1. Introduction................................................................................................................................ 8

1.1. Important safety information ............................................................................................................................................. 8

2. General Information and Ratings ................................................................................................. 9

2.1. Drive model numbers.......................................................................................................................................................... 9

2.2. Identifying the Drive by Model Number ........................................................................................................................... 10

3. Mechanical Installation ............................................................................................................. 11

3.1. General.............................................................................................................................................................................. 11

3.2. Before Installation............................................................................................................................................................. 11

3.3. UL Compliant Installation.................................................................................................................................................. 11

3.4. Mechanical dimensions and Mounting –IP20 Units......................................................................................................... 11

3.5. Mechanical dimensions and mounting –IP66 Units ......................................................................................................... 12

3.6. Mechanical dimensions and mounting –IP55 .................................................................................................................. 12

3.7. Mechanical dimensions and mounting –IP40 Units ......................................................................................................... 13

3.8. Guidelines for Enclosure mounting (IP20 Units) ............................................................................................................... 14

3.9. Guidelines for mounting IP55, and IP66 Units .................................................................................................................. 14

3.10. Guidelines for mounting IP40 Units .................................................................................................................................. 15

3.11. Removing the Terminal Cover........................................................................................................................................... 16

3.12. Gland Plate and Lock Off................................................................................................................................................... 19

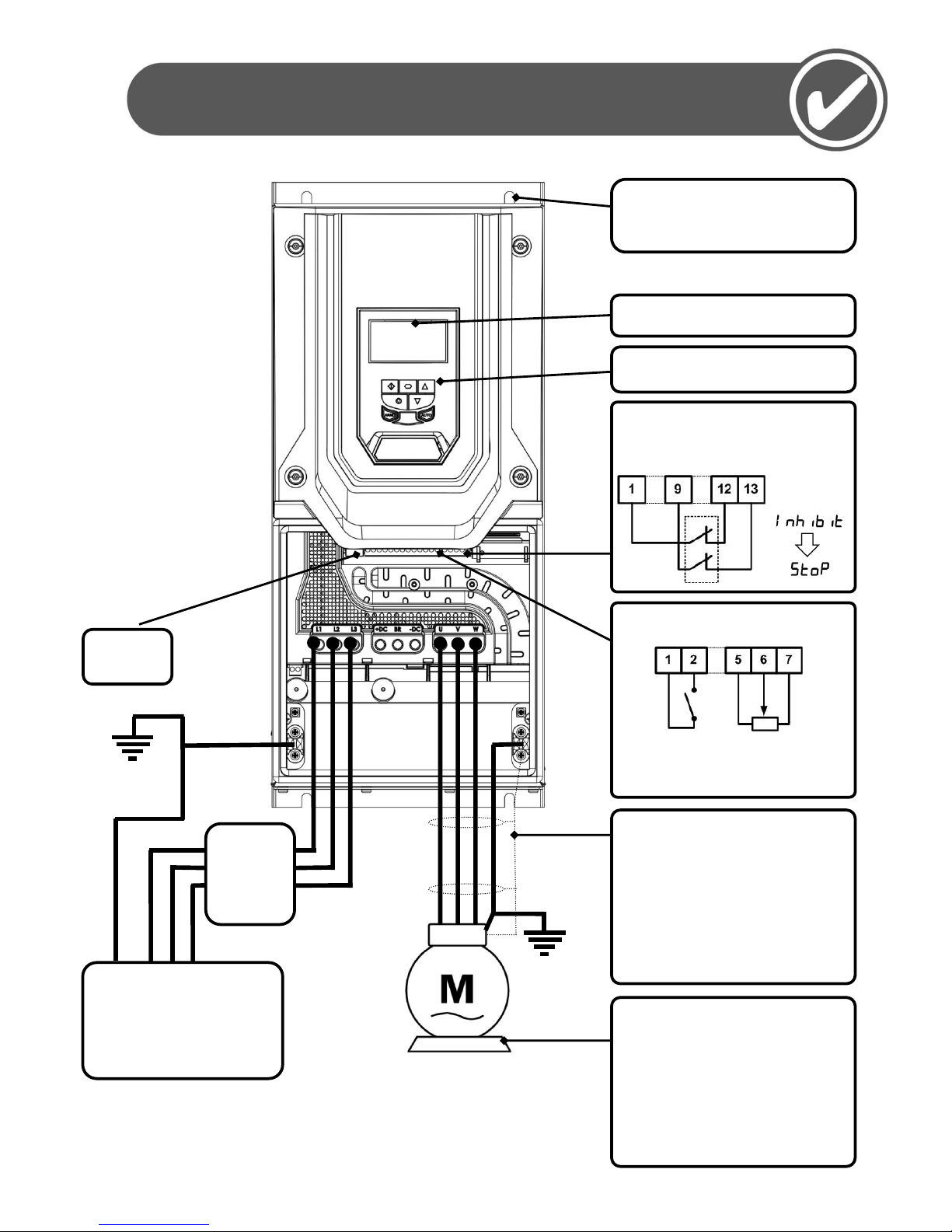

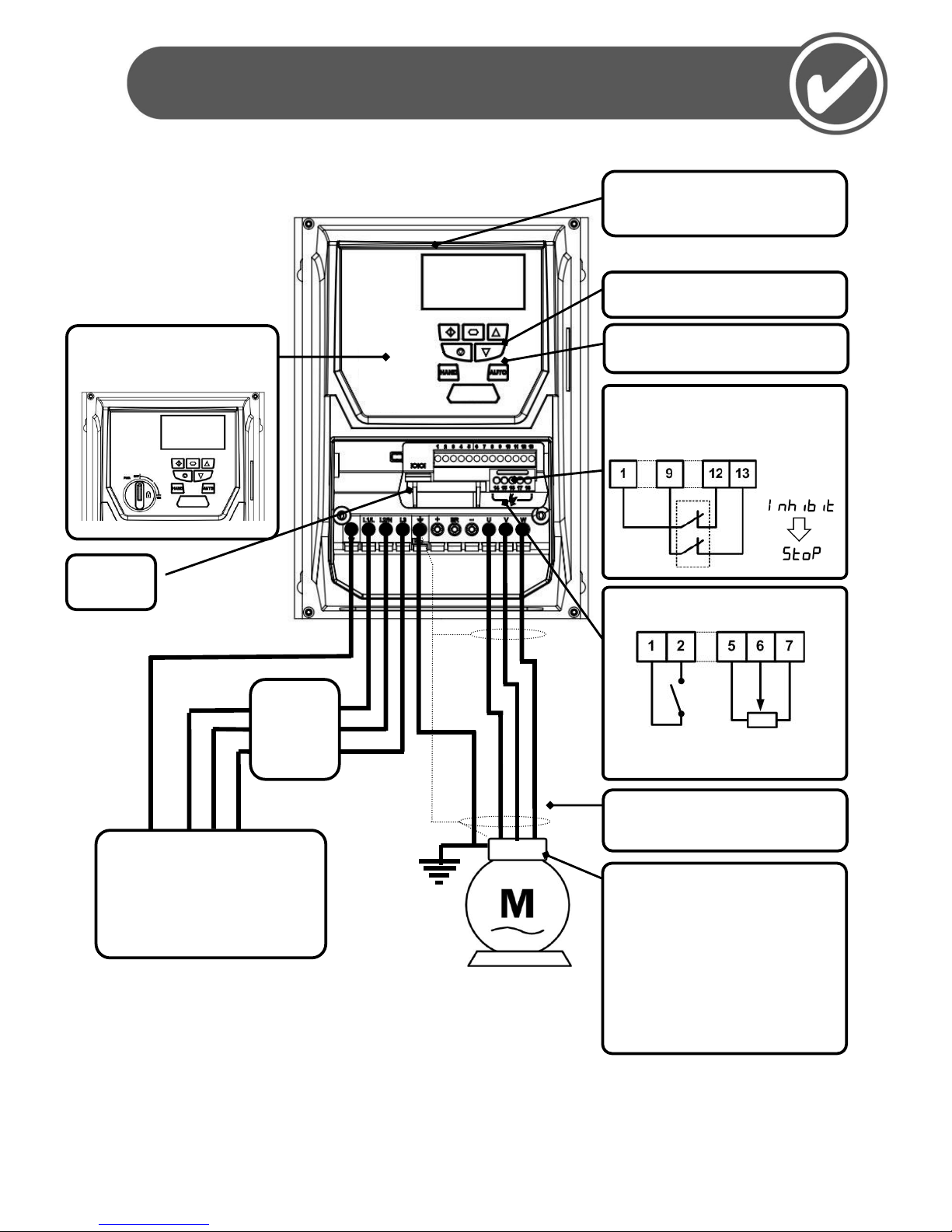

4. Electrical Installation ................................................................................................................. 20

4.1. Grounding the Drive.......................................................................................................................................................... 20

4.2. Wiring Precautions............................................................................................................................................................ 21

4.3. Incoming Power Connection ............................................................................................................................................. 21

4.4. Drive and Motor Connection ............................................................................................................................................ 21

4.5. Motor Terminal Box Connections ..................................................................................................................................... 22

4.6. Motor Thermistor Connection .......................................................................................................................................... 22

4.7. Control Terminal Wiring.................................................................................................................................................... 23

4.8. Connection Diagram ......................................................................................................................................................... 23

5. Managing the Keypad................................................................................................................ 24

5.1. Keypad Layout and Function –Standard LED Keypad (IP20 Drives) ................................................................................. 24

5.2. Changing Parameters –Standard LED Keypad (IP20 Drives)............................................................................................. 24

5.3. Advanced Keypad Operation Short Cuts –Standard LED Keypad (IP20 Drives) ............................................................... 25

5.4. Drive Operating Displays –Standard LED Keypad (IP20 Drives) ....................................................................................... 25

5.5. Keypad Layout and Function –Standard OLED Keypad (IP55 and IP66 Drives)................................................................ 25

5.6. Drive Operating Displays –Standard OLED Keypad (IP55 and IP66 Drives)...................................................................... 26

5.7. Accessing and Changing Parameter Values –Standard OLED Keypad (IP55 and IP66 Drives) ......................................... 26

5.8. Resetting Parameters to Factory Default Settings –Standard OLED Keypad (IP55 and IP66 Drives) ............................... 27

5.9. Resetting Parameters to User Default Settings –Standard OLED Keypad (IP55 and IP66 Drives) ................................... 27

5.10. Changing the Language on the OLED Display –Standard OLED Keypad (IP55 and IP66 Drives) ...................................... 28

5.11. Selecting between Hand and Auto Control –Standard OLED Keypad (IP55 and IP66 Drives).......................................... 28

6. Commissioning.......................................................................................................................... 29

6.1. General.............................................................................................................................................................................. 29

7. HVAC Specific Feature Setup (Menu 8)....................................................................................... 30

7.1. Pump Staging –DOL Cascade............................................................................................................................................ 30

7.2. Pump Staging –Multiple Drive Cascade ........................................................................................................................... 31

7.3. Maintenance Interval Set-up and Reset............................................................................................................................ 32

7.4. Load Profile Monitoring Function ..................................................................................................................................... 33

7.5. Pump Clean Function ........................................................................................................................................................ 34

7.6. Pump Stir Function............................................................................................................................................................ 35

7.7. Bypass Control Function ................................................................................................................................................... 36

7.8. Fire Mode Function ........................................................................................................................................................... 38

7.9. Motor Pre-Heat Function and DC Injection ...................................................................................................................... 40

8. PID Control Applications............................................................................................................ 42

8.1. Overview ........................................................................................................................................................................... 42

8.2. PID Function Set-up .......................................................................................................................................................... 42

8.3. Application Example.......................................................................................................................................................... 45

8.4. PID Pipe Prime (Fill) Mode with Pipe Break Detection. .................................................................................................... 46

9. Parameters ............................................................................................................................... 47

9.1. Parameter Set Overview ................................................................................................................................................... 47

9.2. Parameter Group 1 –Basic Parameters............................................................................................................................ 47

10. Digital Input Functions .............................................................................................................. 49