Table of contents

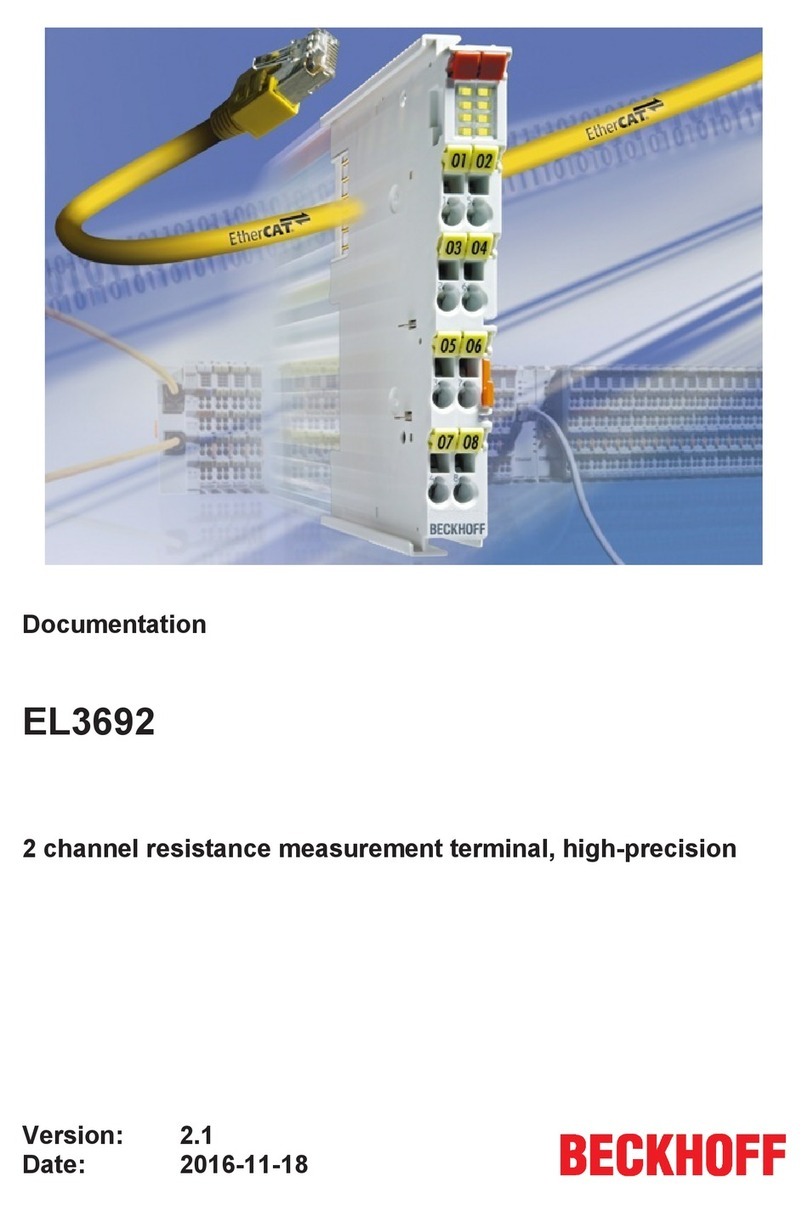

EL36924 Version: 3.1

5.2 TwinCAT Development Environment ..............................................................................................80

5.2.1 Installation of the TwinCAT real-time driver ..................................................................... 81

5.2.2 Notes regarding ESI device description ........................................................................... 87

5.2.3 TwinCAT ESI Updater......................................................................................................91

5.2.4 Distinction between Online and Offline ............................................................................ 91

5.2.5 OFFLINE configuration creation....................................................................................... 92

5.2.6 ONLINE configuration creation ........................................................................................ 97

5.2.7 EtherCAT subscriber configuration ................................................................................ 105

5.3 General Commissioning Instructions for an EtherCAT Slave .......................................................114

5.4 Notices on analog specifications...................................................................................................122

5.4.1 Full scale value (FSV), output end value ....................................................................... 122

5.4.2 Measurement error/measurement deviation/measurement uncertainty, output uncertainty

.......................................................................................................................................123

5.4.3 Temperature coefficient tK [ppm/K]................................................................................ 124

5.4.4 Long-term use ................................................................................................................ 125

5.4.5 Ground reference: single-ended/differential typification.................................................126

5.4.6 Common-mode voltage and reference ground (based on differential inputs) ................ 131

5.4.7 Dielectric strength .......................................................................................................... 132

5.4.8 Temporal aspects of analog/digital or digital/analog conversion.................................... 133

5.4.9 Explanation of the term GND/Ground ............................................................................ 136

5.4.10 Sampling type: Simultaneous vs. multiplexed................................................................138

5.5 Quick start .....................................................................................................................................141

5.6 Operating behavior, diagnostics....................................................................................................144

5.6.1 Control............................................................................................................................ 144

5.6.2 Basic operation .............................................................................................................. 144

5.6.3 Default state ................................................................................................................... 144

5.6.4 Process data .................................................................................................................. 144

5.6.5 4/2-wire mode ................................................................................................................ 144

5.6.6 Measuring mode ............................................................................................................ 145

5.6.7 Autorange function ......................................................................................................... 146

5.6.8 Filter ...............................................................................................................................146

5.6.9 Conversion time ............................................................................................................. 147

5.6.10 Error Codes....................................................................................................................148

5.7 Process data .................................................................................................................................149

5.8 Specific data..................................................................................................................................153

5.8.1 Measuring currents and voltages ................................................................................... 153

5.8.2 Capacitive and inductive influences ............................................................................... 153

5.8.3 Heating of the test specimen.......................................................................................... 153

5.8.4 Calculating the resistance value .................................................................................... 154

5.8.5 Error analysis ................................................................................................................. 155

5.8.6 Resolution ......................................................................................................................156

5.9 Data processing ............................................................................................................................157

5.10 DC operation mode .......................................................................................................................160

5.11 Example program..........................................................................................................................161

5.12 CoE ...............................................................................................................................................165

5.12.1 Most important CoE entries............................................................................................165