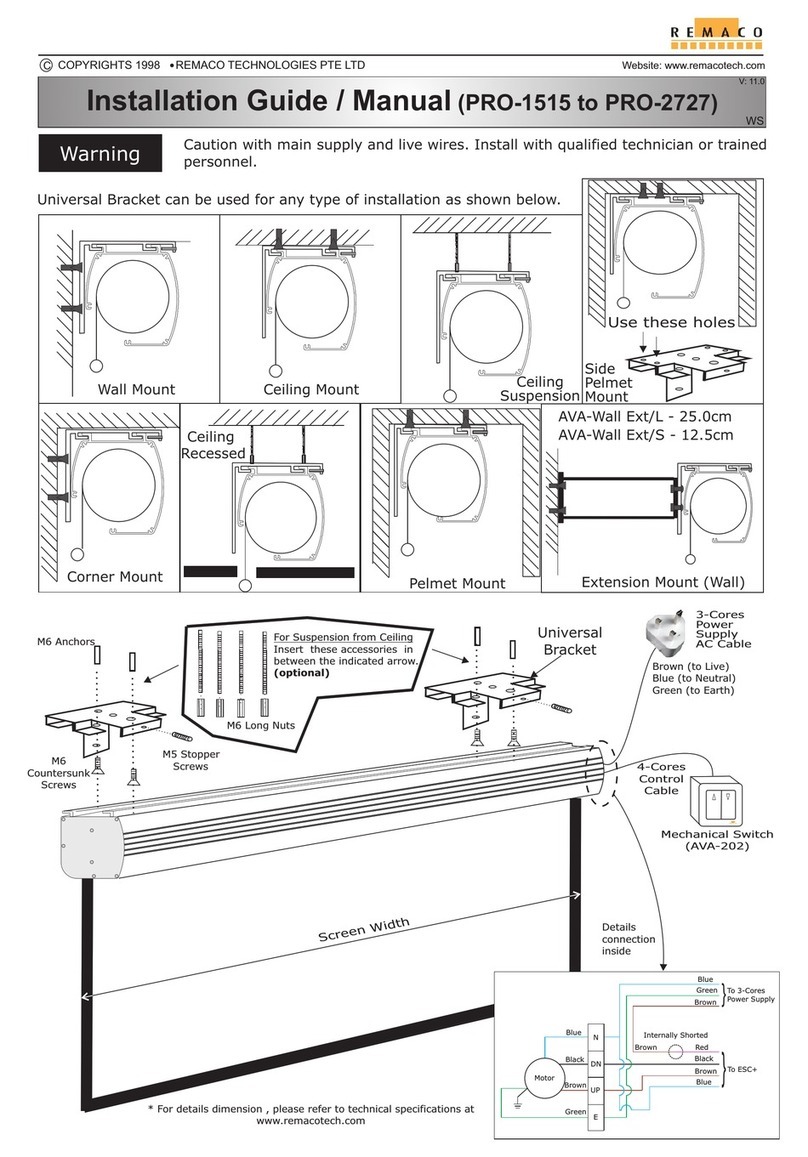

Remaco

Remaco PRO-1515 Installation guide & manual

Da-Lite

Da-Lite IDEA Screen Instruction book

Screen Innovations

Screen Innovations Zero-G owner's manual

Screen Research

Screen Research TheaterCurved Reference X-Mask T-X4R installation manual

Samo

Samo lineabeta Open B4600 Assembly instruction