Sigma Metalytics Precious Metal Verifier INVESTOR 3012 User manual

MANUAL

MODEL #3012

2

Contents

Caution......................................................................................................3

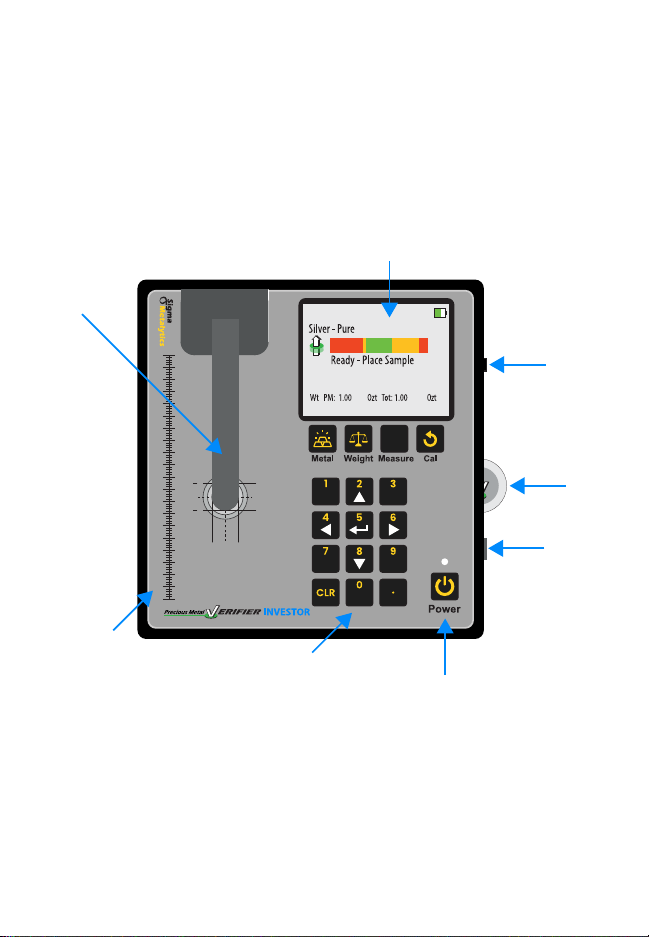

Device Diagram............................................................................................4

PMV Investor Functions...........................................................................5

How to Get the Most out of Your PMV.................................................6

Power On and Calibrate...........................................................................7

Setup...................................................................................................8

Metal Selection.............................................................................................9

Weight Entry...............................................................................................10

Measurement Screen..............................................................................12

Resistivity Testing....................................................................................14

Wand Use.....................................................................................................20

PC Interface.................................................................................................21

Investor Best Practices..........................................................................22

Common Questions..................................................................................24

Warranty....................................................................................................26

3

CAUTION

Read Before Use

The onboard sensor bridge is sensitive to

stress. DO NOT force it left or right, place

heavy objects on it, lift the device by the bridge.

Stress can cause miscalibration and damage.

make no claim, guarantee, or promise that measurements

any sample is or is not genuine. Measurement results, whether

within or without the bounds consistent with the selected

about or action taken with regard to any sample is entirely the

responsibility of the user. To ensure accuracy, thoroughly read

the included instructions and be aware of the special conditions

which may affect the readings.

4

Calibration

mm 10 50454035302505 2015 6055 80757065 100959085

s

a

m

p

l

e

m

u

s

t

c

o

v

e

r

i

n

n

e

r

c

i

r

c

l

e

[ █]

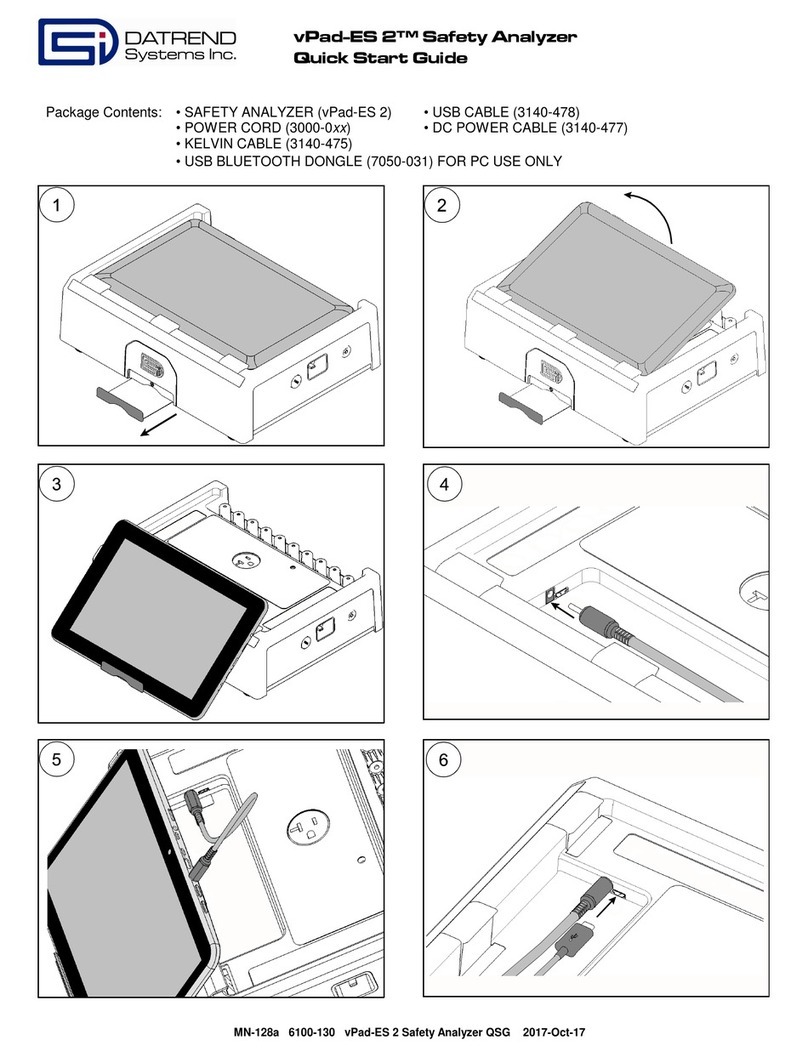

Device Diagram

Wand Port

Cal. Disk

USB C Port

Power Button

Keypad

Sizing Scale

Sensor Arm

Display

The arrow keys are used for

menu navigation and the

number keys are used for

weight entry.

5

PMV INVESTOR Functions

to determine if a coin or bar is consistent with genuine

precious metals.

The four measurements are:

1.

measure the sample’s resistivity just under the surface

of the metal. This ensures there are no contaminants or

foreign metals in or near the surface.

2.

sensor in the arm and in the base of the device to measure

the sample’s bulk resistivity. This measurement checks

the entirety of the sample and ensures there are no

contaminants or foreign metals anywhere between the two

sensors.

3.

electronically measures the thickness of the sample using

the average thickness of the face of the sample.

4.

density. The user must enter the measured weight of the

sample to perform this test.

6

How to get the most out of

your PMV INVESTOR

pass both resistivity and density testing. It’s important to

use the right settings and sensors to make sure your PMV

1. Power on the device and make sure it’s able to calibrate

Press the power button to turn the device on.

PMV calibrates itself while turning on, so be sure there

are no samples onboard. Read the Power On and Calibrate

section (Pg. 7) for more.

2.

Select the expected alloy of the sample and and enter the

weight. Follow the steps in the Metal Selection (Pg. 9)

and Weight Entry (Pg. 10) to do so. If you don’t know the

expected alloy or weight, refer to the Testing Best Practices

section (Pg. 20) for advice.

3. Perform

the resistivity testing by following the steps in the Resistivity

Testing section (Pg. 12). If possible, test the sample’s

(Pg. 14). Use the Results Interpretation section (Pg. 13) to

understand the results from the PMV.

7

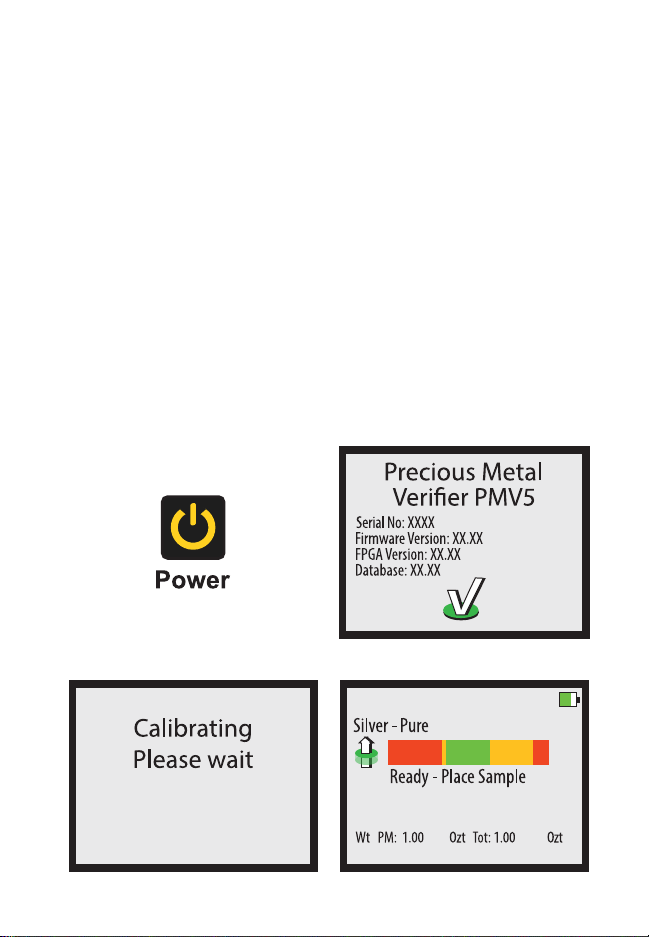

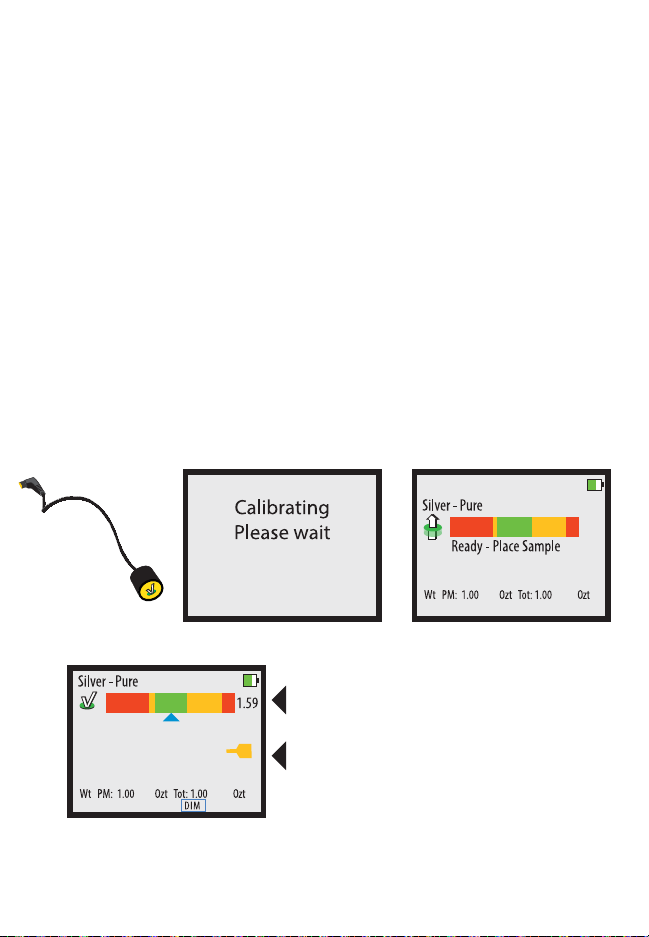

Power On and Calibrate

POWER button.

during the power on stage. While the device is powering on,

ensure there are no samples on the device and that the arm is

in the upright and resting position. This calibration checks the

internal components and prepares the device for use. When

complete, the device will show the READY screen.

8

Setup

You may change some settings in the SETUP screen. To access

the SETUP screen, press the RIGHT button on the READY

screen. Use the UP and DOWN buttons to select the category,

and use the RIGHT and LEFT buttons to change the selection

within a category. Press the ENTER button when done to exit

the SETUP screen.

the settings are saved between uses.

9

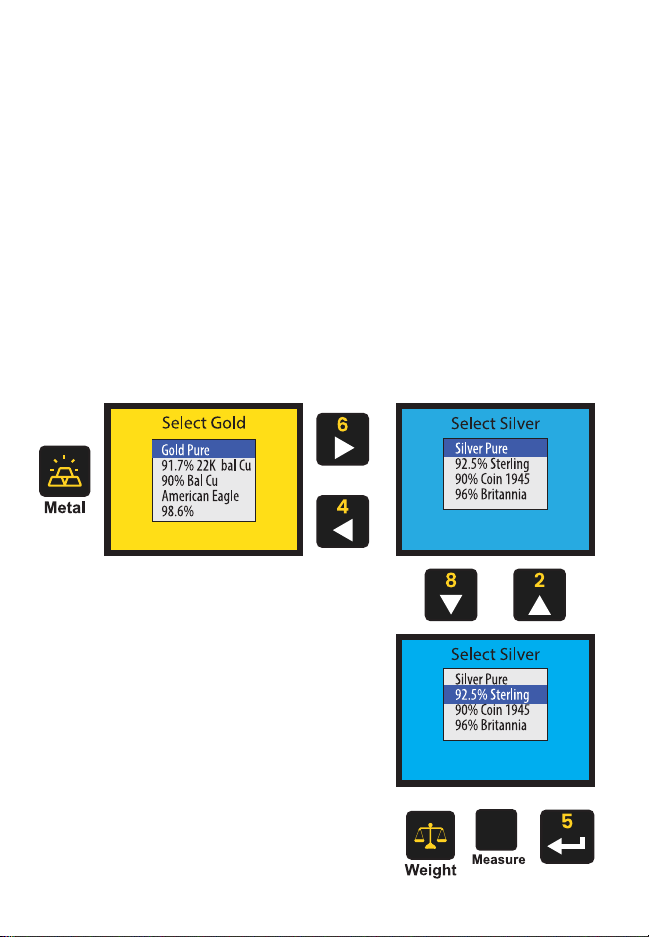

Metal Selection

Prior to taking a measurement, you must select the appropriate

metal or alloy from the metal selection database. Choose the

metal you expect the sample to be. Press the button to

open the selection menu. Use the LEFT and RIGHT buttons to

navigate between metal categories, and use the UP and DOWN

press the ENTER, , or WEIGHT

selection.

[ █]

10

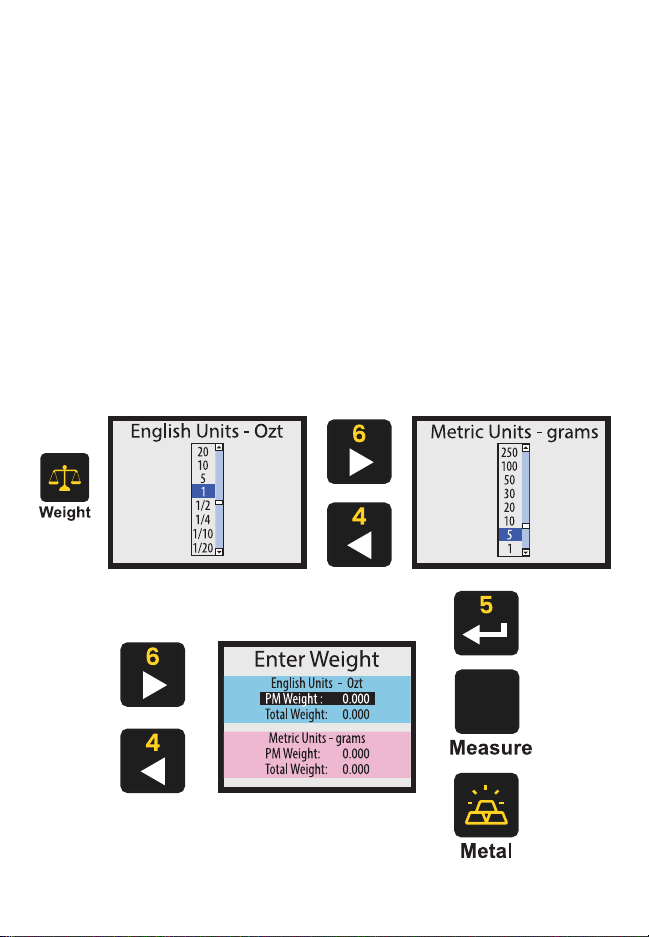

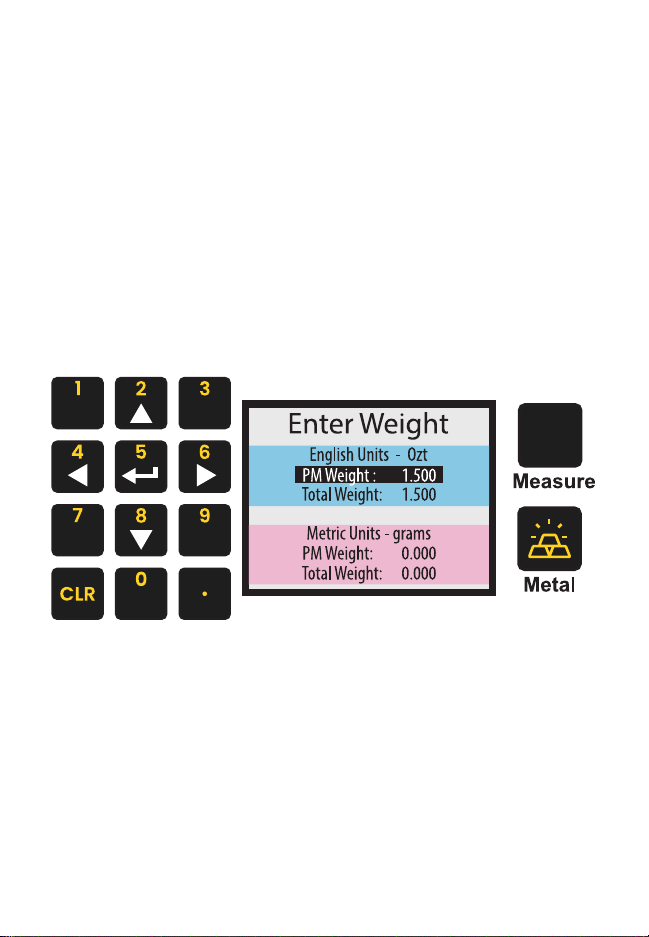

Weight Entry

Press the WEIGHT button to enter the weight of a sample. You

can either select from the options listed in the English Units

(Ozt) and Metric Units (grams) categories, or you can manually

enter a weight on your own. Use the LEFT and RIGHT buttons to

navigate between categories, and use the UP and DOWN buttons

to select options within a category. When ready, press the

ENTER, , or

Entering the correct weight is important to accurately testing

dimensions.

[ █]

11

Manual Weight Entry

To manually enter weight, use the UP and DOWN buttons to

select the type of weight you want to enter. Press the ENTER

button to change the indicated weight. Use the buttons

to enter the desired weight. Press the WEIGHT button when

or button to continue use.

[ █]

PM Weight is the precious metal

weight in the sample.

12

Sample consistent with

selected metal

sample, like size, weight, and markings.

Sample inconsistent

with selected metal

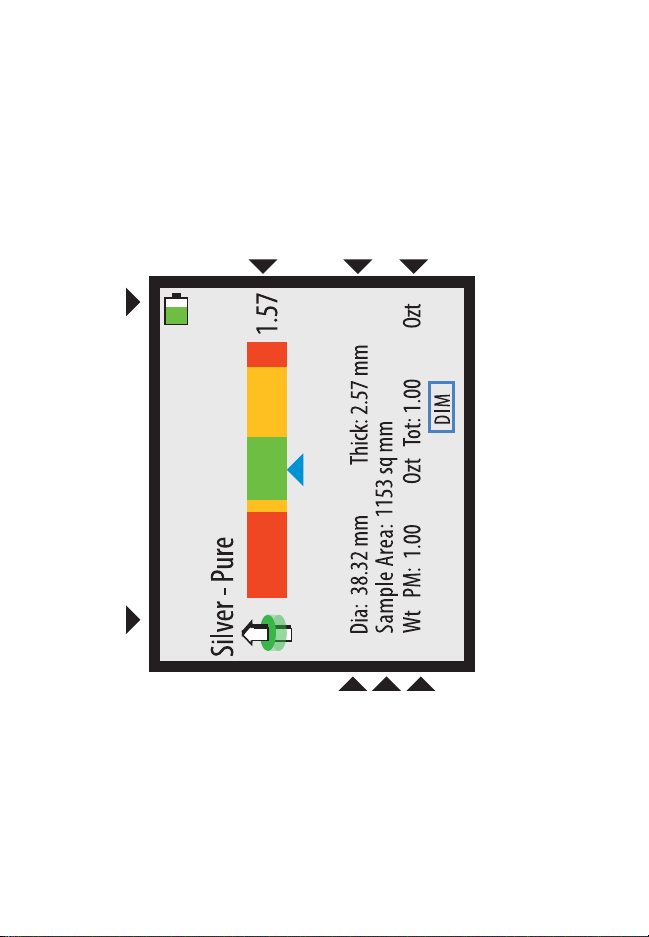

Measurement Screen

The screen will display when taking a reading.

Below is a basic explanation of each part of the screen. The

screen will not display the diameter, thickness, or weight if

weight mode is turned off. When using a Wand attachment, only

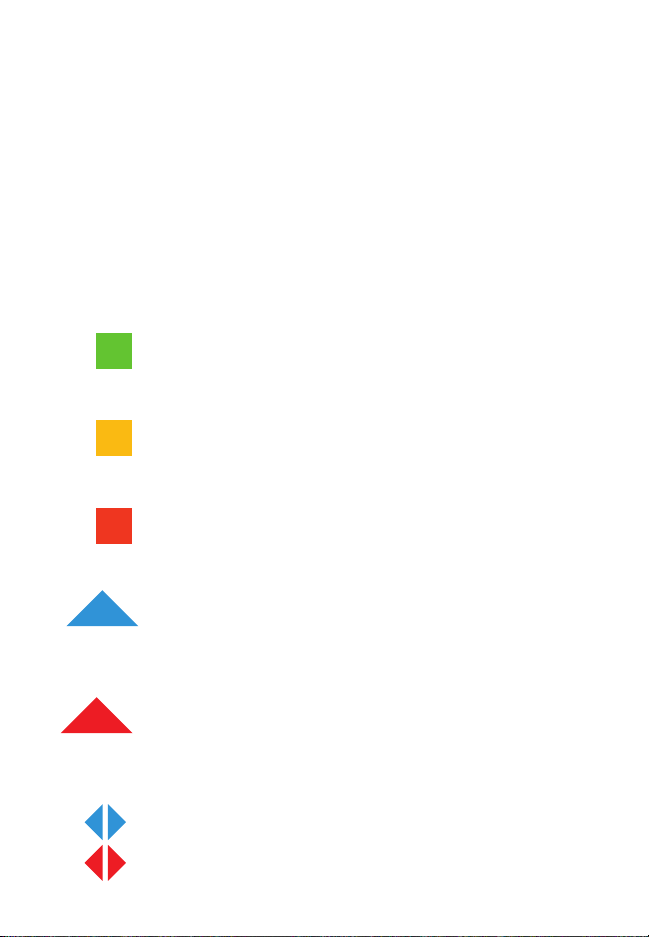

Blue Arrow

Indicates the device is getting a

reliable reading.

Red Arrow

Indicates the device is getting an unreliable

reading, treat result with caution.

Sideways Arrow

Indicates the result is off the

13

Calculated Diameter

Calculated Sample Area

Total Weight

Battery Indicator

14

Resistivity Testing

characteristic resistivity of precious metal coins and bars. Each

precious metal alloy has an expected resistivity value; the PMV’s

sensors test the sample’s resistivity and compare it to the known

resistivity of the selected alloy. To properly test your sample,

follow these steps:

1. Select the expected alloy of the

sample. Follow the steps in the Metal Selection (Pg. 9) to do

so. If you don’t know the expected alloy, refer to the Testing

Best Practices section (Pg. 20) for advice.

2. Place the sample on the

onboard sensor or touch the face of a Wand to the sample.

Refer to the Wand Use section (Pg. 18) for how to use a

wand.

Note: the sample does not need to physically touch the

sensor or wand. The PMV can read through plastic and

cardboard and can read through most cases. You do not

need to remove the sample from the case to test.

3. Refer to the Resistivity Testing

Interpretation section (Pg. 13) for details on determining

the results of your sample’s resistivity test. Generally, green

is good, yellow is caution, and red is questionable.

15

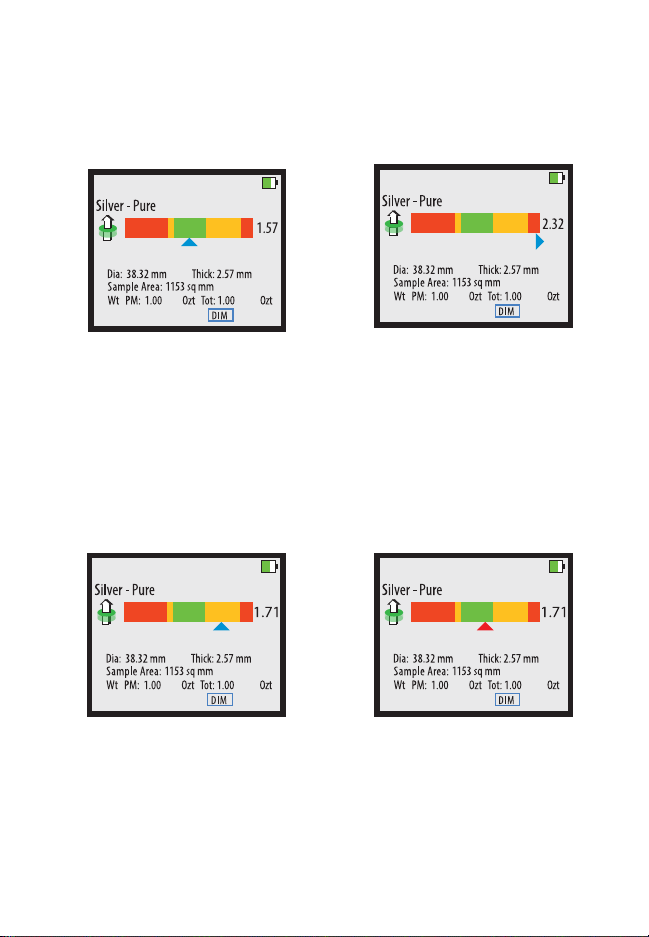

Results Interpretation

Reliable Reading,

Good Sample

The device is getting a

reliable reading and the

reading is consistent with the

selected metal.

Reliable Reading,

Questionable Sample

The device is getting a

reliable reading but the

sample is testing outside

of the expected range and

is inconsistent with the

selected alloy.

Reliable Reading,

The device is getting a

reliable reading but the

result is in the caution range.

sample. If it passes this is a

good sample.

Unreliable Reading

The arrow turns red when

the device is getting an

the testing conditions are

correct before trusting the

results.

16

Dimension Verification

To verify the dimensions of a sample, the correct metal must be

selected and the correct weight must be entered. To verify the

dimensions of a sample, press the button while the

device is reading the sample with the onboard sensor.

device will automatically select the mode that applies to the

using the Wand attachments.

17

Numerical Dimension

Verification

To verify the dimensions of a sample, the correct metal must

be selected and the correct weight must be entered and the

sample must be tested using the onboard sensor. To verify the

dimensions of a sample, press the button while

the device’s onboard sensor is reading the sample. Once the

screen appears, you may move the sample away

from the sensor. The following will be displayed:

You may use the scale printed on the face of the device to

sample’s dimensions are within the dimensions calculated by

Measure the width of your sample.

Press the ENTER button and use the buttons to enter

the measured width. Press the WEIGHT

within the range. If it is not, then the sample is the wrong density.

Measure the diameter of your sample to

wrong density.

18

Visual Dimension Verification

Select the shape of the sample using the UP and DOWN buttons.

away from the sensor.

• align the right edge of the sample to

screen. The left edge of the sample is expected to fall within

the green range indicated on the screen. If the edge falls

within the range, then the sample’s density is consistent

with the selected metal. If the left edge falls outside of the

green range, then the sample’s density is inconsistent with

the selected metal.

• align the right edge of the

black line on the top edge of the screen. Use the UP and

DOWN buttons to adjust the indicated width on the screen

to match the width of the sample. While adjusting the width,

if the device determines that the sample is too long for the

mode. With the top edge, the right edge, and width aligned

properly, the sample’s left edge should fall somewhere

within the green range. If the edge falls within the range,

then the sample’s density is consistent with the selected

metal. If the left edge falls outside of the green range, then

the sample’s density is inconsistent with the selected metal.

If a sample fails the density test, double check to make sure

the correct weight is entered and the correct alloy is selected.

Then, test again before assessing the sample.

19

Round Sample

Visual Dimension Verification

Diagram

[ █]

Rectangular Sample

20

Wand Use

a Wand attachment, plug the Wand into the Wand Connector on

the device will self calibrate. Ensure the head of the Wand is

at least one inch away from any metal during this calibration

process. When the READY screen is displayed, you may touch

the face of the Wand to a sample.

When measuring with the Wand, only the

reading will display. There will also be a yellow Wand

indicator on the screen indicating the device is using the Wand’s

sensor. Wands are not able to perform density testing.

Wand Icon

Bullion

Wand Reading Screen

When the Wand is touched to metal, the screen

will change to show the results of the reading.

There is only one bar and a yellow icon appears

to indicate that the wand is in use.

Table of contents

Other Sigma Metalytics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics IMI SENSORS EX607A11 Installation and operating manual

Omron

Omron H7E manual

Fluidwell

Fluidwell F013-P user manual

Amprobe

Amprobe PRM-4 user manual

Powerbeat

Powerbeat POWERBEAT 1.0 user manual

Precision Digital Corporation

Precision Digital Corporation PD663 instruction manual