8© behr Labor-Technik GmbH

217201

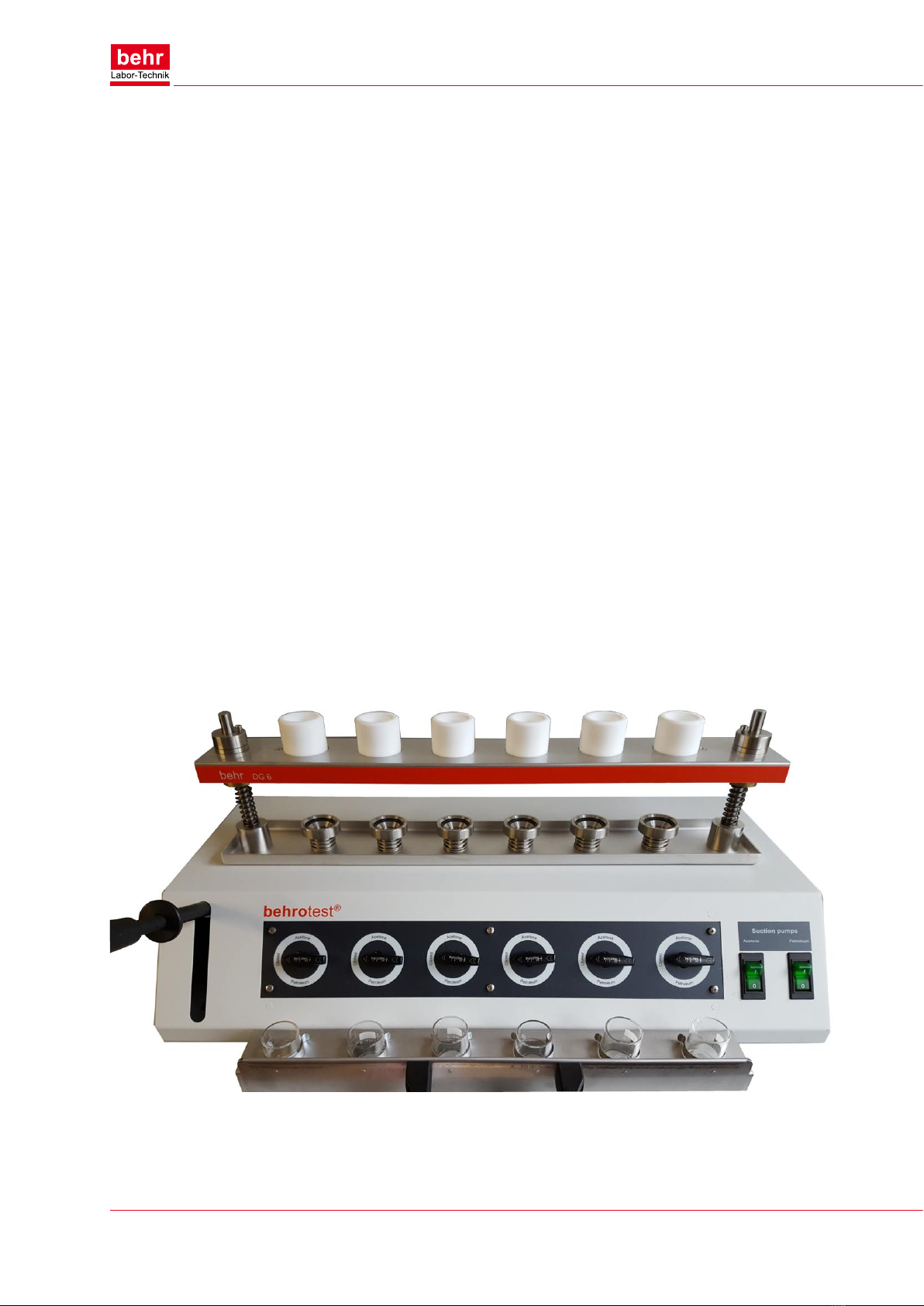

Taking Out and Inserting the Crucibles

Crude-Fibre determination with the CF 2+2 / CF 6

is performed with the same filter crucibles for

digestion, filtration and incineration. The crucibles

are locked under the condensers of the digestion

device. In order to insert the crucibles, to take them

out or to transfer them from the digestion device

to the defattening device and back, there's the

multi-crucible snapper. It makes you sure not to mix

the samples up. (On delivery, the crucibles came

packed separately.)

If you unlock the lock lever without

gripping the crucibles before with the

multi-crucible snapper, the crucibles

will fall out of the device and break.

So always grip the crucibles with the

multi-crucible snapper, then unlock

the lock lever and take the crucibles

out simultaneously. Doing it this way,

you always have the crucibles in the

proper order and are sure not to mix

the samples up.

During a digestion, the crucibles are concealed

behind the heat shield. In order to take the

crucibles out after digestion and filtration, you need

first to take the heat shield off.

Grasping the heat shield with the handle, lift it

up a bit so the two "keyholes" will pass over the

pins that are holding it.

Take the heat shield off and lay it aside.

Now push the multi-crucible snapper on the

crucibles that are locked in the device. You will

need to press quite firmly until all four or six

spring clips have properly locked on the cruci-

bles.

Now you can unlock the crucibles:

Release the lock lever by pressing it down a

bit and pulling the locking grip towards yourself

with your thumb.

Let the lever come up to the end position;

release the locking grip as soon as the lever is

out of the lock position.

With the multi-crucible snapper, take the cru-

cibles out of the device and insert them in the

crucible rack in front of the device.

In order to insert the crucibles in the device again,

proceed in inverse direction. In the same way insert

the crucibles in the optional defattening unit DG 2+2

/ DG 6 and back out.

Some Routine Procedures With This Device