Beechcraft Bonanza V35B-TC User manual

NLJ

ech Gircrah nr pnration

OWNER'S MANUAL

SUPPLEMENT

for

K35, M35, N35,'P35, S35, V35, V35TC, V35A, V35A TC, V3SB, V35B TC

33, A33, B33, C33, E33, F33, G33, C33A, E33A, F33A, 36, A36.

The following information supersedes the information contained in the

Owner's Manuals for the above listed airplanes.

1. Maximum usable fuel of each 25 or 24½gallon main tank is 22

gallons.

2. Maximum usable fuel of each 39 or 40 gallon main tank is 37 gallons.

3. Approximate reduction in range with full fuel due to change in usable

fuel is:

a. 13%on 22 gallon main tank system.

b. 9% on 37 gallon main tank system.

4. On Models K-35, M-35, 33, and A33 Owners Manuals, reduce range by

an additional 190 statute miles to account for climb and 45 minutes

reserve at 45% maximum continuous power.

P/N 35-590118-17 Issued:February 11, 1972

THANK YOU ...

for displaying your confidence in us by selecting a BEECHCRAFT

airplane. Our design engineers, assemblers, and inspectors have utilized

their skills to ensure that your new BEECHCRAFT Bonanza V35B-TC

excels all other airplanes in its class in structural integrity, performance,

workmanship, economy, and comfort.

IMPORT ANT NOTICE

This manual should be read carefully in order that you may

become familiar with the operation of your Bonanza V35B-TC.

Suggestions and recommendations have been made within it to

help you obtain maximum performance without sacrificing

economy. Furthermore, you should also be familiar with and

operate your new BEECHCRAFT in accordance with the Federal

Aviation Administration Approved Flight Manual and/or the

FAA Approved Placards which are located in your

BEECHCRAFT.

As a further reminder, you should also be familiar with the applicable

Federal Aviation Regulations concerning operation and maintenance of

the airplane and FAR Par 91 General Operating and Flight Rules.

Likewise your aircraft must be operated and maintained in accordance

with FAA Airworthiness Directives which may be issued against your

BEECHCRAFT.

The operation, care, and maintenance of your airplane after it is

delivered to you is your responsibility. However, your authorized

BEECHCRAFT Sales & Service Outlets will have all recommended

modification, service, and operating procedures issued by both FAA

and Beech, designed to get maximum utility and safety from your

airplane.

In an effort to provide you with as complete coverage as possible,

applicable to any configuration of the Bonanza V35B-TC, optional

equipment has been included in the scope of this manual. Because of

the versatility of the appointments and arrangements of the aircraft, the

equipment described or depicted herein may not be designated as

optional equipment in every case.

35-590118-7 Issued: November 6, 1969

LIST OF EFFECTIVE PAGES

INTRODUCTION

List of Effective Pages

i through iii

1-1 through 1-21

2-1 through 2-6

3-1 through 3-7

4-1 through 4- 6

5-1 through 5- 7

6-1 through 6-21

7-1 through 7-9

8-1 through 8-3 I

A Bonanza V358-TC

Original

Original

Original

Original

Original

Original

Original

Original

Original

Original

Original

TABLE OF CONTENTS

SECTION I Description and Operation of Systems . 1-1

SECTION II Operating Check Lists . 2-1

SECTION Ill Normal Procedures . 3-1

SECTION IV Emergency Procedures .4-1

SECTION V Limitations . 5-1

SECTION VI Performance . 6-1

SECTION VII Optional Equipment . 7-1

SECTION VIII Servicing . 8-1

Turbo-Bonanza V35B-TC

35-590118-7*2

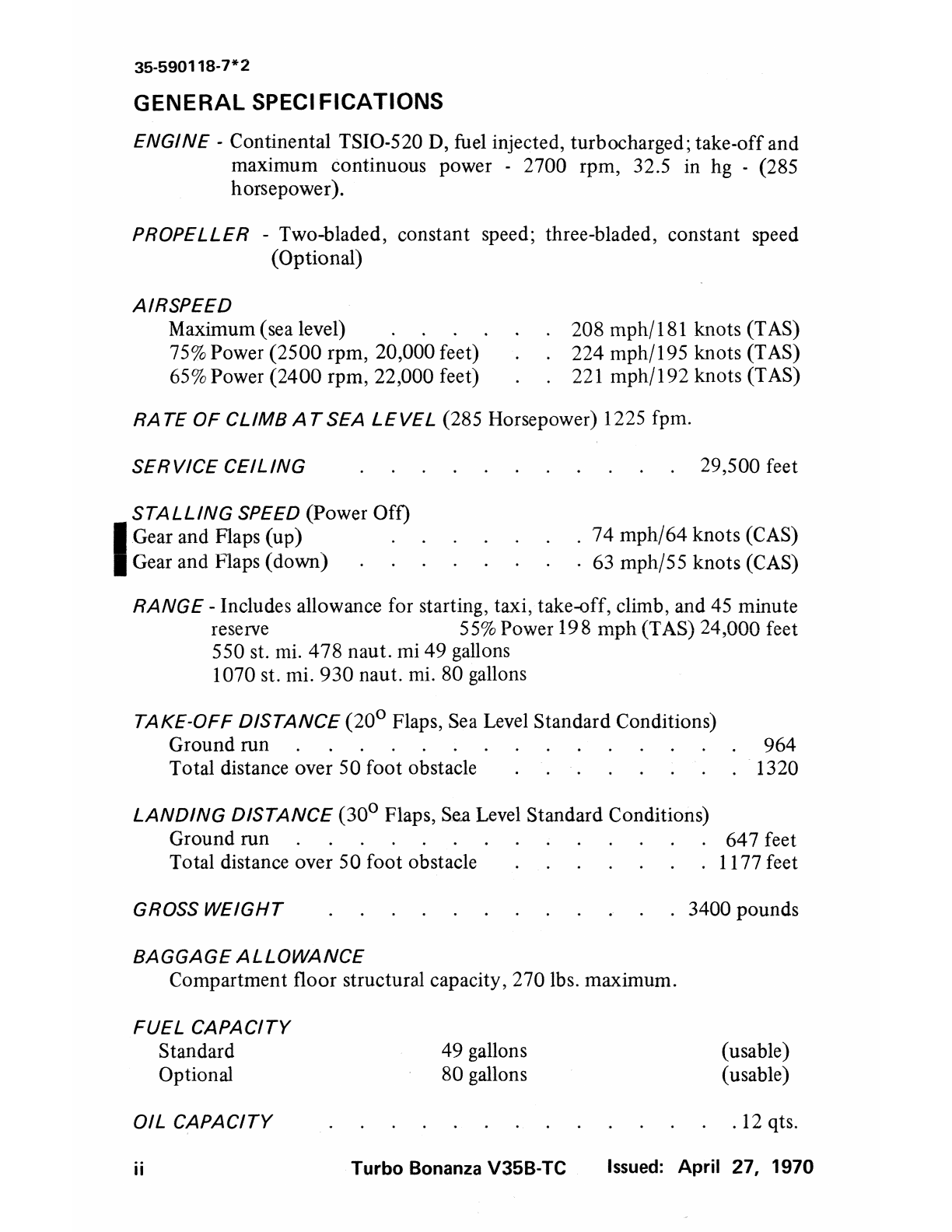

GENERAL SPECIFICATIONS

ENGINE· Continental TSI0-520 D, fuel injected, turbocharged; take-off and

maximum continuous power - 2700 rpm, 32.5 in hg - (285

horsepower).

PROPELLER -Two-bladed, constant speed; three-bladed, constant speed

(Optional)

AIRSPEED

Maximum (sea level)

75%Power (2500 rpm, 20,000 feet)

65%Power (2400 rpm, 22,000 feet)

208 mph/181 knots (TAS)

224 mph/195 knots (TAS)

221 mph/192 knots (TAS)

RA TE OF CLIMB AT SEA LEVEL (285 Horsepower) 1225 fpm.

SERVICE CEILING 29,500 feet

STALLING SPEED (Power Off)

I

Gear and Flaps (up) .

Gear and Flaps (down) . .

. 74 mph/64 knots (CAS)

. 63 mph/55 knots (CAS)

RANGE -Includes allowance for starting, taxi, take-off, climb, and 45 minute

reserve 55%Power 198 mph (TAS)24,000 feet

550 st. mi. 478 naut. mi 49 gallons

1070 st. mi. 930 naut. mi. 80 gallons

TAKE-OFF DISTANCE (20° Flaps, Sea LevelStandard Conditions)

Ground run 964

Total distance over 50 foot obstacle · 1320

LANDING DISTANCE (30° Flaps, Sea Level Standard Conditions)

Ground run 647 feet

Total distance over 50 foot obstacle . 1177 feet

GROSSWEIGHT

BAGGAGE ALLOWANCE

3400 pounds

Compartment floor structural capacity, 270 lbs. maximum.

FUEL CAPACITY

Standard

Optional

OIL CAPACITY

ii

49 gallons

80 gallons

Turbo Bonanza V358-TC

(usable)

(usable)

.12 qts.

Issued: April 27, 1970

7' 7"

91 7. l"---1

---------33' 5. 5"---------.;

Turbo-Bonanza V35B-TC iii

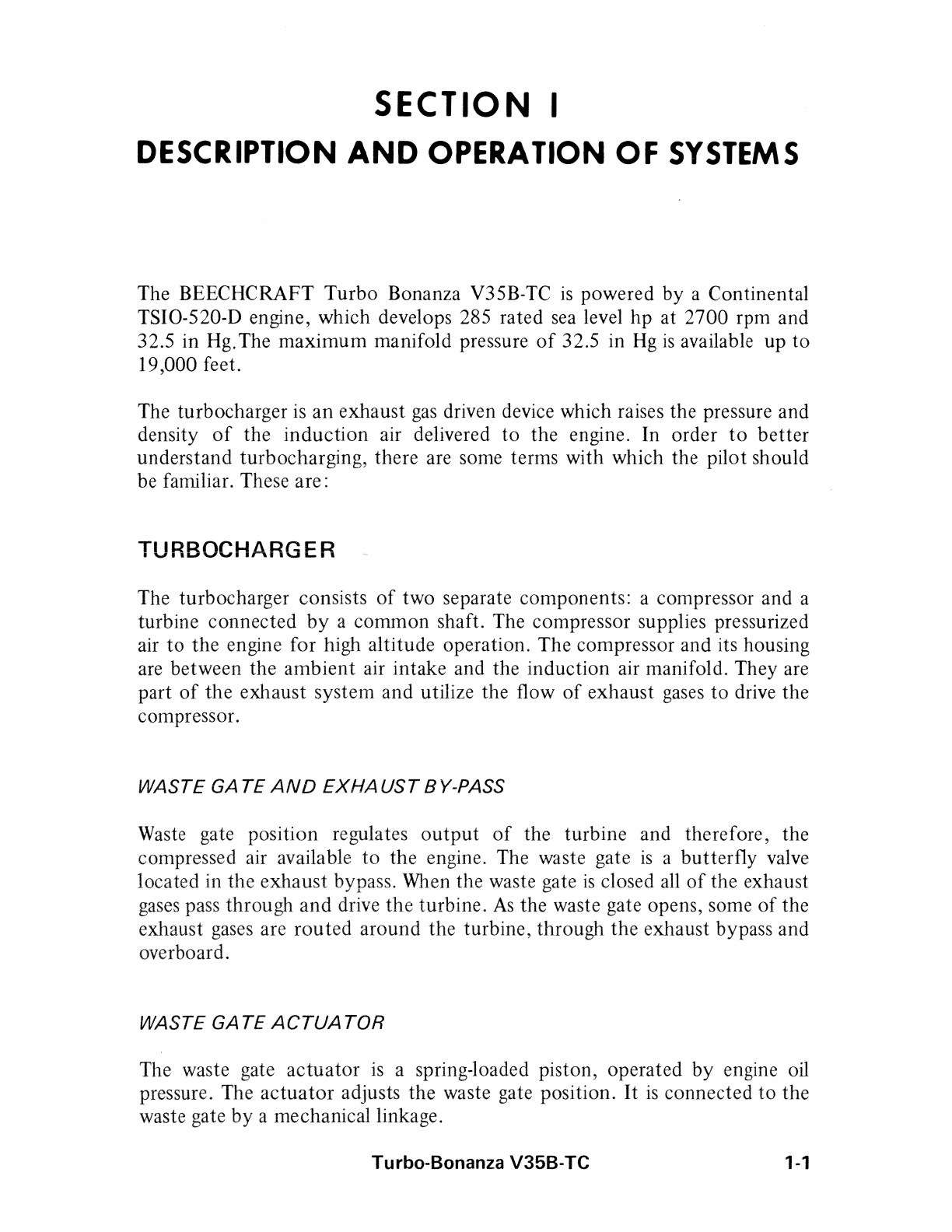

SECTION I

DESCRIPTIONAND OPERATIONOF SYSTEMS

The BEECHCRAFT Turbo Bonanza V35B-TC is powered by a Continental

TSI0-520-D engine, which develops 285 rated sea level hp at 2700 rpm and

32.5 in Hg.The maximum manifold pressure of 32.5 in Hg is available up to

19,000 feet.

The turbocharger is an exhaust gas driven device which raises the pressure and

density of the induction air delivered to the engine. In order to better

understand turbocharging, there are some terms with which the pilot should

be familiar. These are:

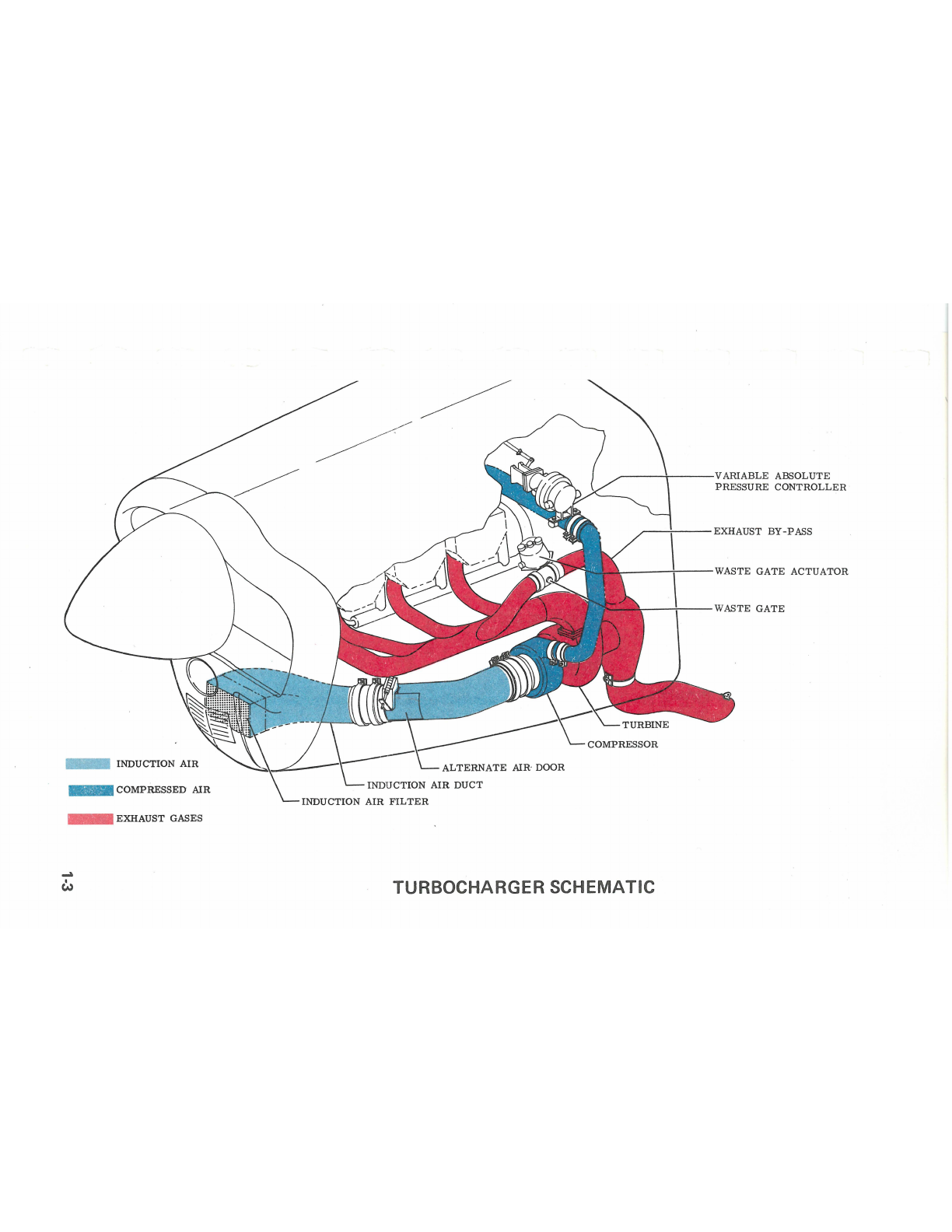

TURBOCHARGER

The turbocharger consists of two separate components: a compressor and a

turbine connected by a common shaft. The compressor supplies pressurized

air to the engine for high altitude operation. The compressor and its housing

are between the ambient air intake and the induction air manifold. They are

part of the exhaust system and utilize the t1ow of exhaust gases to drive the

compressor.

WASTE GA TE AND EXHAUST BY-PASS

Waste gate position regulates output of the turbine and therefore, the

compressed air available to the engine. The waste gate is a butterfly valve

located in the exhaust bypass. When the waste gate is closed all of the exhaust

gases pass through and drive the turbine. As the waste gate opens, some of the

exhaust gases are routed around the turbine, through the exhaust bypass and

overboard.

WASTE GATE ACTUATOR

The waste gate actuator is a spring-loaded piston, operated by engine oil

pressure. The actuator adjusts the waste gate position. It is connected to the

waste gate by a mechanical linkage.

Turbo-Bonanza V35B-TC 1-1

VARIABLE ABSOLUTE PRESSURE CONTROLLER

The control center of the turbocharger system is the variable absolute

pressure controller. This device simplifies turbocharging to one control, the

throttle. Once the pilot has set the desired manifold pressure, virtually no

throttle adjustment is required with changes in altitude. The controller senses

compress Grdischarge pressure requirements for various altitudes, and controls

the oil pressure to the waste gate actuator which adjusts the waste gate

accordingly. Thus, the turbocharger maintains only the manifold pressure

called for by the throttle setting. This provides an efficient engine .

turbocharger combination, due to slower turbine speeds, lower exhaust back

pressure, and less compressor heat rise.

CRITICAL ALTITUDE

The critical altitude is that altitude at which the waste gate moves to the fully

closed position. It is determined when, at full throttle, the desired manifold

pressure is no longer attainable at a given rpm. This altitude will vary

considerably with air temperature, rpm, fuel flow and airspeed.

The following steps illustrate the operation of the system:

1. Induction air is taken in through the air filter and ducted to the

compressor.

2. The induction air is then compressed and ducted to the engine.

3. As the waste gate opens, some of the exhaust gases are routed around the

turbine, through the exhaust bypass and overboard.

4. When the waste gate is closed, all of the exhaust gases pass through and

drive the turbine, which, in turn, drives the compressor.

5. The exhaust gases are dumped overboard.

OPERATIONAL CHARACTERISTICS

Little difference exists between the operating techniques of the turbocharged

engine and the normally aspirated engine when operated below the critical

altitude.

Above the critical altitude certain operational characteristics must be

understood to fully realize the advantages and capabilities of the

turbocharged engine. These are as follows:

1-2 Turbo-Bonanza V35B-TC

- INDUCTION AIR

- COMPRESSED AIR

- EXHAUST GASES

...

c:.,

ALTERNATE AIR DOOR

,,.------------ VARIABLE ABSOLUTE

PRESSURE CONTROLLER

----'---EXHAUST BY-PASS

-----;\,--- WASTE GATE ACTUATOR

, WASTE GATE

TURBOCHARGER SCHEMAT IC

RPM EFFECT ON MANIFOLD PRESSURE

Above the critical altitude, any change in rpm will result in a like change in

manifold pressure. If, on a hot day with full throttle, the desired percent of

power is unattainable for a given rpm, a slight increase in rpm will produce a

significant increase in manifold pressure.

FUEL FLOW EFFECT ON MANIFOLD PRESSURE

Above the critical altitude, with rpm and manifold pressure established for

cruise, leaning will cause a slight increase in manifold pressure. When the

mixture reaches the recommended fuel flow, a slight reduction in manifold

pressure may be necessary.

AIRSPEED EFFECT ON MANIFOLD PRESSURE

Above the critical altitude, any change in airspeed will result in a

corresponding change in manifold pressure. This is true because the increase

in ram air pressure, with an increase in airspeed, is magnified by the

compressor resulting in an increase in manifold pressure. The increase in

manifold pressure creates a higher mass flow through the engine, causing

higher turbine speeds and thus further increasing manifold pressure. This

characteristic may be used to best advantage by allowing the aircraft to

accelerate to cruise speed after leveling off and prior to reducing power.

ENGINE RESPONSE AT HIGH ALTITUDE

Response from normal cruise power to maximum power is nearly

instantaneous at high altitude. In the event the engine is idled, it may be

necessary to lean the mixture, after application of partial throttle, to regain

the turbocharger speed.

EFFECT OF AMBIENT TEMPERATURE ON POWER

The V35B-TC engine will vary its power 1% for every 6°F above or below

standard day temperatures. An increase in temperature will result in a

decrease in power. To attain a given percent of power will then require

increases in manifold pressure with increases in ambient temperature. For

power settings, refer to the Horsepower Settings Chart in Section VI.

1-4 Turbo-Bonanza V35B-TC

CAUTION

The engine manufacturer limits the manifold pressure to

32.5 in Hg.Particular care should be taken in cold weather

when operating with cold oil to avoid exceeding this

limitation. The last 1 - 1/2 inches of throttle travel should

be applied slowly while monitoring the manifold pressure

gage.

FLIGHT CONTROLS

Control surfaces are operated through push-pull rods and conventional cable

systems terminating in bellcranks. The preformed steel cables run over

phenolic pulleys, to minimize wear.

CONTROL COLUMN

The throw-over type control column for elevator and aileron control can be

placed in front of either front seat. Pull the I-handle latch at the base of the

control arm and position the control column as desired. The aileron trimmer

on the control column hub should be held until the column is repositioned.

RUDDER PEDALS

To adjust the rudder pedals, press the spring-loaded lever on each pedal arm

and move the pedal forward or aft. The adjustment lever can also be used to

place the right-hand set of rudder pedals against the floor when not in use.

TRIM CONTROLS

Elevator trim is controlled by a handwheel located to the left of the throttle.

An elevator tab indicator dial is located above and to the left of the trim

control handwheel.

The aileron trimmer on the control column hub displaces the ailerons:

displacement is maintained by cable loads imposed by the trimmer.

WING FLAPS

The wing flaps are controlled by a three-position switch, UP, OFF and

DOWN, located in the subpanel, above the power quadrant. The switch

Turbo-Bonanza V35B-TC 1-5

must be pulled out of detent before it can be repositioned. A dial type

indicator has markings for UP, JO DEGREES, 20 DEGREES and DOWN. The

indicator is located to the left of the control column.

Limit switches automatically turn off the electrical motor when the flaps

reach the extremes of travel. Intermediate flap positions can be obtained by

placing the three-position switch in the OFF position during flap extension or

retraction.

POWER PLANT CONTROLS

THROTTLE, PROPELLER, AND MIXTURE

The push-pull throttle, propeller, and mixture controls are located on the

control console below the center of the subpanel. Each control is released for

repositioning by pushing a button on the knob. With the control secured, fine

adjustments are accomplished by rotating the knob.

if oil pressure is lost, the propeller will go to the full low pitch (high rpm)

position. This is because propeller high pitch (low rpm) is obtained by

governor boosted engine oil pressure working against the centrifugal twisting

movement of the blades.

ALTERNATE AIR

A pull-and-release handle below the propeller control can be used to force

open the alternate air source door in the air intake duct, should the door

become frozen shut. (See Induction System Icing, Section III.)

COWL FLAPS

The forward cowl flaps push-pull control is located directly below the

propeller control. These flaps are to be used as necessary to control engine

temperature with the rear cowl flaps open.

The rear cowl flaps push pull control is located above and to the left of the

throttle control. These flaps are to be open for take-off and climb, closed for

cruise.

1-6 Turbo-Bonanza V358-TC

COWLING

The Bonanza V35B-TC is equipped with Hartwell latch mechanisms on the

right and left upper engine cowling for quick and easy access to the engine

compartments without the aid of tools. Each cowl latch is locked and

released by a single, recessed handle located in the lower cowlmg panel on

each side of the engine. To close the cowling requires only to lower the

cowling to the closed position with the handle in the precatch position. The

handle has three positions; flush with the fuselage • latched: Held fully

forward - unlatch (Open Cowling); Approximately 9rP to the fuselage -

precatch (ready to close cowl). An audible click denotes the bayonet fittings,

located forward and aft on the upper cowl, sliding into the latch safety catch.

The cowl is locked by moving the latch handle to the full recessed position.

The security of the forward latches can be checked by pulling out on the

check tab attached to the lower forward edge of the upper cowling. If the

cowling can be moved after latching, open the cowling and check the latch

alignment and re-latch.

LANDING GEAR SYSTEM

CONTROL SWITCH

The landing gear is controlled by a two-position switch on the right side of

the subpanel. The switch handle must be pulled out of the safety detent

before it can be moved to the opposite position.

POSITION IND/CA TORS

The landing gear position indicator lights are located adjacent to the landing

gear switch handle. Three green lights, one for each gear, are illuminated

whenever the landing gears are "down and locked". The red light illuminates

any time one or all of the landing gears are in transit or in any intermediate

position. All of the lights will be out when the gears are up and locked. The

nose gear also has a mechanical pointer, located at the base of the pedcstaL

which gives the positive position of the nose gear at all times. Pressing the

warning light test button on the instrument panel will verify the landing gear

lamp bulbs are illuminating. The intensity of the lamps are automatically

lowered for night flights when the navigation lights are turned on.

SAFETY SWITCH

To prevent inadvertent retraction of the landing gear on the ground, a safety

switch on the right hand main strut opens the control circuit when the strut is

compressed.

Turbo-Bonanza V35B-TC 1-7

CAUTION

Never rely on the safety switch to keep the gear down

during taxi or on take-off or landing roll. Always make

certain that the landing gear switch is in the down position

during these operations.

WARNING HORN

With the landing gear retracted, if the throttle is retarded below

approximately 12 in Hg manifold pressure, a warning horn on the cabin

forward bulkhead will sound intermittently.

CIRCUIT BREAKER

The landing gear circuit breaker is located on the right hand subpanel. This

circuit breaker is the only pull and reset type breaker on the panel. The

breaker will pop-out under overload conditions.

MANUAL EXTENSION

The landing gear can be manually extended by operating a handcrank at the

rear of the front seats. This procedure is described in Section IV.

BRAKES

The brakes on the main landing gear wheels are operated by applying toe

pressure to the rudder pedals. The parking brake push-pull control is located

on the left side of the lower subpanel. To set the parking brakes, pull the

control out and pump each toe pedal until solid resistance is felt. Push the

control in to release the brakes.

1-8

NOTE

The parking brake should be left off and wheel chocks

installed if the airplane is to be left unattended. Changesin

ambient temperature can cause the brakes to release or to

exert excessive pressures.

Turbo-Bonanza V35B-TC

INSTRUMENTS

ENGINE INSTRUMENTS

The multiple readout engine gage located on the lower left instrument panel,

contains the cylinder head temperature, oil temperature and oil pressure

indicators. The tachometer and a combination manifold pressure and fuel

flow indicator gage, fuel quantity gages and the ammeter are located in the

upper center of the instrument panel.

MUL TJPLE INSTRUMENT GAGE

The cylinder head temperature is calibrated in °F. The sensor is installed in

the engine cylinder, that due to its location in the engine compartment, has

the highest temperature reading. Monitor the cylinder head temperature gage

whenever power setting adjustments are made to assure that the engine

operating temperatures are not exceeded.

The oil pressure normal operating range is 30 to 60 psi. The Oil Pressure Gage

should be checked when starting the engine and with extra attention when

starting during cold weather. The oil temperature operating range is Ioo°Fto

240°F. Monitor the oil temperature gage after starting to assure temperature

is above minimum before advancing the throttle and on descending with

power reduced to avoid overcooling.

MANIFOLD PRESSURE AND FUEL FLOW INDICATOR

The manifold pressure portion of this instrument indicates the pressure of the

fuel-air mixture entering the engine cylinders and is calibrated in inches of

mercury. By observing the manifold pressure gage and adjusting the propeller

and throttle controls, the power output of the can be adjusted to any

of the power settings designated in the power charts in Section VI.

The fuel flow portion of the indicator is calibrated in gallons per hour, the

green arc indicating fuel flow for normal operating limits. Red radials are

placed at the minimum and maximum allowable fuel pressures, as indicated at

the fuel injection manifold valve.

In the cruise power range the green sectors cover the fuel flow required from

45% to 75% power. The lowest value of a given sector is the lean limit setting

Turbo-Bonanza V35B-TC 1-9

1-10

\J

Ci)

~:

' 'O

000

and the highest value of the sector is the best-power setting for that particular

power range.

The take-off and climb range is covered by green sectors for full power at

various altitudes. The full power markings represent the maximum

performance mixtures for the altitudes shown, permitting leaning of the

mixture for maximum power and performance during high altitude take-offs

and full power climbs.

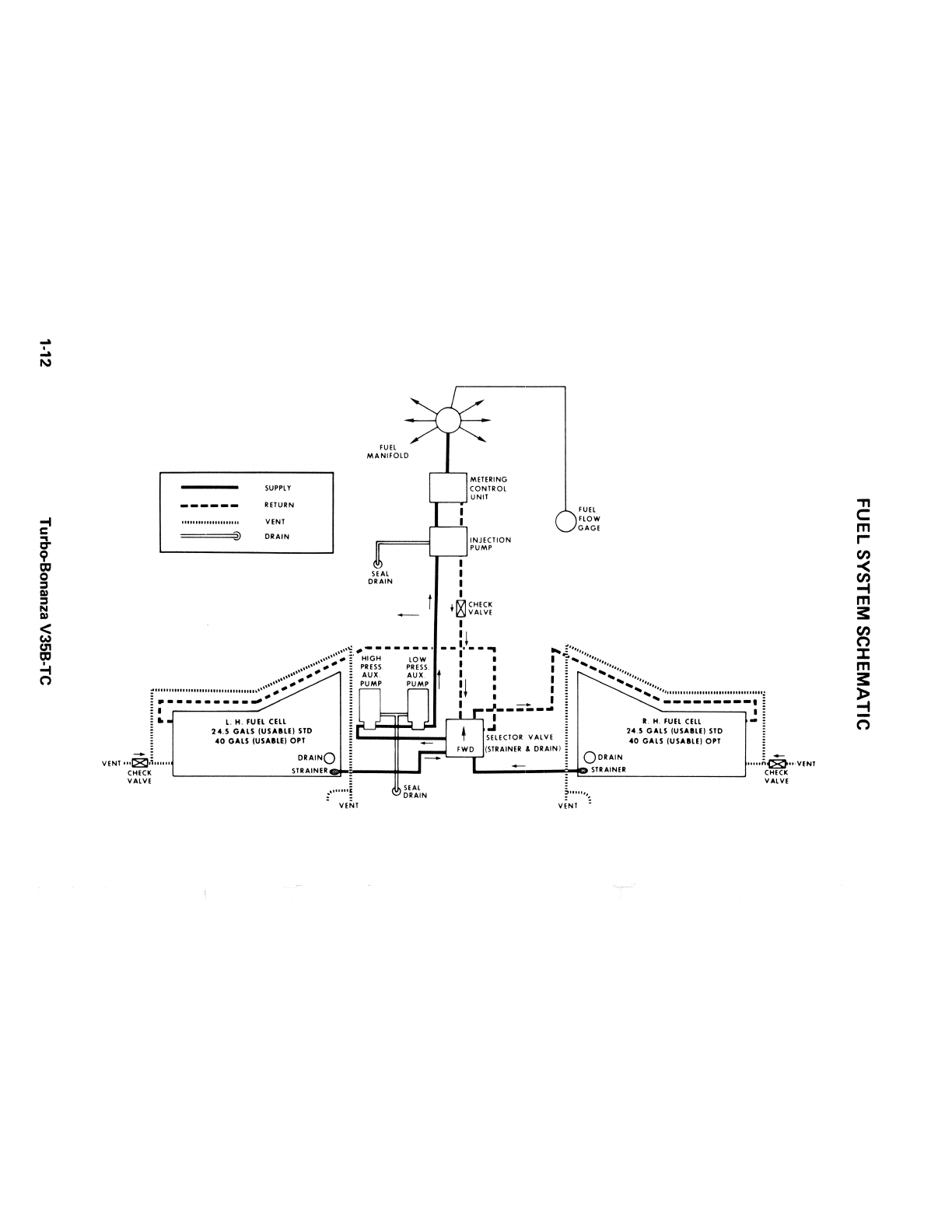

FUEL SYSTEM

The aircraft is designed for operation on 100/130 grade aviation gasoline. In

the event this grade is not available only a higher rated fuel shall be used.

FUEL CELLS

Either the 49 gallon usable standard fuel system or the 80 gallon usable

optional fuel system is available for the Turbo Bonanza. The fuel system

consists of a rubber fuel cell tank in each wing leading edge with a flush type

filler cap. A visual measuring tab is attached to the filler neck to indicate

different levels of servicing. The engine driven fuel injector pump delivers

approximately 10 gals of excess fuel per hour, which bypasses the fuel

control and returns to the tank being used. Three fuel drains are provided,

one in each fuel sump on the underside of each wing and one at the fuel

system low point inboard of the left wing root.

FUEL QUANTITY

Fuel quantity is measured by float operated sensors, located in each wing

tank. These transmit electrical signalsto the individual gagesthat indicate fuel

remaining in the tank. There are two sensors in each wing tank system

connected in series to the individual wing tank gage.

AUXILIARY FUEL PUMP

The electrical auxiliary fuel pumps are controlled by a HI-OFF-LO toggle

switch on the control console. Immediately after starting, the LO auxiliary

fuel pump can be used to purge the system of vapor caused by an extremely

Turbo-BonanzaV35B-TC 1-11

...

.

...

N

I

i

!t

n

===@

SUPPLY

RETURN

VENT

DRAIN

SUL

DRAIN

I

I

I

I

• IQ!CHECK

~VALVE

I

FUEL

FLOW

GAGE

Ii

,,,••':---- -- __ , - -:· - - .. .....=••,,,,,

,,,,,,,.-I HIGH LOW I I I , .....,,,,,,,,

,,,,,, # _. : PRESS. PRESS. I I : ._.._, ,,,,,,

,,,••··~-- : AUX. AUX I I I ; ...., ..,,,,,

,,,,,,,.,, - :; PUMP PUMP lj I : --.,..._ ,,,,,,,

;: 111111 11u1111111111111111uu11111u•' (/1, E I I ! ......._ '•••11111111111111111111111111111111111:

E·------------ ; I : - I i ...,_________ , i

: I ,-------' : _______ .. : "--------, I :

i • L. H. FUELCELL i l'LJ" __ ....__,_ I i I. H. FUELCELL • i

: 24.5 GALS (USAIU) STD i ---1+---~ .I : 24.5 GALS (USAILE) STD (

40 GALS tUSAILE) OPT i re-::-,_ _ __.(:~~~~~~: &V~~~~N) i 40 GALS (USAlf.E) 0'1

VENt111L81,tu111 DRAINQ i - i QoRAIN ,... Jcii,.11,VENT

CHECK STRAINER : : STl:AINElt CHECK

VALVE i i VALVE

.. SEAL :

!1111111 ~ DRAIN :' 11111 •• ..

.. veNt vENt =

.,,

C:

m

r-

(1)

m

31:

::t

m

31:

C')

high ambient temperature or a start with the engine hot. LO boost should

also be used during the climb above 8000 feet and at high altitude cruise, if

required to stabilize fuel flow. HI boost provides for near maximum engine

performance should the engine driven pump fail.

FUEL TANK SELECTION

The fuel selector valve handle is located forward and to the left of the pilot's

seat. Ordinarily, take-offs and landing should be made using the cell that is

more nearly full.

If the engine is allowed to stop firing, due to insufficient fuel it is important

that the following procedure be observed.

I. Retard the throttle to prevent an engine overspeed condition.

2. Mixture - FULL RICH.

3. Switch to the other cell, visually checking the fuel selector valve.

4. Turn the auxiliary fuel pump to the LO position until power is regained.

5. Advance the throttle to the desired position.

OIL SYSTEM

The engine oil system is the full-pressure, wet sump type and has a 12-quart

capacity. Oil operating temperatures are controlled by an automatic

thermostat bypass control. The bypass control will limit oil flow through the

oil cooler when operating temperatures are below normal and will permit the

oil to bypass the cooler if it should become blocked. A full-flow, integrally

mounted oil filter is provided. See Section VIII for servicing procedures.

ELECTRICAL SYSTEM

The system circuitry is the single wire, ground return type, with the aircraft

structure used as the ground return. The battery OFF-ON switch, the

alternator OFF-ON switch and the key lock start switch are located on the

left subpanel. The circuit breaker panel is located on the right subpanel and

contains the protective circuit breakers for the various electrical systems.

Some switch type circuit breakers are located on the left subpanel.

BATTERY

A 33 ampere hour, 12-volt battery is located on the right hand forward side

of the firewall. Battery servicingprocedures are described in Section VIII.

Turbo-Bonanza V35B-TC 1-13

Table of contents

Other Beechcraft Aircraft manuals

Beechcraft

Beechcraft BE76 Duchess User manual

Beechcraft

Beechcraft Duke 60 Series User manual

Beechcraft

Beechcraft KING AIR C90 Owner's manual

Beechcraft

Beechcraft Baron B55 User manual

Beechcraft

Beechcraft Baron 58 Owner's manual

Beechcraft

Beechcraft C-12C Use and care manual

Beechcraft

Beechcraft Debonair C33 User manual

Beechcraft

Beechcraft Debonair 35-33 Owner's manual

Beechcraft

Beechcraft C23 SUNDOWNER 180 Owner's manual

Beechcraft

Beechcraft Bonanza 36 Owner's manual