Source VERSA-SLAB User manual

SOURCE VERSA GATE VALVES

API 6A LICENSE

LICENSE NO. 6A-0541 API 6D LICENSE

LICENSE NO. 6D-0477

Issued 210723

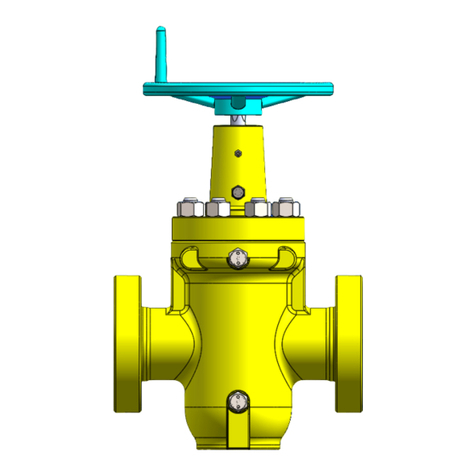

VERSA-SLABTM GATE VALVES

SOURCE VERSA VALVES

Table of Content

VERSA VALVE FEATURES

Versa Slab-LS Gate Valve Brochure

Versa Slab-HS Gate Valve Brochure

TECHNICAL INFORMATION

Valve Reference Dimensions and Weights

Recommended Flange Bolt Lengths and Ring Gasket

Gate Valve Trim Chart

OPERATING AND SERVICE MANUAL

Versa-Slab-LS Gate Valve

Versa-Slab-HS Gate Valve

Versa-Slab High Pressure Gate Valve

Drilling & Production API 6A Gate Valve

API 6A LICENSE

LICENSE NO. 6A-0541

VERSA-SLABTM-LSGATE VALVE

SV-02 R00

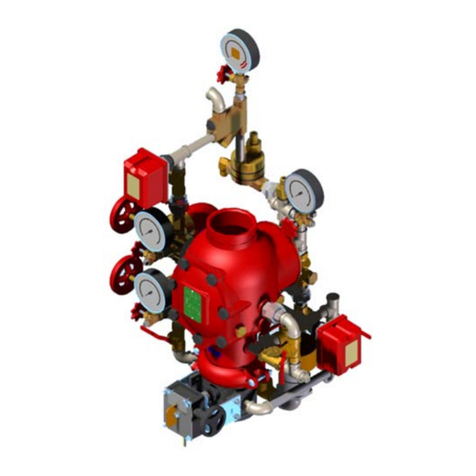

Advantages of the SOURCE Design

The VERSA GATE VALVE series offer an economical field proven oilfield

valve for the oil & gas industry. A choice of versa-slab and versa-wedge gates

is available which are purpose designed to maximize usage of common parts

such as the universal valve body and bonnet assembly to afford an overall

cost effective valve . The versa gate valve line of products are designed and

manufactured to the latest requirements of API 6A specifications and API

Q1/ISO9001 quality assurance.

Metal to Metal stem

backseat sealing

allows stem packing

replacement with

valve under pressure.

Metal to Metal

seat/body and

seat/gate sealing.

Packing design for different

services temperature,

pressure and drilling and

production fluids.

For PR1 service, standard

elastomeric seal packing is

used.

For PR2 service, special

design non-elastomeric SV

stem packing is used.

SV stem packing provides

an excellent service for

chemicals in oil and gas

production fluids.

VERSA-SLAB LS GATE VALVE FEATURES:

‒2000 to 5000 psi

‒2-1/16″ to 5-1/8″

‒Bi-directional Flow and Seal

‒Metal to Metal Sealing (Gate-to-Seat & Seat-to-Body)

‒Non-rising Stem Design

‒Floating Gate and Seat Design

‒Stem Backseat

‒Elastomeric or Non-elastomeric Stem PackingAvailable

‒Low Operating Torque

‒Forged Body and Bonnet

‒Tested to Requirements of API 6A

VERSA SLAB GATE VALVE

Source Manufacturing (Shanghai) Co., Ltd

988 Xiang Jing Road, Songjiang District

Shanghai 201613, P.R.China

Tel: 86 21 57775088

Fax: 86 21 57775068

Email: sales@source-mfg.com

Packing Set

Metal to Metal

Seal Floating

Gate and Seat

Design

Packing

Gland

Metal to Metal

Seal Seat to Body Seat

Body

Bolt & Nut

Gasket

Zerk Fitting

Stem

Handwheel

Grease Fitting

Gate

Bonnet

Lock Nut

Bearing Spacer

Bearing

Lift Nut

Bonnet Cap

Thrust Pin

DRILLING & PRODUCTION API 6A GATE VALVE

API 6A LICENSE

LICENSE NO. 6A-0541

VERSA-SLABTM-HSGATE VALVE

SV-01 R00

VERSA-SLABTM GATE VALVE

The VERSA GATE VALVE series offer an economical field proven oilfield

valve for the oil & gas industry. A choice of versa-slab and versa-wedge gates

is available which are purpose designed to maximize usage of common parts

such as the universal valve body and bonnet assembly to afford an overall

cost effective valve . The versa gate valve line of products are designed and

manufactured to the latest requirements of API 6A specifications and API

Q1/ISO9001 quality assurance.

Metal to Metal stem

backseat sealing

allows stem packing

replacement with

valve under pressure.

Metal to Metal

seat/body and

seat/gate sealing.

Packing design for different

services temperature,

pressure and drilling and

production fluids.

For PR1 service, standard

elastomeric seal packing is

used.

For PR2 service, special

design non-elastomeric SV

stem packing is used.

SV stem packing provides

an excellent service for

chemicals in oil and gas

production fluids.

VERSA-SLAB GATE VALVE FEATURES:

‒2000 to 10000 psi

‒2-1/16″ to 5-1/8″

‒Bi-directional Flow and Seal

‒Metal to Metal Sealing (Gate-to-Seat & Seat-to-Body)

‒Non-rising Stem Design

‒Floating Gate and Seat Design

‒Option of Specific Seat Seal and Bonnet BX or VX Seal Design

‒Option of Tungsten Carbide Coating of Gate and Seat

‒Stem Backseat

‒Elastomeric or Non-elastomeric Stem PackingAvailable

‒Low Operating Torque

‒Forged Body and Bonnet

‒Tested to Requirements of API 6A

VERSA-SLABTM GATE VALVE

Source Manufacturing (Shanghai) Co., Ltd

988 Xiang Jing Road, Songjiang District

Shanghai 201613, P.R.China

Tel: 86 21 57775088

Fax: 86 21 57775068

Email: sales@source-mfg.com

Packing Set

Metal to Metal

Seal Floating

Gate and Seat

Design

Packing Gland

Metal to Metal Seal

Seat to Body

Seat

Body

Bolt & Nut

Gasket

Zerk Fitting

Stem

Handwheel

Grease Fitting

Gate

Bonnet

Lock Nut

Bonnet Cap

Bearing

Lift Nut

Slab Gate Valve 2000~5000 psi

VERSA-SLABTM GATE VALVE

Source Manufacturing (Shanghai) Co., Ltd

988 Xiang Jing Road, Songjiang District

Shanghai 201613, P.R.China

Tel: 86 21 57775088

Fax: 86 21 57775068

Email: sales@source-mfg.com

Slab Gate Valve 10000 psi

Packing Set

Metal to Metal

Seal Floating

Gate and Seat

Design

Packing Gland

Metal to Metal Seal

Seat to Body Seat

Body

Bolt & Nut

Gasket

Zerk Fitting

Stem

Handwheel

Grease Fitting

Gate

Bonnet

Lock Nut

Bonnet Cap

Bearing

Lift Nut

Seat Seal

SOURCE VERSA VALVES

SLAB GATE VALVE REFERENCE DIMENSIONS AND WEIGHTS

A Valve Bore

B Flange Face to Face

C Bore Centerline to Bottom of Valve

D Bore Centerline to Handwheel Top

E Handwheel Diameter

N Number of Turns to Open/Close

WT Estimated Weight

WEDGE GATE VALVE REFERENCE DIMENSIONS AND WEIGHTS

A Valve Bore

B Flange Face to Face

C Bore Centerline to Bottom of Valve

D Bore Centerline to Handwheel Top

E Handwheel Diameter

N Number of Turns to Open/Close

WT Estimated Weight

Nominal

Size

Working

Pressure

(psi)

A B C D E WT NAPI

Ring

in mm in mm in mm in mm in mm lbs kg

2 1/16

2000 2.06

52.3

11.62

295 4.95 126

18.07

459 13 330 158 72

13 1/2

R-23

3000-

5000 2.06

52.3

14.62

371 5.38 137

18.87

479 13 330 180 82 R-24

10000 2.06

52.3

20.50

521 5.5 140 19.7 500 16 406 286 130 13

BX

-

152

2 9⁄16

2000 2.56

65.0

13.12

333 6.18 157

19.65

499 13 330 275 125

20

R-26

3000-

5000 2.56

65.0

16.62

422 6.28 160

19.95

507 13 330 297 135 R-27

3 1⁄8

2000 3.12

79.2

14.12

359 6.93 176

21.35

542 13 330 218 99

20

R-31

3000 3.12

79.2

17.12

435 7.15 182

21.35

542 16 406 299 136 R-31

5000 3.12

79.2

18.62

473 7.15 182

21.35

542 16 406 339 154 R-35

3 1/16 10000 3.12

79.2

24.38

619 8.22 209

22.02

559 16 406 528 240 19

BX

-

154

4 1⁄16

2000 4.06

103.1

17.12

435 8.62 219

23.41

595 16 406 517 235

24

R-37

3000 4.06

103.1

20.12

511 8.8 224

23.41

595 16 406 559 254 R-37

5000 4.06

103.1

21.62

549 8.8 224

23.95

608 20 508 605 275 R-39

10000 4.06

103.1

26.38

670 9.5 241 26.1 663 24 610 924 420 24-1⁄2

BX

-

155

5 1⁄8 5000 5.12

130.0

28.62

727

11.69

297 27.3 693 20 508

1225

557 23 R-44

10000 5.12

130.0

29.00

737

12.71

323 32.5 826 24 610

1364

620 23 1/2

BX

-

169

Nominal

Size

Working

Pressure

(psi)

A B C D E WT

NAPI

Ring

in mm in mm in mm in mm in mm lbs kg

2 1/16

2000 2.06

52.3

11.62

295 4.81 122

19.25

489 13 330 119 54

13

R-23

3000-

5000 2.06

52.3

14.62

371 5.06 129

19.43

494 13 330 123 56 R-24

2 9⁄16

2000 2.56

65.0

13.12

333 5.62 143

20.18

513 13 330 178 81

15

-

1⁄2

R-26

3000-

5000 2.56

65.0

16.62

422 5.93 151

20.43

519 13 330 218 99 R-27

3 1⁄8

2000 3.12

79.2

14.12

359 7.18 182 22.5 572 13 330 218 99

20

R-31

3000 3.12

79.2

17.12

435 7.31 186

21.88

556 13 330 299 136 R-31

5000 3.12

79.2

18.62

473 7.31 186

21.88

556 16 406 339 154 R-35

SOURCE VERSA VALVES

RECOMMENDED FLANGE BOLT LENGTHS & RING GASKET TYPE

Recommended Bolt Lengths

Nominal

Size

Working

Pressure (psi)

Stud Nut

Ring Gasket

Bolt Size and

Thread

Length

+0.125/−0 Qty Qty

2 1/16

2000 5/8-11 UNC 5 8 16 R23

3000-5000 7/8-9 UNC 6.5 8 16 R24

10000 3/4-10 UNC 5.5 8 16 BX-152

2 9⁄16 2000 3/4-10 UNC 5.5 8 16 R26

3000-5000 1-8 UNC 7 8 16 R27

3 1⁄8

2000 3/4-10 UNC 5.75 8 16 R31

3000 7/8-9 UNC 6.5 8 16 R31

5000 1-1/8-8 UNC 7.75 8 16 R35

3 1/16 10000 1-8 UNC 7.25 8 16 BX-154

4 1⁄16

2000 7/8-9 UNC 6.5 8 16 R37

3000 1-1/8-8 UN 7.5 8 16 R37

5000 1-1/4-8 UN 8.5 8 16 R39

10000 1-1/8-8 UN 8.5 8 16 BX-155

5 1⁄8 5000 1-1/2-8 UN 10.5 8 16 R44

10000 1-1/8-8 UN 9.25 12 24 BX-169

LENGTH

= 2(T + t + d) + S + 2(P)

T is total flange thickness;

t is plus tolerance for flange thickness;

d is heavy hex nut thickness;

S is flange face standoff (with “RX” gasket),S=0 for BX connection which has no standoff height;

P is point max. (1.5 x pitch).

SOURCE VERSA VALVES

6A GATE VALVE TRIM CHART

TRIM SERVICE CONDITION BODY BONNET GATE SEAT STEM*3

AA

Non-sour Service

Standard Trim, Non

Corrosive

A487 4C

/4130LA 4130LA 4130LA 4130LA 17-4PH

BB Stainless Trim,

Slightly Corrosive

A487 4C

/4130LA 4130LA 410SS 410SS 17-4PH

CC Full Stainless Trim,

Moderately Corrosive 410SS 410SS 410SS 410SS 17-4PH

DD-0.5

Sour Service

Standard Trim,

Non Corrosive

A487 4C

/4130LA 4130LA 4130LA 4130LA 17-4PH

DD-NL Standard Trim,

Non Corrosive

A487 4C

/4130LA 4130LA 4130LA 4130LA 4130LA

EE-0.5 Stainless Trim,

Slightly Corrosive 4130LA 4130LA 410SS 410SS 17-4PH

EE-1.5 Stainless Trim,

Highly Corrosive 4130LA 4130LA 410SS 410SS 410SS

EE-NL Stainless Trim,

Highly Corrosive 4130LA 4130LA 410SS 410SS

Inconel 718

*4

FF-0.5 Full Stainless Trim

Highly Corrosive 410SS 410SS 410SS 410SS 17-4PH

FF-1.5 Full Stainless Trim

Highly Corrosive 410SS 410SS 410SS 410SS 410SS

FF-NL Full Stainless Trim

Highly Corrosive 410SS 410SS 410SS*3 410SS*3

Inconel 718

*4

HH-NL*5

Highly Corrosive Extreme

Service

4130 W/625

Inlay*5

4130 W/625

Inlay*5

Inconel 718

*4

Inconel 718

*4

Inconel 718

*4

NOTES:

1.This trim chart provides information on materials included in standard valves

offered by Array. Special materials, trims and configurations are available upon

customer request.

2.Standard trim parts are QPQ nitrided. Tungsten Carbide HVOF, Hardfaced

gates and seats are available for any TRIM upon request.

3.Materials for sour service trims conform to latest edition of NACE

MR0175/ISO15156. Explanation for suffixes used for sour trims:

a) 0.5 = 0.5 psi maximum partial pressure of hydrogen sulfide(H2S)

b) 1.5 = 1.5 psi maximum partial pressure of hydrogen sulfide(H2S)

c) NL = No limit to hydrogen sulfide (H2S) exposure.

4.Inconel 718 is an alternative material for upgrade.

5.Inconel 718 is only "NL" for temperatures K thru U. Inconel 725 can be used up

to temp. X.

6.CRA material is not available for temp. Y service.

7.Source reserves the right to use material class ZZ when customers request

materials of construction that do not comply with current NACE MR0175/ISO

standards

Temp.

Class

Temperature Range

℃°F

min. max. min. max.

K –60 82 –75 180

L –46 82 –50 180

N –46 60 –50 140

P –29 82 –20 180

S –18 60 0140

T –18 82 0180

U –18 121 0250

V 2121 35 250

X–18 180 0350

Y -18 350 0650

NOTE

Minimum temperature is the lowest ambient

temperature to which the equipment can be

subjected. Maximum temperature is the highest

temperature of the fluid that can directly contact

the equipment.

Operating & Service Manual

OPS-804 Rev.01

Source Manufacturing (Shanghai) Co., Ltd

988 Xiang Jing Road, Songjiang District

Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068

Email: sales@source-mfg.com

VERSA-SLABTM-LS GATE VALVE

Operating & Service Manual

This document contains Source proprietary and confidential information that is legally privileged and is intended

only for the person or entity to which it is addressed and any unauthorised use is strictly prohibited.

Operating & Service Procedure

Manual VERSA-SLABTM-LS Gate Valve

Date: May 2016

OPS-804 Rev.01

Information provided in this Recommended Procedure is of general nature based on

accepted operating practices. Source Manufacturing or its agents makes no

representation, warranty or guarantee in connection with this recommended

procedure and expressly disclaims any liability or responsibilities when any part of

this recommended procedure is adopted. The user is the best judge when applying

this procedure base on specific equipment installation and the operating conditions.

Operating & Service Manual OPS-804 Rev.01

Table Of Content

Section 1 Warnings.................................................................................................................................................1

Section 2 General Operation................................................................................................................................2

2.1 General Description ...........................................................................................................................2

2.2 Operation Specification.....................................................................................................................2

Section 3 Assembly Procedure...........................................................................................................................3

3.1 Installing Seat Assembly to Valve Body.......................................................................................3

3.2 Installing Bonnet Assembly.............................................................................................................4

3.3 Install Gate to Bonnet Assembly....................................................................................................4

3.4 Installing Bonnet/Gate Assembly to Valve Body........................................................................5

3.5 Lubrication............................................................................................................................................6

Section 4 Regular Field Maintenance ................................................................................................................8

4.1 Stem Bearing Assembly Lubrication.............................................................................................8

4.2 Valve Cavity Lubrication...................................................................................................................8

4.3 Field Replacement of Parts..............................................................................................................9

Section 5 Recommended Spare Parts.............................................................................................................12

Operating & Service Manual 1 OPS-804 Rev.01

Section 1 Warnings

The VERSA-SLABTM–LS Gate Valve is a bi-direction non-rising stem manual operated valve incorporating a

floating gate and seats design. The gate is connected to the stem through a barrel lift nut in the gate. This

arrangement permits the gate to float freely and enhance a pressure assisted seal when acted on by the

differential pressure across the gate. Constant contacts behind the gate and seats are maintained by action of

wave springs located behind the seats and help to keep debris from accumulating into the valve cavity.

The bonnet is bolted to the valve body and pressure integrity is achieved by means of a metal ring gasket.

Pressure energized U-type stem packing are used to isolate pressure in the valve cavity. The stem has a

selective back seat feature to facilitate replacement of stem packing in the field when the valve cannot be

removed from service.

The gate is actuated by rotation of the stem-opening (counter-clockwise rotation) and closing (clock- wise

rotation). The bearing spacer is sandwiched by needle bearing assembly to provide a sturdy low operating

torque gate valve.

The bonnet is equipped with a ½” grease/injection fitting for lubrication of the valve cavity and the bonnet cap

has a standard grease zerk for lubrication of the stem bearing assembly.

ALL OPERATORS AND MAINTENANCE PERSONNEL SHOULD BE THOROUGHLY TRAINED IN THE SA-

FE OPERATION, MAINTENANCE, AND INSPECTION OF THIS EQUIPMENT.

Operating & Service Manual 2 OPS-804 Rev.01

Section 2 General Operation

2.1 General Description

The VERSA-SLABTM–LS Gate Valve means closing member (shutter) movable in the vertical direction of the

channel axis of the valve, the pipe is mainly used as cutting medium effect, i.e., fully open or fully closed use.

As the throttle valve is generally not used. It can be used in high temperature and high pressure, and can be

used in various media.

Rotate stem clockwise to "close", counterclockwise to "open".

2.2 Operation Specification

Refer to specific assembly drawing and parts list.

Size

(Bore)

Working Pressure

(Psi)

Breaking Torque

(FT LBS)

Running Torque

(FT LBS)

No. of Turns

2-1/16"

2000 ~ 5000

<20

<10

16

2-1/16"

10000

<35

<20

14

2-9/16"

2000 ~ 5000

<40

<25

20

2-9/16"

10000

<80

<30

16

3-1/8"

2000 ~ 5000

<50

<30

20

3-1/16”

10000

<100

<50

20

4-1/16"

3000 ~ 5000

<80

<35

23

4-1/16"

10000

<180

<40

23

Breaking Torque denotes torque applied to open valve at full differential rated working pressure.

Running Torque denotes torque applied to operate valve after pressure is equalized across the gate.

NOTE:

It is important to back off ¼ turn after fully opening or closing valve. This is to allow the gate to freely

float acting on by line pressure.

Operating & Service Manual 3 OPS-804 Rev.01

Section 3 Assembly Procedure

3.1 Installing Seat Assembly to Valve Body

a) Thoroughly clean the internal of valve body.

b) Lightly grease seat and install lip seal on the side of groove towards wave spring end of seat.

c) Coat the seat pockets in the valve body with grease.

d) Carefully press seat assembly evenly into the seat pockets, wave spring facing inside of pocket.

e) Place bonnet gasket on valve body and makeup the flange blots or studs into the valve body.

NOTE:

For tap end stud, the shorter end is installed to valve body.

Valve Body

Bonnet Gasket

Assembly

Lip Seal

Wave Spring

Seat Assembly

Diagram Ⅰ(Valve Body/Seat Assembly)

Operating & Service Manual 4 OPS-804 Rev.01

3.2 Installing Bonnet Assembly

CAUTION:

The stem bearing assembly must be firmly lock down by the bonnet cap against the packing gland to

operate properly. Any slack or clearance in the bearing spacer, bearings due to improper assembly

would affect the operating torque as the needle bearings would no longer working effectively.

a) Lightly grease stem and install to bonnet from the bottom.

b) Lightly grease stem packing and slip over stem and evenly press them into bonnet cavity. Ensure no gr-

ease or water is trapped between to two packing. (Note: Stem Packing should be installed with U-cup

side facing down into bonnet pocket)

c) Install packing gland over stem and make up to bonnet. The packing gland should be sitting butt tight on

top of bonnet.

d) Install bearing assembly and bearing spacer over stem and insert thrust pin through bearing spacer and

stem. Rotate stem until stem/bearing assembly sits firmly on top of packing gland.

e) Install the bonnet cap over the stem and make up snugly tight to bonnet.

3.3 Install Gate to Bonnet Assembly

a) Lightly grease the barrel lift nut and insert to the gate. Carefully make up gate assembly to the stem by

left hand rotation, until the stem has fully engaged the lift nut and partially penetrate the gate.

Operating & Service Manual 5 OPS-804 Rev.01

b) Lightly grease the 2 sealing faces of the gate.

3.4 Installing Bonnet/Gate Assembly to Valve Body

a) Carefully lift bonnet/gate assembly over the valve body and stab the gate in the space between the seats.

A seat spreader aid may sometimes be necessary to spread the seats to make it easier for installing the

gate. Once the gate has started between the seats it would easily slide all the way down until the bonnet

comes into contact with the valve body.

Bonnet / Gate

Assembly

Seat Spreader

Aid

Diagram IV a Diagram IV b

Bonnet / Gate

Assembly

Table of contents

Other Source Control Unit manuals

Popular Control Unit manuals by other brands

Maple Systems

Maple Systems iR-AI04-TR Series Installation instruction

Furitek

Furitek IGUANA 20A/40A BRUSHED ESC manual

National Instruments

National Instruments FieldPoint FP-1000 user manual

Ditel

Ditel Kosmos series instruction manual

Nailor

Nailor BAC-8001-36 Installation and operation manual

Atmal

Atmal FPSLIC STK594 user guide

Moxa Technologies

Moxa Technologies ioMirror E3200 Series Quick installation guide

AUMA

AUMA AM 01.1 Operation instructions

Victaulic

Victaulic FireLock NXT 764 Series Replacement instructions

Lenze

Lenze PROFIBUS E84AYCPM Communications manual

Titan

Titan 582 Translation of the original instructions

S&T

S&T kontron COMe-bBD6 user guide