TFP1020

Page 4 of 20

ifications are NPT threaded per ANSI

Standard B1.20.1. Trim port connec-

tions of valves having flanges drilled

to ISO are available either threaded

per ISO 7-1 or NPT threaded per ANSI

Standard B1.20.1. Valves with NPT

threaded ports will readily accept the

trim arrangements shown in Parts 2

and 3 of Figures 3, 4, and 5.

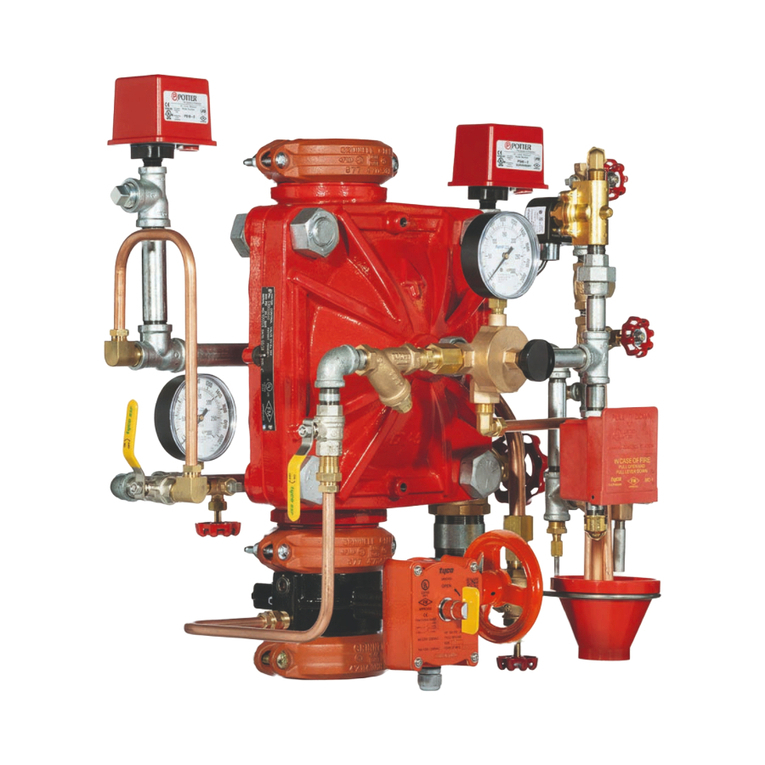

Model DPV-1 Valve assemblies are

shown in Figure 1. The Body and Hand-

hole Cover are ductile iron. The Hand-

hole Cover Gasket is neoprene, and

the Clapper Facing is EPDM. The Air/

Water Seat Ring is brass, the Clapper

is bronze or aluminum bronze, and both

the Clapper Retaining Plate and Latch

are bronze. The Hinge Pin is aluminum

bronze, and the fasteners for the Hand-

hole Cover are carbon steel.

Valve Trim

Installation dimensions are provided

in Figure 6, and Valve Trim and Pre-

Trimmed Valve Assemblies are shown

in Figures 3, 4, and 5.

The valve trim, ordered separately or as

a pre-trimmed valve assembly, forms

a part of the laboratory listings and

approvals of the DPV-1 Valve and is

necessary for the proper operation of

the DPV-1 Valve.

Trim packages or pre-trimmed valve

assemblies include the following

equipment:

• Water Supply Pressure Gauge

• System Air Pressure Gauge

• Air Supply Connections

• Main Drain Valve

• Low Body Drain Valve

• Alarm Test Valve

• Automatic Drain Valve

• Drip Funnel

• Connections For Optional Quick

Opening Device (Accelerator)

Pre-trimmed valve assemblies also

include the following equipment:

• Model BFV-300 butterfly valve

• Figure 577 grooved coupling

• PS10-2 waterflow alarm switch

• PS40-2 low air pressure alarm switch

Order the above equipment sepa-

rately when ordering trim packages

separately.

Note: When the system pressure is

greater than 175 psi (12,1 bar), provision

shall be made to replace the standard

order 300 psi (20,7 bar) Water Pressure

gauge with a separately ordered 600

psi (41,4 bar) Water Pressure Gauge.

Weights

The following are the nominal weights

for Pre-Trimmed Valve Assemblies,

Semi-Assembled Trim, and DPV-1

Valves without trim.

Pre-Trimmed DPV-1 Valve

Assemblies:

2-1/2 in. (DN65) GxG ..............87 lb (40 kg)

3 in. (DN80) GxG.....................90 lb (42 kg)

4 in. (DN100) GxG................. 121 lb (56 kg)

4 in. (DN100) FxG..................135 lb (64 kg)

4 in. (DN100) FxF ..................145 lb (69 kg)

6 in. (DN150) GxG ................. 175 lb (81 kg)

6 in. (DN150) FxG ..................195 lb (90 kg)

6 in. (DN150) FxF...................208 lb (96 kg)

Standard Galvanized

Semi-Assembled DPV-1 Trim:

2-1/2 in. (DN65)........................23 lb (11 kg)

3 in. (DN80) ..............................23 lb (11 kg)

4 in. (DN100) ............................30 lb (14 kg)

6 in. (DN150) ............................30 lb (14 kg)

DPV-1 Valve (Without Trim):

2-1/2 in. (DN65) GxG ...............37 lb (17 kg)

3 in. (DN80) GxG...................... 38 lb(18 kg)

4 in. (DN100) GxG................... 57 lb (26 kg)

4 in. (DN100) FxG.................... 67 lb (31 kg)

4 in. (DN100) FxF .................... 77 lb (36 kg)

6 in. (DN150) GxG ................... 95 lb (44 kg)

6 in. (DN150) FxG.................. 108 lb (50 kg)

6 in.(DN150) FxF ................... 121 lb (56 kg)

Air Supply

Table B shows the system air pres-

sure requirements as a function of the

water supply pressure. The air (or nitro-

gen) pressure in the sprinkler system

is recommended to be automatically

maintained by using one of the follow-

ing pressure maintenance devices, as

appropriate:

• Model AMD-1 Air Maintenance

Device (pressure reducing type)

• Model AMD-2 Air Maintenance

Device (compressor control type)

• Model AMD-3 Nitrogen Maintenance

Device (high pressure reducing type)

The Pressure Relief Valve provided with

the valve trim is factory set to relieve

at a pressure of approximately 45 psi

(3,1 bar). If the normal system air pres-

sure is less than or exceeds 40 psi (2,8

bar), then the pressure Relief Valve

must be reset to relieve at a pressure

that is in accordance with the authority

having jurisdiction.

Quick Opening Device

The Model DPV-1 Dry Pipe Valve may

optionally be equipped with an elec-

tronic or mechanical dry pipe valve

accelerator. Select the VIZOR Elec-

tronic Dry Pipe Valve Accelerator

(4 and 6 in. sizes only) as described

in Technical Data Sheet TFP1105, or

the Model ACC-1 Mechanical Dry Pipe

Valve Accelerator (2-1/2 through 6 in.

sizes) as described in Technical Data

She et TFP1112.

The VIZOR or the ACC-1 is used to

reduce the time to valve actuation fol-

lowing the operation of one or more

automatic sprinklers. In some cases

the use of a quick opening device

such as the VIZOR or the ACC-1 may

be required to meet the requirements of

the National Fire Protection Association

to meet water delivery times.

Nominal

Valve

Size

Flange Drilling Specication

Nominal Dimensions in Inches and (mm)

AN SI B16.11

(Class 125)

ISO 7005-2

(PN16)2

JIS B 2210

(10K)

AS 2129

(Table E)

Dim.

A

Dim.

B

Qty.

N

Dim.

A

Dim.

B

Qty.

N

Dim.

A

Dim.

B

Qty.

N

Dim.

A

Dim.

B

Qty.

N

4 in.

(DN100)

7.50

(190,5)

0.75

(19,0) 87. 0 9

(180,0)

0.75

(19,0) 86.89

(175,0)

0.59

(15,0) 87. 0 0

(178,0)

0.71

(18,0) 8

6 in.

(DN150)

9.50

(241,3)

0.88

(22,2) 89.45

(240,0)

0.91

(23,0) 89.45

(240,0)

0.75

(19,0) 89.25

(235,0)

0.87

(22,0) 8

1. Drilling same as ANSI B16.5 (Class 150) and ANSI B16.42 (Class 150).

2. Drilling same as BS 4504 Section 3.2 (PN16) and DIN 2532 (PN16).

Diameter

Dim. B

Bolt Hole

Diameter

Qty. N

TABLE A

SELECTION OF FLANGE DRILLING SPECIFICATIONS