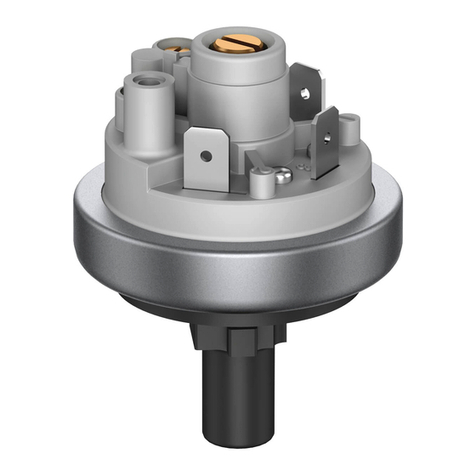

PURPOSE

The purpose of these instructions is to provide

a step-by-step method for replacing the Beck

Group 22 CPS-4 switch assembly. The switch

assembly is a subassembly of the control end and the

switches are preset; no adjustment of the switch arms is

necessary. The assembly is not user-serviceable and

should not be disassembled in the eld. Components

of the switch assembly are listed in Table 1.

The switch assembly is located in the control end on

the rear face of the actuator beneath the Handswitch.

REQUIRED TOOLS

The following tools will be needed:

1/2” socket wrench

Cross-tipped screwdriver

Multimeter

Torque wrenches appropriate for 12 lb-in (1.4 N•m)

and 10 lb-ft (14 N•m)

Scotch™ 847 gasket adhesive or equivalent

Grounding strap

3/16” at-tipped screwdriver

WARNINGWARNING

Electrical shock hazard—disconnect

power before proceeding. Remove the

actuator from line voltage and shut o

any external power sources feeding the

auxiliary switches.

PROCEDURE

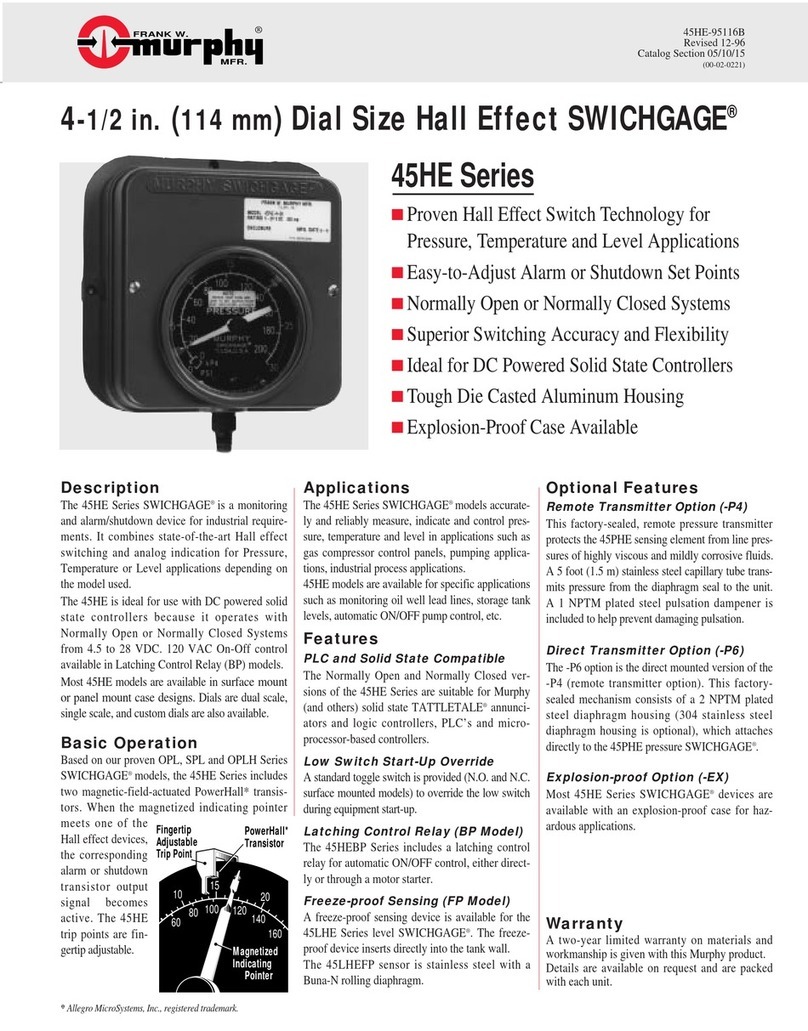

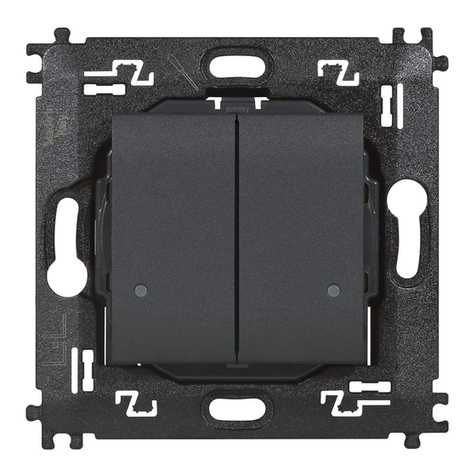

Refer to Figure 1 for component identication.

Remove the old switch assembly:

1. Remove power from the actuator.

2. Remove the control end cover.

CAUTION

To prevent Electro-Static Discharge

damage to the electronics, wear a

grounding strap during this procedure.

3. Disconnect the switch assembly by unplugging the

two connectors leading to the actuator body. To

unplug the connectors, use the 3/16” at-tipped

screwdriver to press the release tab straight back

and slide the plug out of the socket (see Fig. 1).

4. Using the cross-tipped screwdriver, remove the

(2) cross-recessed screws fastening the switch

assembly to the stator (see Fig. 1).

5. Slide the assembly away from the actuator body

until it clears the coupling. Ensure the switch

arms do not catch on the cams or coupling while

removing the assembly.

Install the new switch assembly:

6. Slide the new assembly onto the shaft, ensuring

the switch arms do not catch on the coupling

or cams. Ensure that the small alignment pin

directly adjacent to the large opening in the switch

assembly mounting plate slides into the alignment

hole provided.

7. Check the mounting of the switch assembly to

ensure that it is ush and square to the rectangular

ange on the CPS. Install the (2) provided screws

(and washer, if applicable) and tighten to 12 lb-in

(1.4 N•m) torque.

8. Inspect the control end gasket; replace as

necessary. If the gasket is in good condition, skip

steps 9–10.

9. Clean the mating face of the actuator body to

remove any remaining gasket material and

adhesive. Ensure that the mating surface is free

of defects such as dents or gouges.

10. Peel the backing o the replacement gasket and

carefully apply to the actuator body.

Test for proper operation—check switch operation:

11. Plug the connectors into their respective sockets.

12. Connect power to the actuator.

13. Run the actuator through its full range of motion.

Observe the actuator to verify the correct response.

Note whether or not the actuator stopped at the

correct position.

80-4281-06

Rev. 3.4

REPLACEMENT INSTRUCTIONS

CPS-4 SWITCH ASSEMBLY

REPLACEMENT KIT P/N 12-8061-06 & 12-8061-36

MODEL GROUP 22

ELECTRIC ACTUATORS FOR INDUSTRIAL PROCESS CONTROL