Behncke EWT 95-15 User manual

Installation Instruction

Electric Heat Exchanger

Electric/Swimming Pool Water

EWT 95 - 15

Your BEHNCKE®Specialist Dealer

– Subject to technical alteration! –

Stand 03/2011

Version of March 2011

Dear costomer,

congratulations on purchasing your new, state-of-the-art

electric heat exchanger „Made in Germany“.

Behncke®GmbH has produced high-quality pro-

ducts for the public and private swimming pool and

whirlpool sector for more than 30 years.

Your Behncke®specialist dealer will always give you

advice and support.

Please read this installation instruction with great care.

Store the installation instruction for future use!

Subject to technical alteration!

Inhaltsverzeichnis

27

Table of contents

1 Safety 28

1.1 Risks When Handling Electric Heat Exchanger 28

1.2 Safety Instructions and Information 28

1.3 Intended Use 29

1.4 Sources of Danger 30

1.5 Safety Measures on the Installation Site 30

1.6 Safety Equipment 30

2 Technical Data 31

2.1 EWT 95 - 15 31

3 Set-up/Installation 32

3.1 Transportation/Storage 32

3.2 Set-up and Installation Dimensions 32

3.3 Set-up 33

3.4 Installation 33

3.5 Water Connection 34

3.6 Electrical connection 35

4 Funcional Course 36

5 Service control unit 37

6 Initial Operation 40

7 Maintenance/Repair 40

7.1 Hibernation of the EWT in Frost-proof Rooms 40

7.2 Hibernation of the EWT in Non Frost-proof Rooms 41

8 Troubleshooting 42

9 Circuit Diagram 43

9.1 Connection with Kombi Filter controlling 43

9.2 Connection without Kombi Filter controlling 44

10 Explosion Drawings and Piece Lists 45

10.1 Piece list EWT 95 - 15 46

Safety

28

1 Safety

1.1 Risks When Handling Electric Heat Exchanger

The electric heat exchanger has been built on the basis of state-of-the-art techno-

logy and the approved safety-technical guidelines. Nevertheless, risk might occur

during use such as

- violation of operator or

- third parties

- impairments in electric heat exchanger or

- damage to other material values.

All persons, who are engaged in installation, initial operation, operation, mainte-

nance and repair of the electric heat exchanger, have to:

- be suited accordingly, mentally and physically.

- be qualified accordingly

- strictly observe these installation instructions.

The electric heat exchanger may only be used

- for the intended purpose.

- in a perfect safety-technical state.

In the case of disorders, which might impair safety, a sanitary expert is to be con-

sulted.

It is your safety!

1.2 Safety Instructions and Information

The following symbols are used in this safety instruction:

This symbols means warning of dangerous electric high power to the health of

persons.

Non-observance of this information might lead to severe injury

This symbol means possible danger to the health of persons.

Non-observance of this information might lead to severe injury

This symbol means a possible hazard for the health of persons.

Non-observance of this information might lead to injury to persons, or damage to

things.

This symbol gives important information for correct handling of the system.

Non-observance of this information might lead to disorders in the system or the

environment.

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

take care

take care

Safety

29

1.3 Intended Use

The electric heat exchanger is exclusively designed for heating bathwater with acti-

vated recirculating or filter pump.

Any other mode of application is not regarded as intended use. The manufacturer

Behncke ®GmbH is not liable for any resulting damage.

Other uses are only possible upon agreement with and approval by the

manufacturer.

Important!

The intended use also includes

- observance of all pieces of information in the installation instructions and

- execution of inspection and maintenance activities

Maximum permissible operational overpressure of 3 bar must not be exceeded.

Minimum permissible operational overpressure of 0.1 bar must be achieved.

The minimum throughput is 5000 l/h.

Water with the following values may only be used

Chloride content max. 500 mg/l

Free cholorine max. 1.3 mg/l

pH value 6,8 – 7,8

Retrofits and changes in the heat exchanger are prohibited for safety reasons.

For safety reasons, maintenance and repair activities in piping and electrical installati-

on are only to be executed by specialist personnel

Safety

30

1.4 Sources of Danger

The electric heat exchanger can be damaged.

If the maximum operational pressure of 3.0 bar is exceeded, the electric heat

exchanger might develop leaks.

The risk of burns exist.

The connections and the electric heat exchanger might reach temperatures of up

to 100°C.

In the case of insufficient throughput (<5000 l/h) strong overheating of the electric

heat exchanger is possible.

The electric heat exchanger might be damaged.

If dripping water falls onto the outer skin or if metal particles enter the electric heat

exchanger, the risk of contact corrosion exists.

1.5 Safety Measures on the Installation Site

The electric heat exchanger is to be installed in a frost-proof room with a mounting

device made of plastic or stainless steel.

Please ensure that the maximum operational overpressure of 3.0 bar is not

esceeded.

The electric heat exchanger or the environment can be damaged.

Please check the electric heat exchanger and its connections for tightness and

visible damage once a week during operation.

The danger of combustion exists.

In the case of insufficient throughput (<5000 l/h) strong overheating of the electric

heat exchanger is possible.

Do not store any combustible materials in the environment.

The electric heat exchanger can be damaged.

The electric heat exchanger may only be put into operation if it has been ensured

that the electric heat exchanger is continuously supplied with water during operati-

on. The water troughput must be at least 5000 l/hour.

1.6 Safety Equipment

The electric heat exchanger must be protected by at least two safety circiut

breakers.

The following safety circuit breakers built in by the factory

- a control thermostat, a safety temperature limiter and a flow control switch

The safety devices switch off the electric heat exchanger if impermissible values

are reached.

take care

take care

take care

take care

take care

take care

take care

Technical Data

31

2 Technical Data

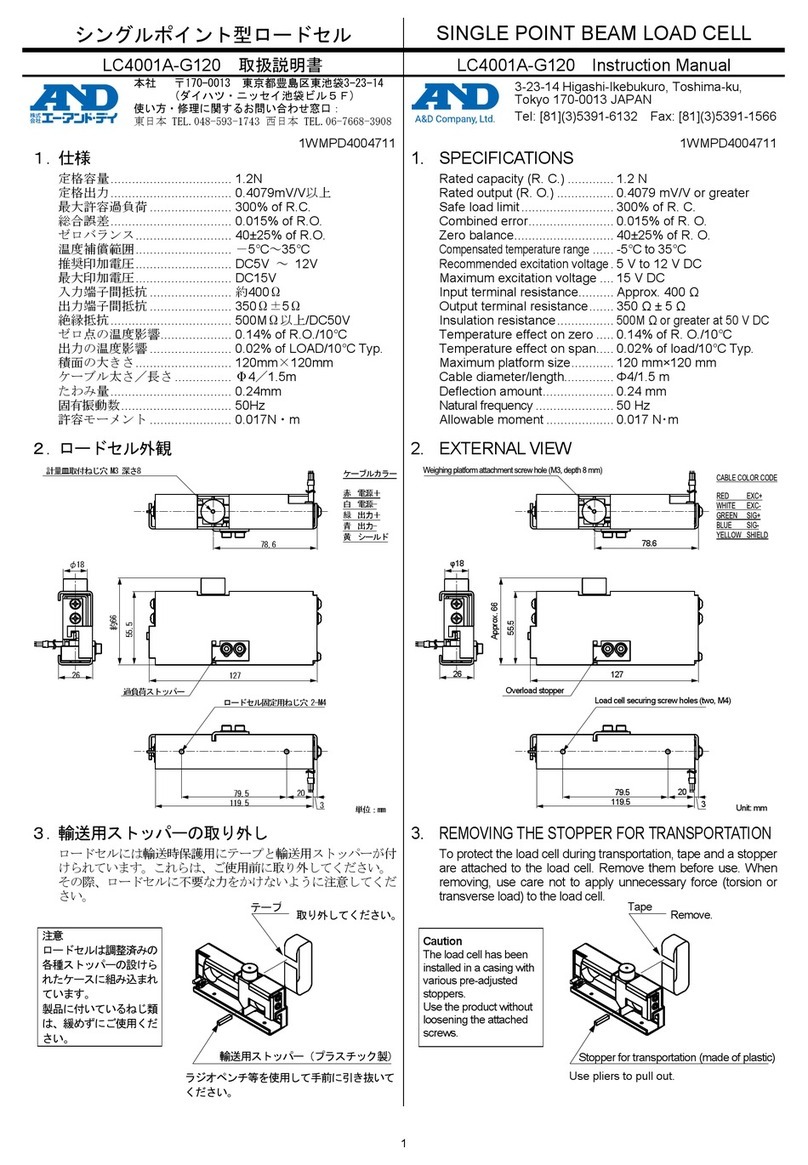

2.1 EWT 95 - 15

Article Power in KW Supply Temperature Article No.

Voltage Selection

in Volt in °C

EWT 95 -15 18 230/400 – 302 051 18

EWT 95 -15 27 230/400 – 302 051 27

EWT 95 -15 36 230/400 – 302 051 36

EWT 95 -15 45 230/400 – 302 051 45

Set-up/Installation

32

3 Set-up/Installation

3.1 Transportation/Storage

Transport the electric heat exchanger only after it has been drained.

Store the flushed and drained electric heat exchanger in interior rooms with

non-aggressive atmosphere only.

3.2 Set-up and Installation Dimensions

Article KW A B C

mm mm Kombi

Socket

EWT 95 -15 18 560 275 d50/11/2”

EWT 95 -15 27 560 275 d50/11/2”

EWT 95 -15 36 675 390 d63/2”

EWT 95 -15 45 845 560 d63/2”

33

Set-up/Installation

3.3 Set-up

Set up the electric heat exchanger in frost-proof and dry rooms with non-agressive

atmosphere only. Dripping water might damage the electric heat exchanger.

Ensure easy access for installation and removal purposes.

The following water values are to be observed for the electric heat exchanger.

EWT 60-20/30

Chloride contents max. up to 500 mg/l

Free chlorine max. up to 1,3 mg/l

pH Value 6,8 – 7,8

Water troughput min. 5000 l/h

Maximum operational overpressure 3,0 bar

The risk of combustion exits in the case of a failure of the safety devices.

Overheating of the electric heat exchanger might cause a fire.

Draining of the electric heat exchanger during operation must be prevented.

Do not store any combustible material in the enviroment.

3.4 Installation

Check the electric heat exchanger before installation for visible damage.

The electric heat exchanger can be installed horizontally above or below water

level.

take care

take care

Set-up/Installation

34

3.5 Water Connection

3.5.1 Installation Layout Above the Water Level

Figure: horizontal installation

Figure: horizontal installation

3.5.2 Installation Layout Below the Water Level

Set-up/Installation

3.5.3 Connecting the Electric Heat Exchanger to the Water Cycle of a

Filter System

Install the electric heat exchanger in the pressure line (to the basin) after pump and

filter.

The electric heat exchanger is integrated into the water cycle with PVC

glued/screwed connections.

The electric heat exchanger can be damaged.

When the heat exchanger is connected to the water cycle, please take care that

metal particles do not enter the electric heat exchanger.

The electric heat exchanger might be damaged by chemicals.

Disinfecting devices are always to be installed in the flow direction after the

electric heat exchanger. The minimum distance must be 1 m and the order:

first water hardness control, than chlorine vaccination is to be observed.

If chemicals (e. g. chlorine gas) are used, gases must not enter the electric

heat exchanger during filter standstill times.

3.6 Electrical connection

The electrical connections are to be executed by an electrical specialist. Local

regulations as well as VDE 0100 are to be taken into consideration.

The electric heat exchanger must be connected on fixed power lines.

The electric heat exchanger must be connected durable and certain on the

ground wire.

The electric heat exchanger must be protected by at least two safety circuit

breakers.

The following safety circuit breakers built in by the factory

- a control thermostat, a safety temperature limiter and a flow control switch

Important!

It should be ensured that the electric heat exchanger can only be switched on if the

water throughput is ensured.

The electrical connections are to be effected in accordance with the switch

diagram.

For safety reasons, an FI safety switch is to be integrated into the voltage supply

(30 mA). All metal parts are to be integraded into equipotential bonding. It ist

absolutely recommended to built in a main protection (circuit diagramm, cap. 9).

By switching of the safety temperature limiter the EWT 95-15 is completely

switched off.

35

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

take care

take care

take care

Functional Course

36

4 Functional Course

In the electric heat exchanger, heat is transferred to the bathwater through the

heating element.

The thermostat regulates the water temperature in accordance with the adjusted

value, range from 4 to 40°C.

By pressing the I/O Button the EWT can be reseted after a breakdown. (LED

Störung is on)

The safety temperature limiter protects from overheating. It switches the electric

heat exchanger off at a temperature of 45°C.

Service control unit

37

5 Service control unit

Event

Pressing button O/I

Unit ON without

FP-running

(FP=filter pump)

Unit ON with

FP-running

(FP=filter pump)

Pressing button X

Pressing button +

Pressing button -

description

Unit is switched ON/OFF

Display shows AUS if the

unit is off

Display shows - 0 -

Display shows the actual

temperature of swimming

pool water

Display shows the target

value (automatically switched

back to actual value after

5 sec.)

If the target value is shown,

the value can be increased

by the + button (permanent

pressed increases the value

quickly)

If the target value is shown,

the value can be increased

by the - button (permanent

pressed decreases the value

quickly)

Symbol

Service control unit

38

Pressing buttons + and -

Pressing button AUTO

Pressing button HAND

Pressing button STUFEN

LED Heizung is flashing

LED Heizung is shining

LED Istwert is shining

LED Sollwert is shining

LED Störung is shining

Degree I is shining

Degree II is shining

If the buttons + and – are

pressed synchronous for 10

sec., display is flashing and the

actual value can be calibrated.

If the button AUTO is pressing

the heating power degree is

automatically selected

If the button HAND is pressing

the heating power degree can

be selected manually. If the

target value is not reached this

heating power degree would

be activated.

At manually selection the

degrees can be choosen

The heating is not activated

because the switch on delay

after starting the filter pump is

running (10 min)

The swimming pool water is

heating

Actual temperature of swim-

ming pool water is shown

Target value is shown. It can

be changed by buttons + and

-

If the security temperature

(45°C) exceeded this LED is

flashing. Could be reseted by

pressing button I/O

Heating of Water by heating

power degree I

Heating of Water by heating

power degree II

Service control unit

39

Degree III is shining

Display shows - 0 -

Display shows FP

Display shows US

Pressing buttons +,-,x

synchronous

Heating of Water by heating

power degree III

Cuurent ok, controller ok, filter

pump not running.

Filter pump is switched offlt

runs the running after time the

filter pump to avoid heating

dam*. To this the filter pump is

switched on 1 min by force.

Flow control switch is activa-

ted. Heating power is

switched off.

switch on delay (10 min) is

skipped.

*running after time to the filter pump only with Kombi-filter controller

(circuit diagram E 302.051.18/51 Chapter 9.1). Recommended.

At AUTO selection the heating power degree would be seleceted by following:

Degree I: The actual value is 0,2°C smaller than the target value.

Degree I and II: The actual value is 0,4°C smaller than the target value.

Degree I and II and II: The actual value is 0,6°C smaller than the target value.

If the target value is not reached by degree I or II after 2 hours, all heating power degree is

activated.

Initial Operation, Maintenance/Repair

40

6 Initial Operation

Have you read and understood these operating instructions – in particular chapter 1,

Safety? Only then are you allowed to start the electric heat exchanger.

• Adjust the desired bathwater temperature in the thermostat

The electric heat exchanger heats the bathwater as long as the adjusted tempera-

ture has not been reached,

The electric heat exchanger can be damaged.

Work in piping and electrical installation are only to be effected by specialist per-

sonnel for safety reasons.

Do not step on the heat exchanger.

Only carry out maintenance and repair work with closed blocking and control units

in the water cycle.

• Ventilate the water cycle

7 Maintenance/Repair

• Check the heat exchanger and its connections for their tightness once a week.

The electric heat exchanger can be damaged.

Work in the electrical heat exchanger are only to be effected by specialist person-

nel for safety reasons.

Do not step on the electric heat exchanger.

Only carry out work in the piping connections with closed blocking and control

units in the water cycle.

7.1 Hibernation of the EWT in Frost-proof Rooms

Intervention in technical systems by unqualified persons might lead to injury or

damage.

For hibernation in frost-proof rooms, the electric heat exchanger must be comple-

tely filled with water or be completely drained.

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

Warnung Vorsicht Gefahr

take care

take care

take care

Maintenance/Repair

41

7.2 Hibernation of the EWT in Non Frost-proof Rooms

Expert Hibernation without frost damage is possible if the following steps are

observed:

• Close blocking units in the water cycle (the blocking units must be

installed in frost-free rooms)

• Flush and drain electric heat exchanger and adjoining pipes until blocking units.

7.2.1 Electric Heat Exchanger with Horizontal Layout

• Remove heat exchanger with horizontal layout.

• Flush heat exchanger in order to remove contamination and

store in a dry place.

Troubleshooting

42

8 Troubleshooting

Effects Checking the possible cause

No performance is te electric heat exchanger connected to the

electrical supply?

have the blocking units been opened?

is the electric heat exchanger completely filled with water?

has the electric heat exchanger been ventilated?

is there sufficient flow (see Technical Data) in the electric

heat exchanger?

Electric heat has the lock between bathwater pump and electrical heat

exchanger is exchanger been activated?

further heated

up, despite

deactivated

bathwater

recirculating

pump

43

Cirquit Diagram

9 Cirquit Diagram

9.1 Connection with Kombi Filter controlling

Cirquit Diagram

44

9.2 Connection without Kombi filter controlling

Table of contents

Other Behncke Industrial Equipment manuals