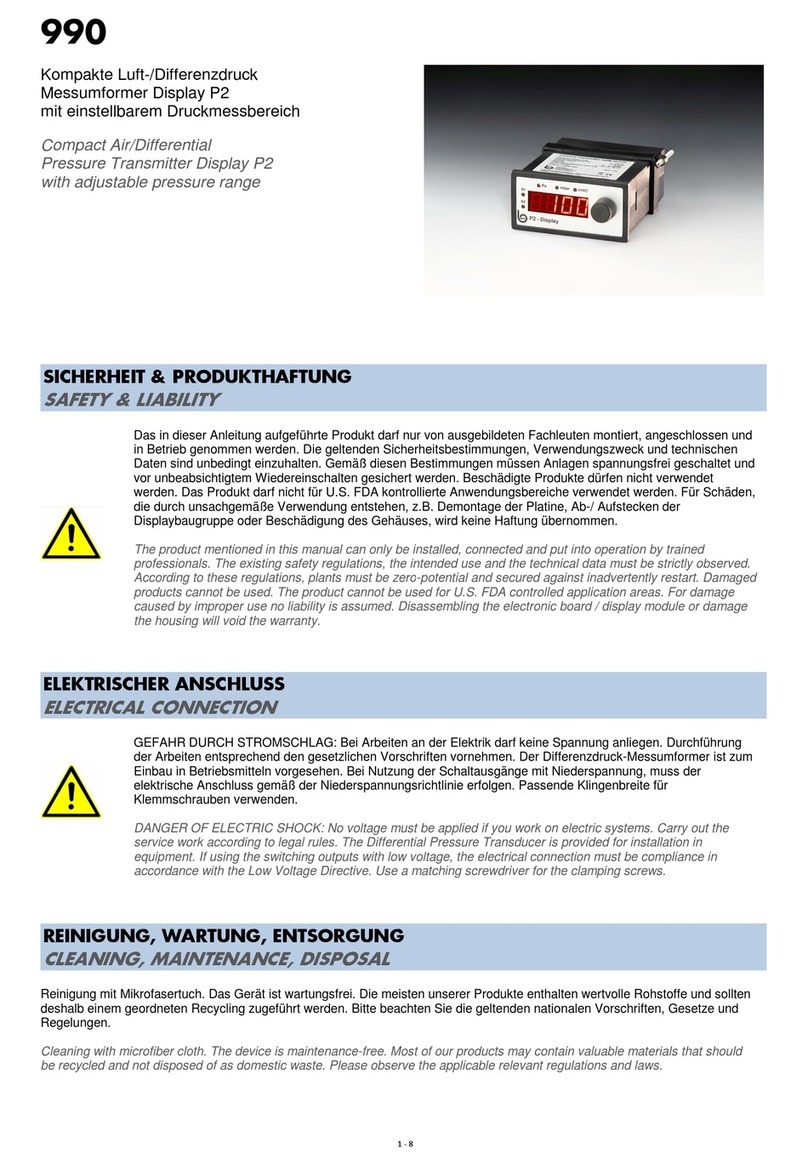

Beck Display P2 Specification sheet

Operating and

Installation Manual

Differential pressure gauge Display P2 for air

with 7 segment LED display,

and 2 switching outputs, for

• Building automation, air-conditioning and

clean-room technology

• Val e and damper control

• Filter, fan and blower monitoring

• Air flow control

Technical data

Pressure measurement ranges

Supply voltage

Type 990M with manual

zeroing

Type 990A with automatic

zeroing

Optional wall power supply

Output signal

Working resistance for output

4 ... 20mA

Power consumption

Pressure medium

Linearity and hysteresis error

Operating temperature

Storage temperature

Long-term stability, typical

16 ... 32VDC

18 ... 30VAC

22 ... 30VDC/AC

100 ... 240VAC(In)/24VDC(Out)

(50 ... 60Hz)

0 ... 10V and 4 ... 20mA

20 ... 480

Ω

< 100mA for DC

< 250mA for AC

Air and non-agressive gases

≤

±

1% of FS

0 ... 50°C

- 10 ... 70°C

≤

±

0.5% to

±

2.5% of FS/year,

Dependent on pressure range

Repeatability

Position dependence

Humidity

Response time, switchable

Process connection

Electrical connection

Attachment

Display

Instrument dimensions

Weight

IP rating after EN 60529

Standards / Conformity

≤

±

0.2% of FS

≤

±

0.02% of FS/g

0 ... 95% rel.,

non condensing

0.0 - 20.0s

4mm + 6mm tube connections

Screw terminals for wires and

braided wire up to 1.5mm²

Control panel

Red 7 segment LED display,

4-figure

143mm x 96mm x 48mm

230g

IP20

EN60770, EN61326

2002/95/EC (RoHS)

Type Pa mbar inWC Safe +ve pressure Burst pressure Temperature error

990A.303 0 ... 25 0.25 0.10 20 kPa 40 kPa

≤

±

5 % of FS

990A.313 0 .... 50 0.5 0.20 20 kPa 40 kPa

≤

±

5 % of FS

990x.323 0 ... 100 1.0 0.40 20 kPa 40 kPa

≤

±

5 % of FS

990x.333 0 ... 250 2.5 1.00 20 kPa 40 kPa

≤

±

5 % of FS

990x.343 0 ... 500 5.0 2.00 20 kPa 40 kPa

≤

±

2,5 % of FS

990x.353 0 ... 1 kPa 10 4.00 20 kPa 40 kPa

≤

±

1 % of FS

990x.363 0 ... 2.5 kPa 25 10.05 40 kPa 70 kPa

≤

±

1 % of FS

990x.373 0 ... 5 kPa 50 20.10 60 kPa 120 kPa

≤

±

1 % of FS

990x.383 0 ... 10 kPa 100 40.20 60 kPa 120 kPa

≤

±

1 % of FS

990x.393 0 ... 25 kPa 250 100.50 300 kPa 500 kPa

≤

±

1 % of FS

990x.3A3 0 ... 50 kPa 500 200.10 300 kPa 500 kPa

≤

±

1 % of FS

990x.3B3 0 ... 100 kPa 1,000 402.00 1.2 MPa 2 MPa

≤

±

1 % of FS

990x.3F3 0 ... 250 kPa 2,500 1,004.75 1.2 MPa 2 MPa

≤

±

1 % of FS

ELECTRICAL CONNECTION AND CONTROL PANEL DIMENSIONS

WARNING! Electrical systems must only be set-up, expanded, changed or updated by authorised electricians

or electrical techicians. Ne er work on electrical systems, if you are not qualified to do so.

When working on the electrical system, it must be at zero olts.

SWITC ING OUTPUT

The differential pressure gauge has two adjustable relay outputs in addition to the analogue output signal

at the terminals 5 ... 10 with a maximum switching capability of 250VAC/5A.

FASTENING & TUBE CONNECTION

N.B.: When connecting and routing tubes ensure they are not kinked or damaged.

Leaking tubes and tube connections cause instrument faults or result in

incorrect measurements.

Tube internal diameter = 3.5 / 5.5mm for optimum clamping. Use tube clamps from 25kPa.

P1 = Positi e pressure measurement

P2 = Vacuum measurement

P1 & P2 = Differential pressure measurement

SAFETY & PRODUCT LIABILITY

The product to which this manual refers must only be installed, connected and commissioned by trained specialists.

The rele ant safety conditions, intended use and technical data must be adhered to without fail. According to these conditions,

systems must be switched to a zero- olts condition and be secured to pre ent unintentional switching back on.

Damaged products must not be used. The product must not be used for US FDA controlled application fields.

No liability is accepted for damage arising from improper use.

DISPOSAL

The crossed out garbage can on this product indicates that at the end of its ser ice life, the product must be

disposed of separately from household waste. In future, please take all electrical and electronic products

to a suitably equipped municipal collection point for their reuse / recyling.

Function settings of the pressure gauge Display P2

Display

Main menu**

Remark

Rotary but-

ton

Press

Turn

Display

Rotary but-

ton

Press

Turn

Display

Sub-menu Unit Information / description

Example

250

Type: 990M.333114

Pressure range: 0 ... 250 Pa

Analogue output: 0 - 10 V

Pa Current pressure alue

OFFS

1

-3

-124 ... 125

0

Pa

Pa

Pa

Zero point (offset) is displayed

Adjust zero point

Sa e zero point (display flashes for confirmation)

SP1

3

25

1 ... 250

50

Pa

Pa

Pa

Switching point is displayed

Adjust switching point

Sa e switching point (display flashes for confirmation)

YS1

3

2

1 ... 250

5

Pa

Pa

Pa

Hysteresis is displayed for SP1

Adjust hysteresis for SP1

Sa e hysteresis for SP1

(Display flashes for confirmation)

SP2

3

75

1 ... 250

100

Pa

Pa

Pa

Switching point is displayed

Adjust switching point

Sa e switching point (display flashes for confirmation)

YS2

3

10

1 ... 250

5

Pa

Pa

Pa

Hysteresis is displayed for SP2

Adjust hysteresis for SP2

Sa e hysteresis for SP2 (display flashes for confirmation)

OuA

3

0-10

0-10 / 4-20

4-20

V

V / mA

mA

Display of the type of analogue output V or mA

Switching between 0-10V / 4-20 mA

Sa e setting (display flashes for confirmation)

AEP 3

250

50 .. 250

200

Pa

Pa

Pa

Display of the working end point (pressure range end)

Adjust AEP

Sa e AEP (display flashes for confirmation)

dAA 3

0,01

0.00 ... 20.00

0.10

s

s

s

Display damping time of the analogue output

Set the damping time

Sa e the damping time

(Display flashes for confirmation)

Func

2

lin

lin/sqrt

sqrt

-

-

-

Display analogue output function

Changeo er between linear / square root

Sa e setting (display flashes for confirmation)

=> Function is enabled by customer order

Default: linear

2

CAL

CAL / rho

rho

0.52

0.01 ... 1.00

0.80

-

-

-

Display Cal-factor

Adjust Cal-factor

Sa e setting (display flashes for confirmation)

2

1.00

0.08 ... 1.50

1.25

-

-

-

Display density rho of the medium

Set rho

Sa e setting (display flashes for confirmation)

I 250 Pa Display maximum applied pressure

Lo 0 Pa Display minimum applied pressure

dISP

10

10 ... 100

50

%

%

%

Display (LED) brightness

Adjust brightness

Sa e brightness (display flashes for confirmation)

=>In programming mode always set to 100%, once pro-

gramming mode is finished, the brightness always goes

smoothly to the set alue

Uni

3

1

1 ... 3

2

Pa

Pa/

mbar/

inWC

mbar

Display the selected unit of pressure

Set the pressure unit (LED 1...2...3) on the front

LED1 Pa; LED2 mbar; LED3 inWC

Sa e pressure unit (display flashes for confirmation)

LED2 illuminates for mbar

=>Pressure units are specified by the customer

OP-h 48 h Operating hours display

Fir F.1.02 Display ersion of firmware

PArA P.021 Display software ersion parameter

PASS

32

32

0 ... 99

77

-

-

-

-

Password (blocks function settings³ in the instrument,

except if the password is "0")

Do not change the password

Set/alter the password

Sa e password (display flashes for confirmation)

Master password = 71

=>enables access to the instrument if the password

is lost

End 2.00 mbar Menu end / back to the pressure display

** The main menu points are reached by turning the rotary knob

1 Not applicable for the 990A type as the version with automatic zeroing.

2 Only available if the optional function "square root" has been ordered.

3 Blocked function setting - except if the password is "0" or "071" (master password).

Beck GmbH

Pressure control technology

Postfach 11 31

D-71140 Steinenbronn

Phone +49 (71 57) 52 87-0

Fax +49 (71 57) 52 87-83

e-mail [email protected]

http://www.druckschalter.de

Other Beck Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Omron

Omron K6CM series Startup guide

Blancett

Blancett QUIKSERT Operation & installation manual

Elster

Elster 6 Series Wiring instructions

Omicron Lab

Omicron Lab Bode 100 Detailed Functional & Calibration Check

Sigma Metalytics

Sigma Metalytics Precious Metal Verifier INVESTOR 3012 manual

DENT Instruments

DENT Instruments PowerScout HD Series Operator's guide