6

Assembly and Operating Instructions

3

5

Mounting the roller shutter drive

Attention

Drives from Becker Antriebe are to be mounted and operated

solely with mechanical accessory components shown in the

current Becker product catalogue.

Prior to mounting, the tter must ensure that the masonry and the shutter box

are sufciently robust (drive torque plus weight of the shutters).

Caution

These drives may not be operated with conventional switching

elements (switches, timers or similar).

If the roller shutters are to be operated in the opposite direc-

tion to the upper stopper, the shutters must be stopped from

being wound up into the shutter box by stoppers or by a right-

angled end slat. We recommend tting covered stoppers into

the guide rails prior to mounting.

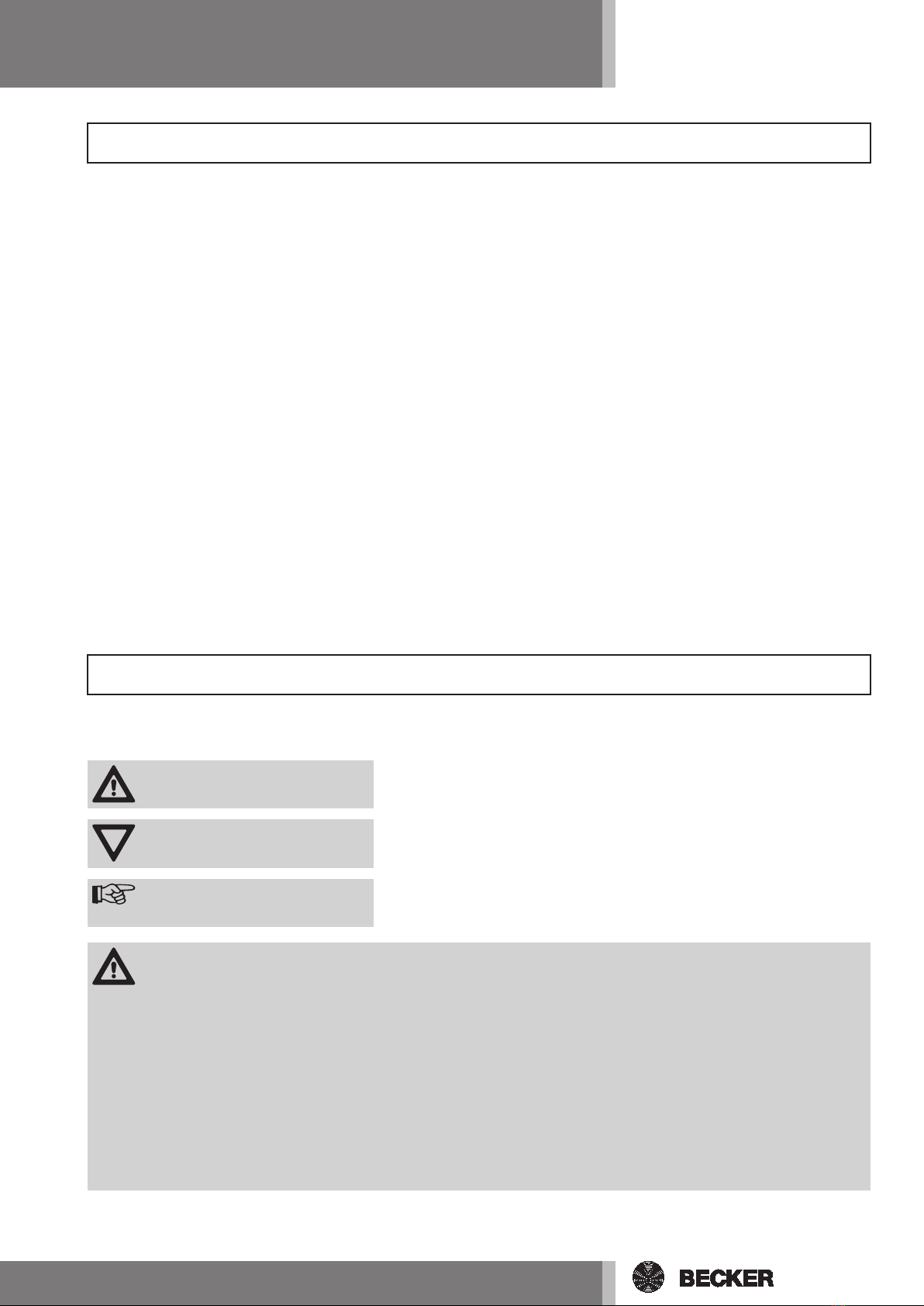

1. The lateral spatial requirements (M) for the box end, the counter bearing

and the motor bearing must be determined in order to calculate the required

length of the roller tube. The length (L) of the roller tube is equal to the clear

dimensions of the roller shutter box (X) minus the total length of the wall

bracket, box end (M) and counter bearing (G): L=X-(G+M) (Fig. 2).

Measure the distance from the wall bracket and connecting head as this

may vary depending on the drive and bearings used.

2. Secure the wall bracket and the counter bearing.

Attention

If anti-lifting devices are being used, closed bearings must be

used. When the shutters are closed, the tubular drive pushes

the shutters downwards to prevent them from being raised or

forced open. Always use suitably robust shutters, for example

made of aluminium, steel or wooden. To prevent the shutters

from being damaged the entire shutter must run in guide rails.

To install the drive, the following instructions must be followed carefully:

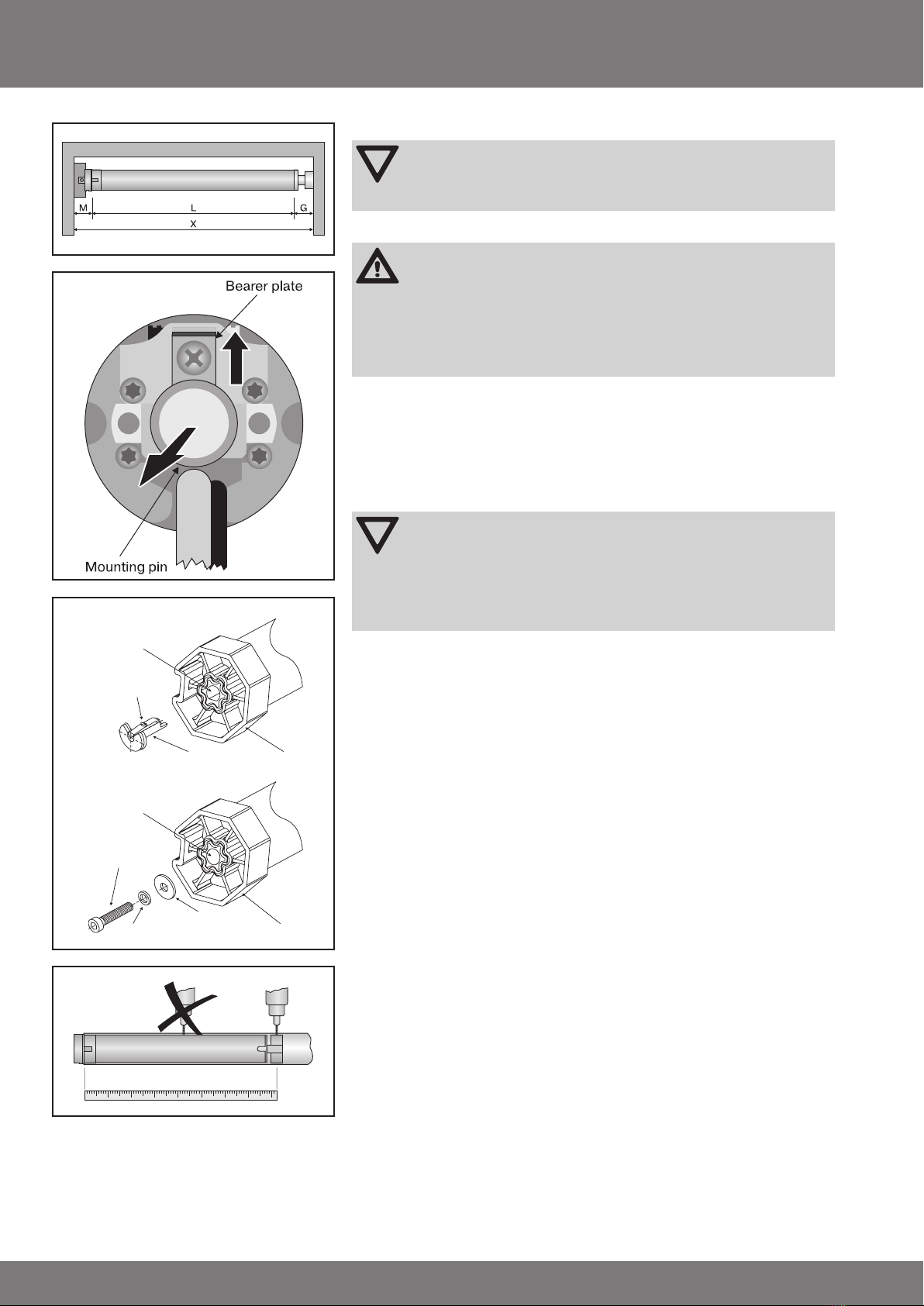

• Removing the mounting pin

The mounting pin engages automatically when inserted. To remove the

mounting pin slide the bearer plate upwards and pull out the mounting pin

(Fig. 3).

• Mounting the drive adapter with safety catch R8/17C PRF+ to

R20/17C PRF+:

The insert direction for the drive adapter is determined by the drive adapter

type (shape). When inserting the drive adapter with safety catch ensure that

the catch engages with the location lug. You will hear a clicking sound when

the drive adapter has engaged properly. Pull lightly on the drive adapter to

ensure that it has been tted securely (Fig. 4).

• Mounting the drive adapter with screw connection R30/17C PRF+ to

R40/17C PRF+:

In this case the drive adapter is fastened with a M6x12 screw, which is

secured by a M6 plain washer and a corresponding toothed lock washer

(Fig. 4).

4

Self-locking hole

Location lug

Drive adapter with safety catch Drive adapter

Drive adapter

Tapped hole

M6x12 screw

Toothed lock washer

Plain washer

R8/17C PRF+ to R20/17C PRF+

R30/17C PRF+ to R40/17C PRF+

2

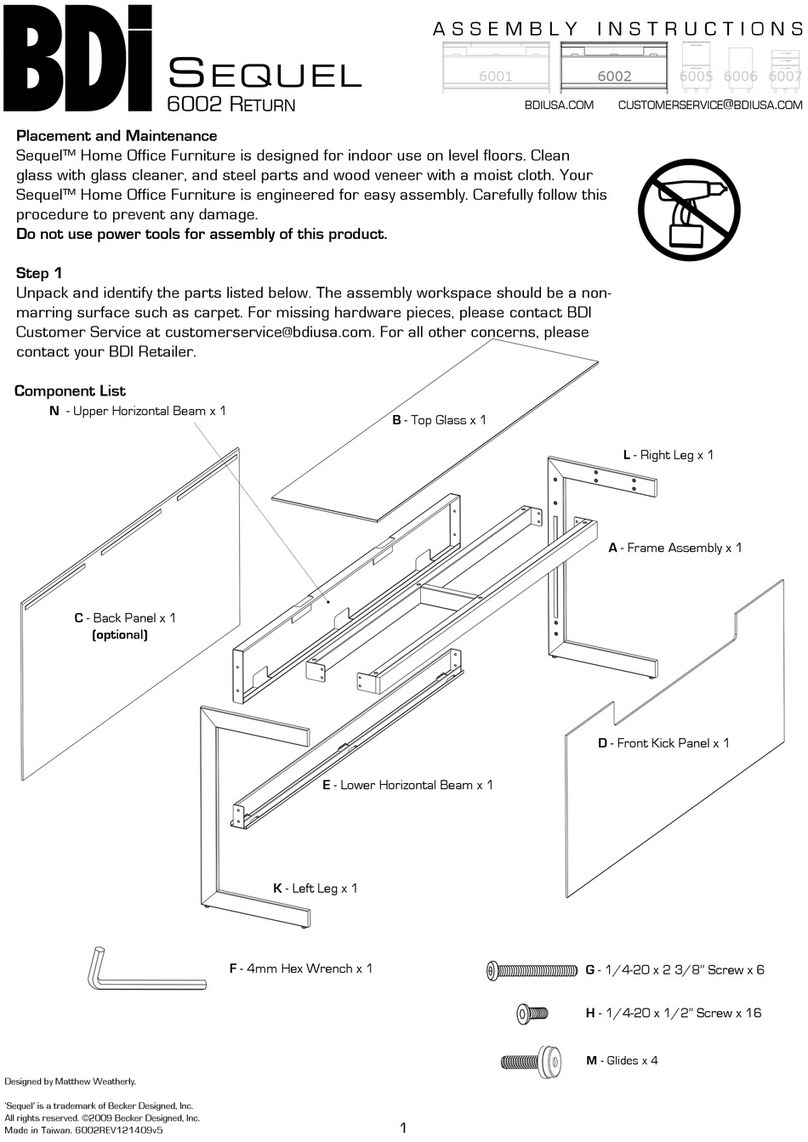

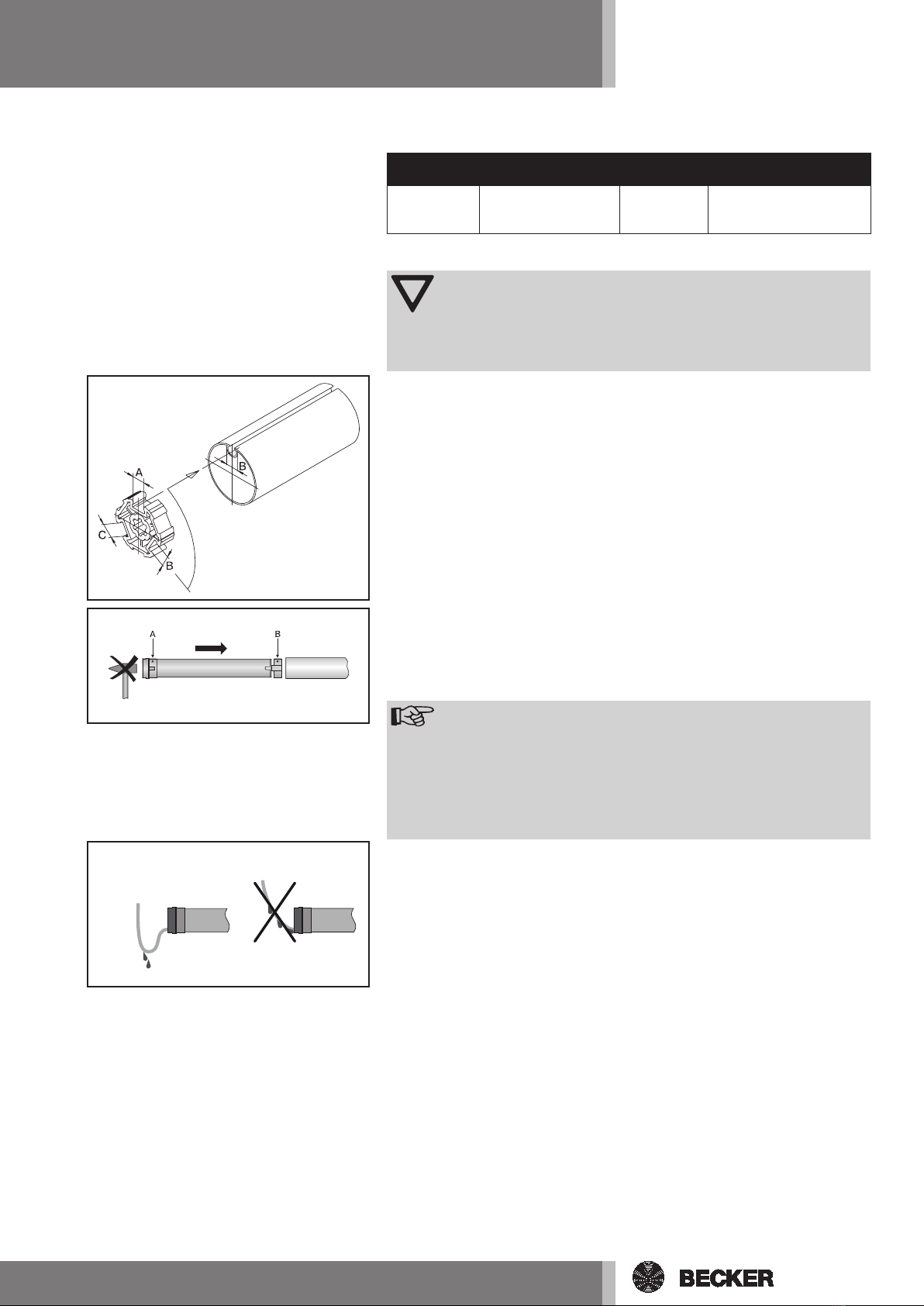

3. Before tting in the barrel, take the measurement from barrel end to the

centre of the drive adapter and mark on the barrel (Fig. 5).