Beck 930...EX Series User manual

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 1 of 18

Ident:

060925-BA-930-R9-2016_englisch_Druckversion.doc

Operating Instructions

The adjustable

Differential Pressure Switches

Model 930...EX

General Instructions

Safety Instructions

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Telephone

Telefax

E-Mail

Internet

VAT-no.

+49 7157 52 87-0

+49 7157 52 87-83

http://www.beck-sensors.com

DE162391354

Bank Accounts

Kreissparkasse Esslingen-Nürtingen (BLZ 611 500 20) 57 011 970

S.W.I.F.T. ESSLDE66 IBAN: DE33 6115 0020 0057 0119 70

Commerzbank Stuttgart (BLZ 600 400 71) 876 179 300

S.W.I.F.T. COBADEFF600 IBAN: DE70 6004 0071 0876 1793 00

Landesbank Baden-Württemberg (BLZ 600 501 01) 2 214 306

S.W.I.F.T. SOLADEST IBAN: DE36 6005 0101 0002 2143 06

UniCredit Bank - HypoVereinsbank Stuttgart (BLZ 600 202 90) 388 773 332

S.W.I.F.T. HYVEDEMM473 IBAN: DE66 6002 0290 0388 7733 32

Location: Steinenbronn

Amtsgericht Böblingen HRB 6050

Managing Directors: Rainer Beck,

Hans-Peter Funk, Dr. Ernst Thielicke

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 2 of 18

1

General instructions...............................................................................................................3

1.1

Safety instructions..............................................................................................................3

1.1.1

General safety instructions ...........................................................................................................3

1.1.2

Safety instructions for potentially explosive areas ........................................................................4

1.1.3

Notes on environmental protection...............................................................................................4

2

Correct purpose of use ..........................................................................................................5

2.1

Application area..................................................................................................................5

2.2

CE conformity.....................................................................................................................5

3

Storage and transportation....................................................................................................6

3.1

Packaging ..........................................................................................................................6

3.2

Storage and transportation conditions................................................................................6

4

Installation...............................................................................................................................6

4.1

Installation..........................................................................................................................7

4.2

Connection.........................................................................................................................7

4.2.1 Pressure connections ...................................................................................................................7

4.2.2

Electrical connections...................................................................................................................7

5

Start-up....................................................................................................................................9

5.1

Parameterisation................................................................................................................9

6

Maintenance / service...........................................................................................................10

6.1

Time intervals...................................................................................................................10

6.2

Troubleshooting................................................................................................................10

7

Repairs ..................................................................................................................................11

8

Dismantling...........................................................................................................................11

8.1

Disposal ...........................................................................................................................12

9

Appendix ...............................................................................................................................13

9.1

Technical data and dimensioned drawing.........................................................................13

9.2

Dimensioned drawings and accessories...........................................................................15

9.3

Declaration of Conformity.................................................................................................16

9.4

EC design test certification...............................................................................................17

9.5

Proof of compliance with explosion protection regulations................................................18

General Instructions

Safety Instructions

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 3 of 18

1 General Instructions

These operating instructions contain all of the information that is required for an efficient start-up

and safe operation of Model 930...EX pressure switches.

Please read these operating instructions before carrying out installations, start-ups,

maintenance and repairs.

Please ensure that these operating instructions are available at all times.

Please follow the applicable instructions and safety regulations.

All of the work that is described in these operating instructions must be carried out by quali-

fied and authorised experts.

In order to avoid problems, the prescribed maintenance must be carried out at regular in-

tervals by appropriately trained personnel.

Symbols used

The meanings of the symbols that are used are as follows:

Useful, important additional information.

Dangers and safety instructions. Important – please read!

Failure to comply with these instructions can have a detrimental

effect on persons and the operation of the equipment.

Important instructions for use in potentially explosive areas.

Danger – please read!

1.1 Safety Instructions

1.1.1 General safety instructions

Please follow the applicable

Instructions and system-specific regulations (e.g. installation

standards etc.)

Safety regulations and accident prevention regulations

All work must be carried out by authorised and qualified personnel. These qualifications

and authorisations include:

Training, experience and knowledge of the regulations, standards

Only personnel with appropriate product knowledge must carry out start-ups and

maintenance

All repairs must be carried out by personnel who have been authorised to do so by

the manufacturer

Only original parts must be used

Ignoring these operating instructions and making modifications to the equipment are not

permitted and can lead to hazardous situations

General Instructions

Safety Instructions

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 4 of 18

1.1.2 Safety instructions for potentially explosive areas

The 930..EX pressure switch is suitable for use in areas where there

is a risk of gas or dust explosion

Please follow the applicable

Instructions and system-specific regulations

The labelling of the product must point out that important explosion protection characteris-

tics must be adhered to during use.

G = Gas; D = Dust

Device category 1, 2, 3 or Equipment Protection Level EPL in the 3 zonal areas

Gas parameters: temperature class (T1…T6), explosion group (A, B, C)

Dust parameters: Explosion group (IIIA, B: non-conductive; IIIC: conductive);

Surface temperature, glow and ignition temperature

When work is being performed such as installation, making electrical connections, making

repairs or opening the housing, it must be ensured that

no potentially explosive atmosphere is present

no electrical voltage is present

unintentional activation is ruled out

Dust deposits must be avoided (installation location, protection, cleaning etc.) in order to

prevent dangerous surface temperature increases

For the installation procedure it is necessary to take care that no electrostatic charging will

be done (no high volume flow, cleaning only with damp cloth,…)

It must be ensured that all technical and organisational protective measures are complied

with and that the operation and effectiveness thereof is checked

No modifications must be made to the equipment, since they may lead to a risk of explo-

sion (ignition)

The specifications of the EC design certificate are binding and must be complied with

If the number of the EC design certificate is followed by an “X”, special conditions or devia-

tions from the standard conditions exist

Installation, start-ups and repeated testing may only be carried out by appropriately quali-

fied personnel

The operator must issue a release for work before any activity (installation etc.) is carried

out in potentially explosive areas.

1.1.3 Notes on environmental protection

Please help to protect the environment. Please pay attention to the environmental notes in these

operating instructions:

Chapter 3.1 “Storage“: Handling of packaging materials

Chapter 8.1 “Disposal“: with regard to the product and its components

Correct Purpose of Use

Application area

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 5 of 18

2 Correct Purpose of Use

2.1 Application area

Purpose of use

The adjustable differential pressure switches have the following main purpose

Monitoring air flow in ventilation shafts for adequate

Dilution of gasses that are hazardous to health or potentially explosive

Air supply (fresh air) and/or exhaust air – extraction of “bad” air

Operational monitoring by monitoring the air flow of

(Air) filters

Air and fire safety flaps

Fans, ventilators

Leak tightness of closed systems

Liquid level monitoring

The media that are being monitored occur in the following different phases

Gaseous (main application)

Potentially explosive gasses and dust (natural gas, bio-gas, solvents etc.)

Liquid

Flammable liquids (petrol, solvent etc.)

Use in zones in potentially explosive areas

Pressure switches are used to monitor the pressure difference in

areas of closed systems where there is a risk of gas explosion.

The device may be used in areas where there is a risk of gas or dust explosion

Two separate zonal areas can be connected via pressure connections P1 and P2 (are-

as 1 and 2)

Zone 1,2 or zone 21,22 may apply to the pressure connections (areas 1 and 2)

The surroundings (area 3) can be zone 1,2 or zone 21,22

2.2 CE Conformity

The product complies with the following European directives:

Explosion protection directive

RoHS directive

Other information and verification can be found in the

Conformity declaration (see Chapter 9.3)

Area-1

Area-2

Surrounding

Area-3

Equipment

category

Equipment

Protection

Level EPL

Zone 1,2 Zone 1,2 Zone 1,2 2G

Gb

Zone 21,22 Zone 21,22 Zone 21,22 2D

Db

Area-3

P1: Area-1

Area-2: P2

Storage and Transportation

Packaging

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 6 of 18

3 Storage and Transportation

3.1 Packaging

The equipment is protected by packaging. The packaging is environmentally compatible and recy-

clable. The following main materials are used:

Cardboard

PE foam or PE film

Please use appropriate recycling companies to dispose of the packaging

3.2 Storage and Transportation Conditions

The following points must be observed in order to prevent damage:

Avoid severe mechanical stress caused by throwing, stacking and dropping.

Keep out of wet and rainy environments

Do not subject to direct sunlight for long periods

The storage temperature must not be lower than -40 °C or higher than +85 °C

4 Installation

The following checks must be performed prior to installing the equipment:

The equipment must not show signs of damage or obvious modifications

The IP protection class of the equipment must correspond with the usage

and environmental conditions

An operator zone definition must be available

Check whether the equipment category corresponds with the specified zones

With intrinsically safe systems (“i") the “associated operating materials" (barrier) must al-

ways be installed outside the potentially explosive area.

The labelling of the product must point out that important explosion protection characteris-

tics must be complied with during use.

G = Gas, D= Dust

Equipment Protection Level

EPL / zone area

Parameters:

Temperature class

(T1...T6)

Explosion group (A, B, C)

Additional information for use in areas

where

there is a risk of dust explosion:

The details of the maximum surface

temperature are valid only for a dust allowance of a maximum of 5 mm.

At higher dust de-

posits must be reduced with the surface temperature.

Determining the maximum permissible surface temperature

Dust cloud with ignition temperature -T

CL

: T

max1

= 2/3 T

CL

Dust layers with glow temperature -T

5mm

:T

max2

= T

5mm

– 75

o

C

The smaller value of both must be considered for the maximum permitted surface tempera-

ture. To prevent from dangerous temperature rises dust deposits should be avoided (ap-

propriate mounting position, use of protection covers, regular cleaning..)

For the installation procedure it is necessary to take care that no electrostatic charging will

be done (no high volume flow, cleaning only with damp cloth,…)

Equipment Pro-

tection Level

EPL

Zone

Equipment

category 0

20

1

21

2

22

1 G,D Ga,Da yes yes yes

2 G, D Gb,Db no yes yes

3 G,D Gc ;Dc no no yes

Installation

Installation

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 7 of 18

The following standards and directives are useful:

EN 1127-1: Explosion protection – basic concepts and methodology

Standards for areas with risk of gas or dust explosion (“G”, “D”):

EN 60079-10: Classification of potentially explosive areas

EN 60079-14: Electrical installations in potentially explosive areas

EN 60079-17: Inspection and maintenance

EN 60079-25: Intrinsically safe systems

4.1 Installation

Choose the installation location from the following aspects;

Ease of access for installation, connection and operation

Protection from direct effects of the weather, such as rain and sun

The IP protection class of the equipment must suit the ambient conditions

In order to prevent dangerous temperature increases on the surface of the equipment, dust

deposits must be avoided (installation location, protective cover, cleaning measures etc.)

Switching pressure specifications apply to vertical installation which is also the recommended

position with pressure-pipe connections pointing downwards. If the switches are installed

horizontally with AMP connection terminals uppermost, the switching values are approx.

20 Pa higher.

4.2 Connection

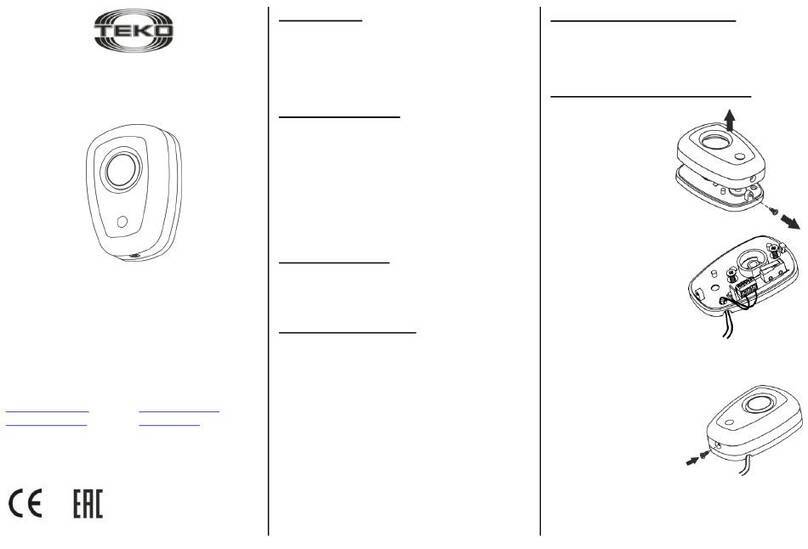

4.2.1 Pressure connections

2 plastic pipe connection pieces (6 mm)

P1 +: for connection to higher pressure

P2 -: for connection to lower pressure

4.2.2 Electrical connections

When work is being performed such as installation, making electrical

connection, making repairs or opening the housing, it must be ensured that

No electrical voltage is present

Unintentional activation is not possible

Proceed as follows in potentially explosive areas:

Check whether the equipment category corresponds with the

specified zones

No potentially explosive atmosphere is present

A release for work must have been issued by the operator

Adherence to the applicable regulations and documentation for the equipment

Special notes for intrinsically safe (“i”) systems:

Each intrinsically safe operating material must have an associated operating mate-

rial inserted before it, outside of the potentially explosive zone.

Separate cable routing for intrinsically safe and non-intrinsically safe power circuits.

For operating voltages of less than 42V AC or 60V AC: Intrinsically safe and non-

intrinsically safe power circuits can be routed together in this case. This only applies

to safety barrier with galvanic separation.

Separation of intrinsically safe/non-intrinsically safe connecting parts: at least 50mm

(tight string length)

Distance between different intrinsically safe power circuits: at least 6mm

Distances between non-insulated conductive parts leading to connecting parts:

air gap of at least 3mm (housing-terminals-conductor tracks, earth etc.)

Installation

Connection

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 8 of 18

Power supply

Each intrinsically safe operating material must have an associated

operating material inserted before it, outside of the potentially

explosive zone:

Pay attention to maximum characteristics (U, I, P, L, C):

Compare the information on the specification plate of the appropriate

equipment and the pressure switch 930..EX

Select connecting cables

The following points must be observed when selecting the cable:

Select cable material that complies with the local resistance

requirements (mechanical, chemical)

The outer diameter may be from 5 to 9 mm

Cable cross-section in accordance with electrical power and data sheet

The following points must be observed when selecting cables for intrinsically safe power

circuits:

Diameter of individual conductors: greater than 0.1mm

Insulation strength of the individual wires: greater than 0.2 mm

Test voltage for intrinsically safe cables:

- between wires, shield and earth: 500V AC

Shield: The shield area must be 60% of the surface coverage or twisting

Labelling of intrinsically safe power circuits: colour preferably light blue

L and C cable characteristics must be available

(C

i

=110nF/km; L

i

=1 mH/km)

Cable routing

If there is a risk of mechanical damage, the cable must be provided with additional

protection (protective tube etc.)

The cable diameter must be complied with in order to provide a tight connection in

the cable lead-in.

The screwed cable connection and the screws of the housing cover must be tight-

ened in order to comply with the IP protection class. Over-tightening damages the

housing.

Connecting the cable

Please ensure that the cables that are being connected are not live.

otherwise there is a risk of igniting a potentially explosive atmosphere

Attach the shield

Attach shield at one end (in non-potentially explosive area)

Attach braiding of shield to earth potential over a wide area.

No potential equalisation current must be flowing between potentially

explosive areas and non-potentially explosive areas.

Separation using a capacitor is permitted in this case

for EMC purposes (total max. 10 nF).

Earthing

The external earthing terminal on the housing must be connected

to the potential equalisation of the potentially explosive area with

low resistance

(removal of electrostatic charge between 0.2-1 MOhms is considered to be earthing)

No potential equalisation current must be flowing between potentially explosive are-

as and non-potentially explosive areas

Minimum cross-section: 2 x 1.5 mm² or 1 x 4 mm²

Intrinsically safe power circuits: Housings made from metal do not need to be

earthed.

(If this is necessary anyway – functional earthing, earthing in one location only…)

Start-up

Parameterisation

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 9 of 18

Documentation

Operating instructions, conformity declaration, EC design test certificate

System and zonal plan

Proof of adherence to explosion protection regulations (see Appendix 9.34)

Equipment selection: category, Equipment Protection Level EPL, temperature

class, explosion group, …

Proof of adherence to intrinsic safety requirements

5 Start-up

Before voltage is applied to the equipment the following checks must be performed:

Check that screws are firmly seated in

Connecting terminals, protective earth conductor terminals and

potential equalisation terminals

Housing cover

Check

The torque of the cable lead-in

The tightness of the seal provided by the cable lead-in

Check whether the equipment is ready for operation

The parameterisation for this application must have been performed

All interfaces such as inputs and outputs for control purposes must be connected

and ready for operation

5.1 Parameterisation

Equipment parameterisation

Define all application-specific parameters.

Adjustment of the pressure ranges

With this pressure switch the pressure can be adjusted without a pressure gauge using a

scaled adjustment knob

The switching differential can also be adjusted with a screwdriver bythe adjustment screw

with the identification “-∆p+”

Type Adjustment range

for trip pressure

from

to

Switching

differential

Tolerance

band of

930.80 EX

20 300 Pa 10 Pa ±15 %

930.83 EX

50 500 Pa 20 Pa ±15 %

930.84 EX

30 400 Pa 15 Pa ±15 %

930.85 EX

200 1000 Pa 100 Pa ±15 %

930.86 EX

500 2500 Pa 150 Pa ±15 %

930.87 EX

1000 5000 Pa 250 Pa ±15 %

Note:

Switching pressure specifications applyto vertical installation which is also the recommended position

with pressure-pipe connections pointing downwards. If the switches are installed horizontally with AMP

connection terminals uppermost, the switching values are approx. 20 Pa higher.

Once the power supply is applied, the equipment is ready for operation immediately.

Maintenance / Service

Time intervals

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 10 of 18

6 Maintenance / Service

The equipment can only be guaranteed to operate safely and reliably in the long term if regular

inspections and servicing are carried out. These include the following:

For cleaning the devices it is necessary to take care that no electrostatic charging will be done (no

high volume flow, cleaning only with damp cloth,…)

An inspection includes

Visual inspection

oMechanical damage

oNon-permitted dust deposits

oOther irregularities or error messages from the equipment

Checking of components (wearing parts) whose functionality or purpose changes and af-

fects the operation of the equipment

Documentation of what was done by whom, and when

Maintenance includes

Functionality checking

oOperating statuses such as alarms etc.

Checking calibration values (= calibration)

oTriggering of alarms by known process parameters (test pressure etc.)

Correction of calibration values (= calibration) must be carried out in the factory

Documentation of what was done by whom, and when

6.1 Time intervals

Inspection:

The condition of the equipment must be checked at regular intervals. The time interval is extreme-

ly dependent on the local situation and the degree of use, and must therefore be adapted to re-

quirements. Extremely short time intervals can be specified such as once per day, every new shift

etc.

Defined by the operator in accordance with local requirements

Maintenance

The interval from the applicable usage regulations must be taken into consideration

As a manufacturer we recommend a maximum interval of 1 year

6.2 Troubleshooting

A list of possible faults (fault indications) can be found in the table below.

The table contains an explanation of how to detect faults.

A list of possible causes and remedial measures also follows.

Fault indication

Possible cause

Measures

Contact won’t switch

Defective diaphragm

Replace pressure switch

Spring defective

Pressure connection blocked

Pressure outside working range

Repairs

Troubleshooting

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 11 of 18

7 Repairs

The following points must be noted before carrying out any work whatsoever on the equipment:

When work is being performed such as installation, making electrical

connections or opening the housing, it must be ensured that

No electrical voltage is present

Unintentional activation is not possible

Repairs must only be carried out by the manufacturer

The following must be observed in potentially explosive areas:

No potentially explosive atmosphere is present

A release for work must have been issued by the operator

The applicable regulations and all documentation for this

equipment must be adhered to

Only original spare parts from the manufacturer must be used

The spare parts must comply with the required equipment category

Interventions that influence explosion protection must only be carried out by experts

A prerequisite is adequate qualification (“capable person”) with regard to explosion

protection and the use of the equipment

8 Dismantling

The following points must be noted before carrying out any work whatsoever on the equipment:

Ensure that the equipment may be removed and that appropriate

replacement measures have been taken.

All of the instructions in chapter 7 “

Dismantling

Disposal

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 12 of 18

Repairs

” must be followed

Exposed cable (ends) must be marked, and it must be ensured that

No electrical voltage is present

Unintentional activation is not possible

8.1 Disposal

The equipment is made from recyclable materials and is designed to make

the housing and the electronics easy to separate. Please ensure that all

parts are disposed of in accordance with legal regulations.

Please contact us if you cannot dispose of the equipment properly.

Appendix

Technical data and dimensioned drawing

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 13 of 18

9 Appendix

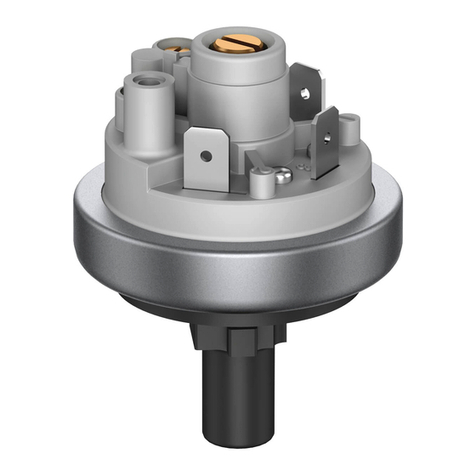

9.1 Technical data and dimensioned drawing

Temperature ranges

Ambient temperature:

from -20 °C to +85 °C

Medium temperature:

up to +85 °C

Storage temperature:

from -40 °C to +85 °C

Diaphragm material

Silicone; others upon request.

Electrical rating

Values indicated for resistive load

for Gas 2G : 60 mA/30 VDC oder 100 mA/24 VDC

for Dust 2D: 30V; 60mA ; 0.6W

Electrical connection

Cable conduit M20x1.5 or cap nut conduit with cable strain relief

AMP flat plug 6.3 mm x 0.8 mm in accordance with DIN 46244 or push-on screw terminals

Arrangement of contacts

Protection category

IP 54

(with Cover)

Weight

150 g

Certifications

CE conformity in according with EC explosion protection directive 2014/34/EU.

EC design test certification by the specified EXAM body (ID 0158) with the following ATEX

labelling:

2G Ex ia IIB T4 Gb

2D Ex ia IIIB T135

o

C Db

Characteristics:

2G : 60 mA/30 VDC oder 100 mA/24 VDC

2D : 30V; 60mA ; 0.6W

L

i

= 0 mH; C

i

= 0 nF

Life

Minimum 10

6

cycles.

Housing materials

Switch body made of PA 6.6

Cover made of PS

1 Brake contact

2 Operating contact

3 Power supply line

Appendix

Technical data and dimensioned drawing

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 14 of 18

Types / Pressure ranges

Type Adjustment range

for trip pressure

Switching

differential

Tolerance

band of

930.80 EX

20 300 Pa 10 Pa ±15 %

930.83 EX

50 500 Pa 20 Pa ±15 %

930.84 EX

30 400 Pa 15 Pa ±15 %

930.85 EX

200 1000 Pa 100 Pa ±15 %

930.86 EX

500 2500 Pa 150 Pa ±15 %

930.87 EX

1000 5000 Pa 250 Pa ±15 %

Note:

Switching pressure specifications apply to vertical installation which is also the recommended posi-

tion with pressure-pipe connections pointing downwards. If the switches are installed horizontally with

AMP connection terminals uppermost, the switching values are approx. 20 Pa higher.

Pressure connections:

2 plastic pipe connection pieces

external diameter: 6.0 mm

Maximum operating pressure:

10 kPa for all pressure ranges

Mounting position

Switching pressure specifications apply to vertical installation which is also the recom-

mended position with pressure-pipe connections pointing downwards. If the switches are in-

stalled horizontally with AMP connection terminals uppermost, the switching values are ap-

prox. 20 Pa higher.

Accessories

Various mounting brackets

(see Chapter 9.2)

Metal mounting bracket S-shaped

Metal mounting bracket L-shaped

Snap-on plastic bracket S-shaped

Snap-on plastic bracket L-shaped

Various connection kits

(see Chapter 9.2

)

Plastic tube for Climaset

©

Angled metall pipe for Climaset

©

Rubber grommet for Climaset

©

Roll with 100 m PVC hose

Various cable conduits

(see Chapter 9.2)

Cap nut conduit including sealing and counter screw

M20x1.5 cable conduit including sealing and counter screw

NPT1/2” cable conduit without counter parts

Appendix

Dimensioned drawings and accessories

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 15 of 18

9.2 Dimensioned drawings and accessories

Appendix

Declaration of Conformity

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 16 of 18

9.3 Declaration of Conformity

Appendix

EC design test certification

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 17 of 18

9.4 EC design test certification

Note: More documentation for EC design test certification you can download from our website.

Appendix

Proof of compliance with explosion protection regulations

Beck GmbH

Druckkontrolltechnik

Ferdinand-Steinbeis-Straße 4

71144 Steinenbronn

Operating instructions – Pressure Switch - Model-930...EX Rev.9 Page 18 of 18

9.5 Proof of compliance with explosion protection regulations

Project

Name

Date

Requirement Complies with Requirement Complies with

Application area

II

(Gas) III

(Dust) II

(Gas) Temperature

class (Gas) Temperature

class (Gas) Temp.

(Dust)

T1

T1 400

o

C

T2

T1-T2 300

o

C

Explosion

group A A T3

T1-T3 200

o

C

B A,B,C A,B T4

T1-T4 135

o

C

C A,B,C A,B,C T5

T1-T5 100

o

C

T6

T1-T6 85

o

C

Requirement Permitted Equip.

Protection Level

EPL (G=Gases)

Certified for

Ignition protection class

Zone 2,22

Gc,Dc Zone 2/22

1,21

Gb,Db Zone 1,2 /21,22 Ex ia IIB / Ex ia IIIB

0,20

Ga,Da Zone 0,1,2/ 20,21,22

CHARACTERICTICS

Intrinsically safe operating materials

Associated operating materials

Designation

Pressure switch Cable

Switch amplifier

Model 930 ..EX

Application area 2G 2D

Ignition protection class

Ex ia … Gb

Ex ia…Db

Explosion group IIB IIIB

Temperature class T4 T135C

Certification BVS 06 ATEX E141X

U

i,a

30V

I

i,a

60mA

P

i,a

600mW

L

i,a

0 1mH

C

i,a

0

Kabelkennwerte: 1

mH

/

km

; 110

nF

/

km

Requirement complied with

Application area

Ignition protection class

Explosion group

Temperature class

Equipment Protection Level EPL/Zone

Proof of intrinsic safety

Associated operating mate-

rials

(barriers)

Require-

ment Intrinsically safe operating

materials

(including cable)

Com-

pliant

U ≤

30V

I

≤

60mA

P ≤

600mA

L ≥

1mH

(1km cable)

C ≥

0,1µF

(1km cable)

This manual suits for next models

6

Table of contents

Other Beck Switch manuals

Popular Switch manuals by other brands

axing

axing premium-line SPU 996-09 Operation instructions

ICP DAS USA

ICP DAS USA ACS-20B-MRTU user manual

KUSSMAUL

KUSSMAUL 091-134 instruction manual

HP

HP StorageWorks 2/16 user guide

NETGEAR

NETGEAR FSM7226RS - ProSafe Switch - Stackable datasheet

Brocade Communications Systems

Brocade Communications Systems Converged Enhanced Ethernet 8000 Hardware reference manual