Beehive International B102 User manual

BlOO

Series

Terminals

BlOO,

B102, B150,

8152,

B160, B162

^

L»i=

Manual

JULY

1978

Thij document has been

prepared

by

Beehive

International and is

furnished

on the condition that it will be used by the customer solely for the purpose

of

supporting

the

operation,

service

and

maintenance

of

Beehive

products.

The

rights

of the

customer

with

respect

to

this

document

will

be

governed

by

mutually

acceptable

provisions

of the

contract

with

Beehive

International.

This

document

shalt

not be

duplicated

bythe

customer,

nor

released,

disclosed

or

used,

in

whole

or in

part,

for

any

purpose

other

than

stated

herein,

without

the expresswritten

permission

of said

Beehive

International.

BEEHIVE

INTER

NATIONAL

«=lr^

=>^fiKS.SniLLBke

C.lvUc.eMa'3125-P'^or-e

IB01)

355

SOOO

•

Twx

9XD

925 5271

UUAi

d

910

Amefca E»r^^^rL

0«^vc

'Bo*

2&6SB

Soil,

Lone

uav.

uten

o ^

—.-oo

.

l/uBOP«.

Scrvpr^oi

A,r-oort

•

D.W-O

7Q

Ee«t

•

Tn«

rv;etne.,ana»

•

Pnone

030->S15a2

1^.

152B

JluF*o«Hil?cJsia

Mesa

540

e.i04

rm

9-0.595-2572

.

Sunnyvale

1^08]

739--560

FLOBJDA

A,«mon.e

Sp^i^

SJoimA

SWM5U45

ILLINOIS

Elk

Grove

Village

(2t2,

S93-1565

MASSACHUteTTS

^"9>on

^6

WFW

VOHK

N9*

YorK

/2I2;

6e?-2760

OHIO

Cinc.nnati

(5t3l

621-8277

PENNSYLVANIA

Plymoulh

Meeang

TEXAS

Dallas

f2''J/3fl7.1856

UTAH

SaB

Lake

Cily

WO

355-6000

TWX

9'0-925-527i

VIBQINIA

Falls

Chufch

C703;

356-5

33

i

TM76-B100-2B/TM38-B150-2B

TABLE

OF

CONTENTS

SECTION

TITLE

PAGE

SECTION

IV -

THEORY

OF

OPERATION

4.1

INTRODUCTION

4-1

4.2

GENERAL

FUNCTIONAL

OVERVIEW.

4-1

4.2.1 Power Supply 4-1

4.2.2

CRT

4-1

4.2.3 Keyboard 4-5

4.2.4 Logic Board 4-5

4.3

OPERATIONAL

FLOW

DIAGRAMS

4-8

SECTION

V -

TROUBLESHOOTING

5.1

INTRODUCTION

5-1

5.2

PREVENTIVE

MAINTENANCE

5-1

5.2.1 Troubleshooting Equipment 5-1

5.3

CORRECTIVE

MAINTENANCE

5-1

5.3.1 Troubleshooting Preliminary Considerations 5-2

5.3.2 Troubleshooting Flow Diagrams . 5-2

5.3.3 Full-Duplex Echoplex Test 5-2

SECTION

VI

-

DRAWINGS

&

SCHEMATICS

APPENDIX

A -

MONITOR

Section

1 -

GENERAL

INFORMATION

1.1

MONITOR

DESCRIPTION

A-1

Section

2 -

THEORY

OF

OPERATION

2.1

VIDEO

AMPLIFIER

A-1

2.2

VERTICAL

DEFLECTION

A-2

2.3

HORIZONTAL

DEFLECTION

...........

A-4

Section

3 -

PRELIMINARY

ADJUSTMENTS

3.1

Synchronization

and

Drive Signals A-6

3.2 Brightness A-6

3.3

Video

Contrast

A-6

3.4 Vertical Adjustments A-7

3.5 Horizontal Adjustments A-7

3.6 Focus Adjustment A-8

3.7 Centering A-8

Section

4 -

TROUBLESHOOTING

and

MAINTENANCE

4.1 Troubleshooting Guide A-9

iii

TABLE OF CONTENTS (concluded)

APPENDIX

B -

GLOSSARY

APPENDIX

C -

PROGRAMMABLE

LOGIC

ARRAY

Programmable LogicArray Inputs

Operation

Code

Assignment.

. C5

ff

Program Listing

TABLE

5-1

FIGURE

4-1

4-2

LIST

OF

TABLES

DESCRIPTION

PAGE

Troubleshooting

Flow

Diagram

Index

5-3

ff

LIST

OF

ILLUSTRATIONS

DESCRIPTION PAGE

Basic

Block

Diagram

-

B100/B102

^*2

Basic

Block

Diagram

-

B150/B152

4*3

4-3

Power

Supply

Block Diagram

4-4

Character

Dot

Matrix

4-5 Character

Dot

Matrix of B150/B152

4-6

Timing

Diagrams

4-7

Basic

Functional

Flow

Diagram

4-9

4-8

Basic

Functional

Flow

Diagram

^•'•0

5-1

Echoplex

Test

Connector

^*2

6-1 B100/B102 Logic Board . • . :

B100/B102

Logic

Board

Schematic b-^ tt

6-2

B150/B152/B160/B162

Logic

Board.

6-18

B150/B152/B160/B162

Logic

Board Schematic

b-19

t-i-

6-3

B100/B150/B160

Case

Removal

6-35

6-4

B100/B150/B160

Disassembly

6-36

6-5

B102/B152/B162

Disassembly

6-37

6-6 Keyboard Disassembly * * '

6-7

B100/B150/B160

Cable

Assembly

Drawing/Schematic.

. .

6-39

6-8

B102/B152/B162

Cable

Assembly

Drawing/Schematic

. . . 640

6-9

B100

Series

Keyboard

Assembly

112-1326

641

6-10

B100

Series

Keyboard

Assembly

112-1775

G-42

6-11

Keyboard

Schematic

112-1326

643

6-12

Keyboard

Schematic

112-1775

644

1

Voltage

Waveform

2

Interconnecting

Cabling

Diagram

A-11

3

Circuit

Board

Components

Location

A-11

4

TV5,

9

and

12

Without

Power

Supply

A-12

IV

SECTION

IV

Theory

of

Operation

4.1

INTRODUCTION

bly. The

DC

regulators used in

the

B100 Series

terminals

are

overcurrent

and

thermally

protected.

The

TOC

type

regulator is a 10 amp in

the

B100/

B102

and

a 2

amp

in

the

B150/B152

and

is

mounted

to

the

chassis via a large finned sink.

The

regulator

subassembly is

connected

to

the

Logic Board

through a cable assembly (see Figure

-3).

For

identification

and

specific

regulator

replacement,

consult

the

B100

Series

Illustrated

Parts

Breakdown

under Section III, "Major Assembly Components."

RECTIFIER

RECTIFIER

TRANSFORMER

♦5

REGULATOR

IS

REGULATOR

ISvOC

This

section

of

the

Service

Manual

contains

the

Theory

of

Operation

for

th6

B100

Series terminals.

This discussion is

presented

as a

functional

descrip

tion

at

a

detailed

block

diagram

level

referencing

appropriate

functional

blocks

on

the

diagram.

This

manual is

intended

to

help

the

customer

service

the

terminal

to

a

subassembly

level.

Individual

compo

nent

replacement

Is

not

discussed

in

detail

and

the

customer

is

advised

to

send

subassemblies

to

a

quali

fied Beehive repair area

for

service, if required.

It

should

be

noted

that

all BlOO

Series

terminals

operate similarly and are essentially identical. Where

there

are

critical

differences,

however,

the

manual

will

indicate

these

with

separate

explanations.

4.2

GENERAL

FUNCTIONAL

OVERVIEW

The

B10G

Series

consists

of

four

basic

functional

components:

the

main Logic Board (with Power

Supply),

the

keyboard,

the

CRTwith electronics,

and

small

separately

mounted

chassis

components

(i.e.,

fan, switches, filter, and regulator/transformer).

Figure

4-1

shows

the

basic functional block diagram

of

the

terminal.

These

functions

are

briefly

described

in following paragraphs.

Note

that

there

are

two

two

different

versions

of

the

block

diagram: Figure

4-1

describes

the

B100/B102

and

Figure

4-2

de

scribes

the

B150/B152.

4.2.1

PowQr

Supply

The

Power

Supply

provides

the

required, regulated

DCvoltages

to

the

terminal.

This

assembly

will

operate

on 100, 115

or

230

VAC

power

50/60

Hz.

Section

II

of

the

Operator

Manual

contains

Power

Supply

voltage

change

information.

The

Power

Supply

provides +5, +15, +12,

—12

VDC

to

the

circuitry

from

a

standard

AC

sourca

Figure

4-3 is a

block

diagram

of

the

Power

Supply

subassem

^

15/230

vACINPUT^

BLOCK

12

REGULATOR

4-1

RECTIFIER

-12

REGULATOR

l2vOC

-l2vOC

Figure4-3 Power Supply Block Diagram

The

power

applied

to

the

Power

Supply

is stepped

down in voltage.

The

transformer

output

voltages

are

rectified

by

three

bridge

circuits.

The

output

from

the

rectifiers

and

filters

provides

power

to

the

+5, +15, +12

and

—12

VDC

regulator

circuits

These

components

are located on

the

Logic Board.

The

main

transformer

is

chassis

mounted

and

con

nected

to

the

Logic Board

through

acable assembly

(see

Parts

Manual

Section

III).

4.Z2

CRT

The

Monitor Assembly includes a 12 inch (30.5cm),

diagonally measured, CRT

and

its

supporting

solid-

state

circuitry.

The

nronitor is

controlled

by

the

n

c

S

CO

_*

o

o

OT

O

ro

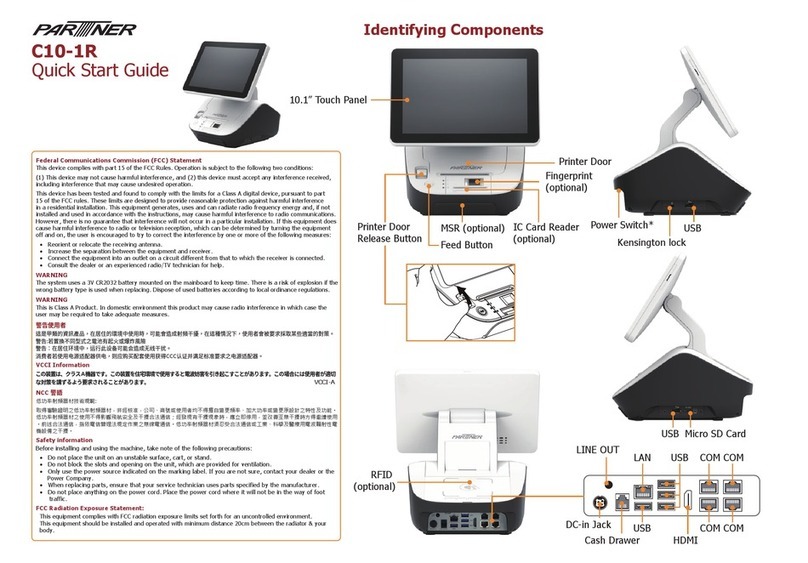

PLA

INPUT

SELECTION

MODE

PROGRAMMABLE

LOGIC

ARRAY

COMMAND

DECODEB

» s a

2«(58S

3 *n « o

MAIN

PORT

AUX

PORT

DATA

op

2

(O

MAIN

PORT

CONFIC.

SELECTION

AUX

PORT

CONFIC

SELECTION

PORT

SELECTION

CIRCUIT

RECEIVER

DATA

INPUT

BUFFER

OPERATION

INS

MODE

format

BUSY

f

MODE

CRVSTAL

OSCULATOR

DATA

UART

TRANSMITTER

MODE

BUSY

DATA

READY

DOT

POSITION

7

DPC

BAUD

CLOCK

SELECTION

ROTARY

CHAR

POSITION

^

96

CPC

CHC

HAUD

CLOCK

CKT.

MAIN

t;LK

AUX

CLK

i

SET/C

CHAR

HLICHT

-10

CHC

CURSOR

POS

CURSOR

LINE

ROLL

WRITE

BUNK

SgTTgp

WRITE

PR01.

CURSOR

POS

eUftjt6R

LINE

SEQUENCE

COUNTER

SEQUENCE

VIDEO

CURSOR

GENERATION

CIRCUIT

CURL

CURSOR

UNE

REG.

BCURL

BUFFERED

CURSOR

LINE

OPERATION

REGISTER

CURSOR

UNE

roll

counter

OPERATION

CHAR

UNE

27

CLC

MEMORY

ADDRESS

MANIPULATION

192(9 X 1

BIT

BLINK

UI.INK

SYNC

CEN.

DRIVE

GEN.

BUNXAOW

CIRCUIT

COMPOSITE

VIDEO

DRIVER

V

DRIVE

H

DRIVE

VIDEO

VIDEO

DRIVER

j CURSOR

VIDEO

SHIFT

REGISTER

TO

REMOTE

_

MONITOR

TO

MONITOR

1921J X I

BIT

PROTECT

PR0fB6t

X 7

BITS

data

REFRESH

MEMORY

CURP

CURSOR

POSITION

REG.

CURSOR

POSITION

BCURP

BUFFERED

CURSOR

POSITION

Roa

VIDEO

CURSOR

"OFF

SCREEN

CIRCUIT

CHARACTER

GENERATOR

UJWER

UPPER

^ CHC \

CASE

CASE

INSEBT/DELBTE

CIRCUIT

1

KEYBOARD

CONTROL

LOGIC

FROM

keyboard

Figure

4-2

Basic Block Diagram —

B150/B152

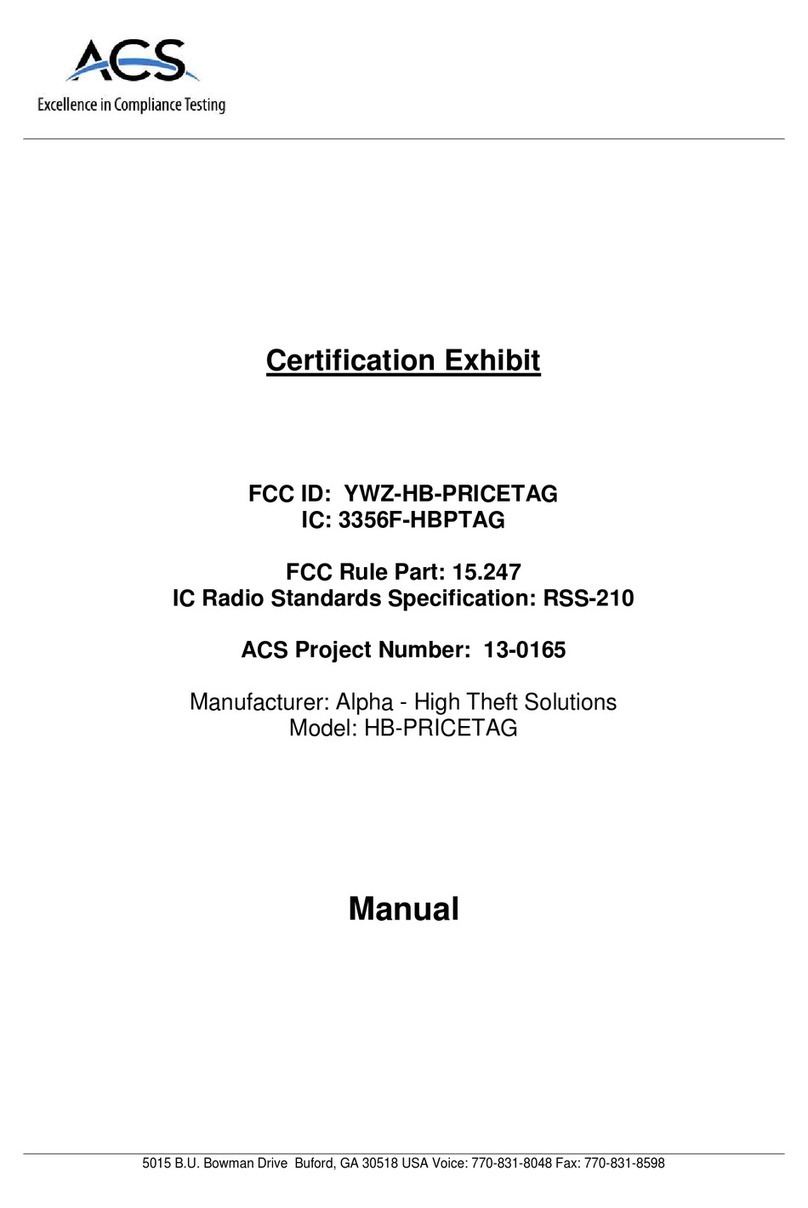

vertical and horizontal synchronization signals

and the video signals generated on the Logic Board

A

fj^l

screen

of

information

consists

of 24

lines

of

80 characters.

The

dot

pattern

for

character

heights

varies

between

B100/B102

and

B150/B152.

The

B100/B102

has

a 9

dot

character

height

with

a

two-raster scan between characters

and

the

B150/

B152 has a

10-dot

character

height

with

one

raster

scan

between

lines

if

lower

case

characters

are

used (see Figures

44

and 4-5).

Brightness

and contrast adjustmentsare provided

by external potentiometers located on

the

rear

panel

(see

Section

II

of the Operator

Manual).

Other monitor adjustments are discussed in Ap

pendix

A.

OOT 0

lUM

ottrtn

eoT

«

eoT

0

•LAM

eMtRiCTM

OltrLAT

eoT

•

tLAM

ano o ooooooooo

"o

•o o o•oo•• • ••o

o•ooo•oo•oooo0

o•ooo•oo•ooooo

CMARACrCII

.

ttlPkAT

o• • •••oo••••oo

o•ooo•oo•o0ooo

o•ooo•oo•ooooo

•ooo•oo•oooo o

oanooo o 0ooooo

1

r\

•AAo o o ooooo

ww

rOMClMOII

oooo o oooooooo

o•••••o o •o

o.

o•o

o•Oooooo•ooo•o

o•oo o ooo•ooo•o

eiUJIACTCII^

o• • ••ooo•••• • o

o• o ooooo•ooo•o

o•ooooo o •ooo•o

^o •oooooo•ooo•o

1

r\

("k o

rj

oo o ooooooo

•*o

oooooo o oooooo

roneuMOM

Figure

4-4

Character

Dot

Matrix

of

B100/B102

4-4

The monitordisplaysdata on the

CRT

in a pattern

determined

bythe

vertical

and

horizontal

synchro

nization

signals

and

the

video

information

driving

signals.

A

+15

DC

voltage

is

applied

bythe

Power

Supply

to

the

monitor.

Vertical Synchronization is applied to the vertical

oscillatorand triggers it at the vertical

refresh

rate

determined by the

driving

logic.

The

vertical

fre

quency isstablized by the vertical frequencycon

trol,

which

determines the point of oscillation. The

output

pulse

of the

vertical

oscillator

is

applied

to

the

driver

amplifier

which

shapes

the pulseand is

controlled by the vertical linearitycontrol. The

output of the

driver

amplifier is

applied

to the

vertical driver by way of the height control. The

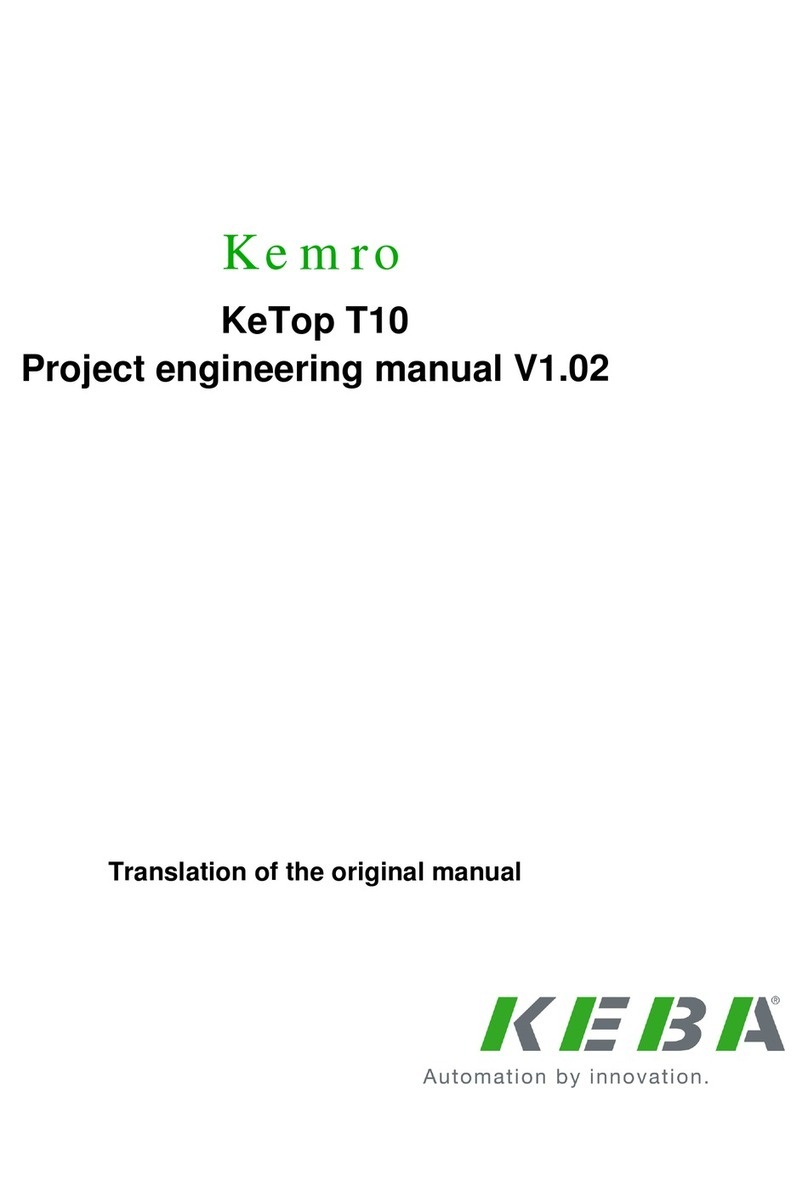

eiuiuett*^

mruT

'

•O

'o

O

O

O

O •

O •

-O •

•o

o

o o

•o

o

o •

o •

o •

o •

o •

o •

o •

•o

o

o o

BOt

«

»ST

0

name

1.

o o

o o

o o

o •

o •

o o

o o

o •

o o

eiuiiieii*

>

o o o

tOT

«

fLUM

Figure 4-5 Character Dot Matrix

of

B150/B152

vertical driver

output

pulse is applied

to

the

yoke

of

the

CRT

and

causes

vertical

deflection.

The

re

fresh

rate

is

50-60

Hz

switch

selectable.

Horizontal

Synchronization

pulses

are

applied

to

the

horizontal amplifier where

they

are amplified

and applied

to

the

horizontal driver.

The

output

of

the

horizontal drive is applied

through

the

width

coil

to

the

yoke, where it causes

the

horizontal de

flection.

The

horizontal

deflection

signal

Ts

stepped

up to approximately 12 kvwhere it is then recti

fied, filtered and applied

to

the anode cap of

the

CRT

to

provide

the

high voltage required.

Video

Information

is applied

to

the

video ampli

fier by way of

the

contrast

control, external

to

the

monitor.

The

video

information

signal

from

the video amplifier is applied

to

the

cathode

of

the

CRT gun

to

cause an ON/OFF

condition

cor

responding

to

light patterns of

the

screen. The

brightness control is external to

the

monitor

and

varies

the

voltage on

the

accelerating grid of

the

CRT.

4.2.3

Keyboard

The Keyboard is

the

input device used by

the

operator to communicate with the terminal. The

Keyboard contains

the

switches and supporting

circuitry to generate

the

appropriate control sig

nals

and

ASCII

codes

utilized

in

the

B100

Series

terminals.

The

Keyboard

conforms

to

the

pro

posed

ANSI

keyboard standard for data keys,

but

has been expanded to facilitate the capabilities

of

the

B100

Series

terminals.

The

ASCII

code

chart

is

found

in

Section

III

of

the

Operator

Manual.

The Keyboard enables

the

operator

to

manually

input information to

the

terminal. When a key

is depressed,

the

keyboard logic generates

the

corresponding 7-bit

ASCII

code and presents the

data in parallel form

to

the

keyboard data lines.

After a short delay for debouncing,

the

strobe is

driven

to

its

active

level

and

returns

after

approxi

mately 30 milliseconds. For those keys which auto-

repeat, the strobe line is pulsed at a 15 character

per second rate. The

BREAK

key is

not

encoded

but

is a

function

line

that

is driven

low

for

approxi^

mately

400

ms when

the

key is depressed. The

following keyscause special 8-bit

(non-ASCII)

4-5

codes:

AUXSEND,

CLEAR/HOM^

SEND,

EOS^

EOL,

and

DELETE

CHAR.

Thesecodes are

used

internal

to

the

CRT

only

and

are

not

trans

mitted.

424

Logic

Board

The

Logic

Board

containsthe majorfunction and

control circuits in

the

B100 Series terminal. It also

holds all of

the

DC

voltage regulators

to

power the

unit

with exception of the +5V regulator. The

basic

operations accomplished by the main

logic

board are: Generation of

data

and control signals

for

the

monitor, interaction with

the

keyboard,

control

of

the

data

sent

between

the

BlOO

terminals and any external device, and generation

of the basic timing signals essential for the oper

ation of

the

terminal. (See Figure 4-6)

Display Organization - B100/B102 —The main

timing chain (oscillator,

dot

position counter,

character position counter, character height

counter, and character linecounter) defines the

configuration of the display on the

CRT.

There

are 30

lines,

six of which are used for vertical

retrace and 24 of which are used

to

display

char

acters.

The

30

lines

are

composed

of

nine

scans

each,each scan being composed of 96 character

positions,

80 for

display

and

16

for

horizontal

re-

traca

Each character block is composed of 7 x 9

dot

matrix

field which

contains

a

5x

7

character

matrixfor the displayed character

(see

Figure44).

DisplayOrganization -

B150/B152

—The main

timing

chain

(oscillator,

dot

position

counter,

char

acter position counter, character height counter,

and character line counter) defines the configuratior

ofthe

display

on the

CRT.

There

are27

lines,

three

of which are used for vertical retrace and 24 of

which are used to display characters. The 27 lines

arecomposed of ten

scans

each, eachscan

being

composed

of 7x 10dot

matrix

field

which

contains

a 5 X7 character matrix for the displayed char

acter (see Figure 4-5).

Oscillator - The oscillator is crystal controlled

with a frequency of

10.8864

MHz.

Two

74H04'!

are connected in series by a lOOpfcapacitor.

osc

jTjuimfmiiruinmiirinjiruin

Bpci

j-unjT__rTJTJ~i_rLrLri

—i_i—u—i—j—u—I

I—1

__i

1 I 1 I 1

DPC8

U

FREQ

-

10.8864

MHz

DOT

POSITION

COUNTER

FREQ

-

1.5552

MHz

CHARACTER

POSITION

COUNTER

CPC1

CPC2

CPC4

_

CPC8

_

CPC16.

CPC32^

CPC64_

CPC80

juinnnjTJinnnnjiriAnnjiruuinjifuuifiiinJUinAnjinruiriJinjiJiAAJiri^

j—I

m

rn

r

CHC1

n__rn

m—r~L

CHC2

CHC4

CHC8

CLC1

J—i_rn

i_f

CLC16

CLC2

CLC4

CLC16

Figure 4-6 Timing Diagrams

4-6

i_r-i_rn_r

CHARACTER

HEIGHT

COUNTER

FREQ.

°

1.800

KHz

CHARACTER

LINE

COUNTER

(50

Hz

OPERATION)

FREQ

"SO

Hz

CHARACTER

LINE

COUNTER

(60

Hz

OPERATION)

Each

74H04

has

a 1

kohm

feedback

resistor

around

it. A

10.8864

iVIHz

crystal is

connected

from

the

input

of

the

first

74H04

to

the

output

of

the

second. The

output

of

the

oscillator

is

buffered,

inverted

and

fed

to

the

Dot

Position

Counter.

Dot

Position

Counter

-

This

divide-by-seven

counter

defines

each

of

the

seven

dots

required

to

compose

one

character.

The

outputs

of

this

four-stage

counter

are labeled DPCl,

DPC2.

DPC4

and

DPC8.

The

counter

actually

presets

to

a

count

of

10,

counts

up

through

the

overflow

point

at 15

to

a

count

of

zero,

and

presets

back

to

a

count

of

10.

The

Dot

Position

Counter

output

DPC8 drives

the

Character

Position

Counter.

Character

t'\»sctcon

Counter

-

The

Character

Position

Counter

is

composed

of

two

binary

type

counters

that

define

96

character

posi

tions,

each

being

seven

dots

wida

The

output

of

the

Character

Position

Counter

drives

the

Character

Height

Counter.

Character

Height

Counter

-

The

Character

Height

Counter

is a

standard

counter

that

de

fines

nine

scans

of

96

characters

each,

with

each

character

being

seven

dots

wide.

The

output

of

the

Character

Height

Counter

drives

the

Character

Line

Counter.

Character

Line

Counter

-

The

Character

Line

Counter

is a

binary

counter

that

starts

at

a

count

of

zero

and

counts

to

a

maximum

of

29

for

a

total

of

30

character

lines.

The

final

out

put

of

this

counter

runs

at

the

vertical refresh

rate.

Horizontal

and

Vertical

Drive

-

The

Horizontal

Drive

is

started

when

the

Character

Position

Coun

ter

leaves

the

video

area

of

the

scan

and

is

active

for

the

following

40

character

positions.

The

high active

ouiput

of

this

flip-flop is

sent

to

the

monitor

on

pin

9

of

connector

J1.

The

Vertical Or've is

generated

during

the

time

the

Character

Line

Counter

is

decoding

24.

Cursor

Location

Counter

identifies

the

location

of

the

cursor.

This

is a

count

made

from

the

Cur

sor

Line

Counter

(called

CURL)

and

the

Cursor

Position

Counter

(called CURP).

These

two

coun

ters, in conjunction with

the

ROLL

counter, are

ised

to

address

the

memory

to

determine

the

entry

joint

of

the

next

character.

The

cursor

location

4-7

counters

are

compared

with

the

next

character.

The

cursor

location

counters

are

compared

with

the

Character

Position

Counter

and

the

Character

Line

Counter

to

generate

the

signal

called

CNTR

CURSOR.

This

signal is used

to

generate

the

cursor

displayed on

the

CRT.

Also associated

with

the

cursor

location

counters

is

the

appropriate

circuitry

to

move

the

cursor

up,

down,

right, left;

home,

etc

A

LINE

FEED

code

causes

the

Cursor

Line

Counter

to

increment

by

one. A CARRIAGE RETURN

code

clears

the

Cursor

Position

Counter.

With

the

terminal

operating

in

Format

Mode,

when

the

cursor

is

incremented

off

the

bottom

line,

the

cursor

automatically

wraps

around

to

the

top

of

the

display,

i.e.,

the

Cursor

Line

Counter

is

reset

to

zero.

However,

if

the

terminal

is

not

in

Format

Mode,

the

display

scrolls

whenever

the

cursor

incre

ments

from

a

count

of

23.

A

scroll

is

initiated

by

any

of

three

functions

if

activated

when

the

cursor

is

on

the

last

line

of

the

display

and

the

terminal

is

not

in

Format

Mode:

a.

LINE

FEED

or

CTRL

J

b.

CURSOR

DOWN

or

ESC

B

c. If

the

cursor

is

on

the

last

position

of

the

last

line

1.

Cursor

right

2.

Any

displayable

character

3.

Space

Memory

is

actually

a

2048

byte

memory.

Each

byte

consists

of

9

bits:

7

for

data,

one

for

protect,

and

one

for

blink. Of

these

2048

bytes,

1920

are

displayabl&

The

program

does

not

have

the

capa

bility

of

displaying

or

writing

into

the

remaining

128. In

order

to

write

data

into

the

page

memory

from

the

receiver,

the

memory

address

is

muxed

over

to

the

cursor

location

registers

and

the

sig

nal WRITE is

generated.

The

UART is

then

reset

and

is

capable

of

receiving

the

next

character.

The

page

memory

output

is

sent

to

the

character

gene

rator

input

buffer

at

the

proper

time

to

generate

the

displayable

characters.

The

program

has

the

capability

of

shutting

down

the

screen

refresh

for

any

given

operation

to

increase

the

program

operating

time.

Character

Generator

is a

read-only

memory

(ROM)

that

is

addressed

by

the

character

(in

ASCII).

The

scan

configuration

and

the

chracter

indicate

the

pattern

desired

on

that

scan. Five-bit

dot

pat

terns

are

generated

which

form

a

portion

of

a

character.

The

output

of

the

character

generator

is

applied

to the

parallel-to-serial

video

shift

regis

ter.

Video Shift Register is parallel-to-serial loaded

with data by the low-active

signal

DPC8

and is

clocked by the

main

oscillatoroutput. The dots

are shifted out, mixed with cursor information

and blanking

signals

and appliedto the monitor

through the

CXDNTRAST

control as

video

infor

mation.

Input/Output Operations

UART

(Receiver) data

can be received by the

B100

Series terminals from

one of

three

sources: from

the

two

I/O interfaces

into

the

receive side

of

the

UART

or

from

the

keyboard through the transmit sideof the

UART

to

the

receive

side

of

the

UART.

The UART is driven by a clock generated

inter

nally off the main counter chain. No separate

oscillator is required. A rotary switch located on

the back panel switches the clock rate for oper

ation from 75

to

19200

baud

The

times-16 clock

isthen applied to the transmitter and

receiver

of

the

UART.

The

EIA line receiver receives

data

at

RS232C

levels

and

gates

them into the

UART

when on

line.

Through

the

same

gating,

data isbroughtin

from

the

transmit

side

of

the

UART,

where

it is

con

verted to parallel (7 bits) data.

UART

(Transmit) keyboard data linesfor bits 1

through 7 areapplied to the transmit input data

lines

along

with the

seven

BUS

lines.

Also

coming

from the keyboard circuit isa load

signal

which

triggers

the

UART

to initiatethe

transmission.

As

the

UART receives

the

character

for

transmission,

it performsthe appropriate parity generation, pro

vides one or two stop bits, divides the X16 clock

to get the baud rate,and transmitsthe character.

The character isapplied through an

EIA

RS232C

interface

to

the

computer

or

modem.

Alsocoming from the

UART

is output data at a

TTL

level

which is applied to the receiver side of

the

UART

through the previously mentioned logic

The

EIA

interface

includes aData

Terminal

Ready

signal

which

indicates

the status ofthe unit to the

computer anda

Request

to

Send

signal

which

in

dicates

that

the

terminal has

data

to

send

to

the

computer. The

Clear

to Send

line

coming

from

the

computer ismonitored at the

EIA

RS232C

inter

4-8

face

levels.

It is received by a line receiver which

converts it to

TTL

levels

and appliesit to the

UART

clock control circuit to control transmission. An

optional

X8

clock

(TTL

levels)

is

available

aspart

of

the

interface.

The

BREAK

key is

on

the

key

board and enables a timer which holds the transmit

data

line

in

a

spacing

condition

fora

predetermined

length

of

time.

Block

Send

Circuit

allows

the

operator

to

compose

a

message

on the terminal

screen

andthen,

depress

ing

the

SEND

key,

cause

the

terminal

to

send

the

entire

message

to the computerat the

selected

baud

rate. Thesequence of operations isdescribed in

Figure

4-8.

The

operation

is as follows:

1.

2.

3.

4.

5.

6.

7.

Raise Request-to-Send

When Clear

to

Send,

send STX (002)

header

Send

data

If FORMAT

and

END OF PROTECTED FIELD,

send

HT

code (III3)

If

not

FORMAT

and

ENDOF

LINE,

send

CR/LF

sequence

(0159/0123)

When

end of

message,

sent

ETX

(OO33)

Time

out

and

drop

Request

to

Send

Auxiliary Send Circuit is identical

to

the

Block

Send except for two points:

1. The

message

istransmitted out the

AUX

port insteadof the

Main

I/O

port

2.

The

delimiters

sent

at

the

start

of

message,

end of unprotected field, end of line, and

ETX

are

selected

from

a

different

portion

of

the

Block

Send

ROM

Special Function

(F1-F16)

sends a code sequence to

the computer from the terminal. The code is

insti

gatedby

pressinggany

one of the 16function

keys.

1. An

STX

istransmitted

(0223)

2.

An

Escape

code

(O333)

3. Code character

(see

/\SCII

Code Chart, Table

3-2)

4. Andends with an

ETX

(OO33)

4.3

OPERATIONAL FLOW DIAGRAMS

See Figures 4-7 and

4-9.

These diagrams

give

the

user an

outline

of

the

B100/B150 terminal

operation. Specific program information is con

tained in Appendix C and a list of programmable

I.

C.

part numbers and program numbers is con

tained

in

the

Parts

Breakdown

Manual.

fx

(b

^escwait)

UU.

IN

UFFE

SAVE

CUBSOR

LOCATION

SEND

CURSOR

TO

UNE

23

REFRESH

DISABLE

SAVE

CURSOR

LOCATKMJ

WRITE

NULL

TO

MEM.

INCaCUR.

POSITION

URSOR

LLEGAL

clear

cur

POSITION

INCR

CUR

UNE

URSO

ILLEGAL

CLEAR

CURSOR

UNE

DECR.CUR

UNE

GO

TO

"BPT"

GO TO

"RTN

CURSOR"

GO

TO

"LF"

NULL

CODE

TO

REG

2

CLEAR

STORED

CURSOR

UNE

PROTECTED>V-

WRITE

NULL

TO

MEM.

INCaCUR.

POSITION

CURSOR

CLEAR

CURSOR

POSITION

CO

TO

"ADV

HOME

CURSOR

SAVE

CUR

LOCATIC»(

GO

TO

"FPr

GO

TO

"RTU

CURSOR

CO

TO

"BKSP

NULL

CODE

TO

REG

2

REG

2

BUS

DISABLE

CLEAR

CUR

POS.

!•

UNE

HOME

CURSOR

FMT

"OFF*

CLEAR

WRITE

PRCT

FLOP

SET

WRITE

PROT.

FLOP

ENABLE

KEYBO.

DISABLE

KEVBa

CO

TO

"FPT"

UTERAL

BUS

FIRE

TIMER

TIME

SEND

1st

BYTE

-SOM-

SEND

2nd

BYTE

-SOM-

CLR

CUR.

POSITION

DECa

STORED

CUR.

UNE

MEMCmY

BUS

DECa

STORED

CURSOR

INCaCUR

POSITION

Figure

4-7

Basic

Functional

Flow

Diagram

SETWRITE

UNK

FLO

CURSOR

ILLEGAL

INCaCUR.

POSITION

CURSO

ILLEGA

URSO

LEAR

W

UNK

FLO

UTERAL

BUS

SEND

lat

BYTE

END

UNPRQ]

SEND

2nd

BYTE

END

UNPRCI

SAVE

CURSOR

CLEAR

CUR.

UNE

ENABLE

AUX.

XMIT.

GO

TO

-FPT-

URSO

SEND

Ist

BYTE

-EOL-

SEND

2nd

BYTE

-EOL-

dECR

STORED

CUa

UNE

CLR.CUR.

POSITION

INCUCUR

UNE

SEND

ist

BYTEEOM

SEND

2nd

BYTE

EOM

I

FIRE

TIM

GO

TO

"IDLE-

SAVE

CURSOR

CLEAR

STORED

CURSOR

UNE

LOVEK

CASE

SAVE

BYTE

UNDER

CURSORl

WRITE

LC

CODE

TO

MEM

LCCODE—•RZ

SAVED

BYTE

TO

MEMORY

FIRE

TIMER

TIME

SEND

Ist

BYTE

-

STX

-

SEND

2nd

BYTE

-

ESC-

SEND

IC

CODE

FROM

R2

ND

3rd

BYTE

-

ETX

-

i

I FIRE

HM^

TIME

o

ULL

I

BUFFER

DEL.

IN

buffer

INCR

CUR

POSITION

ILLEGAL

CLEAR

CURSOR

l>OSlTION

GOTO*lF

lUXGAL

TO

TO'BIt'

CR

CODE

CLEAR

CURSOR

POS.

GO

TO'FPT

HOME

CURSOR

GO

TO

IDU

^N

CURSO^

DECR

STORED

UNE

COUNT

DECR

STORED

POS.

COUNT

ILLEGAL

INCR

CUR.

posmoN

ILLEGAL

LEAR

CURSOR

POSITION

INCR.

CUR.

UNE

DECR.

SrCMED

UNE

COUNT

DECR

STORED

POS.

COUNT

LF

CODE

INCR.CUR.

UNE

CURSOR

LLEGAL

FMT

MODE

SAVE

CURSOR

posmoN

ERASE

BOTTOM

LINE

CURSOR

TO

FIRST

POS.

LASTUNE

GO

TO

RTN

CURSOR

GO

TOTPT

BKSP

CODE

DECR

CUR.

POS.

GO

TOW

URSOR

ILLEGAL

CURSOR

TO

POS.

79

CO

TO'UP

GOTO

•idle*

GO TO'BKSP *

Qpowmoj^

HARDWARE

CLEAR;

i:uR.posiriOM

CUR

UNE

WRITE

PROT

GOTO*EOS

FIRE

BEEPER

GO

TO*FPr*

INCR

CUR.

POSmON

ILLEGAL

CLEAR

CUR

POSITION

IMCR.

CUR.

UNE

ILLEGAL

•home*

CURSOR

GOTO

CODE

SAVE

CURSOR

CLEAR

CURSOR

GO

TO

•start

send*

GO

TO'ADV.*

Figure

4-8

Basic

Functional

Flow

Diagram

C1£AR

INPUT

BUFFER

SETSEQS

GOTO

ESC.VAIT*

!V

CTRU

CODE

INSERT

MODE

SAVE

BYTE

UNDER

CUR.

IN

REG

1

WRITE

NEW

CODE

UNDER

CURSOR

REFRESH

OfF

SAVE

CUR.

POSmON

INCR

CUR.

POSmON

ILLEGAL

RE&2

MEMOBY

WRITE

NEW

BYTE

UNDER

CURSOR

I

GOTO^DV.

CLEAR

CURSOR

POSmON

INCR.

CUR.

GOTO

•rtn

cursor'

SECTION

V

Troubleshooting

5.1

INTRODUCTION

This

section

contains

information

to

aid

in

the

maintenance

of

the

B100

Series

terminsL

Pre

ventive

ard

corrective

maintenance

procedures

are specified, as well as

troubleshooting

aids

and

techniques.

5.2

PREVENTIVE

MAINTENANCE

No

scheduled

periodic

maintenance

is

required.

Hovv-ever, several

precautions

can

be

taken

periodically

to

ensure

proper

operation.

Care

should

bs

exercised

to

see

that

there

is

proper

air

circulation

for

the

fan.

The

terminal

should

not

be

placed

on

ashag

carpet

or

other

soft

sur

face

that

could

impede

the

air

entrance

to

the

fan.

Special

care

must

be

taken

to

ensure

that

no

paper

or

other

loose

articles

are

placed

under

the

terminal.

The

degree

of

dust

density

in

the

air

shou^

be

considered

in

selecting

the

location

of

the

Lsrminal.

The

interior

of

the

unit

may

be

wiped

free

of

dust.

Acci'nr?ulation

of

dirt

causes

overheating

and

component

break

^f)\vn.

Dirt

acts

as

an

insulating

blanket

and

D'e^'-^nts

efficient

heat

dissipation.

A

small

brush

is

very

useful

for

dislodging

dirt;

a

cot

ton-tipped

applicator

is

good

for

narrow

or

hard

to

get

places.

The

following

is a list

of

the

troubleshooting

aids

that

are

provided

in

this

manual

to

assist

in

the

troubleshooting

of

functional

failures.

5-1

Circuit

Schematics

Detail

Block

Diagram

Functional

Flow

Diagram

Timing

Diagrams

Glossary

of

Terms

Troubleshooting

Flow

Diagrams

Disassembly/Assembly

Procedures

Adjustment

Procedures

Configuration

/Strapping

Information

Character

Dot

Matrix

See

Section

VI

See

Section

IV,

Figures

1,2,

7 & 8

See

Section

IV,

Figure

6

See

Appendix

This

Section

See

Section

VI

See

Section

11

See

Section

IV,

Figures 4 & 5

5.2.1

Troubleshooting

Equipment

The

following is a list of tools and

standard

equip

ment

required

to

repair aB100Series terminal:

V/0

Multimeter

Oscilloscope

Assorted

Electronic

Hand

Tools

5.3

CORRECTIVE

MAINTENANCE

This

section

provides

corrective

maintenance

in

formation

to

aid

in servicing

the

B100

Series

termi

nal. It is suggested

that

the

configurations

sheet

end

the

turn-on

procedure

be

consulted

before

performing

the

corrective

maintenance

described

here.

(See

Section

Ml)

5.3.1

Troubleshooting

Preliminary Considerations

The most common problems occurring in the

B100

Series

units

are

switch,

control

and

operation-

related. A simple procedure may be followed

to

help determine if the problem iscontrol and/or

operation related or internal circuitry related

by checking

the

following:

Illegal

Operation

(Refer

to

Section

II)

Improper

Baud

Rate

Setting

Wrong

Transmit

or

Receive

Mode

Loose

Interconnect

Cable

5.3.2

Troubleshooting

Flow

Diagrams

Alist

of

troubleshooting

flow

diagrams

is given

in

Table

5-1.

This

index

lists

apparent

failure

and

refers

the

user

to

the

proper

flow

diagram.

The

table

is

only

intended

to

allow

the

user

to

verify

the

subassembly

where

trouble

exists

and

not

to

indicate

the

specific

problem.

The

user

is

advised

to

return

the

defective

subassembiy

and

have

that

subassembly

repaired

or

replaced by an

authorized

service

agent.

1.

Find

the

apparent

trouble

in

the

Trou

bleshooting

Flow

Diagram

Index.

2.

Proceed

to

the

specified

Troubleshoot

ing

Flow

Diagram

in

the

diagram

section

and

begin

the

troubleshooting

procedure.

3.

If an

adjustment

procedure

is

referen

ced

in

the

Troubleshooting

Flow

Diagram,

perform

the

adjustment

and

return

to

the

flow

diagram

to

complete.the

trouble

shooting

process.

4.

Reference

is

made

to

Timing

diagrams

contained

in

(Section

VI)

this

manual.

5.3.3

Full-Duplex

Echoplex

Test

Aspecially

wired

connector

may

be assembled

that

will

allow

the

operator

to

perform

this

test.

This

connector

tester

allows

the

terminal

to

be

operated

and

tested

Independent

of

an

external

data

device.

The

connector

mates

with

the

Main

I/O

Port.

Set-up

for

the

test

is as

follows:

FDX (Full

Duplex

Mode)

Baud

Rate

-

Any

Setting

Test

Connector

Installed

in

the

I/O

Port

5-2

Enter data from

the

keyboard as you would if you

were on-line

to

acomputer. If data is displayed

on

the

screen properly, then

the

8100 series unit is

transmitting and receiving data properly.

The

Test

Connector

is

wired

as

follows:

(Refer

to

Figure

5.1.)

Connects

Transmitted

Data

Line

out

of

the

terminal

to

received

data

line

into

the

terminal.

Pin

2

to

Pin

3

of

the

I/O

Port.

Pin

3

Pin

2

Jumper

between

Pin

2

and

Pin

3

0

(D

Amphenol

Male

Type

Connector

Beehive

Part

No.

606-0011-25

AP

FIGURE

5-1

ECHOPLEX

TEST

CONNECTOR

Table 5-1.

Troubleshooting

Flow DIagrann Index

Apparent

Failure

Troubleshooting

Flow

Diagram

GENERAL

No

raster

present

5-1A

No

raster

present

5-1B

OFF

LINE

Cursor

either

absent,

multiple

cursors,

cursor

not

in

home

position

or

screen

filled

with

video

blocks

5-2A

No

character

displayed

when

written,non

cursor

advance

5-2B

Wrong

character

displayed

5-2C

No

escape

functions

5-2D

No

control

functions

5-2E

ON

LINE

No

data

being

transmitted

5-3A

Transmits

invalid

data

5-3B

No

reception

5-3C

Receives invalid

data

and/or

improper

parity

5-3D

DISPLAY

All

displayed

characters

out

of

focus

5-4A

Roiling

display

5-4B

Display

too

tall/short

for

screen

size

5-4C

Height

of

displayed

characters

uneven

5-4D

Display

too

wide/narrow

for

screen size

5-4E

Display

not

centered

5-4F

Tilted

display

5-4G

Others

A.

Single

vertical

line

B. Physical

damage

C.

Dot

in

center

of

screen

D. Uneven

intensity/focus

E.

Burned

phosphor

F.

Uneven

display

dimensions

G. Excessive H.V.

Arcing

5-4

H

5-3

START

IS

KBD

plugged

IN

YES

IS

'"BRIGHTNESS"'

CONTROL

ADJ

YES

IS

monitor

PLUGGED

in

YES

NO

PLUG

IN

KEYBOARD

NO

ADJUST

BRIGHTNESS

CONTROL

AT

REAR

OF

UNIT

NO

PLUG

MONITOR

IN

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

IS

15

VDC

PRESENT

^MON

PI

2-6,

IS

+

15

VDC

PRESENT

LOGIC

CAR

NO

REPLACE

BOARD

YES

IS

HORIZ

DRIVE

SIGNAL

PRESEN

REPLACE

WIRING

HARNESS

FROM

LOGIC

CARD

TO

MONITOR

NO

REPLACE

LOGIC

/

CARD

\

IS

PROBLEM

SOLVED

END

YES

REPL

MON

^CE

ITOR

5-nA

CjEj

5-4

)

START

IS

TERMINAL ^

PLUGGED ^

IN

IS

POWER

SWITCH

ON

IS

CIRCUIT

BREAKER

GOOD

AR

TRANS

IRE

HARNESSE

ONNECTE

IS

POWER

SWITCH

ON

IS

5VDC

OR

+

15VDC

PRESENT

at

Power

Supply

(

NO

NO

PLUG

TERMINAL

INTO

PROPER

POWER

SOURCE

TURN

POWER

SWITCH

LOCATED

ON

REAR

PANEL

TO

THE

ON

POSITION

DEPRESS

CIRCUIT

BREAKER

LOCATED

ON

BACK

PANEL

mammmuiMamm

CONNECT 1

WIRE

;

NO

HARNESSES

3

REPLACE

SWITCH

REPLACE

LOGIC

CARD

5-5

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

IS

PROBLEM

SOLVED

(

(

CHD

5-nB

)

REFER

TO TURN ON

procedure

CONTRAST

PROPERLY

w

adj.

>

YES

miGHTNESi

PROPERLY

w

adj.

^

YES

^

VIDEO

^

information

WCORRECTV

YES

replace

monitor

NO

NO

NO

PROPERLY

ADJUST

CONTRAST

PROPERLY

ADJUST

BRIGHTNESS

REPLACE

LOGIC

CARD

END

5-6

PROBLEM

SOLVED^

NO

PROBLEM

SOLVED^

NO

END

YES

YES

END

END

IS

KBD

PLUGGED

IN

NO

PLUG

IN

KEYBOARD

CARD

YES

REPl

LOGIC

.ACE

CARD

C

END

IS

KBD

PC

PLUGGED

IN

M-6

5-7

IS

PROBLEM

SOLVED

CONNECT

KEYBOARD

PC

TO

P-9

ANDTIMING

REPLACE

KEYBOARD

IS

PROBLEM

SOLVED

REPLACE

KEYBOARD

HARNESS

IS

PROBLEM

SOLVED

YES

This manual suits for next models

5

Table of contents

Other Beehive International Touch Terminal manuals

Popular Touch Terminal manuals by other brands

impro technologies

impro technologies IMPROX O16 installation manual

Kollmorgen

Kollmorgen AKI-CDT-MOD-10T installation manual

Tektronix

Tektronix 4023 instruction manual

Casio

Casio DT-X10 series user guide

Mitsubishi Electric

Mitsubishi Electric GT1155-QTBD Startup guide

Elavon

Elavon VeriFone Tranz 380 Quick reference guide