Beijer Electronics GT-5422 User manual

User Manual

GT-5422 PWM Output Module

2 ch, 24 VDC, 2 A, source, cage clamp, 18 pt removable terminal

Doc ID: 131321

2024-01

Copyright © 2023 Beijer Electronics AB. All rights reserved.

The information in this document is subject to change without notice and is provided as

available at the time of printing. Beijer Electronics AB reserves the right to change any

information without updating this publication. Beijer Electronics AB assumes no responsibility

for any errors that may appear in this document. All examples in this document are only

intended to improve understanding of the functionality and handling of the equipment. Beijer

Electronics AB cannot assume any liability if these examples are used in real applications.

In view of the wide range of applications for this software, users must acquire sufficient

knowledge themselves in order to ensure that it is correctly used in their specific application.

Persons responsible for the application and the equipment must themselves ensure that each

application is in compliance with all relevant requirements, standards, and legislation in respect

to configuration and safety. Beijer Electronics AB will accept no liability for any damage

incurred during the installation or use of equipment mentioned in this document. Beijer

Electronics AB prohibits all modification, changes, or conversion of the equipment.

Head Office

Beijer Electronics AB

Box 426

201 24 Malmö, Sweden

www.beijerelectronics.com / +46 40 358600

Table of Contents

1. About This Manual ......................................................................................... 5

1.1. Symbols Used in This Manual ................................................................... 5

2. Safety ....................................................................................................... 6

2.1. Product Certifications ........................................................................... 6

2.2. General Safety Requirements .................................................................. 6

3. About the G-series System ............................................................................... 7

3.1. I/O Process Data Mapping ....................................................................... 8

4. Specifications .............................................................................................. 9

4.1. Environmental Specifications ................................................................... 9

4.2. General Specifications ........................................................................... 9

4.3. Output Specifications ........................................................................... 10

5. Wiring Diagram ........................................................................................... 11

6. LED Indicator .............................................................................................. 13

7. Mapping Data Into the Image Value ................................................................... 14

8. Parameter Data ........................................................................................... 15

9. Hardware Setup .......................................................................................... 16

9.1. Space Requirements ............................................................................ 16

9.2. Mounting and Dismounting from DIN Rail .................................................... 17

9.3. Mounting and Dismounting an IO Module .................................................... 18

9.4. Dismounting a Removable Terminal Block ................................................... 19

9.5. Wiring ............................................................................................. 19

Beijer Electronics, Doc ID: 131321 3 2024-01

4

1. About This Manual

This manual contains information on the software and hardware features of the Beijer Electronics

GT-5422 PWM Output Module. It provides in-depth specifications, guidance on installation, setup, and

usage of the product.

1.1. Symbols Used in This Manual

This publication includes Warning, Caution, Note and Important icons where appropriate, to point out

safety-related, or other important information. The corresponding symbols should be interpreted as

follows:

WARNING

The Warning icon indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury, and major damage to the product.

CAUTION

The Caution icon indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury, and moderate damage to the product.

NOTE

The Note icon alerts the reader to relevant facts and conditions.

IMPORTANT

The Important icon highlights important information.

About This Manual

Beijer Electronics, Doc ID: 131321 5 2024-01

2. Safety

Before using this product, please read this manual and other relevant manuals carefully. Pay full

attention to safety instructions!

In no event will Beijer Electronics be responsible or liable for damages resulting from the use of this

product.

The images, examples and diagrams in this manual are included for illustrative purposes. Because of

the many variables and requirements associated with any particular installation, Beijer Electronics

cannot take responsibility or liability for actual use based on the examples and diagrams.

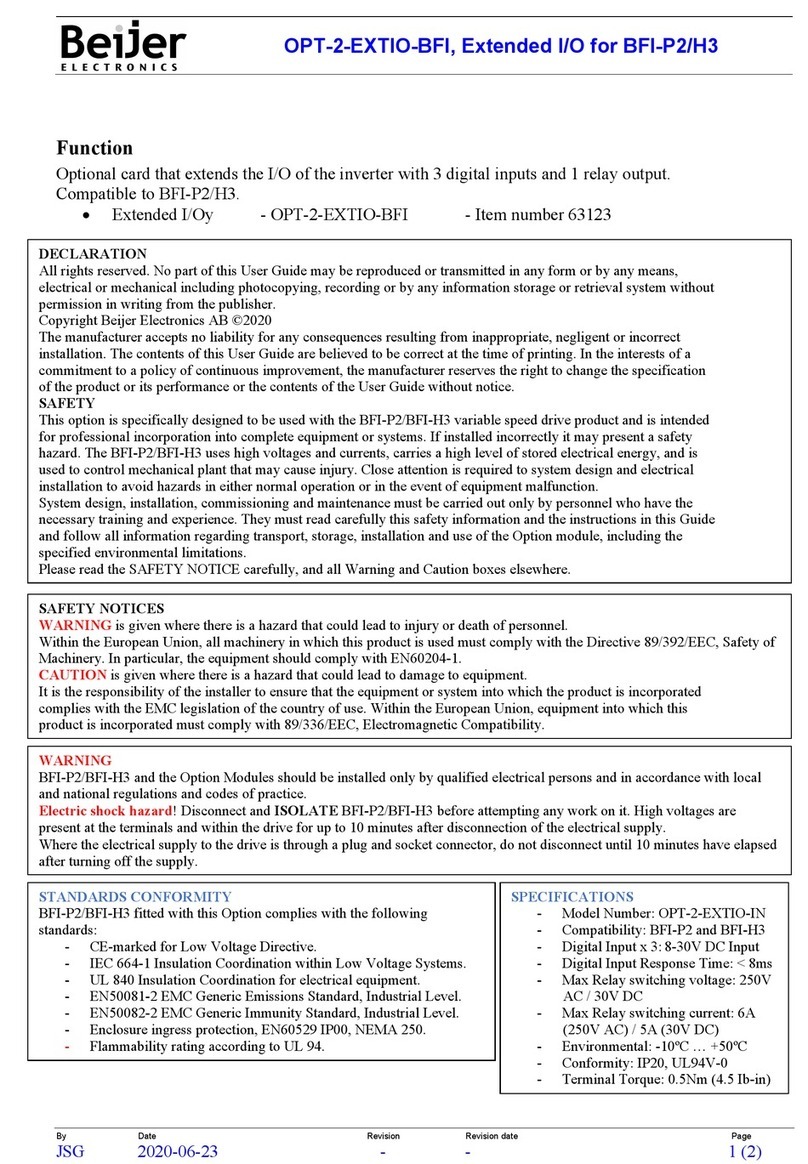

2.1. Product Certifications

The product has the following product certifications.

2.2. General Safety Requirements

WARNING

• Do not assemble the products and wires with power connected to the system.

Doing so cause an "arc flash", which can result in unexpected dangerous events

(burns, fire, flying objects, blast pressure, sound blast, heat).

• Do not touch terminal blocks or IO modules when the system is running. Doing so

may cause electric shock, short circuit or malfunction of the device.

• Never let external metallic objects touch the product when the system is running.

Doing so may cause electric shock, short circuit or malfunction of the device.

• Do not place the product near inflammable material. Doing so may cause a fire.

• All wiring work should be performed by an electrical engineer.

• When handling the modules, ensure that all persons, the workplace and the

packing are well grounded. Avoid touching conductive components, the modules

contain electronic components that may be destroyed by electrostatic discharge.

CAUTION

• Never use the product in environments with temperature over 60℃. Avoid placing

the product in direct sunlight.

• Never use the product in environments with over 90% humidity.

• Always use the product in environments with pollution degree 1 or 2.

• Use standard cables for wiring.

Safety

2024-01 6 Beijer Electronics, Doc ID: 131321

3. About the G-series System

System overview

•Network Adapter Module - The network adapter module forms the link between the field bus and

the field devices with the expansion modules. The connection to different field bus systems can be

established by each of the corresponding network adapter module, e.g., for MODBUS TCP, Ethernet

IP, EtherCAT, PROFINET, CC-Link IE Field, PROFIBUS, CANopen, DeviceNet, CC-Link, MODBUS/Serial

etc.

•Expansion Module - Expansion module types: Digital I/O, Analog I/O, and Special modules.

•Messaging - The system uses two types of messaging: Service messaging and I/O messaging.

About the G-series System

Beijer Electronics, Doc ID: 131321 7 2024-01

3.1. I/O Process Data Mapping

An expansion module has three types of data: I/O data, configuration parameter and memory

register. The data exchange between the network adapter and the expansion modules is made via I/O

process image data by internal protocol.

Data flow between network adapter (63 slots) and expansion modules

The input and output image data depend on the slot position and the data type of the expansion

slot. The ordering of input and output process image data is based on the expansion slot position.

Calculations for this arrangement are included in the manuals for Network adapter and Programmable

I/O modules.

Valid parameter data is based on the modules in use. For example, analog modules have settings

of either 0-20 mA or 4-20 mA, and temperature modules have PT100, PT200, PT500 etc. The

documentation for each module provides a description of the parameter data.

About the G-series System

2024-01 8 Beijer Electronics, Doc ID: 131321

4. Specifications

4.1. Environmental Specifications

Operating temperature -20 ℃ - 60 ℃

UL temperature -20 ℃ - 60 ℃

Storage temperature -40 ℃ - 85 ℃

Relative humidity 5 % - 90 % non-condensing

Mounting DIN rail

Shock operating IEC 60068-2-27 (15G)

Vibration resistance IEC 60068-2-6 (4 g)

Industrial emissions EN 61000-6-4/A11 : 2011

Industrial immunity EN 61000-6-2 : 2019

Installation position Vertical and horizontal

Product certifications CE, FCC, UL, cUL

4.2. General Specifications

Power dissipation Max. 75 mA @ 5 VDC

Isolation I/O to Logic: Photocoupler isolation

Field power: Non-isolation

UL field power Supply voltage: 24 VDC nominal, Class 2

Field power Supply voltage: 24 VDC nominal

Voltage range: 15-30 VDC

Power dissipation: Max. 15 mA @ 24 VDC except load

Single wire I/O Cable Max. 0.823mm² (AWG18)

Weight 63 g

Module size 12 mm x 109 mm x 70 mm

Specifications

Beijer Electronics, Doc ID: 131321 9 2024-01

4.2.1. Dimensions

Module dimensions (mm)

4.3. Output Specifications

Number of channels 2 channels

Number of outputs 2 outputs, push-pull type

Indicators 2 green pulse output LEDs

Output voltage Nominal 24 VDC (depends on field power)

Output current 2 A per channel

4 A per module

Automatically switch current (sink/source) according to external

load

Pulse output frequency 1-5 kHz ± 0.5 %

Pulse output duty 0.0 - 100.0 % ±1.0 % (0.1 % / 1 LSB), Ton > 1 us, Toff > 1 us

Protection Short protection

Common type 2 common (field power 0 V is common)

Specifications

2024-01 10 Beijer Electronics, Doc ID: 131321

5. Wiring Diagram

NOTE

Automatically switch current (sink/source) according to external load.

Pin no. Signal description

0 PWM output channel #0

1 Field Power 0 V, common

2 Not connected

3 Not connected

4 Not connected

5 Not connected

6 Not connected

7 Not connected

8 PWM output channel #1

9 Field Power 0 V, common

10 Not connected

11 Not connected

12 Not connected

Wiring Diagram

Beijer Electronics, Doc ID: 131321 11 2024-01

Pin no. Signal description

13 Not connected

14 Not connected

15 Not connected

16 Shield

17 Shield

Wiring Diagram

2024-01 12 Beijer Electronics, Doc ID: 131321

6. LED Indicator

LED no. LED function / description LED color

0 PMW output channel #0 Green

1 PMW output channel #1 Green

Channel Status

Status LED Indicates

No signal Off No output signal

On signal Green Normal operation

LED Indicator

Beijer Electronics, Doc ID: 131321 13 2024-01

7. Mapping Data Into the Image Value

Input image value

Bit no. Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 Reserved

Byte 1 Reserved

Output image value

Bit no. Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 Frequency CH#0, low byte

Byte 1 Frequency CH#0, high byte

Byte 2 Duty CH#0, low byte

Byte 3 Duty CH#0, high byte

Byte 4 Frequency CH#1, low byte

Byte 5 Frequency CH#1, high byte

Byte 6 Duty CH#1, low byte

Byte 7 Duty CH#1, high byte

NOTE

Range of each Duty is 0 (0.0 %) - 1000 (100.0%). Ex. If Duty value is 365, then duty

rate is 36.5 %.

Mapping Data Into the Image Value

2024-01 14 Beijer Electronics, Doc ID: 131321

8. Parameter Data

Valid parameter length: 2 Bytes

Bit no. Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 Reserved

Byte 1 Reserved

Parameter Data

Beijer Electronics, Doc ID: 131321 15 2024-01

9. Hardware Setup

CAUTION

Hot surface! The surface of the housing can become hot during operation. If the

device is used in high ambient temperatures, always let the device cool down before

touching it.

CAUTION

Working on energized devices can damage the equipment! Always turn off the power

supply before working on the device.

9.1. Space Requirements

The following drawings show the space requirements when installing the G-series modules. The

spacing creates space for ventilation, and prevents conducted electromagnetic interference from

influencing the operation. Installation position is valid vertical and horizontal. The drawings are

illustrative and may be out of proportion.

CAUTION

NOT following the space requirements may result in damaging the product.

Hardware Setup

2024-01 16 Beijer Electronics, Doc ID: 131321

9.2. Mounting and Dismounting from DIN Rail

The module should be fixed onto the DIN rail with the locking lever. See the instructions below for

mounting and dismounting a module from the DIN rail.

Mounting on DIN rail

Dismounting from DIN rail

Hardware Setup

Beijer Electronics, Doc ID: 131321 17 2024-01

9.3. Mounting and Dismounting an IO Module

The module should be fixed onto the DIN rail with the locking lever. See the instructions below for

mounting and dismounting an IO Module.

Dismounting an IO module

Locking lever

Hardware Setup

2024-01 18 Beijer Electronics, Doc ID: 131321

9.4. Dismounting a Removable Terminal Block

The terminal block can be removed using the locking switch. See the instructions below for

dismounting a removable terminal block.

9.5. Wiring

See the instructions below for connecting and removing cables to the terminal block.

WARNING

Always use recommended supply voltage and frequency!

Hardware Setup

Beijer Electronics, Doc ID: 131321 19 2024-01

20

Table of contents

Other Beijer Electronics Control Unit manuals