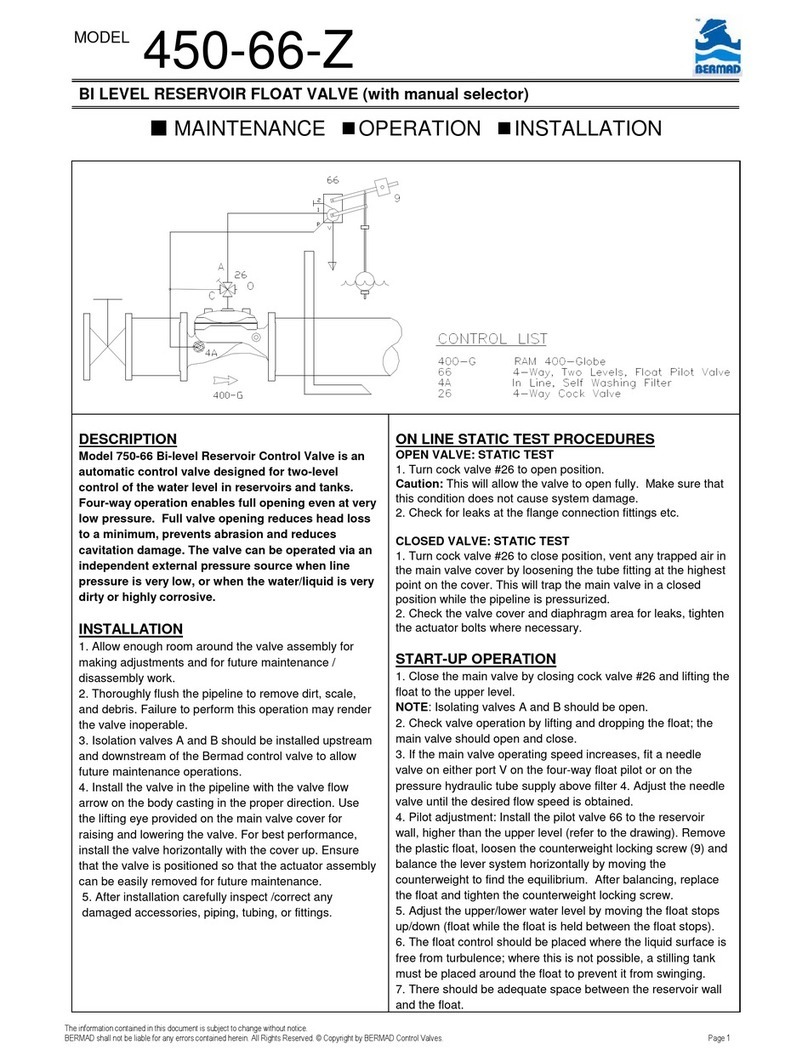

MODEL 450-60

RESERVOIR VALVE (FLOAT VALVE)

INSTALLATIONOPERATIONMAINTENANCE

The information contained in this document is subject to change without notice.

BERMAD shall not be liable for any errors contained herein. All Rights Reserved. © opyright by BERMAD ontrol Valves. Page 1

DESCRIPTION

Model 450 -60 Reservoir Valve is an automatic control

valve designed to fill reservoir or tanks and to shut off

when the water reaches a pre-determined level.

The valve opening will modulate, adjusting the fill rate to

a discharge flow while maintaining a constant upper

level in the reservoir.

An upper control chamber, operating on a two way

control principle, has varying pressure produced by pilot

modulation and opens in conjunction with an upstream

restriction needle valve.

If the water rises to a pre-determined level, float action

will tend to close the pilot valve, and the main valve

modulates to close

INSTALLATION

1. Allow enough room around the valve assembly for making

adjustments and for future maintenance / disassembly work.

2. Thoroughly flush the pipeline to remove dirt, scale, and

debris. Failure to perform this operation may render the valve

inoperable.

3. It is recommended that an isolation valve be installed

upstream of the Bermad control valve to allow for future

maintenance operations.

4. Install the valve in the pipeline with the valve flow arrow on

the body casting in the proper direction. Use the lifting eye

provided on the main valve cover for raising and lowering the

valve. Install the valve horizontally with the cover up for best

performance.

5. After installation carefully inspect /correct any damaged

accessories, piping, tubing, or fittings.

6. Install the 2 way float pilot valve #22 inside the water tank

connecting it to the wall 30 cm. above the desire upper water

level.

7. Connect the horizontal port of the float to cock valve #2

on the valve, using 1/2” pipe.

ON LINE STATIC TEST PROCEDURES

OPEN VALVE: STATIC TEST

1. Close cock valve #1 and #2 to isolate the pilot control

system. This prevents dirt exposure in the control loop.

2. Remove plug from the cover of the valve.

Caution: This will allow the valve to fully open. Make sure

that this condition does not cause system damage!

3. Check for leaks at the flange connection fittings etc.

CLOSE VALVE: STATIC TEST

1. Open cock valve #1 and close cock valve #2.

2. Close the plug on the cover. Pressure will be built in the

main valve cover. Release tube connector slightly to release

air traps and then close it. The main valve should close.

3. Check the valve cover and diaphragm for leaks, tighten

bolts if necessary.

START-UP OPERATION

Note: Ensure upstream pressure exist.

1. Close cock valves 1 and 2 to isolate the control system.

This prevents dirt exposure in the control loop.

2. Remove the cover plug on the main valve cover, allowing

the valve to fully open.

3. Open isolation valves.

4. Replace the cover plug and close cock valve #2, the main

valve will close.

5. The needle valve #5 is factory set at one to one-and-a-half

turns. Turn the needle valve clockwise - to reduce the

closing rate speed of the main valve - or vice versa.

6. Check valve operation by slowly opening / closing cock

valve #2.

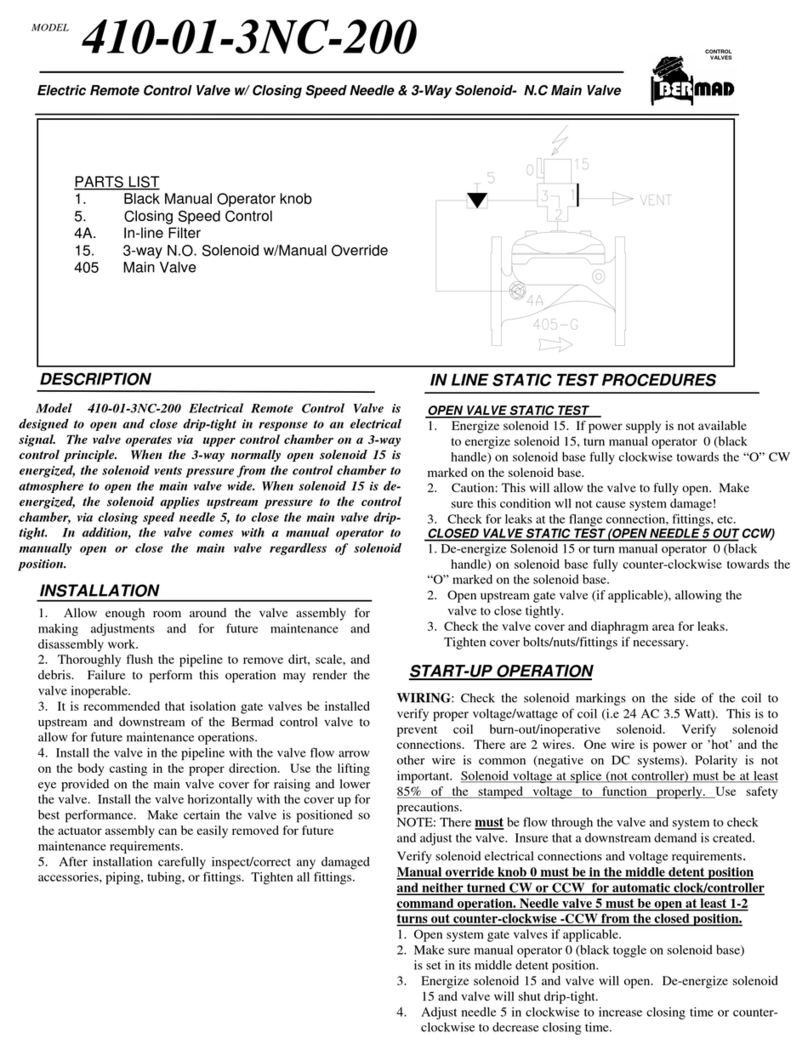

PARTS LIST

1, 2 Cock Valve.

4B Stagnation In Line Self Washing Filter.

5 Needle Valve.

22 2-Way Float Pilot Valve.