IMPORTANT

(flease

attach

this Owner's Manual Supplement to the inside cover

of

the .

OWner's Manual or

other

suitable location which

is

readily available

to

the

pilot.)

.

~

OWNER'S

MANUAL

SUPPLEMENT

for

K35, M35, N35, P35, S35, V35, V35TC, V35A,

V35ATC,V35B,

V35B TC

33,

AS3, B33, C33, E33,

F33,

G33, C33A, E33A,

F33A,

36, A36.

The

follo

.

~ing

information supersedes the informatiori contained in the

Owner's Manuals for the above listed airplanes.

1:

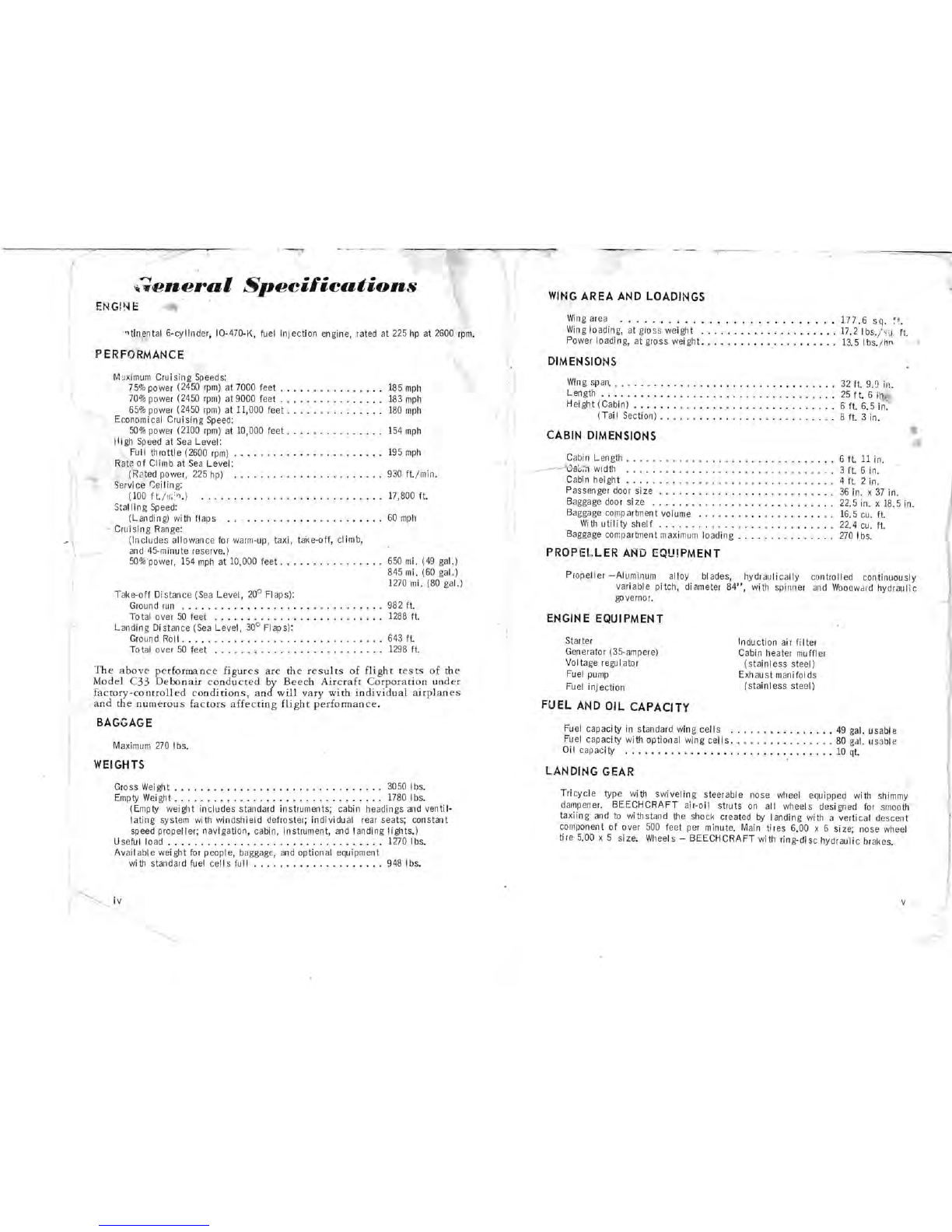

Maximum usable· fuel

of

each 25

or

24~

gallon main tank

is

22

gallons.

Maximum usable fuel

of

each

39

or

40

gallon main

tank

is

37 gallons.

3. Approximate reduction in range with füll fuel due to change in usable

fuel is:

a. 13%

on

22

gallon main ·tank system.

b. 9% on 37 gallon main

tank

system.

4.

On

Models K-35, M-35,

33,

and A33 Owners Manuals, reduce range by

an additional 190 statute rniles to account for climb and 45 minutes

rese:r:ve

at

45% maximum continuous power.

P/l'J

35-590118-17 lssued: February 11, 1972 . ,

~Weechcraft

Debonair

you

should:

-

:ii

-

-

~

.

·

~

,_

.

...

.

tr"

Y"'"

""

( '

Get

~~qnainted

with

your

airplane

Read

al

1

of

thi

.s

manual

carefully

to

become

fam

i1

iar

wi

th

the

operation

of

your

new

Debonai

r.

K

ee

p

yo

~

r

airplane

loo

kin~

a

nd

r

u

n

n~

ng

lik

e .

n

e~v

\ "

Know

wh

en

to

have

y

'Q

u'r

Debonai

r

servi

·

\;ed

insi

de

and

out.

\ \

'ikechcr.aft

Deb

~'li

1fr

'

~M

-s

;:ser

vice

r -....„ -„„_

·

'.'_o~

r

air

pl

a n

e!l-s

-

·

~

f~Je

1~il

is

your

B

eecL:~raft

.

·

~

~-

-

..

..

„__

Certified

Servi~e

Staitio1m

He'll

be

glad

to

answer

your

questions

or

discuss

any

problems

you

may

have

concerning

your

airplane.

The

operation,

care

and

maintenance

of

your

airplane

after

its

delivery

to

you

is

your

responsibilfty.

Your

author-

ized

Beechcraft

Sales

and

Service

Outlets

have

all

the

current

recommended

modification,

service

and

operational

procedures

designed

to

get

maximum

utility

and

safety

from

your

airplane.

iii