Beaumont LC10 Manual

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10

Specifications

Connections:

Threaded: 1 1/2” and 2”

Flanged: 2” to 8”

Union: 4” and 5”

Pressure Rating:

Threaded: 6000 psi

Flanged: Up to ANSI 2500 Class

Union: 1500 psi

Temperature Range:

-50° F to 400° F (Varies by Material Selections)

Pilot Connections: 1/4” NPT

Pilot Max Pressure: Limited by Gauges

Electric Switch Ratings:

SPDT: 15 A @ 125, 250, 480 VAC

DPDT: 10 A @ 125 VAC

Application

The LC10 is a liquid level controller. It uses a displacer balanced by a

spring to detect the level of a liquid inside a vessel. As the liquid level

rises and falls the LC10 gives either an increasing or decreasing

output signal using a pneumatic pilot or electric switch.

The LC10 is available with many different options making it an

extremely versatile device that can be set up in a variety of ways.

Three different pneumatic pilots options are available as well as two

electric switch options. Left hand, right hand, and back mount

options are available to fit a variety of vessels and piping layouts.

Many different connections sizes, arm lengths, displacer sizes and

materials make for an endless combination of available models to fit

almost any need.

Many of the options of the LC10 are able to be changed right in the

field. The pilots can be easily removed from the LC10 making it easy

to change them out in the field. The standard LC10 can be swapped

from right to left hand or vice versa in the field. The LC10 can also be

changed from direct to reverse acting in the field. The displacer and

arm can also be easily swapped out at any time or changed from a

horizontal to vertical orientation.

LC10B

LC10/

LC10S

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Installation

Installation

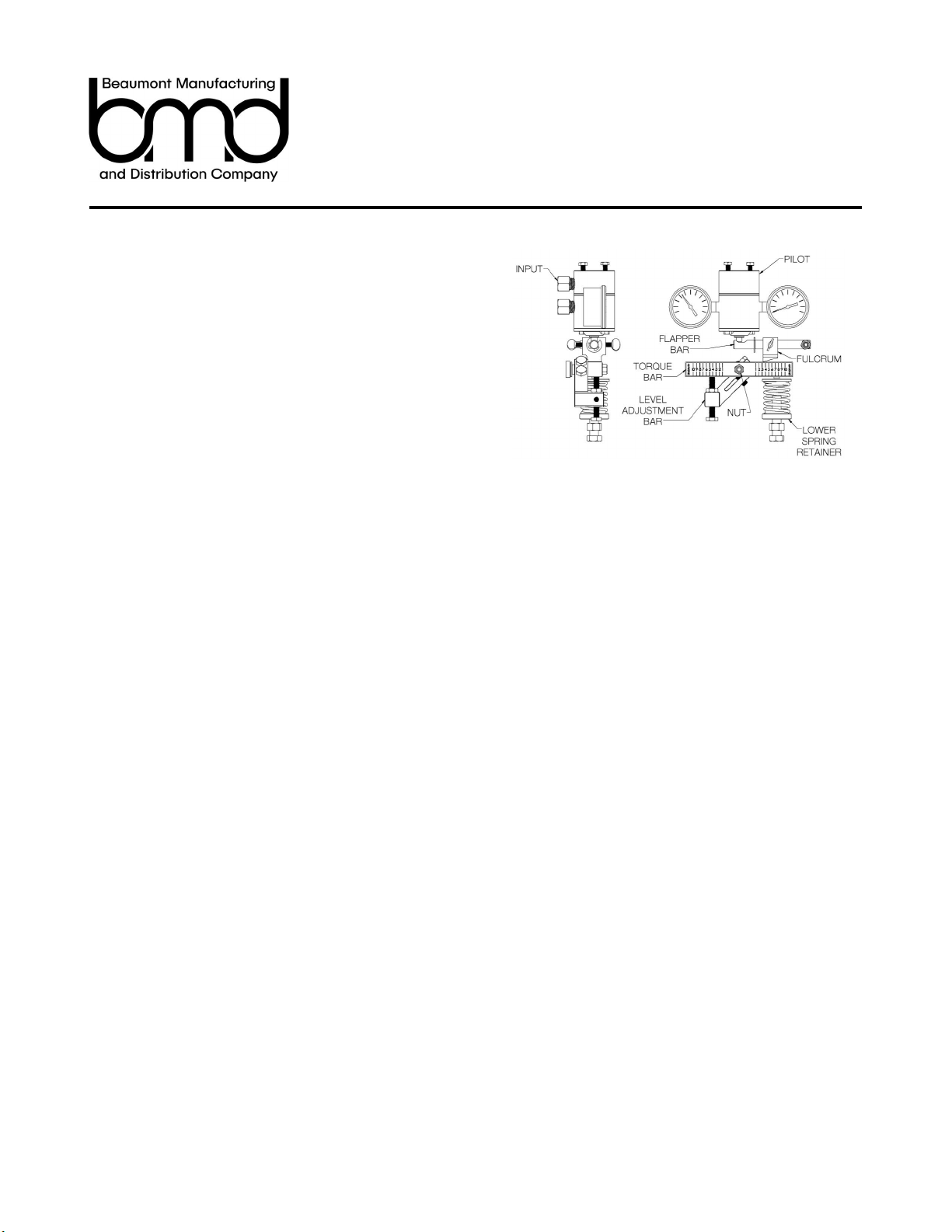

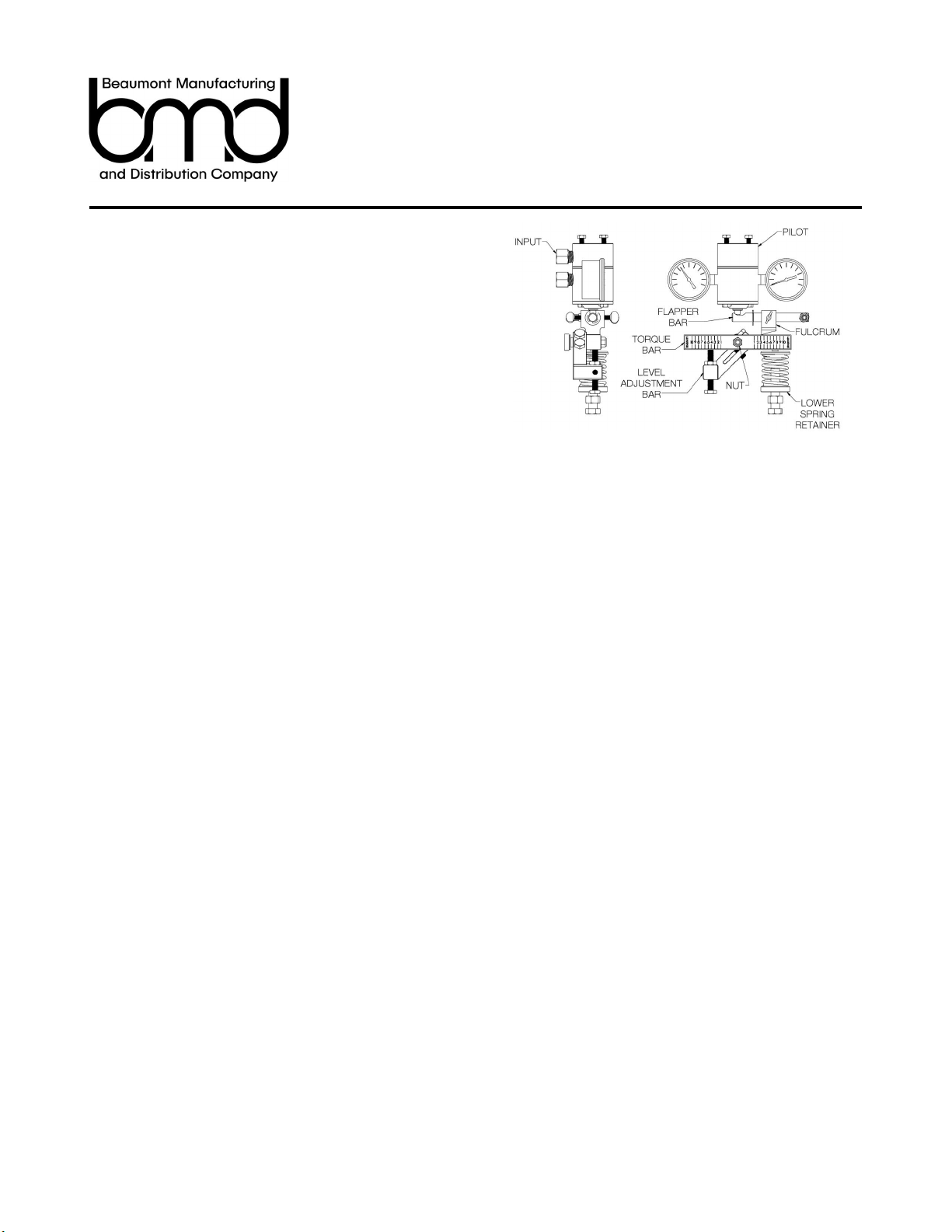

Arm and Displacer (See Figure 1)

The Arm and Displacer are shipped in the box with the LC10 and will

need to be attached before the LC10 is installed into a vessel. Thread

the Arm into the Shaft inside the LC10 Body. This can be done

inserting the Arm into the hole in the end of the LC10 Body and

pushing it in until it can be threaded into the hole in the Shaft located

near the back of the Body. The Shaft may need to be rotated slightly

until the threaded hole is aligned to the front. For a horizontal

arrangement screw the Displacer directly onto the Arm. For a vertical

arrangement, attach the Arm followed by the Swivel Assembly, then

add the Displacer. If vibration is a concern, Loctite can be added to

the Arm threads before installation.

Body

For a threaded Body verify that the condition of the threads on the

vessel and the LC10 are undamaged and free of debris. Apply pipe

compound or Teflon tape to the threads. Insert the Displacer and Arm

into the vessel and thread the LC10 onto the vessel.

For a flanged Body LC10 use the correct Gasket and bolts to connect

the LC10 to the vessel.

For a union connection be sure to put the Hammer Nut over the Body

before threading the LC10 Body into the blind flange. Then put the

blind flange on the end of the Weld Neck and thread on and tighten

the Hammer Nut.

For any installation make sure that there is enough clearance for the

Arm and Displacer to move freely in the vessel without touching the

vessel sides or bottom.

Pilot/Switch (See Figure 3)

Connect low pressure supply gas to the LC10 Pilot. The 1/4 NPT Pilot

connections can be found at the back of the LC10 Case. CAUTION:

Be sure not to exceed the pressure range of the Pilot Gauges.

Doing so can damage the gauges and pilot. The standard Gauges

are 0-30 or 0-60 psi.

If installing an LC10 with an Electric Switch, follow the proper

electrical codes when making connections and installing conduit. See

Figure 2.

Figure 2 Figure 3

Figure 1

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Operation

Principles of Operation

The LC10 uses Archimedes' principle in order to detect the level of

liquid in a vessel. The Displacer weighs less when submerged in a

liquid, because of the buoyant force acting on the Displacer when it is

submerged. Since the weight of the Displacer is balanced by the

LC10 Spring, the buoyant force from the liquid is enough to lift the

Displacer and Arm upward rotating the Level Adjustment Bar. The

Level Adjustment Bar pushes on the Torque Bar which acts upon the

Fulcrum on the Level Adjustment Bar. The Level Adjustment Bar then

pushes the Pilot Pin triggering the Pilot.

Level Adjustment

When using an LC10 with a vertical Displacer orientation, the liquid

level in the vessel can be adjusted by turning the Lower Spring

Retainer as shown in Figure 4. Turning the Lower Spring Retainer

changes the amount of load provided by the Spring which in turn

changes the amount of support provided to the Displacer’s weight.

Turning the Lower Spring Retainer clockwise provides less spring load

and less offset of the displacers weight. This means that the liquid will

have to rise higher on the Displacer in order to lift it and trigger the

LC10. Turning the Lower Spring Retainer counter-clockwise provides

more spring load meaning the liquid level does not need to rise as

high on the Displacer to trigger the LC10. Therefore turning the Lower

Spring Retainer clockwise raises the liquid level in the vessel, and

turning it counter-clockwise lowers the level.

Note that amount that the level can be adjusted is limited by the

length of the Displacer.

Direct vs Reverse Acting (See Figure 6)

A direct acting LC10 arrangement will increase the Pilot output as the

Displacer is lifted. Reverse acting arrangement will decrease the Pilot

output as the Displacer is lifted.

Figure 4

Figure 5

Reverse

Direct

Figure 6

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Operation Cont.

Sensitivity & Span

The span of the Level Controller is the distance that the level changes

between when the Pilot opens and closes. To adjust the span loosen

the Thumb Screw located on the Fulcrum. Then slide the Fulcrum

along the Flapper Bar. Moving the Fulcrum toward the center of the

Case increases the sensitivity of the Displacer to changes in liquid

level thereby decreasing the span. Moving the Fulcrum away from the

center of the Case decreases the sensitivity and increases the span.

Increasing the span means that a dump valve actuated by the LC10

will stay open longer draining more of the liquid in the vessel before it

closes. Decreasing the span close the dump valve sooner draining

less fluid.

Figure 7

Figure 8 Figure 9

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Maintenance

Setting the LC10

To set the LC10 first connect an airline to the input of the Pilot. Next,

adjust the Lower Spring Retainer so that, when the Arm is in its set

position and then lifted, the Flapper Bar triggers the Pilot.

Mounting Change

The LC10 is field reversible which is convenient for arrangement

changes. To switch the LC10 from left to right or vice versa, first

remove the nut holding the Torque Bar and Level Adjustment Bar on

the Shaft. Next, remove the Torque Bar and Level Adjustment Bar.

The Body is held on by two hex head screws. Remove the screws

and rotate the Body to the desired orientation and reinstall the screws

to secure the Body. The Level Adjustment Bar will need to be rotated

clockwise or counter clockwise depending on the initial setup. The

screw will need to be removed from the Level Adjustment Bar and

threaded into the correct hole once the Bar has been rotated. The

Spring, Upper and Lower Spring Retainer, and Screw will swap to the

other side. Put the Level Adjustment Bar and Torque Bar back on the

Shaft and use the nut to secure them. Finally, The Fulcrum Assembly

will need to be moved to the opposite side. Unscrew the nut holding it

on the stud and simply swap to the other side. Reference Figure 11.

Action Change

To change an LC10 from reverse to direct or vice versa simply

unscrew the nut holding on the Flapper Bar. Remove the Flapper Bar

and move it to the other side of the Case. Don’t forget to swap the

Thumb Screw around to the front. Re-install the nut taking care not

to over tighten it. Overtightening the nut will hinder the Flapper Bar

from rotating and will cause the unit to malfunction. For best

performance the nut should be snugged up against the Flapper Bar

then backed off about 1/8 of a turn.

Body Maintenance (See Figure 12)

To replace the soft goods in the Body of the LC10 unscrew the nut

holding on the Torque Bar and Level Adjustment Bar, remove them

from the Shaft, and remove the Body from the Case by unscrewing

the two hex head screws. Once the Body is removed, unscrew both

Bearing Blocks to reveal the two O-rings and Backup Ring on each

side. Remove the old O-rings and Backup Rings and replace them

with the new ones provided in the repair kit. Before installing the new

O-rings, grease them with multi-purpose synthetic grease for reduced

wear and longer life expectancy. Reinstall the Bearing Blocks into the

Body and attach it back to the Case securely tightening the two hex

head screws. Put the Level Adjustment Bar and Torque Bar back on

the Shaft and secure them with the nut.

Figure 10

Figure 12

Figure 11

Left Hand Reverse Right Hand Reverse

Left Hand Direct Right Hand Direct

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Maintenance Cont.

Pilot Change

Standard Case (See figure 13)

To remove the Pilot, first turn the Lower Spring Retainer all the way to

the bottom to relieve the tension on the Spring. Next, unscrew the two

screws located on top of the Case. Push down the Torque Bar on the

Spring side as far as it will go. This will allow the Pilot to be removed.

Put in the new Pilot, and replace the upper screws to hold it to the top

of the Case. Make sure that the Flapper Bar is positioned so that the

Pilot Pin rests in the slot. The Pilot Pin should be able to move freely

in the slot without binding as the Flapper Bar moves up and down .

Sealed Case (See Figure 14)

To remove the Pilot, first turn the Lower Spring Retainer all the way to

the bottom to relieve the tension on the Spring. Next, unbolt the Pilot

Plate that covers the front of the Pilot. Push down the Torque Bar on

the Spring side as far as it will go. This will allow the Pilot to be

removed. Remove the Gasket behind the Pilot. To reassemble replace

the Pilot Gasket with a new one and put in the new Pilot. Put the Pilot

Plate back on and reinstall the pilot plate screws. Make sure that the

Flapper Bar is positioned so that the Pilot Pin rests in the slot. The

Pilot Pin should be able to move freely in the slot without binding as

the Flapper Bar moves up and down .

Pilot Repair (See Figure 15)

Remove the two screws holding together the Pilot to expose the

components within. When replacing the components, the Gasket

needs to be checked so that the orientation of the cutouts match the

holes on the Body. Reassemble and test the Pilot with a supply line to

check for leaks before installing back into the Case. Mount the Pilot

back into the Case with the two screws and make sure the Flapper

Bar is positioned correctly on the Pilot Pin.

Figure 13

Figure 15

Figure 14

1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com Model LC10 Maintenance Cont.

Symptom Probable Cause(s) Corrective Action(s)

Air leaking through pneumatic pilot

continuously

Snap Pilot: Ball isn't seating

properly

Connect an air supply line to the inlet port on the

Pilot and actuate the pilot 2-4 times

Throttle Pilot: Lower pin (peanut)

not seating

Connect an air supply line to the inlet port on the

Pilot and actuate the pilot 2-4 times.

Debris on the sealing surfaces

Clean out the inside of the top cap and body of

any debris and actuate the pilot 2-4 times with

air connected to the inlet port.

Snap ring not in the groove on the

pin

Check to be sure the snap ring is sitting in the

groove on the pin.

Pilot output gauge not indicating an

output pressure signal on a direct

acting controller when the fluid level is

above displacer or on a reverse acting

controller when the fluid level is below

the displacer.

The gasket is not installed properly Ensure the gasket cutouts match the holes in the

body when replacing.

The spring isn't compressed

enough and therefor not applying

enough pressure on the torque

bar.

Turn the lower spring retainer counter-clockwise

until the output pressure signal is indicated on

the gauge. Verify when the fluid level falls or rises

for direct and reverse acting, respectively.

The displacer arm is set too low or

the displacer is bottoming out on

something inside the vessel

Check the displacer arm by moving the level

adjustment bar up and down. If the level

adjusting bar only moves in one direction it

indicates the displacer arm is sitting at either the

top or bottom of the vessel connection. If it

moves too freely, the displacer is no longer

connected to the arm. Re-center the displacer

arm in the vessel connection.

Pilot output gauge not indicating an

output pressure signal on a direct

acting controller when the fluid level is

above displacer or on a reverse acting

controller when the fluid level is below

the displacer.

The spring is compressed too

much and therefor applying too

much pressure on the torque bar.

Turn the lower spring retainer clockwise until the

output pressure signal is relieved on the gauge.

Verify when the fluid level falls or rises for direct

and reverse acting, respectively.

The displacer arm is set too high

or the displacer is bottoming out

on something inside the vessel

Check the displacer arm by moving the level

adjustment bar up and down. If the level

adjusting bar only moves in one direction it

indicates the displacer arm is sitting at either the

top or bottom of the vessel connection. If it

moves too freely, the displacer is no longer

connected to the arm. Re-center the displacer

arm in the vessel connection

Controller does not repeat at the same

fluid level after each dump and

sometimes fails to either dump or

shut-off

Debris has accumulated inside the

level control body

Remove the controller from service and clean the

body with a solvent

Table 1. Trouble Diagnosis

This manual suits for next models

2

Table of contents

Other Beaumont Lawn And Garden Equipment manuals