5

All P5/16PRF+ to P9/16PRF+ tubular drives are intended solely for the operation of roller shutters. The tubular drive is tted with

springs which support both the shutter suspension and mechanical anti-lifting devices (e.g. Zuruh-Feller, Simu, GAH Alberts or

Deprat). These are detected automatically.

Other applications, utilisation and modications are not permitted in order to protect the safety of the users and others, since

these actions can impair the system’s safety, resulting in personal injuries and property damage. Becker-Antriebe shall not

accept liability for damages arising from such actions. Always observe the information in these instructions when operating or

repairing the system. Becker-Antriebe shall not accept liability for damages resulting from incorrect usage.

Attention

Anti-lifting devices may only be used if sufciently rigid roller shutter laths are used. When closed, the shut-

ters must not extend over the guide rails, as this may put too great a load on the joint between the top two

slats, which could consequently be damaged.

Before reaching the lower end limit, the roller shutters must have made at least 1.5 revolutions. This is normally the case when

the window height is ve times the effective tube diameter.

Example:

60-series octagonal tube with anti-lifting device from Zuruh-Feller:

Effective tube diameter: 9 cm -> min. window height > 45 cm

Mounting the roller shutter drive

Attention

Drives from Becker Antriebe are to be mounted and operated

solely with mechanical accessory components shown in the

current Becker product catalogue.

Prior to mounting, the tter must ensure that the masonry and the shutter box

are sufciently robust (drive torque plus weight of the shutters).

Caution

These drives may not be operated with conventional switching

elements (switches, timers or similar).

If the roller shutters are to be operated in the opposite direc-

tion to the upper stopper, the shutters must be stopped from

being wound up into the shutter box by stoppers or by a right-

angled end slat. We recommend tting covered stoppers into

the guide rails prior to mounting.

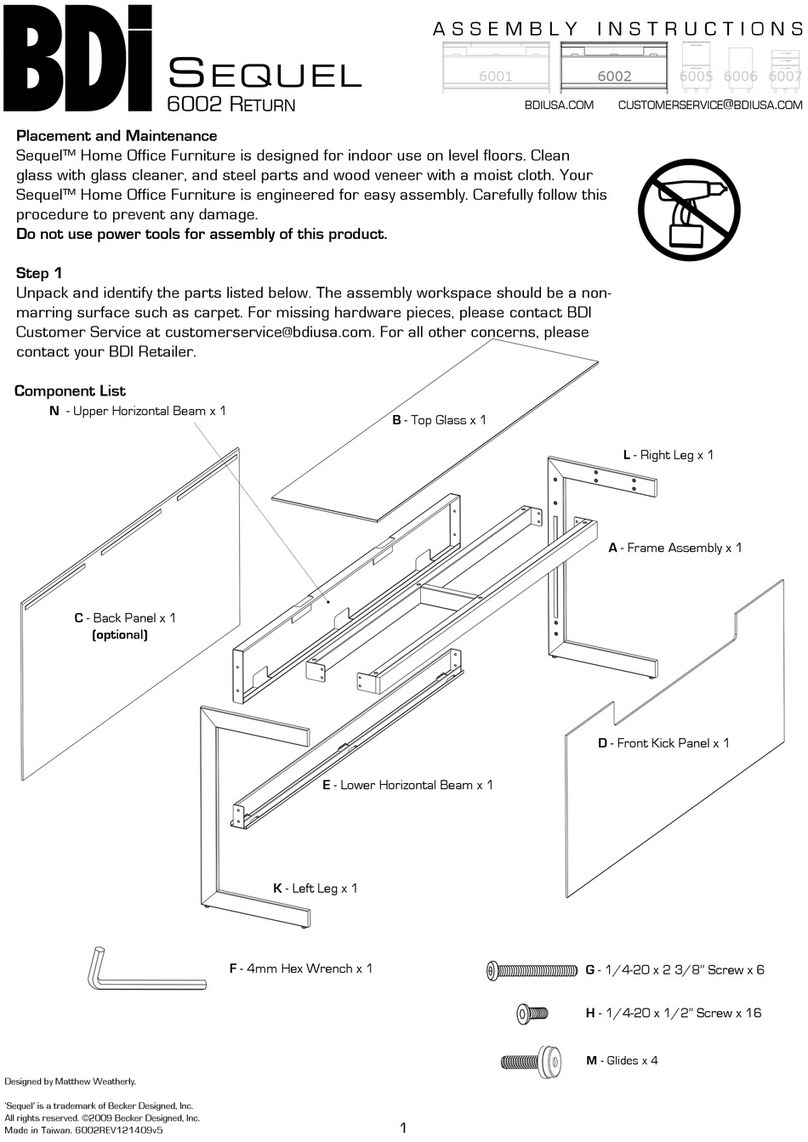

1. The lateral spatial requirements (M) for the box end, the counter bearing

and the motor bearing must be determined in order to calculate the required

length of the roller tube. The length (L) of the roller tube is equal to the clear

dimensions of the roller shutter box (X) minus the total length of the wall

bracket, box end (M) and counter bearing (G): L=X-(G+M).

Measure the distance from the wall bracket and connecting head as this

may vary depending on the drive and bearings used.

2. Secure the wall bracket and the counter bearing.

Attention

If anti-lifting devices are being used, closed bearings must be

used. When the shutters are closed, the tubular drive pushes

the shutters downwards to prevent them from being raised or

forced open. To prevent the shutters from being damaged the

entire shutter must run in guide rails.

Intended Use

Mounting and installation instructions