Beechcraft Baron B55 User manual

Military Visualizations Beechcraft® Baron® B55 Quick Start Guide

Here it is! The bare bones! The “kick the tires and light the fires and get airborne guide.”

You read this and you get off the ground. You want to

learn how the airplane actually works and flies properly,

then you read the Pilot’s Operating Handbook (POH)

when you feel like it.

Step one: You have booted up FSX in Free Flight and

you’re sitting in the cockpit. On the keyboard, press Shift-

1 to bring up the setup menu box (figure 1). If you

want a two-blade prop, click the “Swap Props” button Figure 1

red. You want three blades again, click it green! You want to remove the chocks, click that

button. Click it again to bring them back. You want the pilot visible and the engine plugs and

pitot covers removed, then click that button to make it green. Want the pilot gone and the

plugs and covers back, click it red.

Step two: You want to light the fire! OK, here’s how:

1. On the left side of the cockpit, beside the yoke, see that box (figure 2)? It has your starter

buttons, master battery switch, and left/right

alternator switches. See the triangular arrayed

switches (figure 3)? The top of the triangle is the

master battery. The two base switches are the left

and right alternator switches. Flip all three up to the

on positions.

Figure 2

2. Look in the center of the panel, see those six levers? The two in the middle are your

throttles –that’s right Beech put the throttles for the Baron 55 in the middle! Use your

keyboard, mouse, or your physical controllers and push those two throttles forward about a

half inch forward from the full aft position. Make sure your two prop control levers are full

forward and the two mixture levers are full forward.

3. See that huge yoke? Covers up near everything doesn’t it? Let’s hide it temporarily!

See the bare aluminum shaft that pierces the panel in the center? Hover your mouse pointer

Figure 3

over the base where it pierces the panel and click it (figure 4). You want the yoke back? Click

that open hole and it comes back. Now that it’s hidden, we can see our way to the rest.

Figure 4

4. Reference the pilot’s lower panel with all those switches in a long row (figure 5). In the

center, there is one labeled “Beacon.” You should click it up to the on position. This turns on

the rotating red beacon light and warns people you’re about to turn on the engines. It is

ultimately the “Get out of the way or forever lose your head” warning!

Figure 5

Once the engines are started, and you have confirmed power is supplied by the alternators

(referencing the two load meters) you should turn on the rest of your lights. To learn more

about the details, plus also how to use the two auxiliary fuel pumps, please

read the POH.

5. Take another look at that left console panel (figure 2). See the two

vertically arrayed knobs (figure 6)? Those knobs perform two integrated

functions. They are starters as well as magneto switches. The top knob

controls the left engine and the bottom one controls the right engine. They

rotate clockwise and counter-clockwise by using your mouse to hover over

the knobs, click and hold the left mouse button, and slide the mouse right or

Figure 6 left to rotate the knobs. The starter is engaged when you rotate the knob

full clockwise. When you release the left mouse button the knob returns to the BOTH position

which activates the two magnetos.

Rotate those two starter/mag knobs to crank both engines. When you want to learn to check

the individual magnetos, you use those same knobs and rotate

them counter-clockwise to isolate the right and left mags for each

engine (note the “R” and “L” labels). When both engines are

started, then you are ready to proceed to the next step.

Figure 7

Step three: Turn on the rest of your lights and your avionics on the radio stack. To turn on the

avionics, reference the left side of the pilot’s panel and you will see one lone switch labeled

“Radio Master” (figure 7). This is your avionics master switch labeled in the style things were

named back in the era this aircraft was constructed. Once you toggle this switch on you should

see the avionics on the radio stack turn on. To operate the two Garmin GPS/Moving Map

Comm/Nav radio units, you must read the separate manuals provided in your aircraft’s folder in

FSX.

Step four: Now you are ready to taxi. You should know how to use the FSX menus for radio

interaction and control. So, do what you need to do to taxi to the runway. Line up for takeoff

and apply brakes. Throttle up to 2100 RPM’s with the brakes applied and reference your

engine instruments (on the far right side of the pilot’s panel – yep they are just that

conveniently located in the real airplane also!). If all looks good, release the brakes and

smoothly apply full power. Note: the plane will require significant degrees of rudder inputs to

maintain runway centerline. This is how it really is. How do you learn to do it accurately and

keep on centerline? Three words: Practice, Practice, Practice!

Step five: See the airspeed gauge. The red line (called the red radial) on the airspeed gauge at

the 80 KIAS mark is your Vmc (minimum control airspeed on single engine). If you want to

learn all about the Vmc speed, you need to read the POH! When your airspeed reaches that

mark, rotate for takeoff. It’s a powerful airplane here, don’t try to zoom up like an F-15C! Keep

the pitch within five degrees up or you will see things happen you don’t want to see happen!

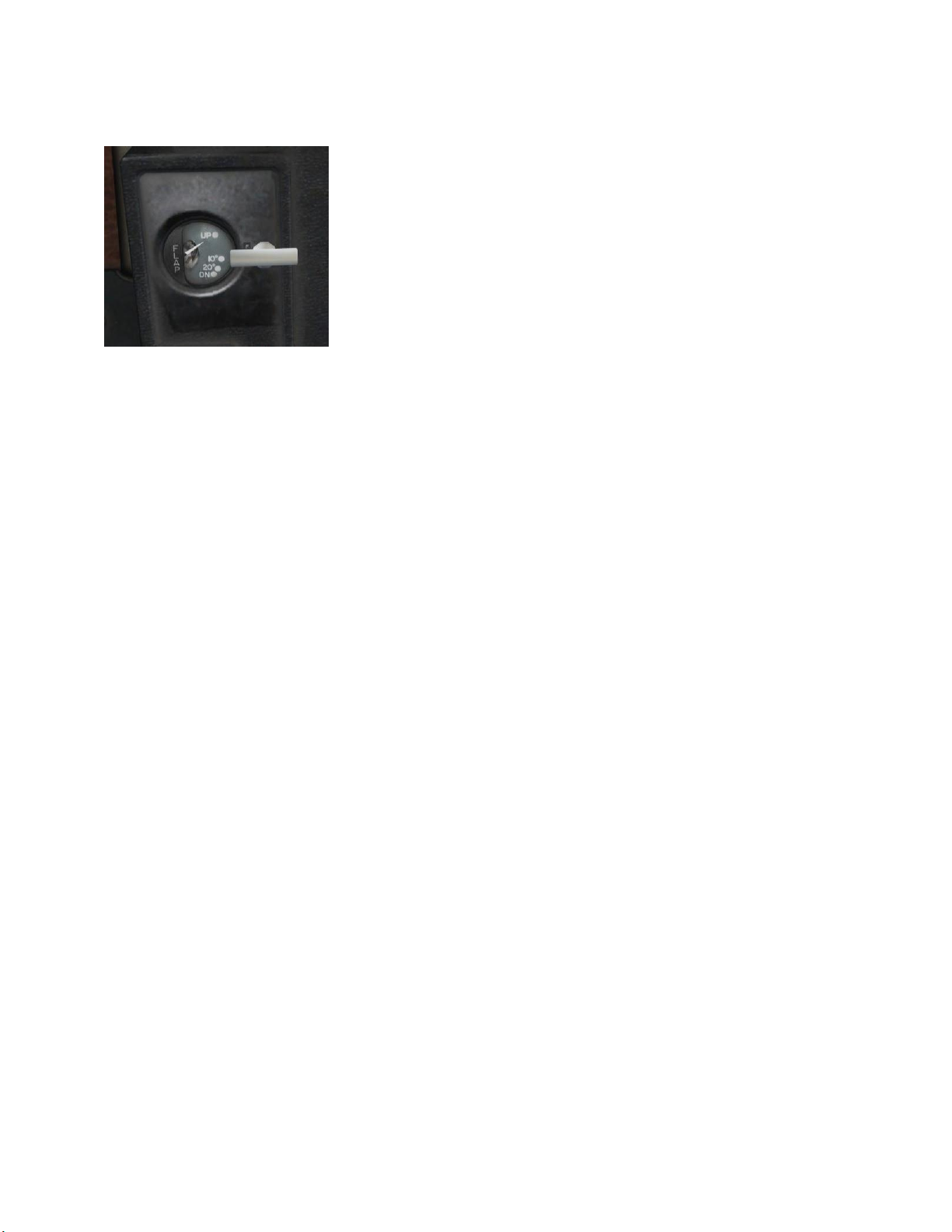

Step six: When you get airborne, you need to retract the gear. Locate the

gear handle (figure 8), which is located in a marvelously convenient and easy

to see location in the real airplane (putting tongue back in cheek now!). This

is why we allow you to hide the yoke bar! That gear lever is located on the

left half of the center console just below the mixture levers.

You can either cycle the gear using a physical controller button (the easy

way) or use your mouse to hover over top of the virtual knob in the VC,

left click and hold, then slide the mouse to toggle the handle up or down

way). Either way, the gear will retract. When the three green lights are

all illuminated, then it means all three landing gear are down and locked

and you can safely land on the gear. When the red light is illuminated, it

means the gear are “in transit,” meaning they are either moving up to retract or moving

down to extend. When all the lights are off it means the landing gear are fully retracted.

Step seven: Now you are flying, and frankly at this point if you want to understand all the

myriad of factors involved in properly flying a piston twin aircraft, you have no choice but to

read the POH. Because if we tried to explain it all here, then we’d duplicate the POH in about

all its slightly over 100 page glory! So, once again, please allocate the time to read the POH.

Figure 8

At the minimum, you will need to trim the elevators very frequently as speed and power

settings are changed. The easiest way to trim is to assign the function to a physical controller

button, ideally a rocker type button. When we say “trim constantly,” we mean just that!

Airplanes like this don’t fly automatically. They require constant loving attention from the pilot

and trim is essential to make the it friendly. The best description is that you force the yoke in

the position required to achieve the flight condition you desire, and then you trim out the

control forces your muscles are exerting. This is where pilots learn to become pilots and once

you learn, you learn to love doing it!

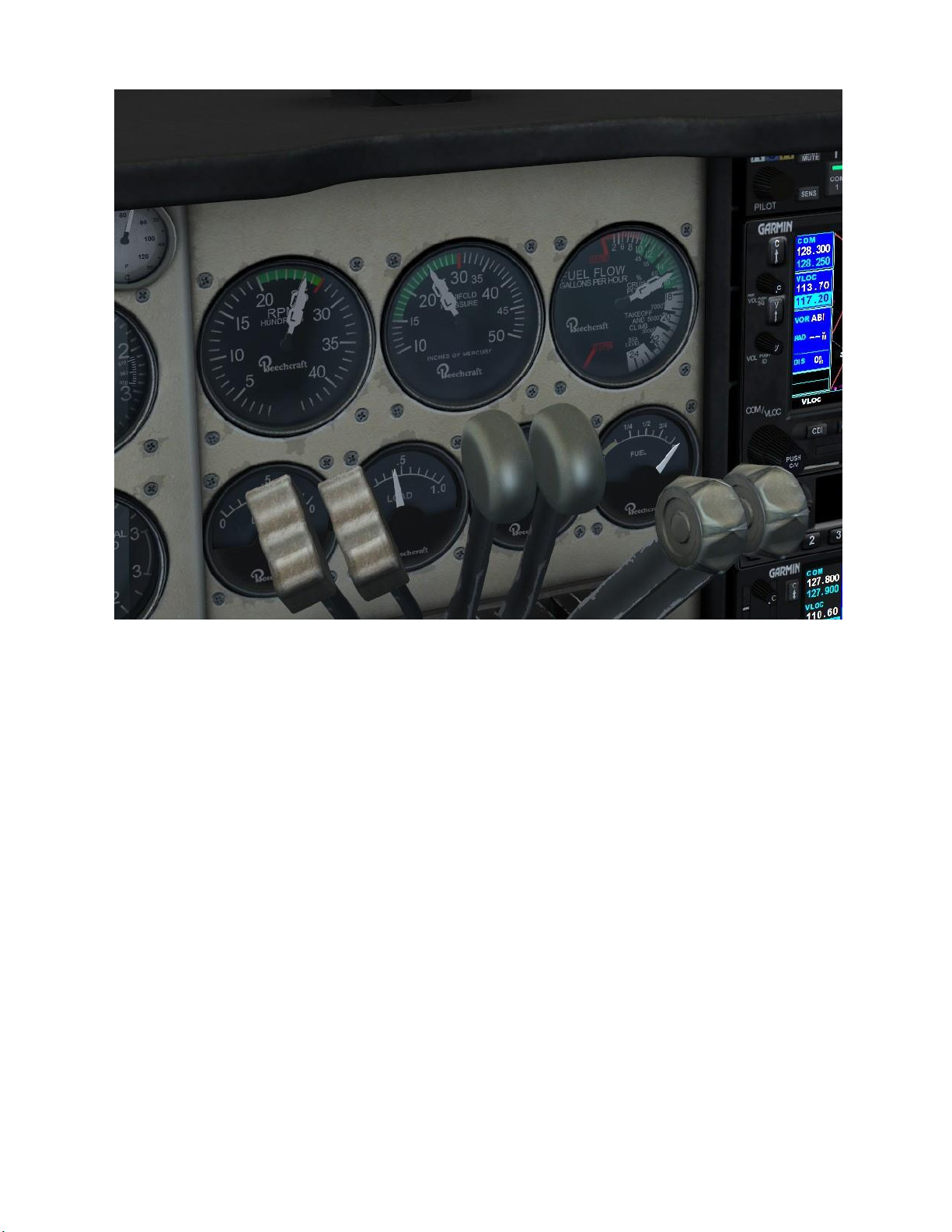

To climb, you set what is called “25 squared.” This means you set 25 inches of manifold

pressure (or full throttle when the air gets too thin above 5,000 feet MSL to no longer allow 25

inches of MP), and 2500 RPM’s. Additionally, you have to lean the engine’s fuel flows as you

climb into the thinner air. To do this, you use the two mixture controls on the right side of the

throttle quadrant. You have a fuel flow gauge to the immediate right of the Manifold Gauge to

help this leaning function. Where the bottom of the green arc is located, you see something

labeled 75% power. Lean back until the two needles (for left and right engines) mark this

position.

At this point, you have leaned out to optimal fuel/air ratio and are producing the maximum

amount of power you can at your current manifold and RPM settings (figure 9). Properly

controlling aircraft power in the myriad of flight conditions associated with climb, cruise, and

descent is complicated and once again can only be fully understood with a complete reading of

the POH!

Figure 9

Note that in figure 9 how the six levers on the throttle quadrant are arrayed, and how the

needles on the three primary engine gauges appear. This is the quintessential “25 squared”

setting as you can see how the RPM, manifold, and fuel flow values are symmetrical for the left

and right engines (overlapping needles) and are set at 2500 RPM’s, 25 inches of MP, and that

75% power fuel flow status. Note, this screen capture was taken just as the aircraft was passing

5,000 feet MSL and that is why the throttles in the center are full forward. Climb above 5,000

feet MSL will see the MP decline the higher you go from there even with the throttles full

forward.

Step eight: There is an old as aviation adage, “Takeoffs are optional – landings are mandatory!”

Now it is time to think about landing. Piston twins are designed for raw climb power and

speed. So, to land them we have to fly them slower than their ideal cruising speeds. To do this,

we need to know the proper power and aircraft attitude management techniques, which is a

fancy way of saying to configure the flaps and gear, plus use the engine controls (throttles, prop

controls, and mixtures) to set the ideal manifold pressures and RPM’s on the left and right

engines.

One of the prime pieces of gear used to perform slower flight required to approach and land

are the flaps. To control the flaps on this Baron 55, you have a

flap handle located on the left side of the center throttle console

(figure 10).

In the real airplane, you have to press and hold the flap handle

down or up to extend or retract the flaps, and then you release

when the indicator immediately left shows the desired flap

setting. In this virtual Baron 55, you should assign the flaps

operation to a two-way button on your physical controller. In

Figure 10 addition, vice flaps anywhere you practically want them, you have

two positions pre-set and selected in sequence.

You can also perform this operation by hovering the mouse pointer over the handle, press and

hold the left mouse button, and slide the mouse to slew the handle down or up as desired.

Flaps are just a small part of the total. Ultimately, a good approach and landing is management

of power to attain and maintain desired speeds and pitch on approach, final approach, crossing

the runway, and ultimately touchdown. You then use constant elevator trim to remove any

control input forces on the yoke required to maintain the desired pitch. To measure all this,

use those same instruments shown in figure 9 and also reference your airspeed gauge. So, how

do we do this, in the nutshell?

1. When you get about ten miles from your destination airport, throttle down to about 19

inches of manifold pressure and wait for the airspeed to bleed down in level flight to at or

below 160 KIAS. Then, lower the flaps its first notch ONLY. (Note: if you drop the flaps to the

full down position of 30 degrees when faster than 122 KIAS, then you can damage the flaps.)

The speed should bleed down further to below 153 KIAS where you can lower the landing gear

without damaging it. Again, position the yoke to achieve the pitch angle required to maintain

level flight with this configuration and then trim the elevators to remove the yoke control

forces needed.

2. You should already be familiar with what is called an airport traffic pattern. If you are

not, then view the FSX tutorial pilot training videos. Once you understand the pattern, then

when you are on the downwind leg and abeam your intended touchdown spot on the runway,

lower your landing gear and set 17 inches of manifold pressure, push the prop control levers

full forward to their maximum RPM settings, and then set the mixtures to either their full

forward (full rich) position, or to the setting required for a high altitude airport (an airport

above 5,000 feet MSL). Trim the aircraft elevators to support a descent rate of about 500 feet

per minute and at a constant airspeed of 100 KIAS (referred to as Vyse or “blue line speed”

because of that long blue radial line on the airspeed gauge). If you want to know what the deal

is with Vyse and why it is so vital to safe operation of a piston twin, then again, read the POH!

3. When your intended runway touchdown spot gets behind your shoulder on about a 45

degree angle, then turn to your base leg. When the runway is at your ten o’clock position (no

wind), then turn to final approach. When you are about one to two miles from the approach

zone of the runway and the runway is clear and then commit to landing. Extend your flaps to

full down, and use your rudders to make very fine adjustments as necessary to remain on

runway centerline. As you approach the runway leading edge, smoothly throttle back to idle

and keep the nose pointed at your runway aim point (which should be about 300 feet prior to

your intended touchdown point).

4. When you are about a half a wing length above the runway (hopefully on centerline)

rotate the nose to level and watch the airspeed bleed down. (In real aviation, this become

more a feel of listening to the airstream plus gauging the speed of the ground rushing by as you

keep your eyes glued to the far edge of the runway to maintain orientation). As the speed

bleeds down close to stall speed, pull the yoke a bit more aft so you touchdown on the main

landing gear (this is called the flare).

In summary, good landings are essentially all about pitch, power and speed control. When you

need to increase descent rate, you reduce power and pitch the nose down. When you need to

decrease descent rate, you add power and pitch the nose up. You adjust the power and the

pitch the nose at the same time –this is called “pitch and power.” Pitch and power on

approach to land are like conjoined twins –they go together and stay together!

To accurately touchdown on the optimal spot on the runway, you use a three-step process,

called “Aim, Level, Flare.” On final approach, you aim the aircraft’s nose at a spot about 300

feet prior to your desired touchdown spot on the runway. As written above, when you get

about a half a wing’s length above the runway, you pull back the yoke and rotate the nose to

level pitch. As your airspeed approaches stall speed (bottom of the white arc on your airspeed

gauge with gear and flaps down) you pull the yoke back further to the nose high flare position,

which should be about five to ten degrees nose high. Ideally, this is done in one continuously

smooth and fluid yoke motion.

At this point, you should touchdown. If you have crosswinds, then you have to use rudder to

point the nose down centerline and use the ailerons to “bank into the wind” to cancel out any

sideways drift caused by the crosswind. This is called “cross-controlling” the aircraft. This is

easy to explain, but pulling it off accurately is rightly called the “artwork of piloting.” To perfect

this we have three words: Practice, Practice, and Practice!

One final point, nothing in aviation is perfect. While the principles of aviation are very much

scientific, the reality of piloting an airplane is very much practiced artwork based upon sound

understandings of the scientific principles involved! Once you study the POH, you will

reference the power settings and speeds required for a good approach to landing. But, you

must remember that every day is different in temperature and atmospheric conditions. A given

manifold pressure setting will achieve the ideal speed on one day, but on another day will need

tweaking to achieve the optimal speed. This becomes the variations in aviation that pilots also

come to love –the constant challenge of taking a machine into the air and plying your craft

with precision and skill.

Congrats! You have flown the Baron 55! Now, once the initial joy subsides, follow that most

timeless of all instructor admonitions to student pilots, “Get in the books!”

Cheers,

Ken Stallings

Military Visualization Staff

Contract US Air Force Instructor Pilot

FAA Commercial AMEL/ASEL Pilot

Beechcraft® Baron® B55 is a trademark of Textron Aviation Inc. and is used under license to

RailSimulator.com Ltd d/b/a Dovetail Games.

Other Beechcraft Aircraft manuals

Beechcraft

Beechcraft Duke 60 Series User manual

Beechcraft

Beechcraft Bonanza 36 Owner's manual

Beechcraft

Beechcraft C-12C Use and care manual

Beechcraft

Beechcraft Baron G58 Owner's manual

Beechcraft

Beechcraft Debonair 35-33 Owner's manual

Beechcraft

Beechcraft C23 SUNDOWNER 180 Owner's manual

Beechcraft

Beechcraft Bonanza V35B-TC User manual

Beechcraft

Beechcraft Debonair C33 User manual

Beechcraft

Beechcraft Baron 58 Owner's manual

Beechcraft

Beechcraft TRAVEL AIR 95 Install guide