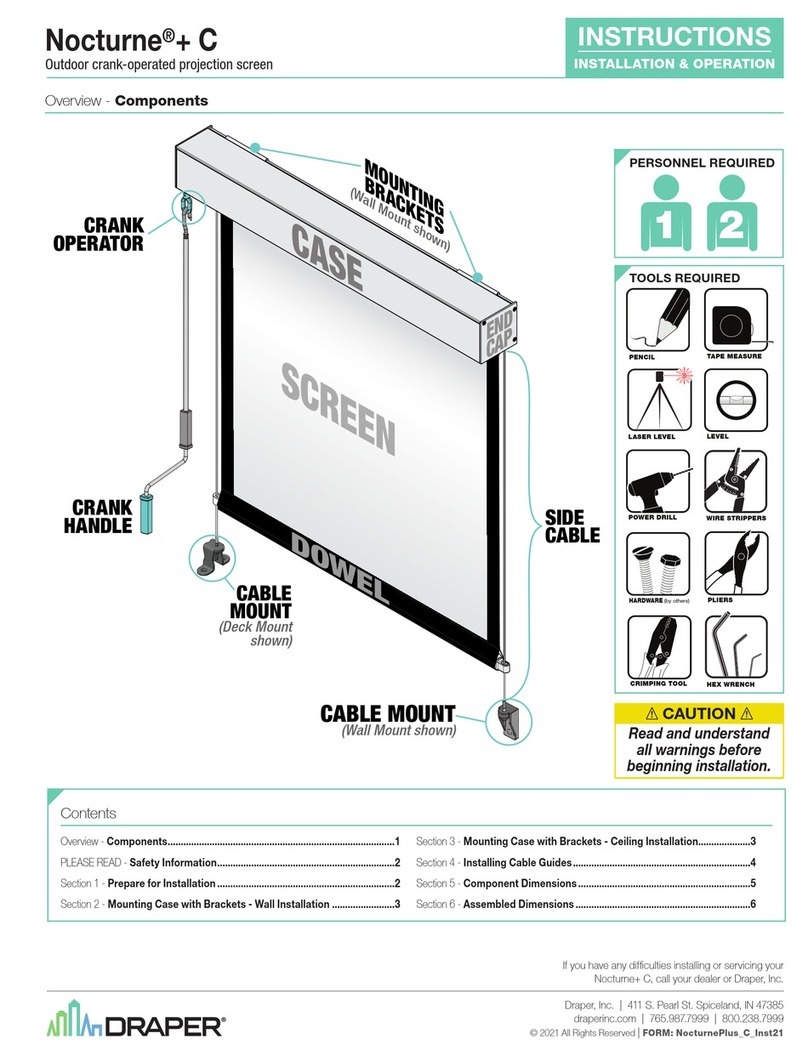

Assembly/Mounting Instructions

Clarion Permanently Tensioned Projection Screen by Draper

#8 x 3/8"

Pan Head

Screw

Corner Gusset

#8 x 3/8"

Pan Head

Screw Audience

Side

Slot Receives Screw

Base

Frame

#10-24 x 1/2"

Flat Head

Screw

See detail for

configuration

possibilities

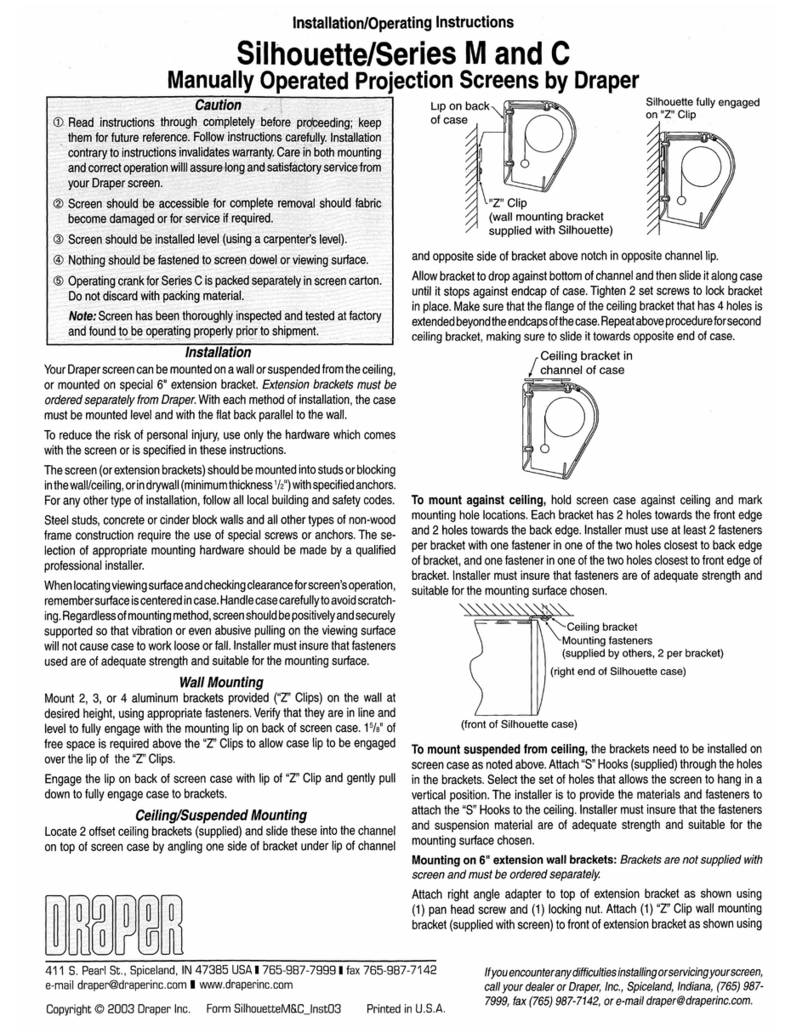

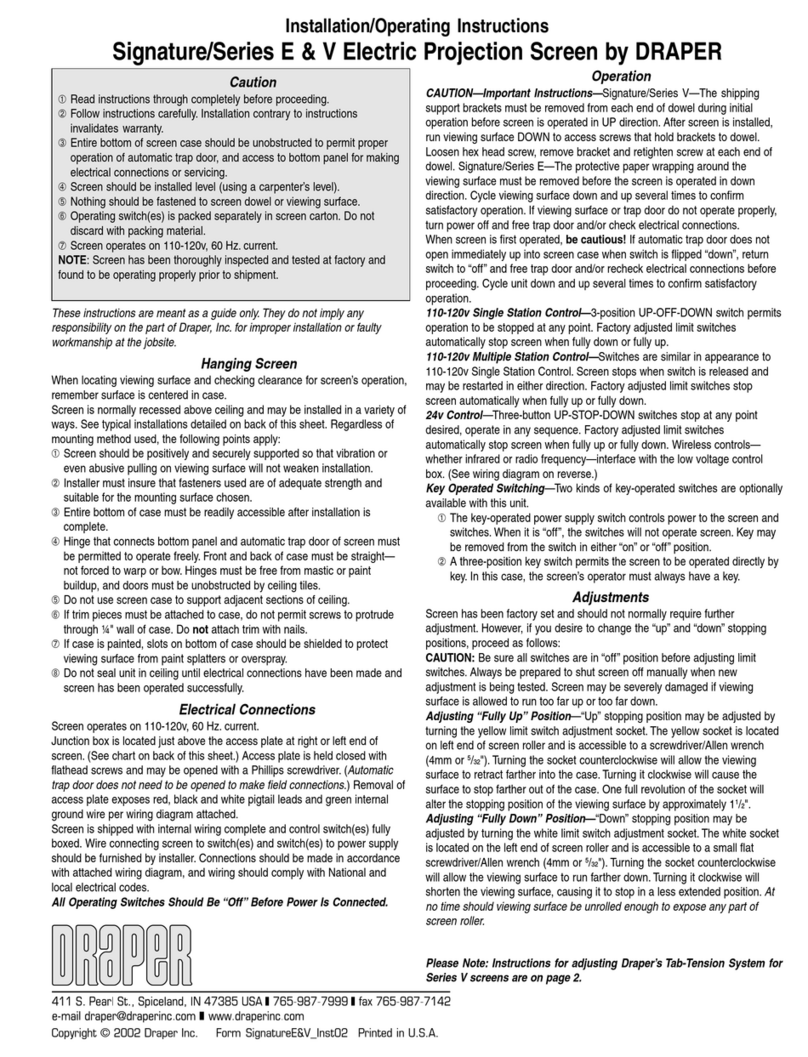

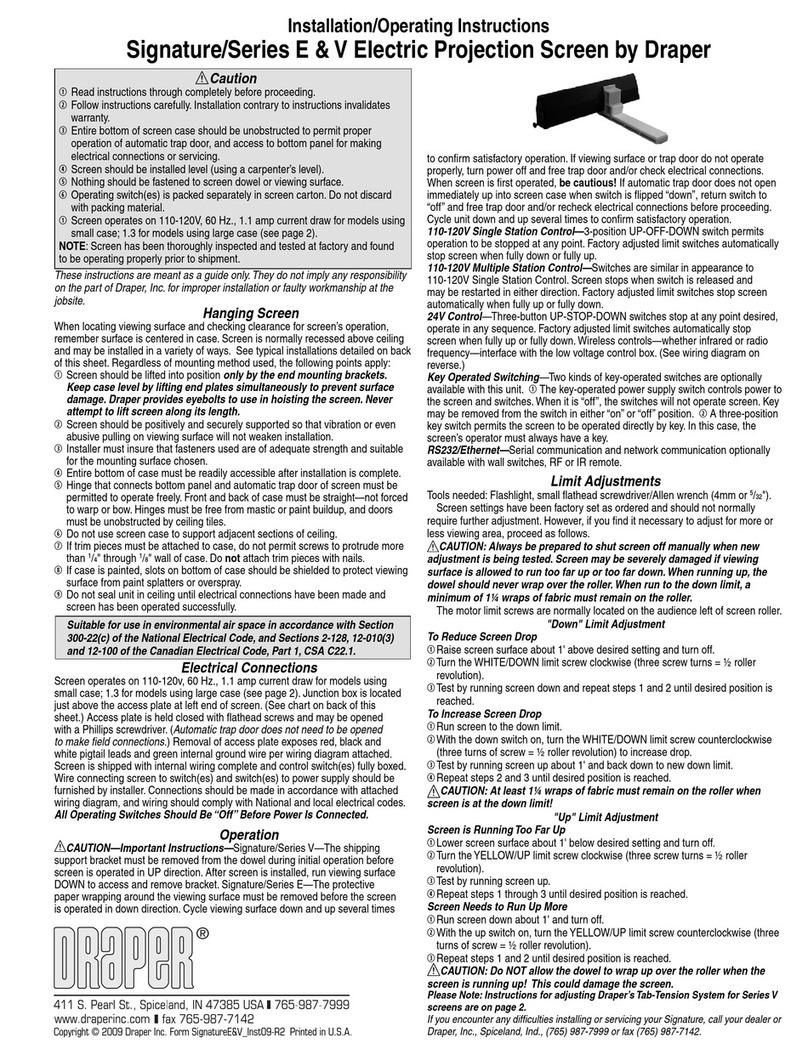

Caution

➀Read instructions through completely before proceeding.

➁Follow instructions carefully. Installation contrary to instructions

invalidates warranty.

➂Screen should be accessible for complete removal should fabric

become damaged or should other service be required.

➃Screen should be installed level (using a carpenter’s level).

➄Nothing should be fastened to screen frame or viewing surface.

➅Operating switch(es), for electric tilting screens, packed separately in

screen carton. Do not discard with packing material.

➆Electric tilting mechanism operates on 110-120v, 60 hz. current.

➇Tools Required: Medium (#2) Phillips Screwdriver, Carpenters Level,

Soft face (rubber) Hammer & Measuring Tape.

NOTE: Screen has been thoroughly inspected and tested at factory and

found to be operating properly prior to shipment.

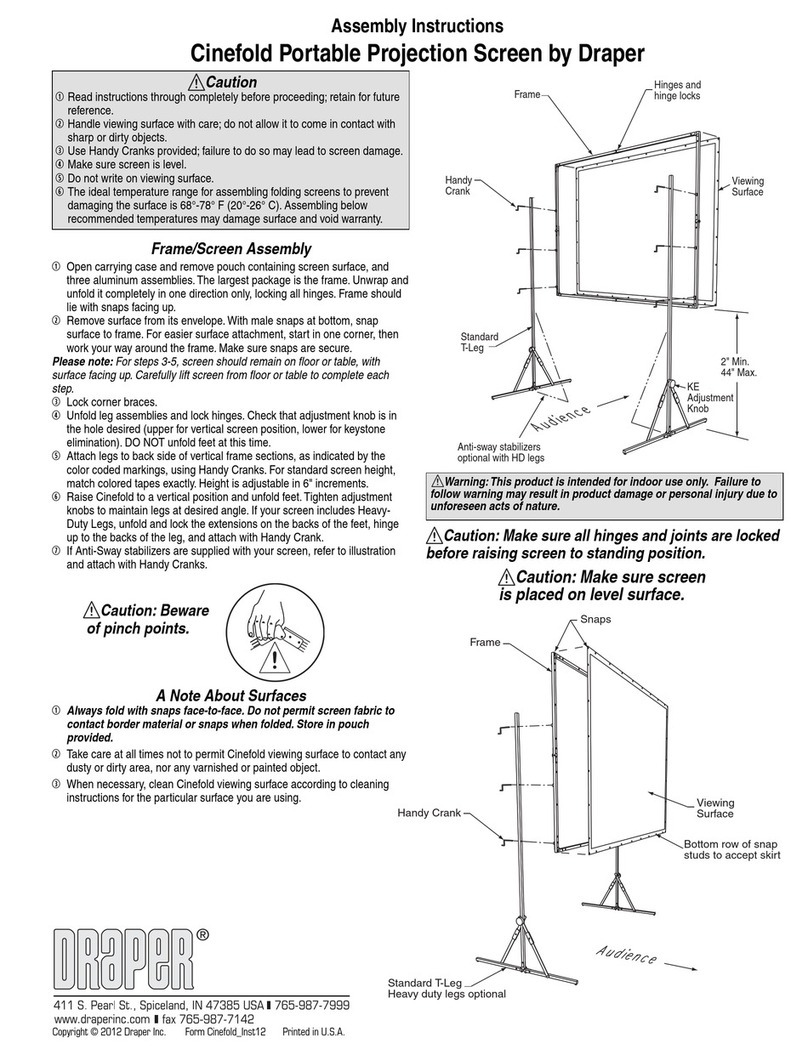

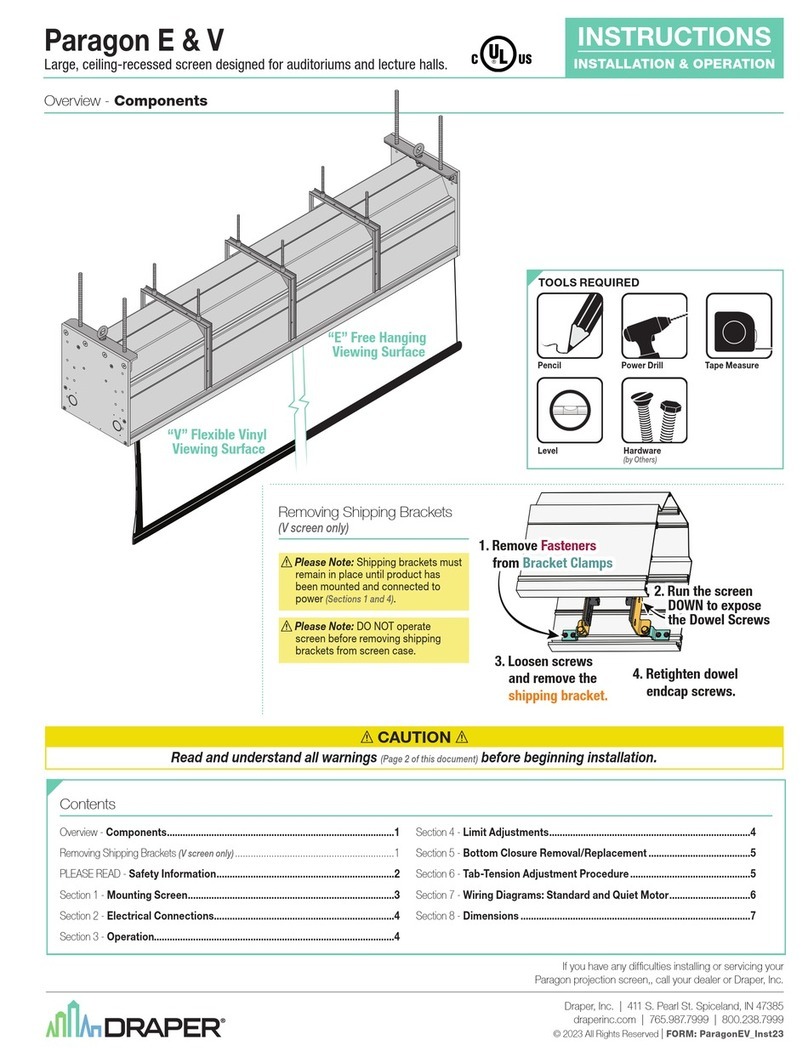

Assembly of “Knocked-Down” Screen

General—

➀

Assemble inner frame on large table or on floor. Refer to exploded drawing on

page 2 as you read these instructions.

➁

Open cartons along the length, not at ends. Remove all pieces from the carton.

Lay out the four sections of the inner frame (top, bottom, left and right) with the

front sides facing up. (Back of frame is side with snaps.)

Please Note: The frame is labeled "Stage Left" and "Stage Right." Stage Left

means the left side side of the screen as it faces the audience, which is the right

side as you face the screen. When these instructions refer to the left or right side

of the screen, they refer to the left or right side as you face the screen.

➂

Screw the left and right sides to the top and bottom frame members using #6 x

1" screws through the two pre-drilled holes in each end of sides. Screws should

thread into the circular screw channels. Make sure frame assembly is square by

measuring across frame diagonals (see Fig. 1).

➃

Place and screw one corner gusset to the inner frame assembly at each corner

with (6) #8 x

3

/

8

" pan head screws. Screws pass through pre-punched holes in

gussets and thread into screw channel on inner frame (see Fig. 2).

➄

Connect horizontal brace and vertical brace using (2) #10 x

1

/

2

" screws (see Fig.

3). See page 2 for the various configurations.

➅

Place bracing assembly inside the inner frame so the plates at each end

of braces are completely visible from the front. Make sure these braces are

perpendicular to the inner frame sections. Insert #8 x

3

/

8

" screws through the

holes in these plates and into the screw channel on the inner frame (see Fig. 4).

The inner frame assembly is now complete.

➇

Align and start engagement of bracket in the side trim with slot in top trim by

hand. Use rubber hammer to drive trims fully together. Repeat for the other

corners of screen (see Fig. 5).

Attachment of Viewing Surface

Two people should attach the viewing surface of large screens, to prevent

possible damage.

➀

Unroll the viewing surface from the core with the viewing side face down. Be

extremely careful to protect the viewing surface by unrolling it onto a clean

cloth or paper.

➁

Place the inner frame assembly, with front side down, against the back of the

viewing surface. Make sure the top piece of frame corresponds with the top side

of the viewing surface.

➂

Pull border snaps on viewing surface around the inner frame and snap to the

back side of the frame. Engage the two snaps at each corner first, then go

along each side and engage the remaining snaps.

➃

Pivot the frame/fabric assembly up into a vertical position and inspect surface.

➄

Lay frame/fabric assembly with viewing surface up. Frame is ready for

installation of trim frames.

➅

Place the four trim sections next to the correct sides of the frame/fabric

assembly. The side trim sections will have connecting brackets located in each

end. These brackets will align and hold the face of the trim sections together.

➆

Place the top and bottom trims over the top and bottom of the frame/fabric

assembly. (Do not slide the trim sections along the outside edges of the

frame/fabric assembly. Doing this could damage the fabric viewing

surface.)

Copyright © 2004 Draper Inc. Form Clarion_Inst04 Printed in U.S.A.

Figure 1

# 6 x 1

Pan Head

Screw

Figure 2

Figure 3

Figure 4

Figure 5

➈

After all four corners of trims are connected, turn entire screen assembly over

so viewing surface is face down. Be sure to protect surface in this position.

➉

The trims must be fastened to the inner frame with #8 x

3

/

8

" screws. Each trim

has predrilled holes in the back flange. Start by screwing the corners together

first. It may be necessary to squeeze the trims together at corners to close any

gaps. Do this before screwing trim to inner frame. Finish attaching trims along

their length with additional screws (see Fig. 6, top of page 2).

If you encounter any difficulties installing or servicing your Clarion

screen, call your dealer or Draper Inc., Spiceland, Indiana, (765)