Installation/Operating Instructions

Targa and Premier Electric Projection Screens—Large Sizes by Draper

Hanging Screen

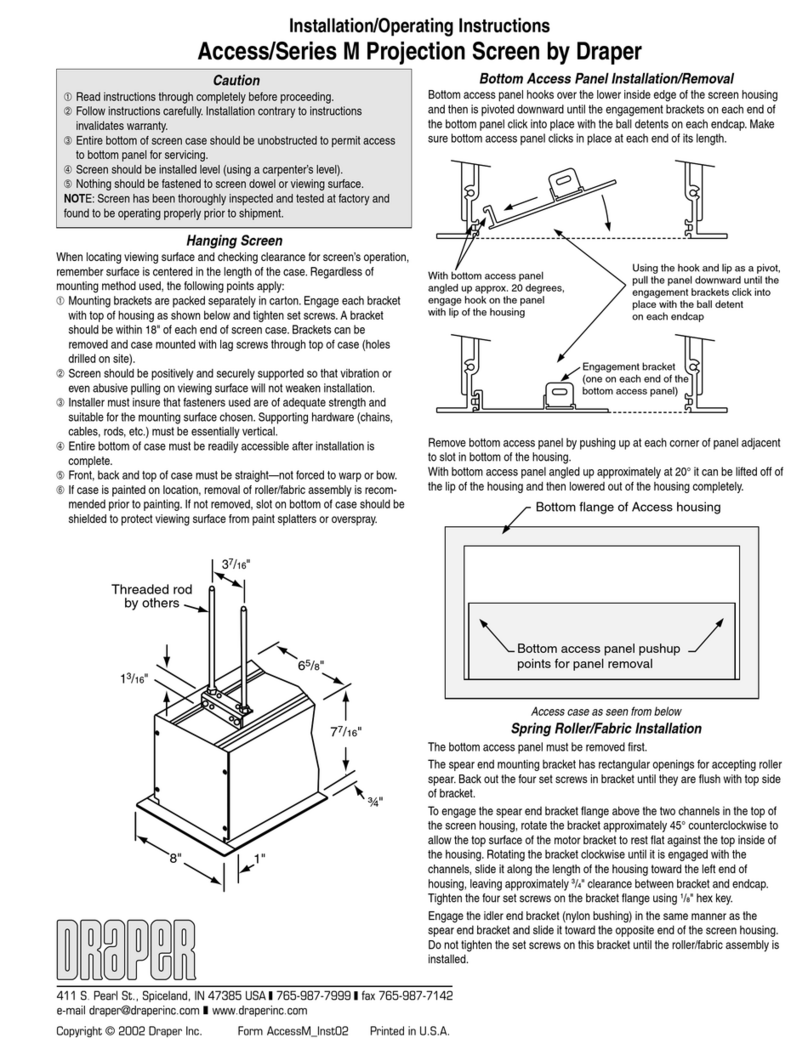

General:

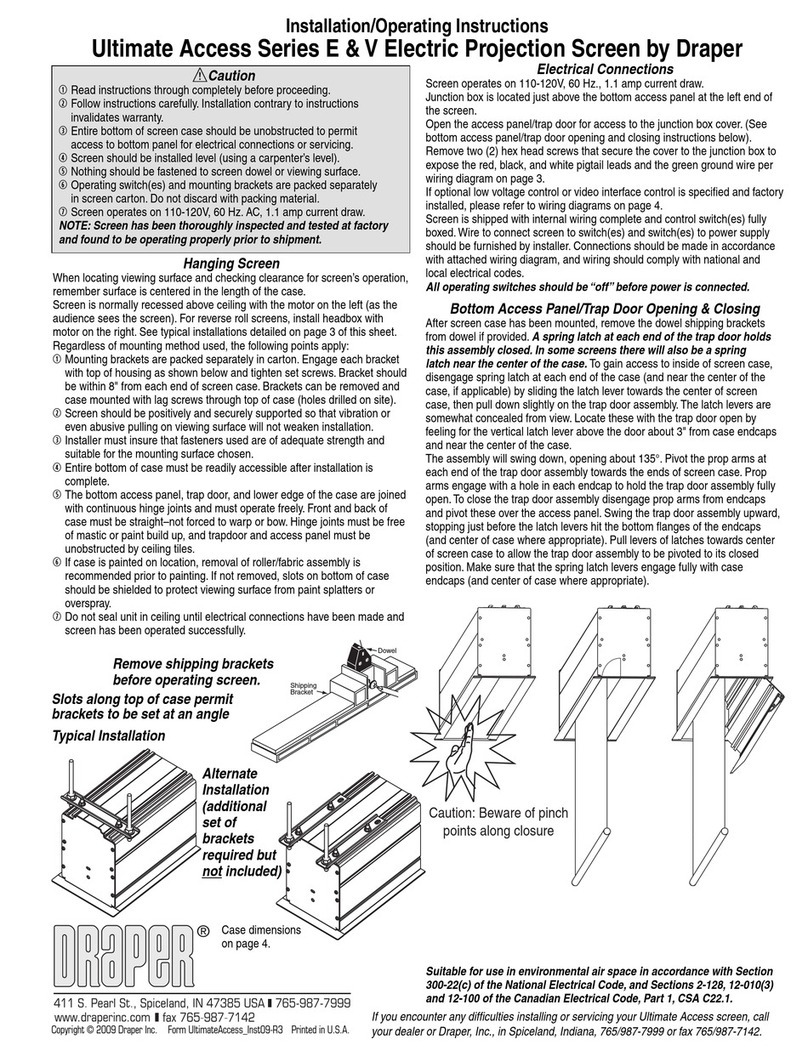

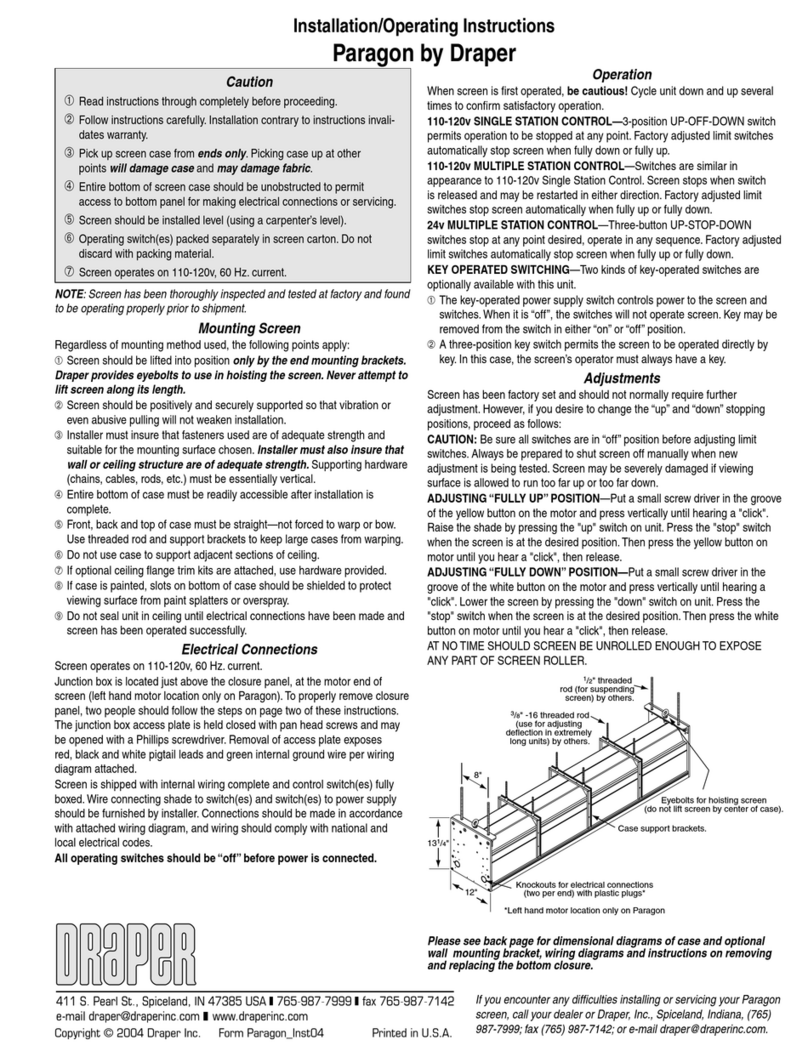

Screen should be lifted into position only by the end mounting brackets.

Never attempt to lift screen along its length.

Installer must also insure that wall or ceiling structure is of adequate

strength. Supporting hardware must be essentially vertical. Do not suspend this

product using chain or cable (see note at bottom right regarding this screen

with Tork Star). The screen must be securely fastened using at least two of the

mounting holes provided in each of the case mounting brackets.

When locating viewing surface and checking clearance for screen’s operation,

remember surface is centered in case. Handle case carefully to protect its finish.

Regardless of mounting method, screen should be positively and securely

supported so that vibration or even abusive pulling on the viewing surface will not

cause case to work loose or fall. Installer must insure that fasteners used are of

adequate strength and suitable for the mounting surface chosen.

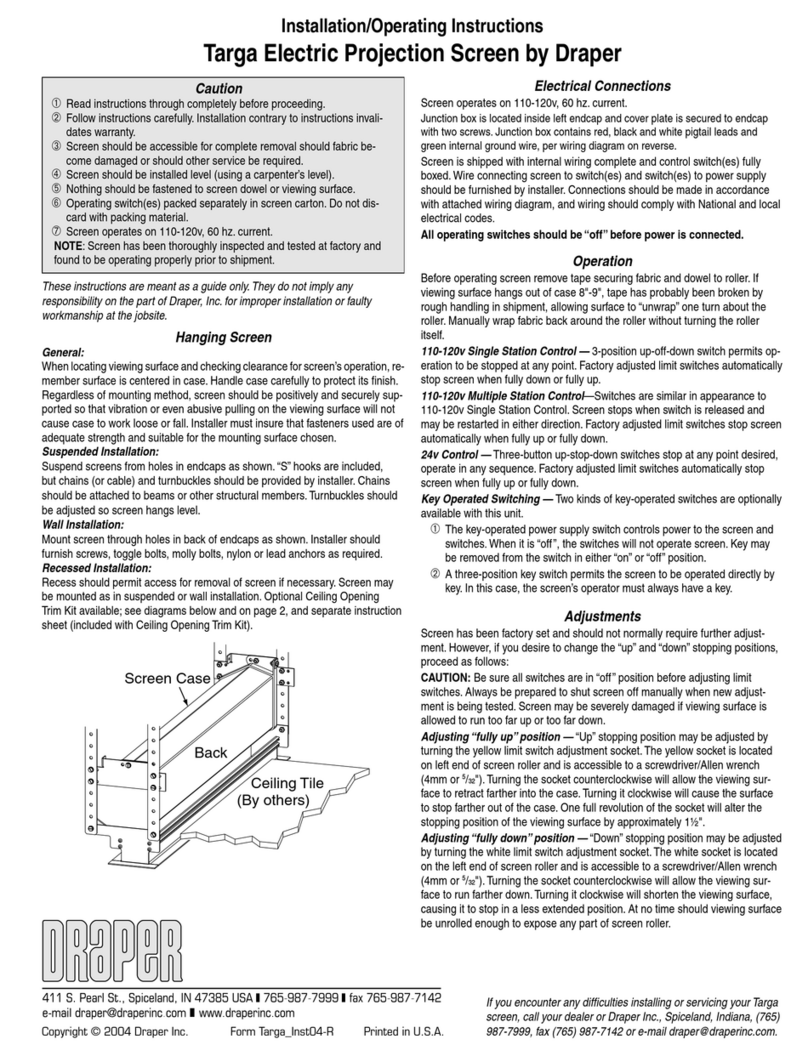

Ceiling Installation:

Product is very heavy: Installer must provide adequate attachment hardware

and anchors as required. Installer must also insure that ceiling structure is of

adequate strength.

Wall Installation:

Product is very heavy: Installer must provide adequate attachment hardware

and anchors as required. Installer must also insure that wall structure is of

adequate strength.

These instructions are meant as a guide only. They do not imply any responsibility on

the part of Draper, Inc. for improper installation or faulty workmanship at the jobsite.

Caution

➀Read instructions through completely before proceeding.

➁Follow instructions carefully. Installation contrary to instructions invalidates

warranty.

➂Screen should be accessible for complete removal should fabric become

damaged or should other service be required.

➃Screen should be installed level (using a carpenter’s level). The case must

also be installed so that the top of the case is level (front-to-back) to prevent

the fabric from contacting the case housing.

➄Nothing should be fastened to screen dowel or viewing surface.

➅Operating switch(es) packed separately in screen carton. Do not discard

with packing material.

➆Screen operates on 110-120V, 60 hz. current.

NOTE: Screen has been thoroughly inspected and tested at factory and

found to be operating properly prior to shipment.

Copyright © 2009 Draper Inc. Form Targa_Premier-LargeSizes_Inst09-R2 Printed in U.S.A.

Operation

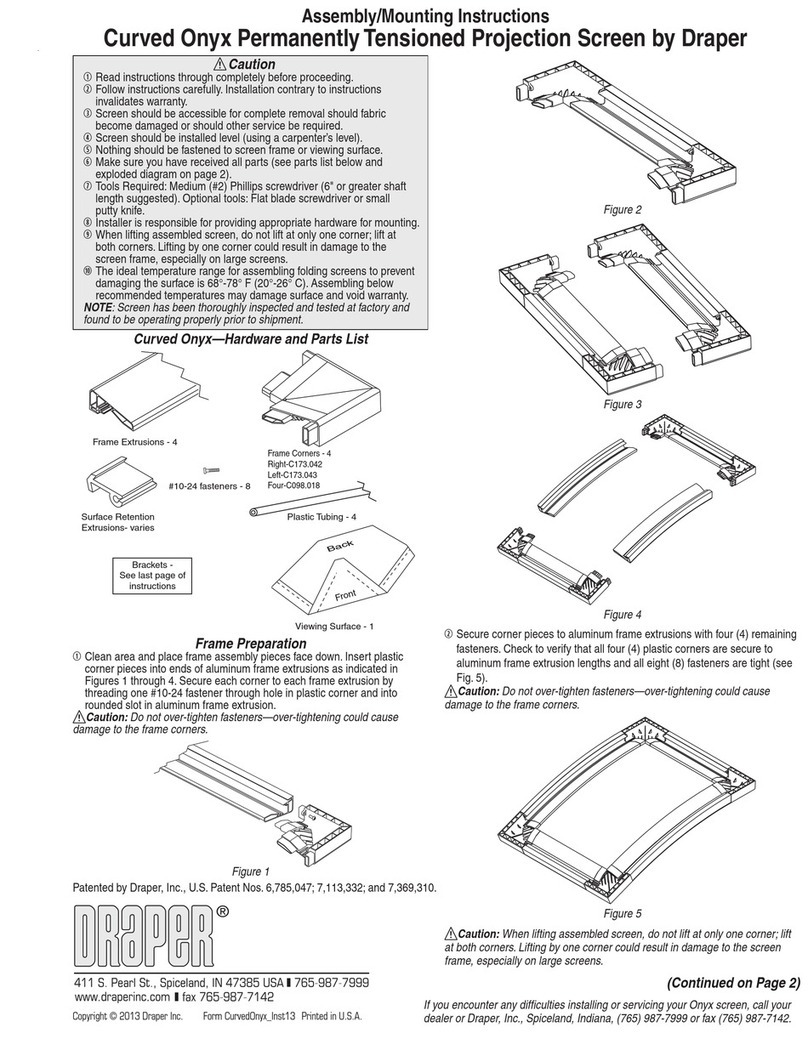

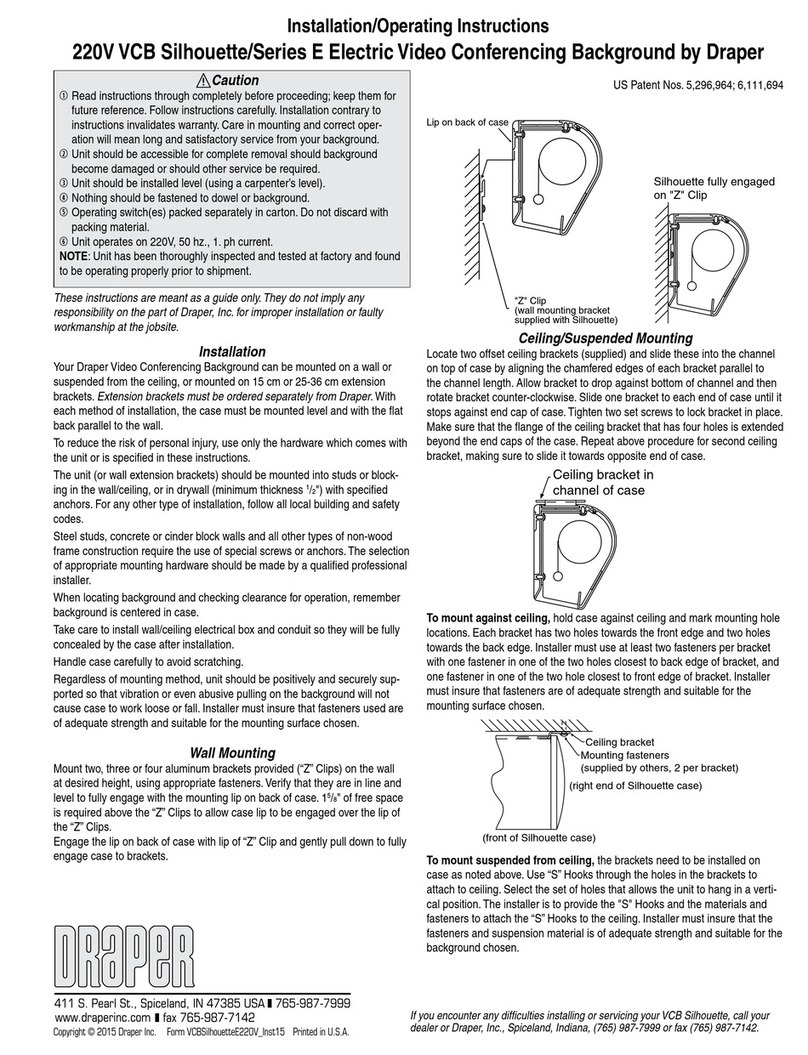

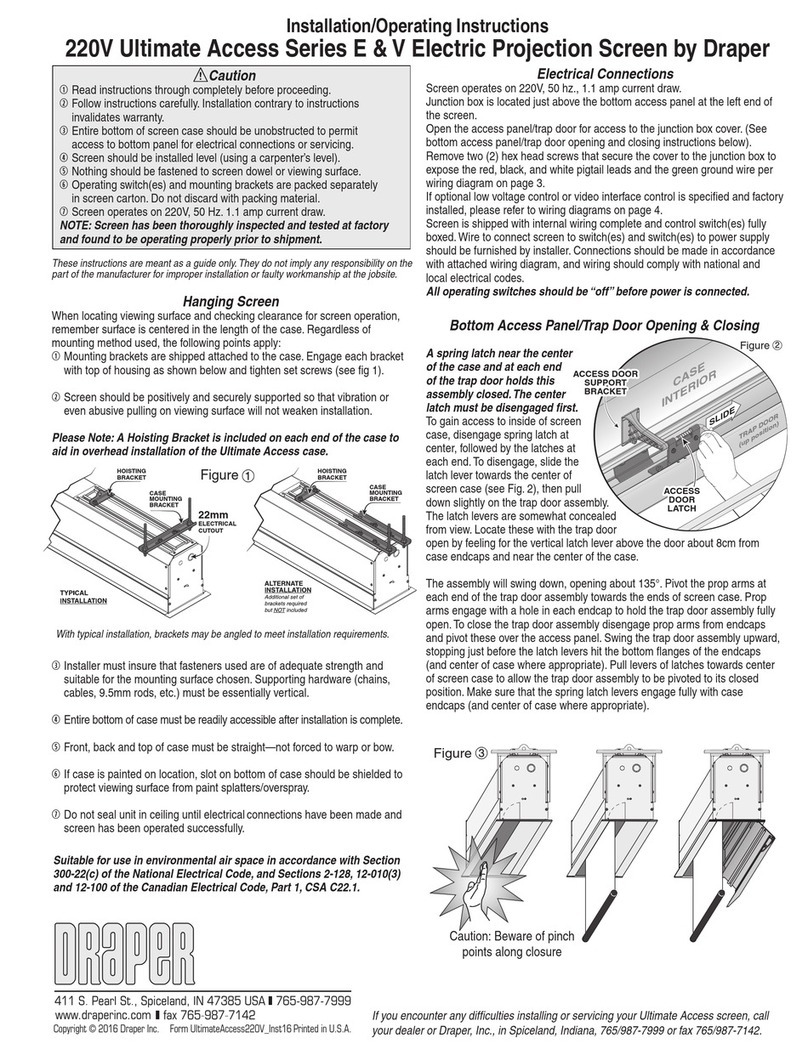

Before fully operating screen: On Large Targa, remove tape; on Large Premier,

lower viewing surface enough to fully expose shipping brackets, then remove ship-

ping brackets by loosening screws, removing end shipping brackets, sliding center

shipping brackets off dowel, and re-tightening screws (see diagram).

110-120V Single Station Control — 3-position up-off-down switch permits opera-

tion to be stopped at any point. Factory adjusted limit switches automatically stop

screen when fully down or fully up.

110-120V Multiple Station Control — Switches are similar in appearance to

110-120V Single Station Control. Screen stops when switch is released and may be

restarted in either direction. Factory adjusted limit switches stop screen automati-

cally when fully up or fully down.

24V Control — Three-button up-stop-down switches stop at any point desired,

operate in any sequence. Factory adjusted limit switches automatically stop screen

when fully up or fully down.

Key Operated Switching — Two kinds of key-operated switches are optionally

available with this unit. ➀The key-operated power supply switch controls power to

the screen and switches. When it is “off”, the switches will not operate screen. Key

may be removed from the switch in either “on” or “off” position. ➁A three-position

key switch permits the screen to be operated directly by key. In this case, the

screen’s operator must always have a key.

RS232/Ethernet — Serial communication and network communication optionally

available with wall switches, RF or IR remote.

Adjustments

Screen has been factory set and should not normally require further adjustment.

However, if you desire to change the “up” and “down” stopping positions, proceed

as follows:

CAUTION: Be sure all switches are in “off ” position before adjusting limit switch-

es. Always be prepared to shut screen off manually when new adjust-ment is being

tested. Screen may be severely damaged if viewing surface is allowed to run too far

up or too far down.

Adjusting “fully up” position —You should never have to adjust this limit! If

you do, however, the “Up” stopping position may be adjusted by turning the yellow

limit switch adjustment socket. The yellow socket is located on left end of screen

roller and is accessible to a screwdriver/Allen wrench (4mm or

5

/

32

"). Turning the

socket counterclockwise will allow the viewing surface to retract farther into the

case. Turning it clockwise will cause the surface to stop farther out of the case. One

full revolution of the socket will alter the stopping position of the viewing surface by

approximately 1½".

Adjusting “fully down” position — “Down” stopping position may be adjusted

by turning the white limit switch adjustment socket. The white socket is located on

the left end of screen roller and is accessible to a screwdriver/Allen wrench (4mm

or

5

/

32

"). Turning the socket counterclockwise will allow the viewing surface to run

farther down. Turning it clockwise will shorten the viewing surface, causing it to stop

in a less extended position. At no time should viewing surface be unrolled enough to

expose any part of screen roller.

®

If you encounter any difficulties installing or servicing your Targa or Premier screen, call

your dealer or Draper Inc., Spiceland, Indiana, (765) 987-7999 or fax (765) 987-7142.

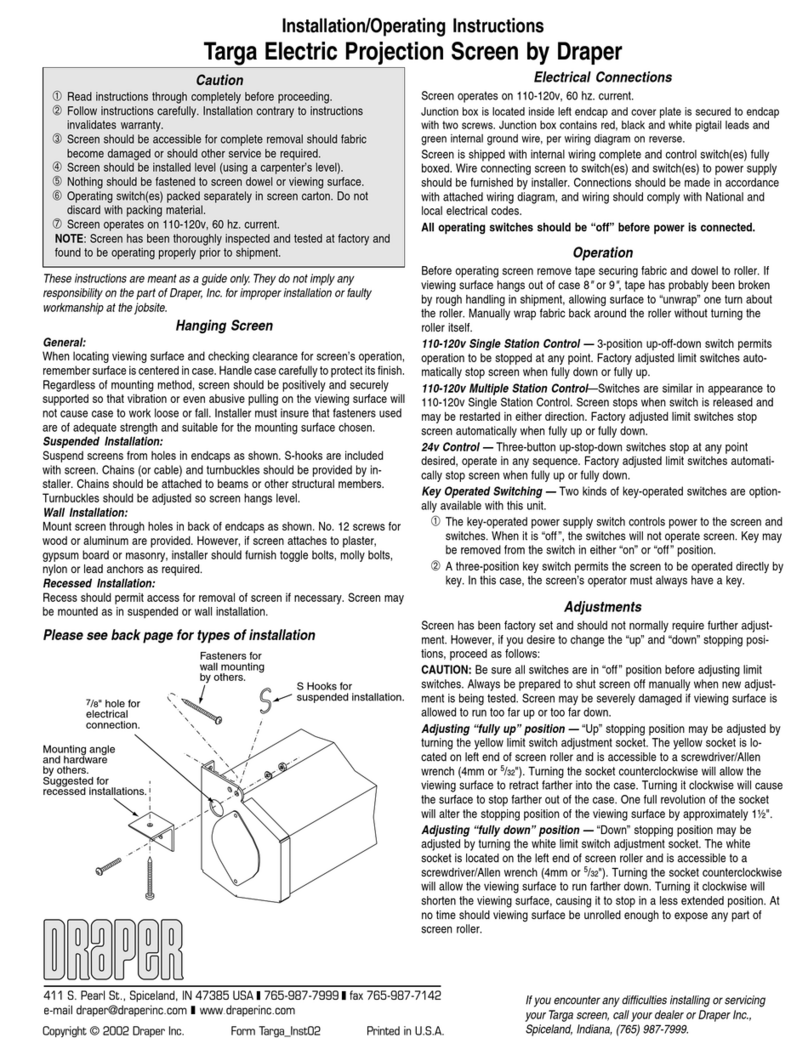

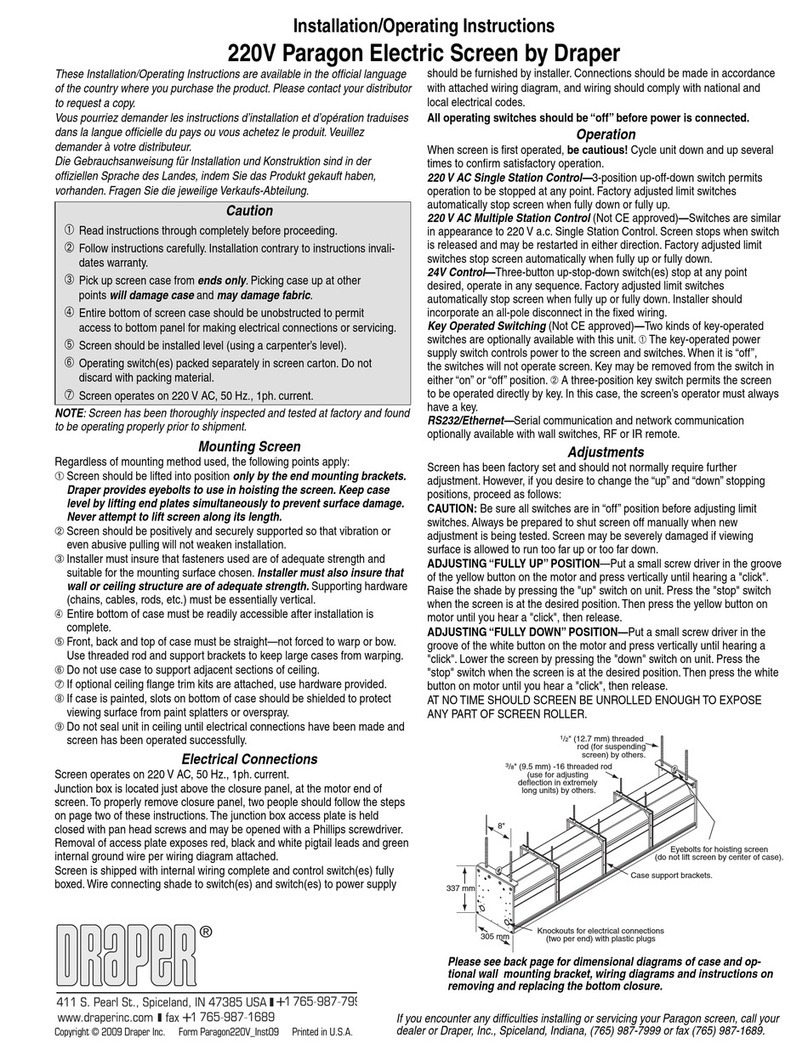

Electrical Connections

Screen operates on 110-120V, 60 Hz. current. Screen is shipped with internal

wiring complete and control switch(es) fully boxed, and standardly supplied with a 6'

cable lead. Longer lead can be substituted by removing two screws in motor end of

roller, removing lead, plugging new lead in, and replacing screws. Wire to connect

screen to switch(es) and switch(es) to power supply should be furnished by installer.

Connections should be made in accordance with attached wiring diagram, and

wiring should comply with national and local electrical codes.

All operating switches should be “off” before power is connected.

6

5

/

8

"

6

5

/

8

"

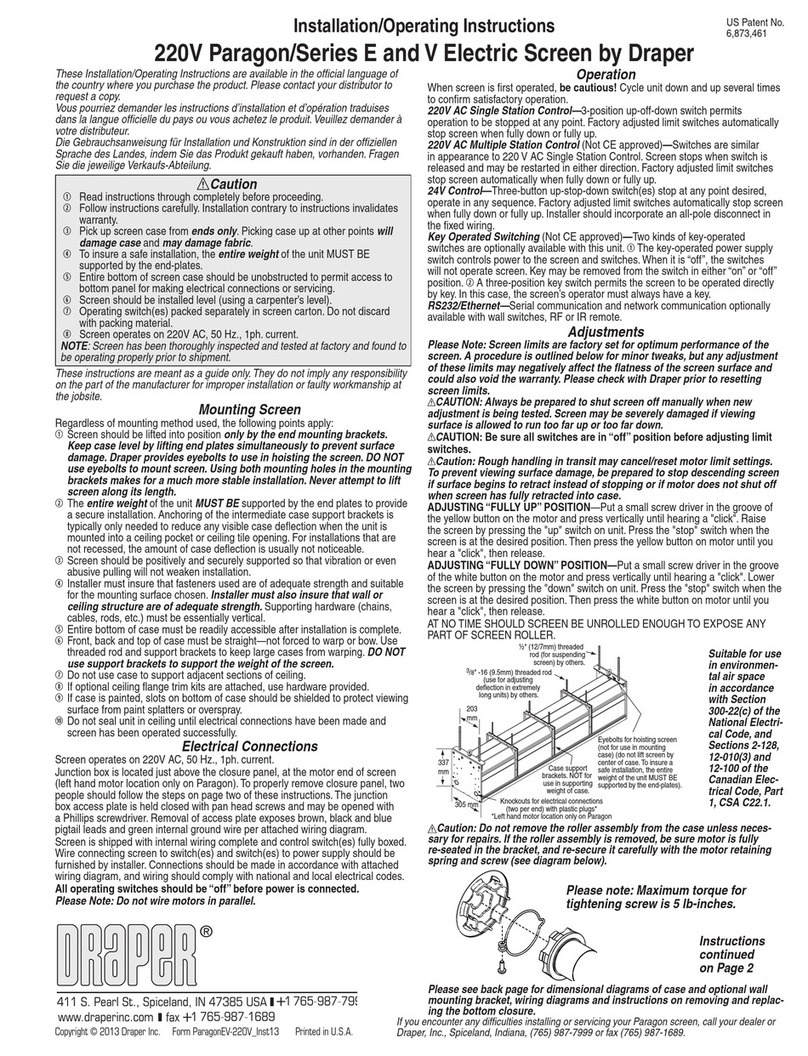

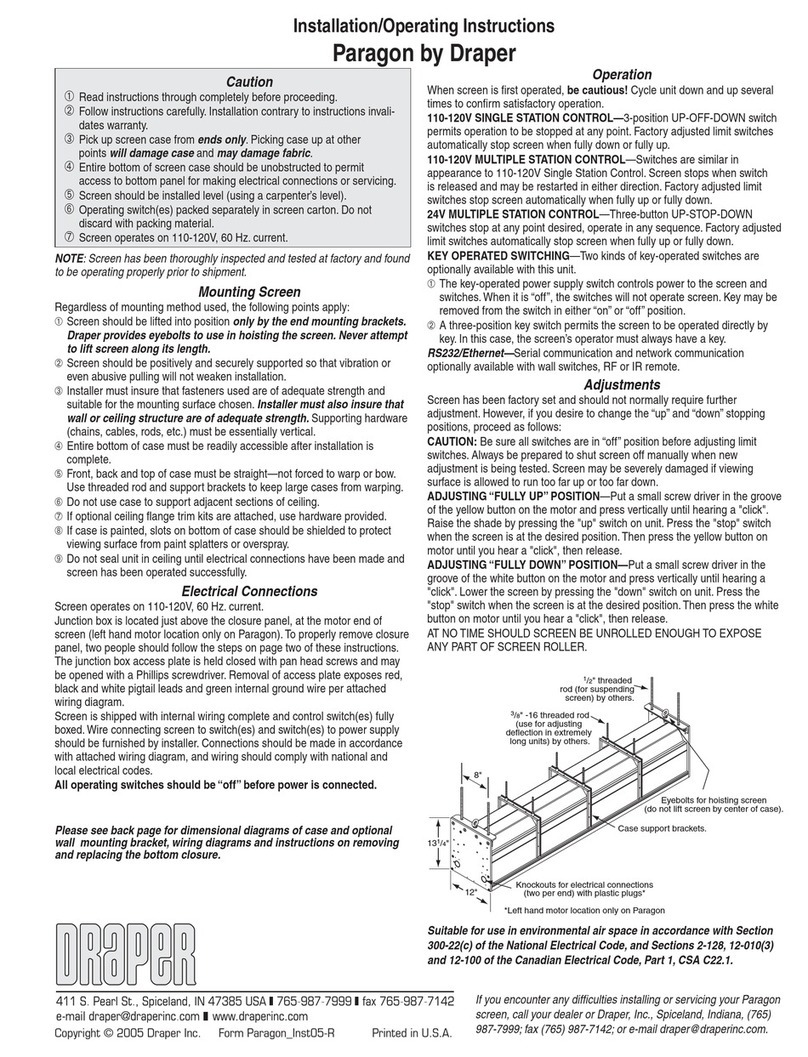

Caution: Do not remove the roller assembly from the case unless neces-

sary for repairs. If the roller assembly is removed, be sure motor is fully

re-seated in the bracket, and re-secure it carefully with the motor retaining

spring and screw (see diagram below).

Please note: Do not use a power screwdriver to tighten screw.

Maximum torque for tightening screw is 5 lb-inches.

6

5

/

8

"

6

5

/

8

"

Targa Premier

Screw is included

with Large Targas

and Large Premiers.

IMPORTANT

Use of Large Case Targa or Large Case Premier screens with TorkStar Utility Li-

neset requires specially modified Large Premier or Large Targa case and mount-

ing brackets. DO NOT use TorkStar with standard Large Case Targa or Premier

screen and brackets. Contact Draper for details.