Behncke QWT User manual

Heat exchanger

INSTRUCTION MANUAL

WTI 100

SWT 100

QWT 100

Supercharged

BEHNCKE GmbH

Bavaria:

Michael-Haslbeck Straße 13

D-85640 Putzbrunn

Phone: +49 (0)89 / 45 69 17-0

Fax: +49 (0)89 / 45 69 17-61

Saxony-Anhalt:

Stötterlinger Straße 36 a

D-38835 Bühne

Phone: +49 (0)39421 / 796-0

Fax: +49 (0)39421 / 796-30

Website: www.behncke.com

Contents

1 Important basic information 1

1.1 General 1

1.2 Symbols and signal words 1

1.3 Copyright protection 1

1.4 Terms of warranty 1

1.5 Product liability 1

2 General information and safety information 2

2.1 Product-related information 2

2.2 Dangers when handling the heat exchanger 3

2.2 Safety measures at the installation site 4

3 Accessories 4

4 Water requirements 5

5 Technical data 5

5.1 QWT 100 5

5.2 SWT 100 6

5.3 SWT 100 titanium 6

5.4 WTI 100 7

5.5 Supercharged 7

6 Installation and connection dimensions 8

6.1 Transport and storage 8

7 Installation 8

7.1 Installation arrangement above the water level 8

7.2 Installation arrangement below the water level 9

7.3 Connecting the heat exchanger 10

7.3.1 Connecting WTI / SWT / QWT to a circulation pump / filter system 10

7.3.2 Connecting QWT 100-140/100-209 and WTI 100-140/100-209 to a filter system 10

7.4 Start-up 10

7.5 Function 11

8 Maintenance and servicing 11

8.1 Storing the heat exchanger over winter in frost-free rooms 11

8.2 Store the heat exchanger over winter in spaces at risk of frost 11

8.2.1 Emptying the heat exchanger in a vertical position 11

8.2.2 Emptying the heat exchanger in a horizontal position 11

9 Diagnosing malfunctions 12

10 Removal and disposal 12

11 Technical illustrations Index: Technical illustrations

12 Declaration of conformity Index: Technical illustrations

Heat exchanger QWT, SWT, WTI / Contents

ENGLISH

1

Heat exchanger QWT, WTI, SWT / Important basic information

1 Important basic information

Thank you for choosing our product. To make sure you can enjoy it for a long time, we ask that you

followthese instructions on how to connect and handle the product correctly.

You must carefully read and understand this instruction manual before connecting and setting up the

product!

The manufacturer does not assume any warranty and/or liability in the event of improper/inappropriate

use.

Before assembly, check that the delivery is complete and that none of the items delivered are damaged.

Keep this instruction manual in a safe place as it contains all the important information about

theproduct.

1.1 General

Symbol Signal word / meaning

DANGER

Alerts you to a dangerous situation that will result in serious injury or death

ifitis not avoided.

CAUTION

Alerts you to a dangerous situation that will result in minor to moderate injury

ifit is not avoided.

ELECTRICAL CONNECTION

Alerts you to a dangerous situation that may result in electric shock and

severeinjury.

NOTE

Alerts you to possible material damage and other important information.

1.2 Symbols and signal words

NOTE

The information, text, plans, images and other illustrations contained herein

are protected by copyright law and are subject to industrial property rights.

Anymisuse is punishable by law.

1.3 Copyright protection

Warranty according to current German legal regulations.

1.4 Terms of warranty

Errors excepted and subject to technical changes.

1.5 Product liability

2

Heat exchanger QWT, WTI, SWT / General information and safety information

ENGLISH

2 General information and safety information

• All BEHNCKE products are made from high-quality materials.

This guarantees years of trouble-free operation.

• These properties will be retained for many years so long as the installation parts are handled

carefully and operated and maintained in accordance with our instruction manual.

• We recommend arranging a maintenance contract with your specialist swimming pool dealer.

Thisis an optimal prerequisite for safe operation, even beyond the warranty period.

• The cross-wound coil heat exchanger is designed for heating swimming pool water in private pools

in non-explosive spaces.

CAUTION

Watch out for edges and corners during unpacking and assembly.

Wear gloves.

• Assembly, installation and maintenance may only be carried out by trained and authorised

specialists.

• Only use specially suitable stainless steel tools when handling stainless steel.

• Within the agreed warranty period, no unauthorised procedures or modications may be carried

outunless done with the express consent of our company. Failure to comply with this will

invalidate the warranty.

• Please order replacement parts from your specialist swimming pool dealer.

• Only use the components / accessories supplied. If a component or accessory is missing,

you can request the missing original part from us.

The heat exchanger is designed for heating swimming pool water in private pools in non-explosive areas.

The heat exchanger in the QWT series is designed exclusively for heating up pool water by means of a hot

water heater.

The SWT series heat exchanger is designed exclusively for heating pool water using a heat pump,

solarpower system or a low-temperature heating system.

The WTI series heat exchanger is designed exclusively for heating pool water by means of a hot

waterheater; suitable for water with an increased chloride content (e.g. brine pools, therapy pools,

seawater pools).

The SWT-T series heat exchanger is designed exclusively for heating pool water using a heat pump,

solarpower system or a low temperature heating system; suitable for water with an increased chloride

content (e.g. brine pools, therapy pools, seawater pools).

Any other use or use that goes beyond this is considered improper use.

The manufacturer, Behncke GmbH, is not liable for any damage resulting from this.

Other uses are only possible following consultation with and approval from the manufacturer.

2.1 Product-related information

3

Heat exchanger QWT, WTI, SWT / General information and safety information

DANGER

Proper use also includes

•observing all the instructions in the installation instructions

•complying with inspection and maintenance works

Modications and alterations to the heat exchanger are forbidden for

safetyreasons!

CAUTION

The maximum permissible positive operating pressure must not be exceeded:

Heating coil (primary side) max. 1000 kPa (10 bar)

Pool water (secondary side) max. 300 kPa (3 bar)

DANGER

The heat exchanger must be connected to additional protective potential

equalisation.

When it comes to electrical installations in swimming pools, please observe

DIN VDE 0100 Part 702.

The heat exchangers are state-of-the-art and built in accordance with recognised safety regulations.

However, their use – especially if used or operated incorrectly – may pose a risk:

•to the life and limb of the operator or a third party or

•of damage to the heat exchanger or other material assets.

Anyone involved with assembly, start-up, operation, maintenance and servicing the heat exchanger must:

•be mentally and physically suitable for it.

•be trained in its use.

•strictly follow this instruction manual..

2.2 Dangers when handling the heat exchanger

CAUTION

There is a risk of combustion as the heating connections from the heat

exchanger can reach a temperature of 100°C.

CAUTION

Contact corrosion is a risk due to water dripping onto the outer skin or when

metal parts are washed into the heat exchanger.

4

Heat exchanger QWT, WTI, SWT / Accessories

ENGLISH

CAUTION

The heat exchanger itself can heat up to the ow temperature of the heating

water if the pool water does not ow through it.

Connected plastic lines may be subjected to unacceptable thermal loads and

damaged as a result.

If the heating circuit is not locked with the circulation/lter pump, the heat

exchanger may heat up to the ow temperature of the heating water.

The heat exchanger must be installed in a frost-free room with the mounting bracket supplied.

Ensure that the maximum positive operating pressures of 300 kPa (3 bar) on the secondary side or

1000kPa (10 bar) on the primary side are not exceeded.

2.2 Safety measures at the installation site

CAUTION

The heat exchanger and its surroundings may be damaged if the guidelines

are not followed.

Check the heat exchanger and its connections for leaks and visible damage

at least once a week while the pool is in use.

3 Accessories

Below you will nd all suitable products we have on offer:

Product: Item number

Pipe clamp attachment for QWT 100-20 30/40 305 100 10

Pipe clamp attachment for QWT100-70 to 209, SWT 100-40/52 305 100 12

InovaNH 25/40 heating pump, 230 volts, 50 Hz 391 091 11

InovaNH 25/60 heating pump, 230 volts, 50 Hz 391 091 12

Non-return valve MS 3/4 391 017 00

Non-return valve MS 1 391 018 00

Immersion sensors 309 190 10

5

Heat exchanger QWT, WTI, SWT / Water requirements

5 Technical data

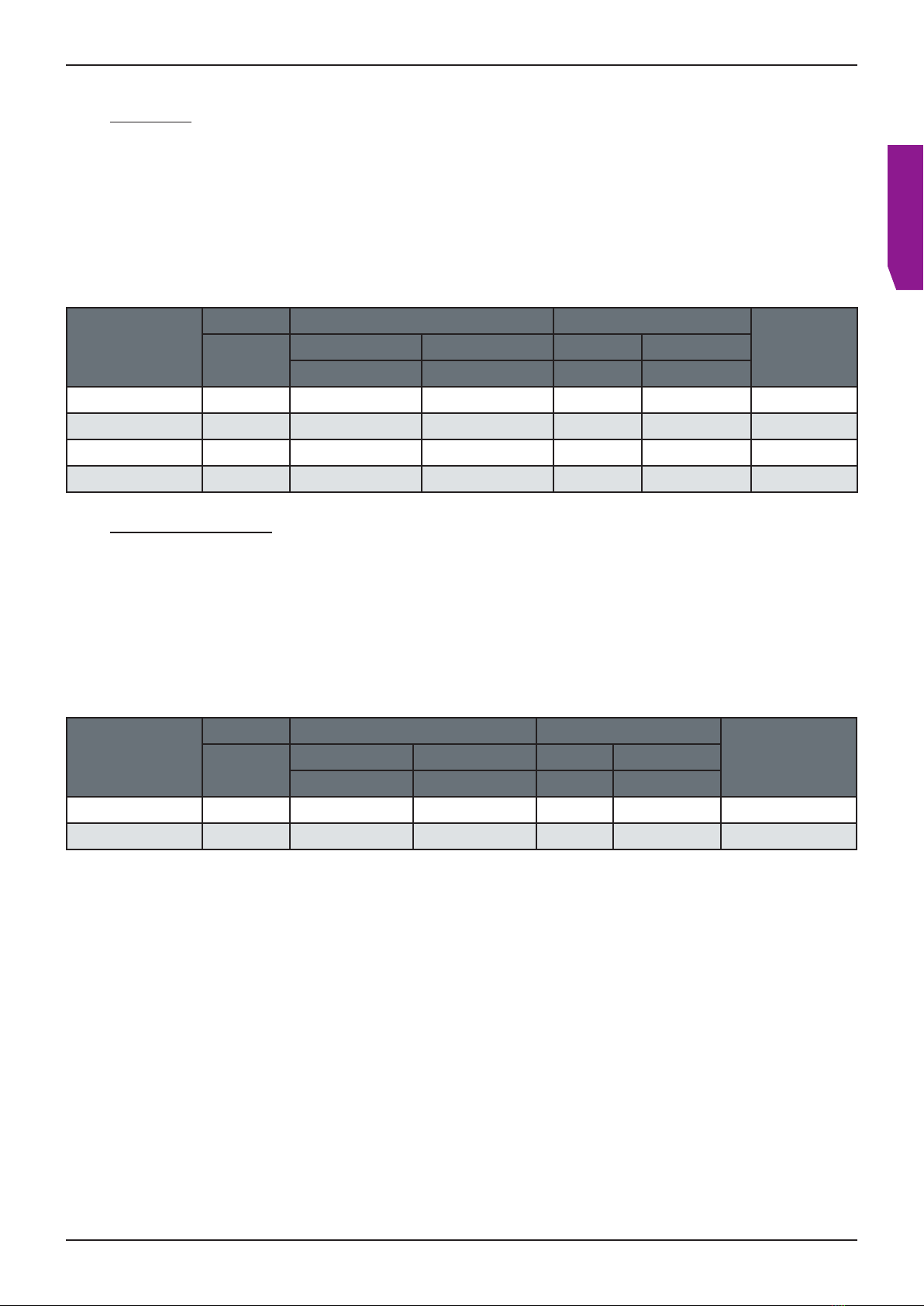

Item

output Minimum pump capacity Pressure loss

Item no.

kW at 90° Heating Pool water Heating Pool water

m³/h m³/h kPa kPa

QWT 100-20 23 2 10 4.1 4.3 305 018 00

QWT 100-30 32 2 10 6.2 4.9 305 026 00

QWT 100-40 46 2 10 9.3 5.3 305 003 00

QWT 100-70 75 3 12 3.4 7.2 305 017 00

QWT 100-104 137 5 15 13.2 11.3 305 027 00

QWT 100-140 168 2 x 3 20 2 x 3.4 14.1 305 037 00

QWT 100-209 304 2 x 3 25 2 x 13.2 17.0 305 047 00

2 combi sockets 1 ½” x DN 40 or 2” x DN50

For heating the pool water by connecting to a central heating system.

Consisting of a stainless steel jacket with a welded-in stainless steel coil, complete with a thermowell

forthe installation of an electronic temperature sensor. Holder and rubber hose assembly kit.

5.1 QWT 100

Operating pressure: on the heating side: 10 bar

on the pool water side: 3 bar

QWT, SWT WTI, SWT-T

Chloride max. 500 mg/l max. 3000 mg/l

Free chlorine content max. 1.3 mg/l unlimited

pH value min. 6.8 min. 6.5

max. 8.2 max. 8.2

Iron max. 0.1 mg/l max. 0.1 mg/l

Copper max. 0.2 mg/l max. 0.2 mg/l

Salt content max. 0.08% max. 3.5%

Temperature max. 40°C max. 40°C

Langelier index of -0,3 – +0,3 of -0,3 – +0,3

4 Water requirements

Water in swimming/bathing pools or swimming/bathing ponds must not exceed or fall short of the

following values.

6

Heat exchanger QWT, WTI, SWT / Technical data

ENGLISH

Item

output Minimum pump capacity Pressure loss

Item no.

kW at 50° Heating Pool water Heating Pool water

m³/h m³/h kPa kPa

SWT 100-20 22 1.2 10 4.1 5.8 330 004 00

SWT 100-25 38 1.8 10 6.2 6.9 330 006 00

SWT 100-40 46 3.0 10 9.3 5.5 330 008 00

SWT 100-52 67 3.6 12 3.4 9.2 330 010 00

Combo socket 1 ½” x DN 40

For heating the swimming pool water by connecting to a solar power system, heat pump or

alow-temperature heating system.

Consisting of an outer stainless steel jacket with welded-in stainless steel coil, complete with a thermowell

for the installation of an electronic temperature sensor. Including a holder and rubber hose assembly kit.

5.2 SWT 100

Operating pressure: on the heating side: 10 bar

on the pool water side: 3 bar

Item

output Minimum pump capacity Pressure loss

Item no.

kW at 50° Heating Pool water Heating Pool water

m³/h m³/h kPa kPa

SWT 100-20 22 1.2 10 7.6 5.8 330 004 00 -19

SWT 100-40 46 3.0 10 6.9 5.5 331 008 00 -19

2 sockets 1 ½” (titanium)

For use with water with a high chloride content (unlimited)

For heating the pool water by connecting to a central heating system, complete with a welded thermowell.

Less prone to calcication.

5.3 SWT 100 titanium

Operating pressure: on the heating side: 10 bar

on the pool water side: 3 bar

7

Heat exchanger QWT, WTI, SWT / Technical data

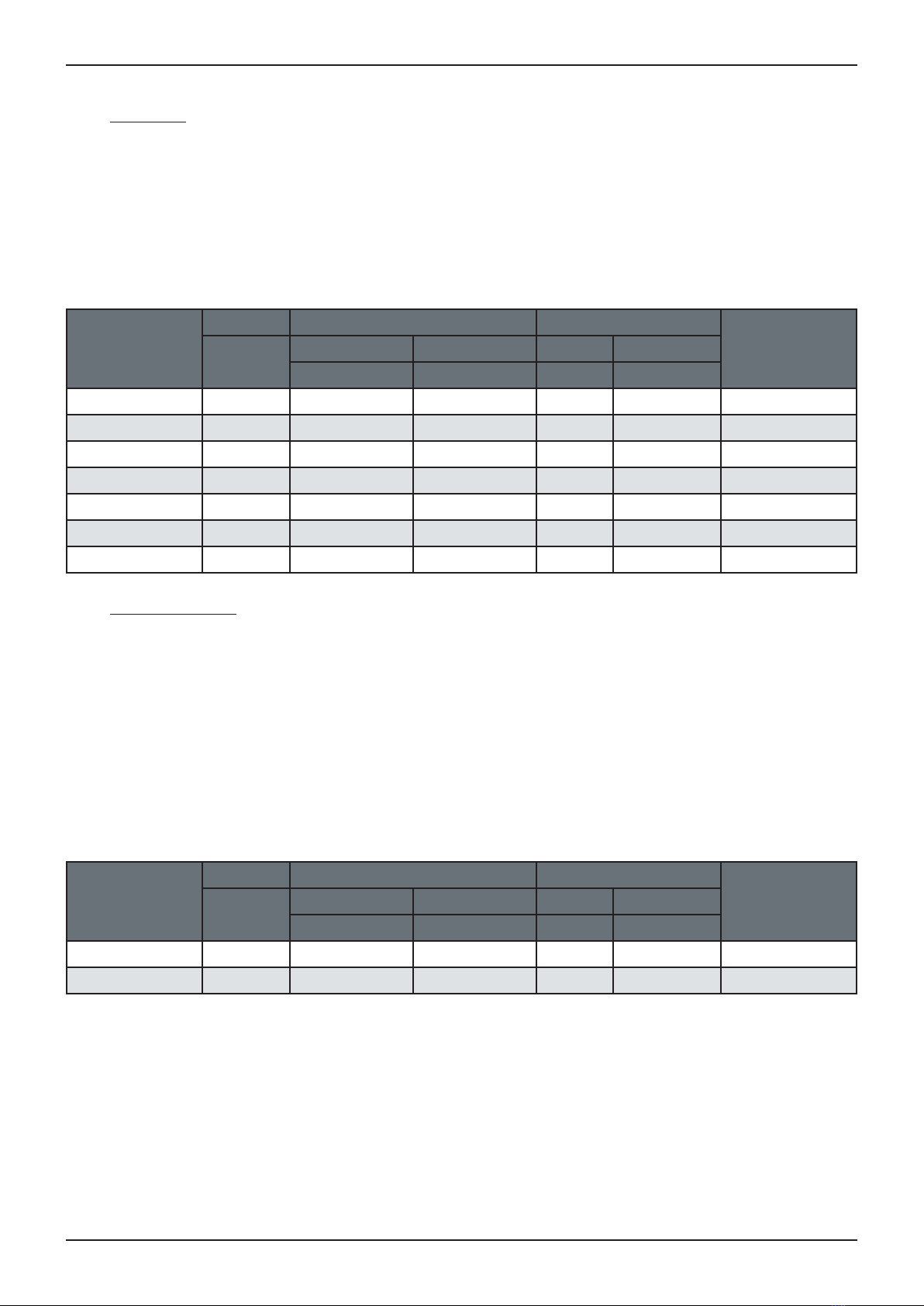

Item

output Minimum pump capacity Pressure loss

Item no.

kW at 90° Heating Pool water Heating Pool water

m³/h m³/h kPa kPa

WTI 100-20 23 2 10 4.1 4.3 305 080 55-19

WTI 100-30 32 2 10 6.2 4.9 305 081 55-19

WTI 100-40 46 2 10 9.3 5.3 305 082 55-19

WTI 100-70 75 3 12 3.4 7.2 305 083 55-19

WTI 100-104 137 5 15 13.2 11.3 305 084 55-19

WTI 100-140 168 2 x 3 20 2 x 3.4 14.1 305 085 55-19

WTI 100-209 304 2 x 5 25 2 x 13.2 17.0 305 086 55-19

2 sockets 1 ½” or 2” (titanium)

For use in water with a high chloride content (unlimited).

For heating the pool water by connecting to a central heating system, complete with a welded thermowell.

Less prone to calcication.

5.4 WTI 100

Operating pressure: on the heating side: 10 bar

on the pool water side: 3 bar

Item

output Minimum pump capacity Pressure loss

Item no.

kW at 90° Heating Pool water Heating Pool water

m³/h m³/h kPa kPa

SC 50 50 2 10 33.4 5.2 305 050 00

SC 100 85 3 12 10.2 6.6 305 050 10

Combo socket 1 ½” x DN40

For heating the pool water by connecting to a central heating system.

Consisting of an outer stainless steel jacket with a cross-wound coil, complete with a thermowell for the

installation of an electronic temperature sensor.

Holder and rubber hose assembly kit.

Efciency increased by 20%.

Safe from calcication!

5.5 Supercharged

Operating pressure: on the heating side: 10 bar

on the pool water side: 3 bar

8

Heat exchanger QWT, WTI, SWT / Installation and connection dimensions

ENGLISH

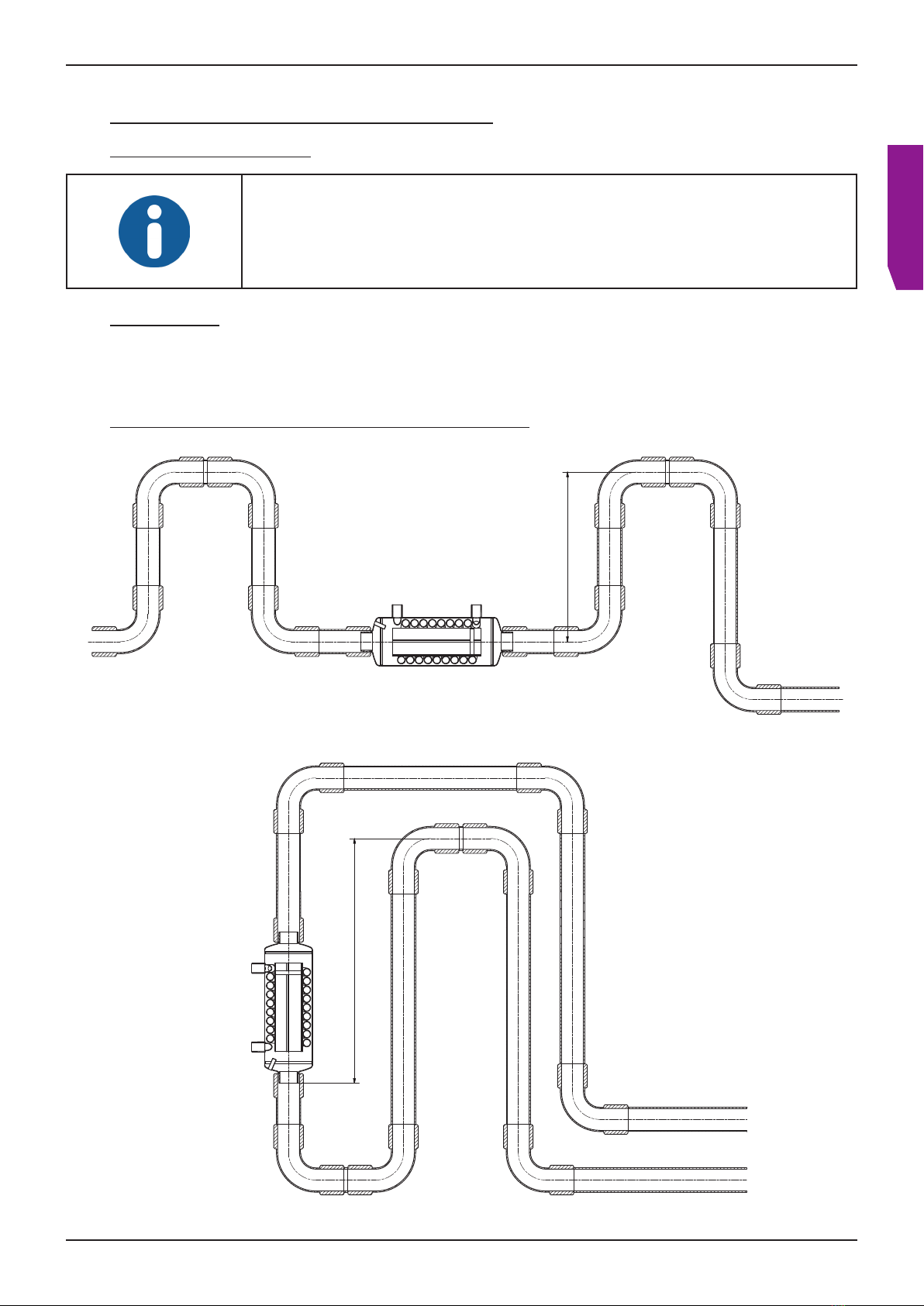

7 Installation

Before installation, check the heat exchanger for visible damage.

The heat exchanger can be installed horizontally or vertically above or below the water level.

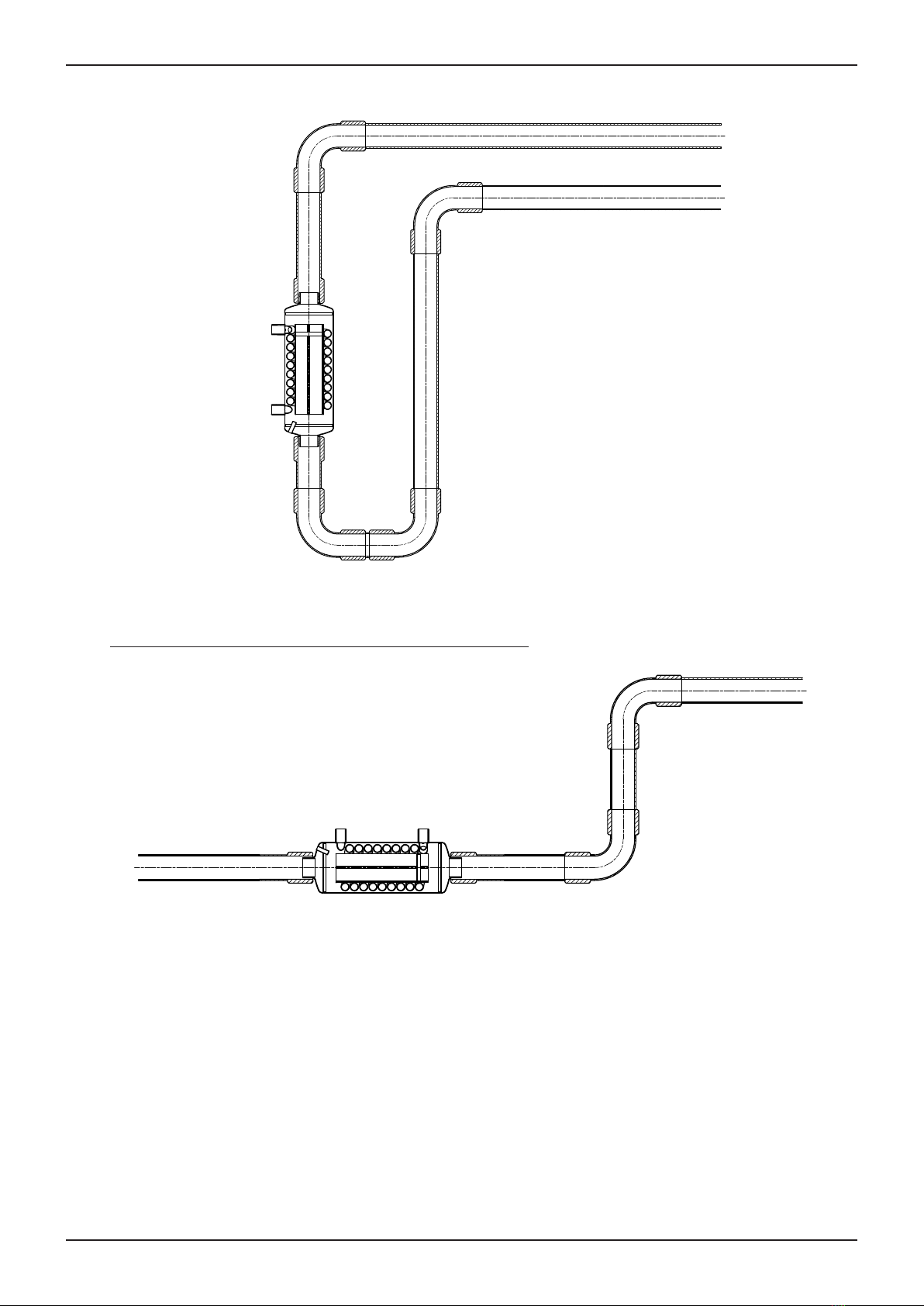

7.1 Installation arrangement above the water level

A-A ( 1 : 5 )

A

A

min. 1m

Horizontal installation, above the water level

B-B ( 1 : 5 )

B

B

min. 1m

Vertical installation, above the water level

6 Installation and connection dimensions

6.1 Transport and storage

NOTE

Only transport the water heat exchanger when it is empty!

Only store the rinsed and drained water heat exchanger inside rooms with

anon-aggressive atmosphere.

9

Heat exchanger QWT, WTI, SWT / Installation

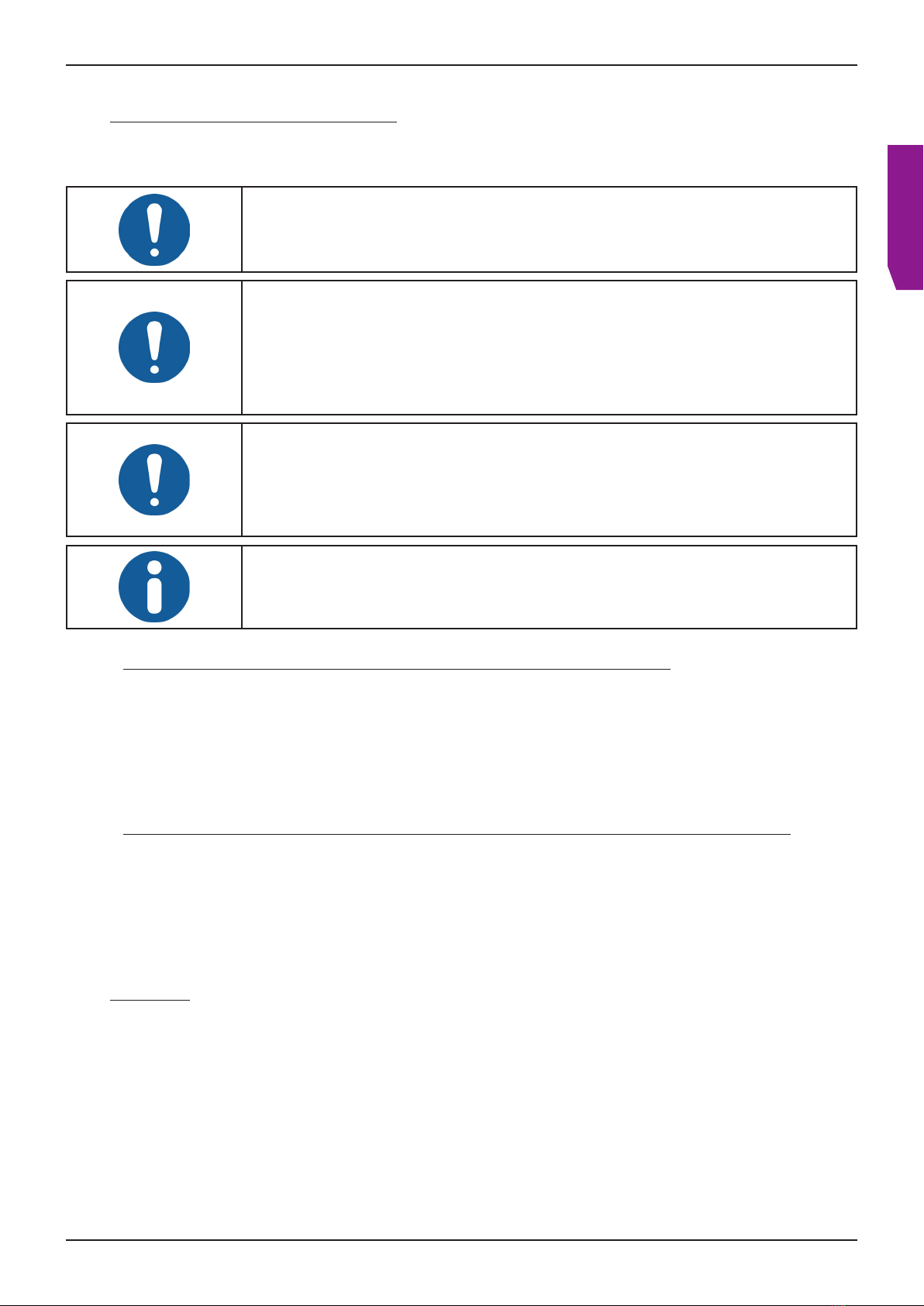

7.2 Installation arrangement below the water level

B-B ( 1 : 6 )

B

B

Horizontal installation, below the water level

C-C ( 1 : 5 )

C

C

Vertical installation, above the water level

10

Heat exchanger QWT, WTI, SWT / Installation

ENGLISH

CAUTION

Ensure that the water quality and the maximum pressures are maintained.

CAUTION

When connecting to external circuits, ensure that no metal parts are introduced

into the heat exchanger.

Brass connections between the heat exchanger and the steel pipes are

electrically isolated

CAUTION

The heat exchanger may be damaged by chemicals.

If chemicals (e.g. chlorine gas) are used, no gases may enter the heat

exchanger during lter downtimes.

NOTE

Generally, disinfectors must be installed after the heat exchanger.

•Connect the heating water circuit to the primary side of the heat exchanger.

•Connect the secondary side of the heat exchanger to the pool water pipework via hose

connections with hose clamps or via the internal thread with plastic and brass ttings.

•Connect the WTI and SWT-T to the pool water pipework on the secondary side using

PVCpipe adhesive joints.

7.3 Connecting the heat exchanger

•Connect both heating coils of the heat exchanger to the heating water circuit.

•Connect the secondary side of the heat exchanger to the pool water pipework via hose

connections with hose clamps or via the internal thread with plastic and brass ttings.

•Connect the WTI to the pool water pipework on the secondary side using PVC pipe

adhesive joints.

7.3.1 Connecting WTI / SWT / QWT to a circulation pump / filter system

Have you read and understood this instruction manual – in particular “Chapter 1 – Safety”?

Do not activate the heat exchanger until you have!

The heat exchanger may be damaged.

Do not climb on the heat exchanger.

Only carry out maintenance and cleaning work when the shut-off valves are closed in both water circuits!

Bleed the air from both water circuits.

7.3.2 Connecting QWT 100-140/100-209 and WTI 100-140/100-209 to a filter system

7.4 Start-up

Install shut-off valves and drain valves in the ow and return lines of the heating circuit within the frost-

proof building area.

11

Heat exchanger QWT, WTI, SWT / Maintenance and servicing

In the counter-current heat exchanger QWT, the heat is transferred from the heating water circuit to the

pool water circuit.

In the counter-current heat exchanger WTI , the heat is transferred from the heating water circuit to the

pool water circuit.

In the counter-current heat exchanger SWT, the heat is transferred from the low-temperature heating water

circuit or the solar power system to the pool water circuit.

The SWT-T is made of titanium and is suitable for use in water with increased free chlorine levels

(e.g.brine pools, therapy pools, seawater pools).

A temperature sensor can be inserted into the integrated clamping device in the thermowell. In conjunction

with a control system, the temperature of the pool water can be regulated via the thermostat.

7.5 Function

Check the heat exchanger and the connections for leaks every week.

8 Maintenance and servicing

CAUTION

Procedures carried out on technical systems by non-experts may lead to

injuries and material damage.

8.1 Storing the heat exchanger over winter in frost-free rooms

When shutting down in frost-free rooms, the heat exchanger must be completely lled with water.

8.2 Store the heat exchanger over winter in spaces at risk of frost

It is possible to store the heat exchanger over winter without frost damage if the following steps are taken.

•Close the shut-off valves in both water circuits.

•Drain the heat exchanger and the connecting pipework to the shut-off devices.

8.2.1 Emptying the heat exchanger in a vertical position

Completely drain the heat exchanger via drain ttings.

8.2.2 Emptying the heat exchanger in a horizontal position

Remove the heat exchanger properly, then rinse thoroughly to remove impurities and store when dry.

CAUTION

Do not store the heat exchanger in the immediate vicinity of chemicals.

12

Heat exchanger QWT, WTI, SWT / Diagnosing malfunctions

ENGLISH

9 Diagnosing malfunctions

DANGER

Maintenance and repair may only be carried out by trained and approved

specialists. We recommend making a maintenance contract that includes

inspecting and servicing the heat exchanger.

Assessment Possible causes Remedy

No output

Are the shut-off valves open?

Is the heat exchanger completely

lled with water in both circuits?

Has the heat exchanger been bled?

Is there sufcient ow (see technical

data) in the heating circuit?

Lower output Calcication of the heat exchanger Remove the appliance and rinse with

limescale-removing acid.

Formation of corrosion Missing connection to protective

potential equalisation Check connection (if possible)

Chloride content too high

pH value too low

Check water values Check

targetvalues and adjust

settings if necessary Increase

fresh water supply If possible,

removecorrosionRemove

10 Removal and disposal

DANGER

Removal and disposal may only be carried out by trained and approved

specialists.

You can dispose of the heat exchanger packaging materials separately

in their respective household waste bin.

Before starting work, disconnect the heat exchanger from the water supply; the supply and discharge

linesmust be closed beforehand.

Remove the heat exchanger properly.

Please also dispose of the stainless steel parts according to the applicable local regulations,

separatelyfrom other materials, and take the scrap stainless steel to a recycling plant.

11 Technical illustrations Index: Technical illustrations

12 Declaration of conformity Index: Technical illustrations

CAUTION

Ensure your own safety during removal.

Wear safety equipment (e.g. safety gloves, boots and goggles)!

Stainless steel edges may be sharp after disassembly.

This manual suits for next models

49

Table of contents

Other Behncke Industrial Equipment manuals