BECKWITH ELECTRIC M-6200A User guide

Application Guide

M-6200A B-2355 Series

Cooper Hardware Kit

Installation Instructions

WARNING

DANGEROUS VOLTAGES, capable of causing deat or serious

injury, are present on t e external terminals and inside t e equip-

ment. Use extreme caution and follow all safety rules w en an-

dling, testing or adjusting t e equipment. However, t ese internal

voltage levels are no greater t an t e voltages applied to t e exter-

nal terminals.

DANGER! HIGH VOLTAGE

– This sign warns that the area is connected to a dangerous high voltage, and you

must never touch it.

PERSONNEL SAFETY PRECAUTIONS

The following general rules and other specific warnings throughout the manual must be followed during application,

test or repair of this equipment. Failure to do so will violate standards for safety in the design, manufacture, and intended

use of the product. Qualified personnel should be the only ones who operate and maintain this equipment. Beckwith

Electric Co., Inc. assumes no liability for the customer’s failure to comply with these requirements.

–This sign means that you should refer to the corresponding section of the operation

manual for important information before proceeding.

Always Ground the Equipment

To avoid possible shock hazard, the chassis must be connected to an electrical ground. When servicing

equipment in a test area, the Protective Earth Terminal must be attached to a separate ground securely

by use of a tool, since it is not grounded by external connectors.

Do NOT operate in an explosive environment

Do not operate this equipment in the presence of flammable or explosive gases or fumes.To do so would

risk a possible fire or explosion.

Keep away from live circuits

Operating personnel must not remove the cover or expose the printed circuit board while power is ap-

plied. In no case may components be replaced with power applied. In some instances, dangerous volt-

ages may exist even when power is disconnected.To avoid electrical shock, always disconnect power and

discharge circuits before working on the unit.

Exercise care during installation, operation, & maintenance procedures

The equipment described in this manual contains voltages high enough to cause serious injury or death.

Only qualified personnel should install, operate, test, and maintain this equipment. Be sure that all per-

sonnel safety procedures are carefully followed. Exercise due care when operating or servicing alone.

Do not modify equipment

Do not perform any unauthorized modifications on this instrument. Return of the unit to a Beckwith

Electric repair facility is preferred. If authorized modifications are to be attempted, be sure to follow

replacement procedures carefully to assure that safety features are maintained.

PRODUCT CAUTIONS

Before attempting any test, calibration, or maintenance procedure, personnel must be completely familiar

with the particular circuitry of this unit, and have an adequate understanding of field effect devices. If a

component is found to be defective, always follow replacement procedures carefully to that assure safety

features are maintained. Always replace components with those of equal or better quality as shown in the

Parts List of the Instruction Book.

Avoid static charge

This unit contains MOS circuitry, which can be damaged by improper test or rework procedures. Care

should be taken to avoid static charge on work surfaces and service personnel.

Use caution when measuring resistances

Any attempt to measure resistances between points on the printed circuit board, unless otherwise noted

in the Instruction Book, is likely to cause damage to the unit.

i

B-2355 Cooper – Table of Contents

TABLE OF CONTENTS

M‑6200A Application Guide

B‑2355 Series Cooper Hardware Kit

Installation Instructions

1.0 Introduction ..................................................................................................................................1

2.0 Mechanical/Physical Information ...............................................................................................1

Figure 1 M-6200A Outline Dimensions...................................................................................2

Figure 2 M-6200A Rear Layout ..............................................................................................3

3.0 External Connections..................................................................................................................4

Terminal Block Assignments ..........................................................................................................4

Typical Connections .......................................................................................................................4

Grounding .....................................................................................................................................4

Unit Isolation ..................................................................................................................................4

Torque Requirements.....................................................................................................................4

Control Power Backup Input Connection ......................................................................................4

Backup Power Requirements.........................................................................................................5

Figure 3 Typical Connections for Cooper CL-2, CL-2A,

CL-4A, CL-4B, CL-4C, CL-5 and CL-6 Regulator Controls .......................................................6

Terminal Block Assignments (TB1) ...............................................................................................7

Non-Sequential Operation .............................................................................................................7

Auto Tapchange Inhibit...................................................................................................................7

Auxiliary Input (Aux 2)....................................................................................................................7

Table 1 Multi-Step Voltage Reduction External Connections..................................................7

Auxiliary Input (Aux 1)....................................................................................................................7

Terminal Block Assignments (TB2) ...............................................................................................9

Figure 4 Typical Control Power Backup Connection for M-6200A

Utilizing M-2026 or M-2027 Supply .........................................................................................10

Figure 5 B-0920 Control Power Backup Input 3-Wire Harness ............................................10

4.0 Cooper CL-2, CL-2A, CL-4A, CL-4B, CL-4C, CL-5 and CL-6 Regulator Controls

Replacement...............................................................................................................................11

Application ...................................................................................................................................11

Typical Connections .....................................................................................................................11

External Connections...................................................................................................................11

Lightning Protection .....................................................................................................................11

Non-Sequential Operation/ Counter Input....................................................................................11

Multi-Step Voltage Reduction ......................................................................................................12

Removal of the Cooper Control....................................................................................................12

Figure 6 Cooper Control in Cabinet......................................................................................13

Installing the M-6200A in a Cooper Regulator .............................................................................13

B-2355-C1/B-2355-C2 Hardware Kit Configuration .....................................................................14

Table 2 B-2355-C1 and B-2355-C2 Hardware Kit.................................................................14

Figure 7 B-2355-C1/B-2355-C2, B-2355-C3/B-2355-C4 Hardware Kit Orientation .............15

Figure 8 M-6200A (B-1128) Cooper Wiring Harness (Fanning Strip) for CL-2 through

CL-5 Regulators......................................................................................................................16

Figure 9 M-6200A (B-1157) Cooper Wiring Harness (Gray Plug) for CL-6 Regulators........17

ii

M-6200A Application Guide

B-2355-C3/B-2355-C4 Hardware Kit Configuration .....................................................................18

Table 3 B-2355-C3 and B-2355-C4 Hardware Kit.................................................................18

Figure 10 B-2355-C3 (B-1255 and B-1259) Cooper Wiring Harness ...................................19

Figure 11 B-2355-C4 (B-1255 and B-1260) Cooper Wiring Harness ...................................20

5.0 TapTalk S-6200 Communications Software Installation .........................................................21

Starting TapTalk ...........................................................................................................................21

Figure 12 S-6200 TapTalk Program-Item Icon ......................................................................21

6.0 Activating Initial Local Communications.................................................................................21

Figure 13 USB Port Connection Dialog Screen....................................................................22

Figure 14 Failed to Connect Error Screen............................................................................22

Figure 15 Failed to perform Access Code Verification Error Screen ....................................23

Figure 16 Successfully Connected Read-Only Access Screen............................................23

Appendix A HMI

A.1 HMI Menu Flow........................................................................................................................ A–2

Figure A-1 Monitor Menu Flow .......................................................................................... A–2

Figure A-2 Setpoints Menu Flow ...................................................................................... A–3

Figure A-3 Configuration Menu Flow (1 of 2)..................................................................... A–4

Figure A-3 Configuration Menu Flow (2 of 2)..................................................................... A–5

Figure A-4 Communication Menu Flow ............................................................................. A–6

Figure A-5 Utilities Menu Flow........................................................................................... A–7

A.2 HMI Screen Review ................................................................................................................. A–8

Monitor/Metering....................................................................................................................... A–8

Monitor/Present Demand.......................................................................................................... A–9

Monitor/Demand History ........................................................................................................... A–9

Monitor/Energy Metering......................................................................................................... A–10

Monitor/Status......................................................................................................................... A–11

Monitor/Motor Current............................................................................................................. A–14

Monitor/Harmonics.................................................................................................................. A–14

Monitor/Tap Information .......................................................................................................... A–15

Setpoints/Profile Settings........................................................................................................ A–17

Setpoints/Common Settings ................................................................................................... A–17

Setpoints/Power Flow Forward ............................................................................................... A–18

Setpoints/Power Flow Reverse ............................................................................................... A–18

Setpoints/Voltage Reduction................................................................................................... A–19

Setpoints/Limits....................................................................................................................... A–20

iii

B-2355 Cooper – Table of Contents

Setpoints/VAr Bias .................................................................................................................. A–20

VAr Bias (Step) ....................................................................................................................... A–20

VAr Bias (Linear)..................................................................................................................... A–21

Configuration/Tapchanger Type .............................................................................................. A–22

Configuration/Tap Settings...................................................................................................... A–22

Configuration/Programmable Alarm........................................................................................ A–24

Configuration/System Clock.................................................................................................... A–24

Configuration/Mtr Current Profile ............................................................................................ A–24

Configuration/CBEMA Setup .................................................................................................. A–25

Configuration/Harmonics Setup.............................................................................................. A–25

Configuration/Data Logging .................................................................................................... A–26

Configuration/Run Through Neutral ........................................................................................ A–27

Configuration/Nameplate ........................................................................................................ A–27

Communication/Comm Settings ............................................................................................. A–30

Communication/Memory Card ................................................................................................ A–31

Communication/Ethernet ........................................................................................................ A–32

Communication/HMI ............................................................................................................... A–34

Communication/Bluetooth....................................................................................................... A–34

Communication/RS232 ........................................................................................................... A–35

Utilities/Calibration-Test .......................................................................................................... A–36

Utilities/About.......................................................................................................................... A–38

iv

M-6200A Application Guide

© 2010 Beckwith Electric Co. All Rights Reserved.

Printed in U.S.A. (07.30.01)

800-B-2355-AG-05 04/17

B‑2355 Cooper

–1–

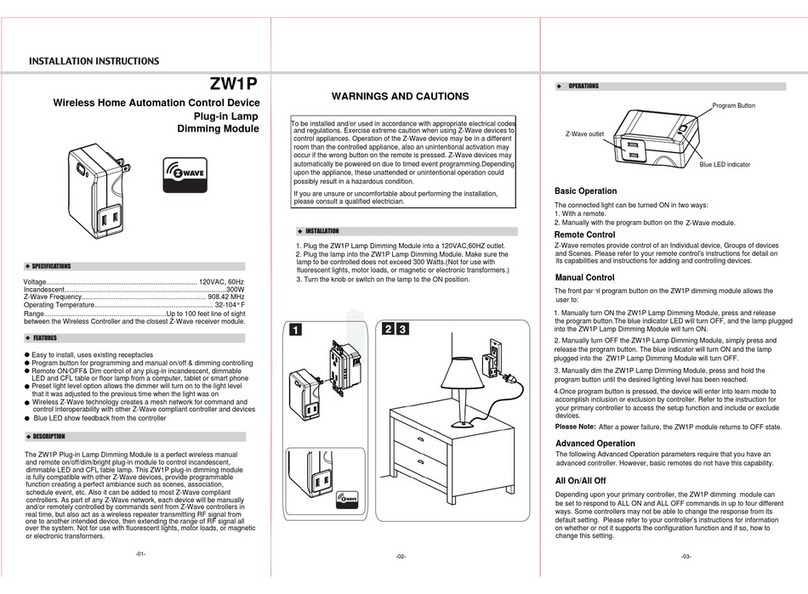

1.0 Introduction

This Application Guide is intended for those personnel that are responsible for the installation

of the M-6200A Digital Regulator Control. It provides the mechanical orientation of inputs

and outputs as well as physical dimensions of the control. External connections to the

control are detailed to assist installation personnel with various applications of the control.

The M-6200A through the use of hinge brackets, a latch bracket where required and a unit

specific wiring harness allow the unit to directly replace Cooper CL-2, CL-2A, CL-4A, CL-4B,

CL-4C, CL-5 and CL-6 regulator controls.

Detailed instructions are provided for those specific applications where the M-6200A is

directly replacing Cooper controls.

Also provided are instructions for the installation of TapTalk S-6200 Communications

Software and establishing initial local communications with the target control.

2.0 Mechanical/Physical Information

The M-6200A Regulator Control physical dimensions are illustrated in Figure 1. General

Layout of the M-6200A components are illustrated in Figure 2.

Do not position the M-6200A in a way that will make it difficult to operate the power disconnect

device.

The following is a brief summary of specifications that may be required for installation.

Voltage Withstand: 140 V continuous

240 V for one second

480 V for one cycle

Voltage measurement linear to 140 V

Current Withstand: Load Current:

0.48 amps continuous

4.0 amps for one second

Output Raise and Lower circuits:

6 amps AC

Alarm Contacts: Programmable Alarm/Selftest (Deadman)

6.0 amps AC, 125 V

0.2 amps DC, 125 V

M-6200A Application Guide

–2–

15.00

[12.5]

Smart Flash SD Card

S O U R C E

V O LT A G E

INT

E X T

O F F

USB

RX

TX

9.18

[23.32]

0.65

[0.17]

1.10

[2.8]

1.0

[2.54]

9.77

[24.82]

1.0

[2.54]

3.22

[8.18]

0.88

[2.24]

OK

LOWER ALARM

EXTERNAL

POWER

METER

OUT

MANUAL

LOCAL

RAISE

REMOTE

LOCAL

SCADA

CUTOUT

DRAG HANDS

RESET

VOLTAGE

REDUCTION

REVERSE

POWER

COM

!

Made in U.S.A.

Digital Voltage Regulator Control

M-6200A

HTIWKCEB

CIRTCELE

.CNI.OC

EXIT

WAKE

VOLT

RED

ENT

UTIL

SETP

COMMMNTR

CNFG

MANUAL

AUTO

OFF

LOWER

RAISE

NEUTRAL

LIGHT

Figure 1 M-6200A Outline Dimensions

B‑2355 Cooper

–3–

TB1-8,10 90 -140 8 VA

TB1-5,6,9 240 6 A

TB2-6,7,8 120 6 A

TB1-1,2,4,7,11,16 12 0.100 A

TB2-11,12 10-16 5 W

TB2

RX

TX SH B A

1

TB1

1 16

2345678910 11 12 13 14 15

FIBER

OPTIC

RS485

TB2

TB1-14, 15

+12

-11

BECKWITH ELECTRIC CO., INC.

6190-118th Avenue North - Largo, Florida 33773-3724 U.S.A.

PHONE (727)544-2326 FAX (727)546-0121

www.beckwithelectric.com

OFF

ON

FIBER

REPEAT

MODEL: M-6200A-XXXXXXXXX

FIRMWARE: _______________

SERIAL # XXXXXX

VOLTAGE

TEST

MOTOR

POWER

0.5A 250V 3AG

GE, SIEMENS, HOWARD

CONNECT

TB2-2 TO TB2-5

COOPER

CONNECT

TB2-1 TO TB2-2

50 Hz 60 Hz

0.48A CONTINUOUS

4.0A 1 SECOND

!

FIBER

REPEAT

SWITCH

3A 250V 3AG

6A 250V 3AG

Figure 2 M-6200A Rear Layout

M-6200A Application Guide

–4–

3.0 External Connections

Terminal Block Assignments

The external connections to the control are made to the two terminal blocks located on the

rear of the control, see Figure 3. See "Terminal Block Assignments" later in this section for

a description of each terminal assignment. For example, if external dry contacts are being

used to control the Voltage Reduction Step #1 function, connections for these contacts

may be made between TB1-4 and TB1-7 as shown in Figure 3. The dry contact inputs for

non-sequential input, voltage reduction must be "wetted" by connecting to terminal TB1-4.

See Table 1.

Typical Connections

Figure 3 illustrates typical connections for a regulator control. Motor Power and sensing

voltage can be obtained from a common source or from an independent source having a

nominal 120 Vac output. Normally, this is line-to-neutral voltage, although line-to-line voltage

can be used if recognition is made of any phase shift between the voltage and current signals

when using line drop compensation.

CAUTION:▲The current input to the M-6200A is rated at 0.48 A continuous, and

4.0 A for 1 second.

Load current must be reduced by an appropriate auxiliary transformer to 0.2 A "full scale"

before connecting to the regulator current inputs.

Grounding

WARNING:8The protective earth grounding terminal must be connected to

the installation earth ground anytime external connections have

been made to the unit.

Ground the control by connecting a 14 AWG, 300 V min., 105° C green insulated wire inserted

in an Amp 51864-8 or equivalent ring connector wire to the marked protective earth terminal

located adjacent to either side of TB1. Connect to the installation ground.

Unit Isolation

Sensing inputs should be equipped with test switches and shorting devices where necessary

to isolate the unit from external potential or current sources.

A switch or circuit breaker for the M-6200A's power shall be included in the building

installation, and shall be in close proximity to the control and within easy reach of the

operator, and shall be plainly marked as being the power disconnect device for the control.

Torque Requirements

Terminals TB1-1-16 & TB2-1-12: 7.5 in-lbs, minimum and 8.0 in-lbs, maximum.

Control Power Backup Input Connection

The Control Power Backup Input (Figure 4) is designed to sustain communication port

operation in the event of the loss of AC control power. In the event of a loss of AC input

power to the control, this feature permits uninterrupted operation of the control by supplying

+12 Vdc to the control. In addition, the control retains functionality with the exception of the

actual operation of the tapchanger mechanism.

When the AC input voltage drops below approximately 85 Vrms, the Control Power Backup

Input will activate and all automatic tapchange operations will then be suspended. If Motor

Power is available, manual tapchanges may be initiated.

When the control is being powered only by the backup DC input the Auto/Manual switch

status and the Local/Remote switch status are functional. When a control is being supplied

by both AC and DC via the backup power input and the backup DC input is lost the unit will

report it via DNP.

B‑2355 Cooper

–5–

When the control is being powered from the Control Power Backup Input, it will continue to

read any input voltage present.

The control retains full functionality, and if the control's Motor Power remains energized

then Raise and Lower commands from SCADA are possible. Fiber-Optic port operation is

maintained. All communication ports, data-logging, status monitoring, configuration, and

setpoint capability are also maintained.

Beckwith Electric offers two Control Power Backup supplies for use with the M-6200A.

The M-2026 AC-DC Control Power Backup Supply is a fused, surge protected and reverse

polarity protected AC-DC Control Power Supply that accepts an AC or DC input (21 to 32,

42 to 60 and 105 to 145 V) and outputs regulated +12 Vdc at up to 1.5 Amp.

The M-2027 Control Power Backup Supply - AC Only is a fused and surge protected Control

Power Backup Supply that will accept an AC input range of 105 to 140 Vac, 50/60 Hz and

output +12 Vdc to 1 A.

Both the M-2026 and M-2027 are housed in non-weathertight enclosures and are equipped

with screw terminal blocks for both input and output connections.

Backup Power Requirements

The Control Power Backup Input that does not utilize the M-2026 or M-2027 should only be

used with the optional (B-0920) 3-Wire Harness. The harness (Figure 5), includes a 3 Amp

fast-blow fuse, and connects to TB2-11 (–) and TB2-12 (+) of the control.

CAUTION:▲Use of Non-Beckwith Electric converters to provide +12 V to the

Control Power Backup Input may compromise system integrity due

to a lack of adequate protection of the power converter. For reliability

of the M-6200A, the power converter must meet the following

requirements:

Temperature: Operational from -40° C to + 85° C.

IEC 60068-2-1 Cold, -40° C

IEC 60068-2-2 Dry Heat, +80° C

IEC 60068-2-78 Damp Heat, +40° C @95%RH

IEC 60068-2-30 Damp Heat Condensing cycle 25° C, +55° C @95%RH

Surge Withstand Capability:

IEEE C37.90.1-2002 2,500 V pk Oscillatory

4,000 V pk Fast Transient Burst

IEEE C37.90.1-1989 2,500 V pk Oscillatory

5,000 V pk Fast Transient

Radiated Electromagnetic Withstand Capability:

All units are protected against electromagnetic radiated interference from portable

communications transceivers.

Electrostatic Discharge:

IEC 60255-22-2 (8 Kv) – Point Contact Discharge

IEC 60255-22-2 (15 Kv) – Air Discharge

Fast Transient/Burst Immunity:

IEC 60255-22-4-2008

Class A (4 Kv, 5 kHz)

M-6200A Application Guide

–6–

Position

Indicator Reset

Voltage In

(Reg 120 V)

Neutral

(Grd Stud)

(Motor Return)

Motor

L R

Voltage Reduction

Step #1 Contact

Voltage Reduction

Step #2 Contact

1

2

3

4

5

6

7

8

9

10

11

12

TB2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TB1

16

+12 Vdc Wetting Supply

Source Voltage

Load Current (+)

Load Voltage Input

Regulator Raise Output

Motor Power Input

Voltage Reduction Step #2 Input

Neutral Tap Position Input

Neutral

Regulator Lower Output

Non-Sequential Operation/Auto

Tapchange Inhibit Input

Voltage Reduction Step #1 Input

No Connection

Drag Hands Reset Output

Operations Counter Input(+)

Load Current (-)

Neutral Tap Position Input

Control Backup Power (-)

Control Backup Power (+)

Motor Seal-In

Alarm (NC)

Alarm Common

Alarm (NO)

No Connection

No Connection

No Connection

Neutral Light

Switch

CT

Line

Current

CT Shorting

Switch

M-6200A

VS

G

L3

R3

NL

DHR

C1

C3

Motor Power In

(Unregulated 120 V)

VM

HS Motor Seal-In Input

NOTE: Jumper wire from TB1-8 to

TB1-16 is supplied with harness.

YY

M-6200A

Terminals

xx Cooper Terminals

Cooper

Configuration

Jumper

WARNING:8In no case should the line current circuit be interrupted with

the regulator or transformer energized. Do not remove auxiliary

current transformers without shorting the current inputs. Death

or severe electrical shock can occur.

Figure 3 Typical Connections for Cooper CL-2, CL-2A,

CL-4A, CL-4B, CL-4C, CL-5 and CL-6 Regulator Controls

B‑2355 Cooper

–7–

TERMINAL BLOCK ASSIGNMENTS (TB1)

TB1‑1 Non-Sequential Operation/Auto Tapchange Inhibit (or Aux 2)

Non-Sequential Operation

CAUTION:▲Voltage applied through dry contacts to actuate non-sequential input

and voltage reduction inputs must be nominal +12 Vdc obtained from

TB1-4 of the M-6200A Regulator Control. The use of 120 Vac will

result in damage to the control.

The operation of the control can be interrupted during tapchanger operation by applying the

"wetting" voltage of TB1-4 to TB1-1 (timer reset for non-sequential operation input) on the

control through an external contact. This causes the output to de-energize and reinitialize

the time delay circuit when the reset signal is removed. This function can be used to cause

the Regulator, if so equipped, to wait for the unit to time out between tapchanges.

Non-sequential operation is invoked by momentarily connecting this input to the nominal

+12 Vdc wetting source (TB1-4) through an external Form "a" dry contact. When this function

is enabled, the tapchanger control times out with the Time Delay setting between every

tapchange.

Auto Tapchange Inhibit

Auto tapchange inhibit is invoked by closing and maintaining a Form "a" dry contact connected

to this input and to the nominal +12 Vdc wetting source (TB1-4). As long as this contact is

closed, the tapchanger will not time out, thereby prohibiting raise and lower commands.

Auxiliary Input (Aux 2)

To monitor the Battery Alarm Status, the optional Battery Pack sense line must be connected

to TB1-1 and the Non-Sequential input must be configured as "Aux 2".

TB1‑2 Voltage Reduction Step #2 (or Aux)

TB1‑7 Voltage Reduction Step #1 (or Aux 1)

CAUTION:▲Voltage applied through dry contacts to actuate non-sequential input

and voltage reduction inputs must be nominal +12 Vdc obtained from

TB1-4 of the M-6200A Regulator Control. The use of 120 Vac will

result in damage to the control.

On the M-6200A Digital Regulator Control, TB1-2 and TB1-7 are used together to provide

up to three levels of voltage reduction. The external connections to achieve these steps

are shown in this Table 1. Voltage reduction amounts are set within the M-6200A Digital

Regulator Control software. If these voltage reduction steps are instituted by communications,

the contacts are not being used simultaneously.

NOTE:QEnabling both voltage reduction Step #1 and Step #2 inputs simultaneously

will result in the level of voltage reduction as specified on the voltage

reduction Step #3 screen of the control.

These digital inputs are typically enabled by connecting it to the nominal +12 Vdc wetting

source (TB1-4), through an external Form "a" dry contact. The amount of voltage reduction

implemented is determined by the setting.

Voltage Reduction Setpoint:

Multiplier Range

Apply "Wetting Voltage"

From TB1-4 to TB #

Voltage Reduction Setpoint #1: 0 to 10% TB1-7

Voltage Reduction Setpoint #2: 0 to 10% TB1-2

Voltage Reduction Setpoint #3: 0 to 10% TB1-7 and TB1-2

Table 1 Multi-Step Voltage Reduction External Connections

Auxiliary Input (Aux 1)

To monitor Intrusion Detection Status, the optional Intrusion Detection sense line must

be connected to TB1-7 and the Voltage Reduction 1 input must be configured as "Aux 1".

M-6200A Application Guide

–8–

TB1‑3 No Connection or Source Voltage

TB1‑4 +12 Vdc Wetting Voltage

This is the output of an unregulated dc power supply internal to the control. It is referenced to

neutral and can supply up to 100 mA. It is used for powering the digital inputs of the control

through external dry contacts. Depending on the voltage supplied to TB1-10 and loading,

its output can vary from +10 to +18 Vdc. The output is current limited with a 1 ohm resister.

TB1‑5 Regulator Raise Output

This switched output connects the tapchanger raise winding to the source of motor power.

When the control calls for a raise, it is capable of switching up to 6 A at 120/240 Vac.

TB1‑6 Regulator Lower Output

This switched output connects the tapchanger lower winding to the source of motor power.

When the control calls for a lower, it is capable of switching up to 6 A at 120/240 Vac.

TB1‑8 Neutral

This is the return for the nominal +12 Vdc “wetting” voltage (TB1-4) and the voltage input

(TB1-10).

TB1‑9 Motor Power Input

The source for powering the tapchanger motor is connected here. It may have a maximum

voltage of 240 Vac.

TB1‑10 Load Voltage Input

This input accepts nominal 120 Vac, 60 Hz (or 50, Hz as ordered) to operate the control's

power supply and voltage sensing input. The acceptable voltage range for proper control

operation is from 90–140 Vac.

Power consumption is less than 8 VA. The input voltage is referenced to line neutral (TB1-8).

TB1‑11, TB1‑16 Neutral Tap Position Inputs

This digital input registers neutral position switch closures on regulators. The pins are

isolated from neutral to permit connection of the input based on regulator configuration.

TB1‑12 Drag Hands Reset

The drag hand reset output (TB1-12) connection is commonly used to reset the drag hand

on the regulator. When the Drag hand switch on the M-6200A is activated, this will cause

the unit to output 120 V to TB1-12. This voltage can be used to energize the drag hand

circuitry on the regulator.

TB1‑13 Operations Counter Input

This digital input registers the counter contact closure. The operations counter will increment

when TB1-13 is grounded by way of the regulator dry operation count switch. This contact is

needed for using the intertap time delay. Once a valid counter input is detected, the intertap

time delay will begin counting down.

B‑2355 Cooper

–9–

TB1‑14 Load Current (+)

CAUTION:▲The current input to the M-6200A is rated at 0.48 A continuous, and

4.0 A for 1 second.

The line current input range is 0–640 mA (480 mA continuous) with 200 mA representing

the 1.0 per-unit value. The measured current value is used for line drop compensation and

metering calculation.

TB1‑15 Load Current (-)

This is the non-polarity input to the load current measuring transformer. The companion

polarity input is TB1-14. The line current transformer input is isolated from other pins.

TERMINAL BLOCK ASSIGNMENTS (TB2)

TB2‑1 Jumper TB2-1 to TB2-2 for Cooper regulators

TB2‑2 Jumper TB2-2 to TB2-5 for all regulators except Cooper

TB2‑3 Neutral Light Source

TB2‑4 No Connection

TB2‑5 Motor Seal-in

Receives an Input from the Cooper Regulator Motor Cam Switch. Hardware Jumper TB2-2

to TB2-5 for all other regulators except Cooper.

TB2‑6, TB2‑7, TB2‑8 User Programmable Alarm

This set of terminals is a Form "C" alarm relay contact rated for 6 A at 120 Vac, or 100 mA at

120 Vdc. This alarm indicates when any of the programmable alarm conditions are detected.

Refer to the M-6200A Instruction Book.

TB2‑9, TB2‑10 No Connection

TB2‑11, TB2‑12 Control Power Backup Input

This input allows connection of external 12 Vdc control power backup power. The control

retains functionality with the exception of the actual operation of the tapchanger mechanism.

M-6200A Application Guide

–10–

Facility AC-DC Source

21 - 32 V

42 - 60 V

105-145 V

M-2026 AC-DC Control

Power Backup Supply

Facility AC Source

105-140 Vac

M-2027 Control Power

Backup Supply AC

Only

+12 V

B-1021 Backup

Power Harness

TB2

10 11 12 13 14 15 16

1

2

3

4

5

6

7

8

9

10

11

12

Backup Power (-)

Backup Power (+)

Figure 4 Typical Control Power Backup Connection for M-6200A

Utilizing M-2026 or M-2027 Supply

3 Amp

Fast Blow Fuse

+12 V (White)

GND (BLK)

GND CHASSIS (DRAIN)

TB2

10 11 12 13 14 15 16

1

2

3

4

5

6

7

8

9

10

11

12

Backup Power (-)

Backup Power (+)

Figure 5 B-0920 Control Power Backup Input 3-Wire Harness

B‑2355 Cooper

–11–

4.0 Cooper CL‑2, CL‑2A, CL‑4A, CL‑4B, CL‑4C, CL‑5 and CL‑6

Regulator Controls Replacement

The Beckwith Electric M-6200A Digital Regulator control directly replaces Cooper CL-2,

CL-2A, CL-4A, CL-4B, CL-4C, CL-5 and CL-6 Regulator Controls.

The M-6200A may be purchased with the factory installed hardware kits:

• B-2355-C1 CL-2 through CL-5

• B-2355-C2 CL-6

• B-2355-C3 CL-2 through CL-5

• B-2355-C4 CL-6

The contents of the hardware kits provide the means to install the M-6200A in the existing

Cooper Regulator Control cabinet. The B-2355-C1, B-2355-C2, B-2355-C3, B-2355-C4

are available separately from the factory for field installation.

The difference between the B-2355-C1/B-2355-C3 and B-2355-C2/B-2355-C4 hardware

kits is the B-2355-C1/B-2355-C3 contains the harnesses for CL-2 through CL-5 control

replacement and the B-2355-C2/B-2355-C4 contain the harnesses for CL-6 control

replacement. The remaining kit contents are the same.

Application

Typical Connections

In general, the tapchanger motor must be operated from a different transformer than the

VT used to measure regulated voltage. If this is not done, hunting at the upper band edge

may result. As soon as the motor starts, and before it is sealed in, the motor current can

drop the voltage within the band and reset the control. Some motor seal-in schemes are

fast enough to prevent this, but others are not.

Pulsed output can be used on the M-6200A (see Instruction Book, Section 4.2 System

Setup, Output Pulse).

External Connections

Power and voltage sensing are obtained either from a common source or from independent

sources having a nominal 120 Vac output. Normally, this is line-to-neutral voltage, although

line-to-line voltage can also be used if recognition is made of any phase shift between the

voltage and current signals when using line drop compensation.

The external connections for the M-6200A are made to terminal blocks TB1 and TB2 on the

rear of the control panel. The wiring harness and external connections for the M-6200A are

shown in Figure 8, Figure 9, Figure 10, and Figure 11.

Lightning Protection

CAUTION:▲For proper protection against system surges, chassis ground must be

connected to earth ground.

It has been determined that transient voltages in excess of 1500 Vac RMS can exist on the

"ground" lead normally tied to TB1-8. In the regulator controls, these voltages are suppressed

by varistors which still permit the unit to pass a 1500 Vac hi-pot test for one minute, with a

leakage of approximately 15 mA, all terminals to ground.

Multiple VT grounds far apart must be avoided, since a varying difference in ground voltage

could add or subtract from the effective voltage, and cause variation in the tapchanger

control’s bandcenter voltage setpoint.

Non-Sequential Operation/ Counter Input

Not normally used with Cooper Regulators.

M-6200A Application Guide

–12–

Multi-Step Voltage Reduction

CAUTION:▲Voltage applied through dry contacts to actuate Voltage Reduction

Steps 1, 2, and 3 must be +12 Vdc obtained from terminal TB1-4 of

the M-6200A Regulator Control.

The M-6200A uses terminals TB1-2 and TB1-7 together to provide up to three levels of

voltage reduction. The external connections to achieve these steps are shown in Table 1

and Figure 3. Voltage reduction amounts are set in the M-6200A Regulator Control software.

Removal of the Cooper Control

WARNING:8In no case should the line current circuit be interrupted with

the regulator or transformer energized. Do not remove auxiliary

current transformers without shorting the current inputs. Death

or severe electrical shock can occur.

1. Verify that the regulator control wiring is in a safe condition that will allow removal

of the Cooper Regulator Control from the control cabinet.

• The control wiring is de-energized and isolated from any potential safety

hazards.

• All local Safety Tagging rules have been applied as necessary.

2. Open the cabinet door of Cooper control.

3. Loosen the thumb screws on the control panel (Figure 6), and swing the panel

outward.

WARNING:8In no case should the line current circuit be interrupted with

the regulator or transformer energized. Do not remove auxiliary

current transformers without shorting the current inputs. Death

or severe electrical shock can occur.

4. De-energize the control by opening the VT disconnect switch and placing the

CT switch in the shorting position. Ensure that the CT in the regulator has been

properly shorted.

5. Loosen the screws on the spreader bar terminal block at the bottom of the cabinet,

then pull down on the spreader bar to disconnect it.

NOTE:QThe two hinge pins must be saved from the original control.

6. Remove and save the two hinge pins, then lift the panel off of the hinges and

remove it from the cabinet.

B‑2355 Cooper

–13–

Cabinet Door

Control

Panel

➀

Control

Panel

Knob

→

Hinge Pins

McGRAW-EDISON

Figure 6 Cooper Control in Cabinet

Installing the M-6200A in a Cooper Regulator

The hinge leaves and latch bracket mechanism are oriented to match the existing hinge

leaves and latch of the Cooper control cabinet.

If Bench Testing of the M-6200A is required, then refer to Instruction Book, Chapter 7,

Testing.

WARNING:8In no case should the line current circuit be interrupted with

the regulator or transformer energized. Do not remove auxiliary

current transformers without shorting the current inputs. Death

or severe electrical shock can occur.

1. Verify that the applicable B-2355-C1, B-2355-C2, B-2355-C3 or B-2355-C4

hardware kit has been installed on the the control.

If the applicable hardware kit is not installed, then proceed to the appropriate

hardware kit configuration section to install the hardware kit.

2. Verify that the regulator control wiring is in a safe condition that will allow installation

of the M-6200A in the control cabinet.

• The control wiring is de-energized and isolated from any potential safety

hazards.

• All local Safety Tagging rules have been applied as necessary.

3. Mount the M-6200A Regulator Control onto the hinges in the control cabinet

(Figure 6), then install the two hinge pins saved from the original control. Leave

the panel in the open position so that the back of the panel is accessible.

4. If the frame that the latch bracket is mounted to requires the use of longer panel

thumbscrews, then replace the two panel thumbscrews with the longer versions

provided in the cloth bag.

5. Connect the M-6200A’s wiring harness to the terminal block at the bottom of the

cabinet. Refer to Figure 8, Figure 9, Figure 10, and Figure 11.

6. Set the toggle switch to the Manual position.

Table of contents

Other BECKWITH ELECTRIC Control Unit manuals